Construction method for hoisting platform steel upright post

A construction method and technology for steel columns, which are applied to columns, piers, pillars, etc., can solve the problems of long hoisting time, large number of personnel, time-consuming and labor-intensive, etc., and achieve the effects of enhanced safety, simple and convenient operation, and simple equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

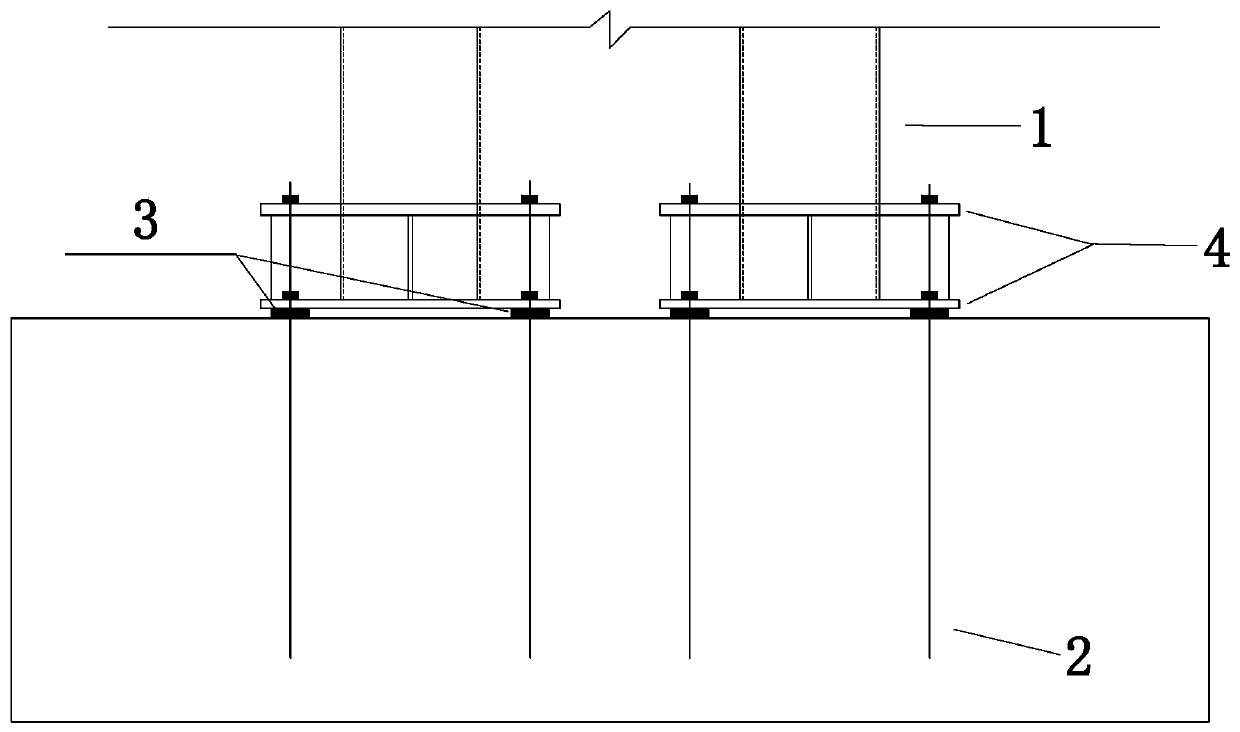

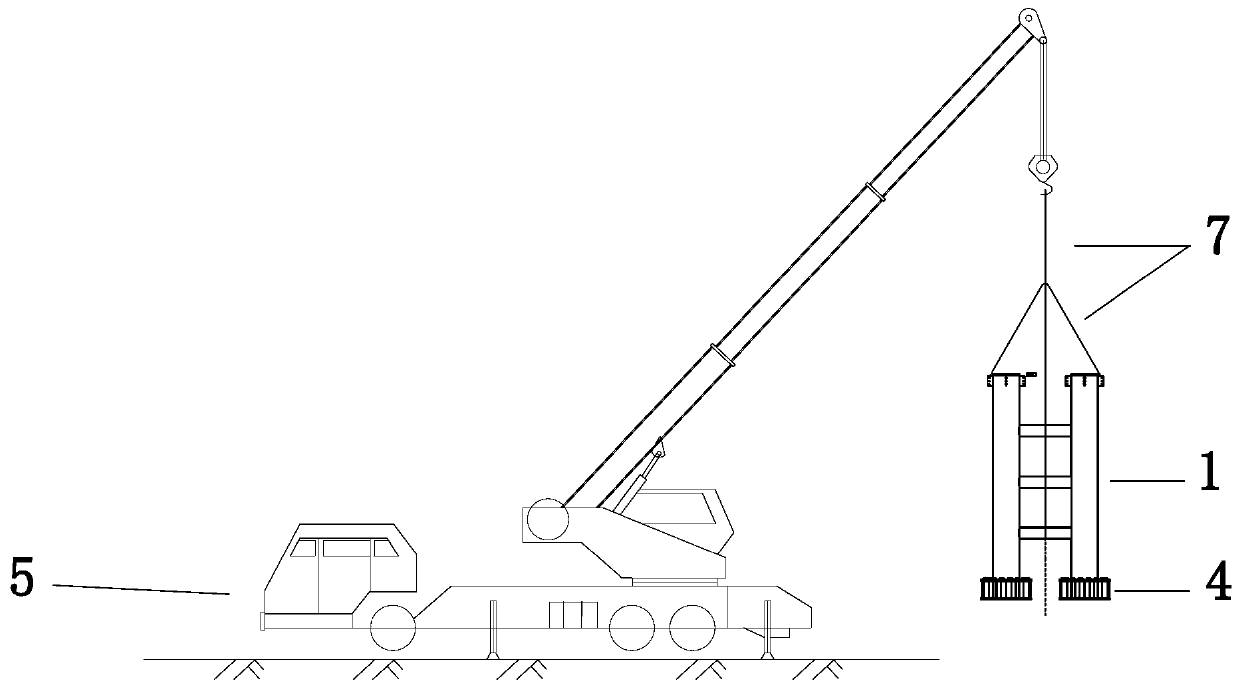

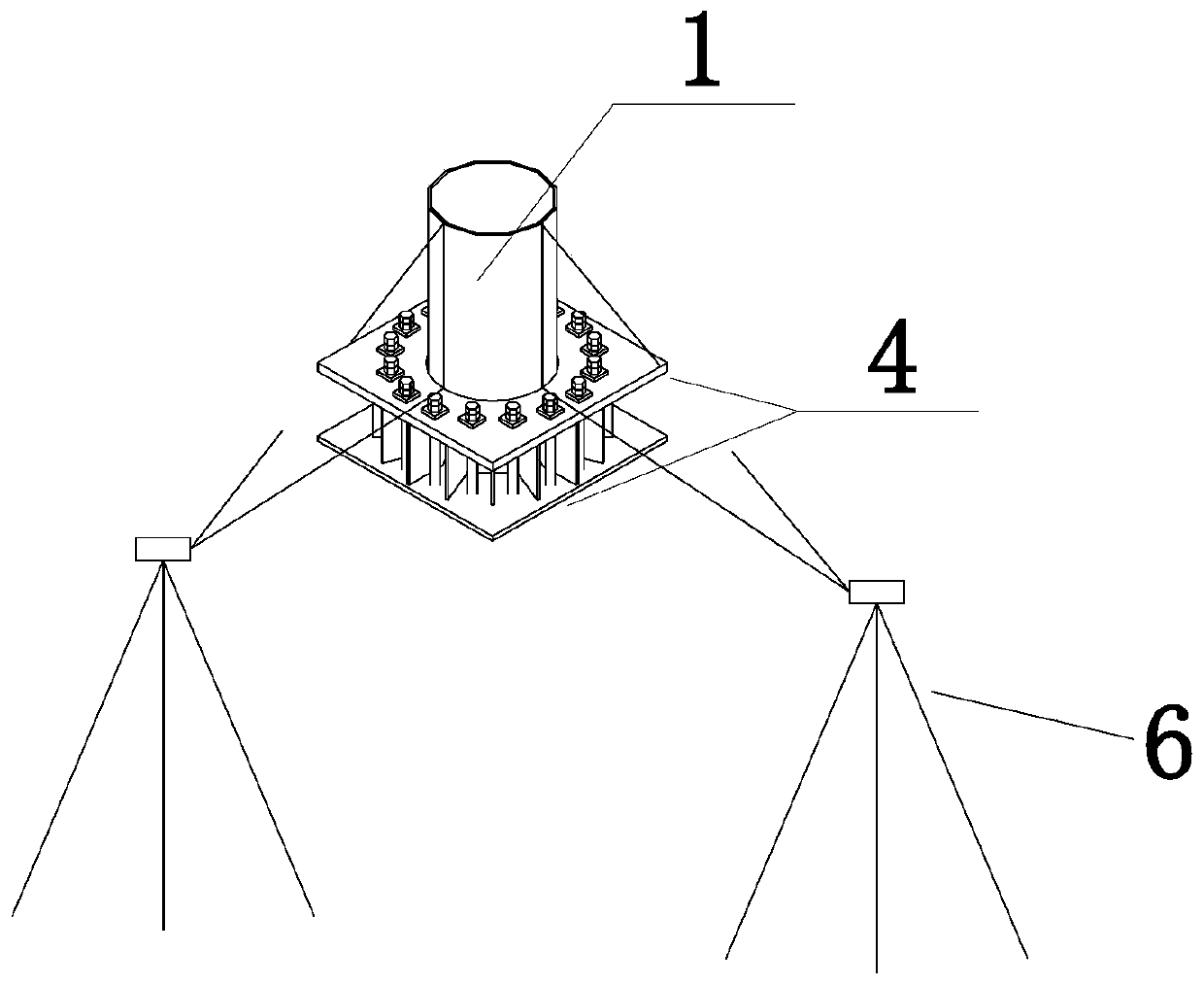

[0021] The construction method for hoisting the platform steel column provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0022] Now take the reconstruction project of a railway station in a certain city as an example: the railway station is located in the center of the urban area, the newly built canopy steel structure covers an area of 43754.3m2, and the total width is 114.6m. The east-west directions PA, PB, PC, PD has four axes, 18 axes in the north-south direction, with a total length of 381.8m. The vault elevations of the canopy are 14m and 16.8m respectively, and the corresponding steel column top elevations are 17m and 19.8m (P7-P9 axis and P10-P12 axis) respectively.

[0023] Such as Figure 1 to Figure 3 As shown, the construction method of platform steel column hoisting provided by the invention comprises the following steps carried out in order:

[0024] 1) Before the stee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com