Patents

Literature

34 results about "Terminal cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Terminal cleaning is a cleaning method used in healthcare environments to control the spread of infections.

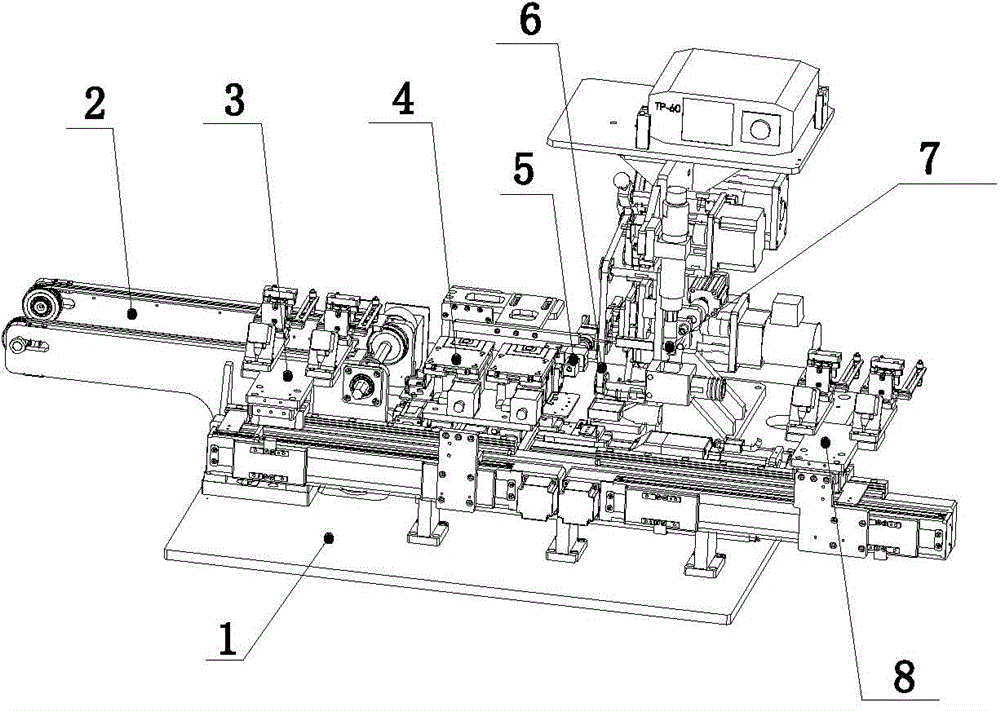

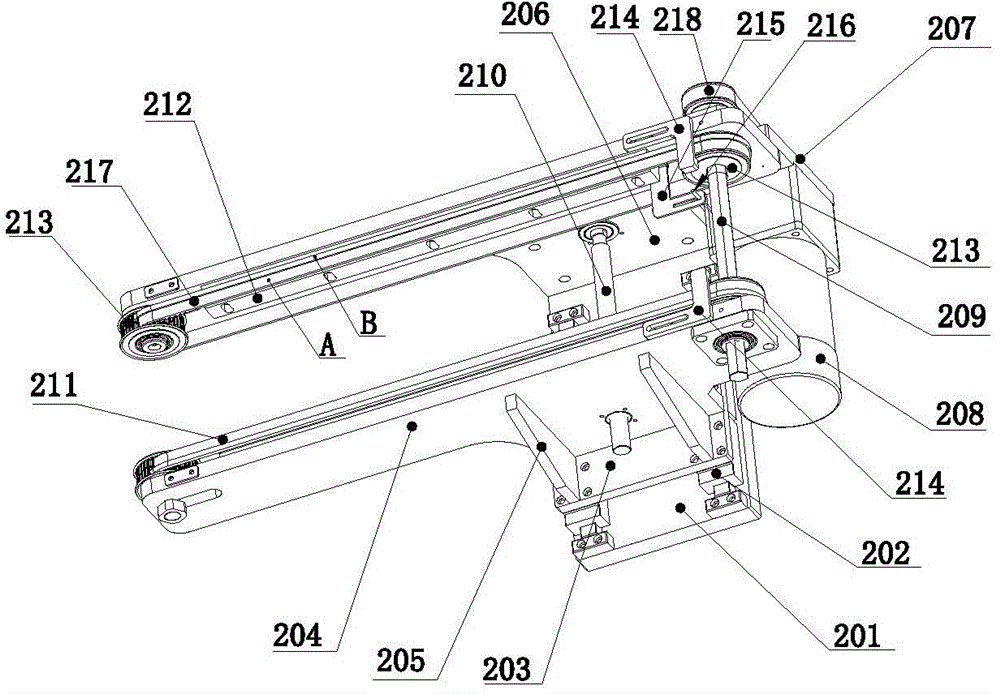

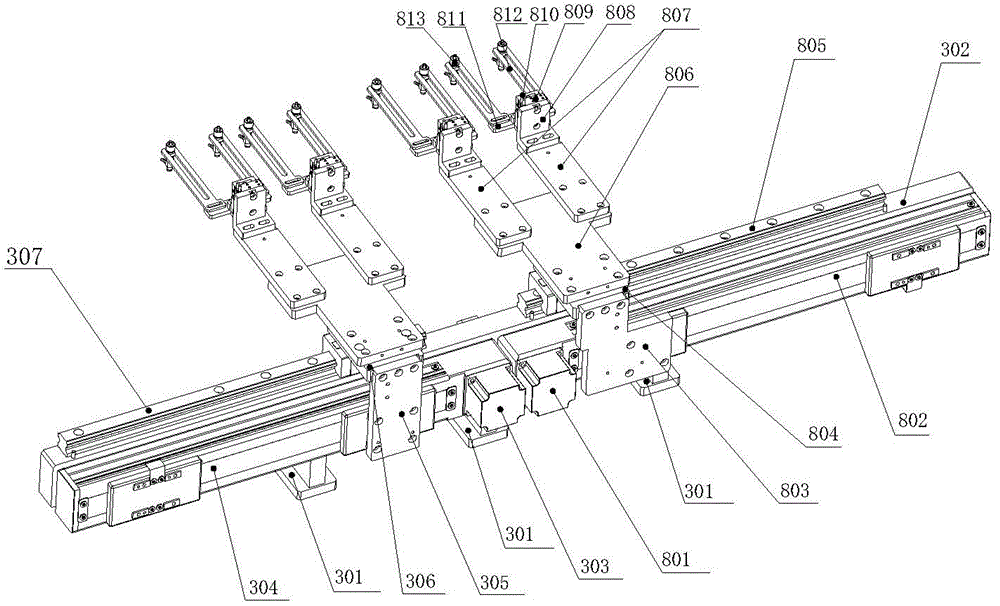

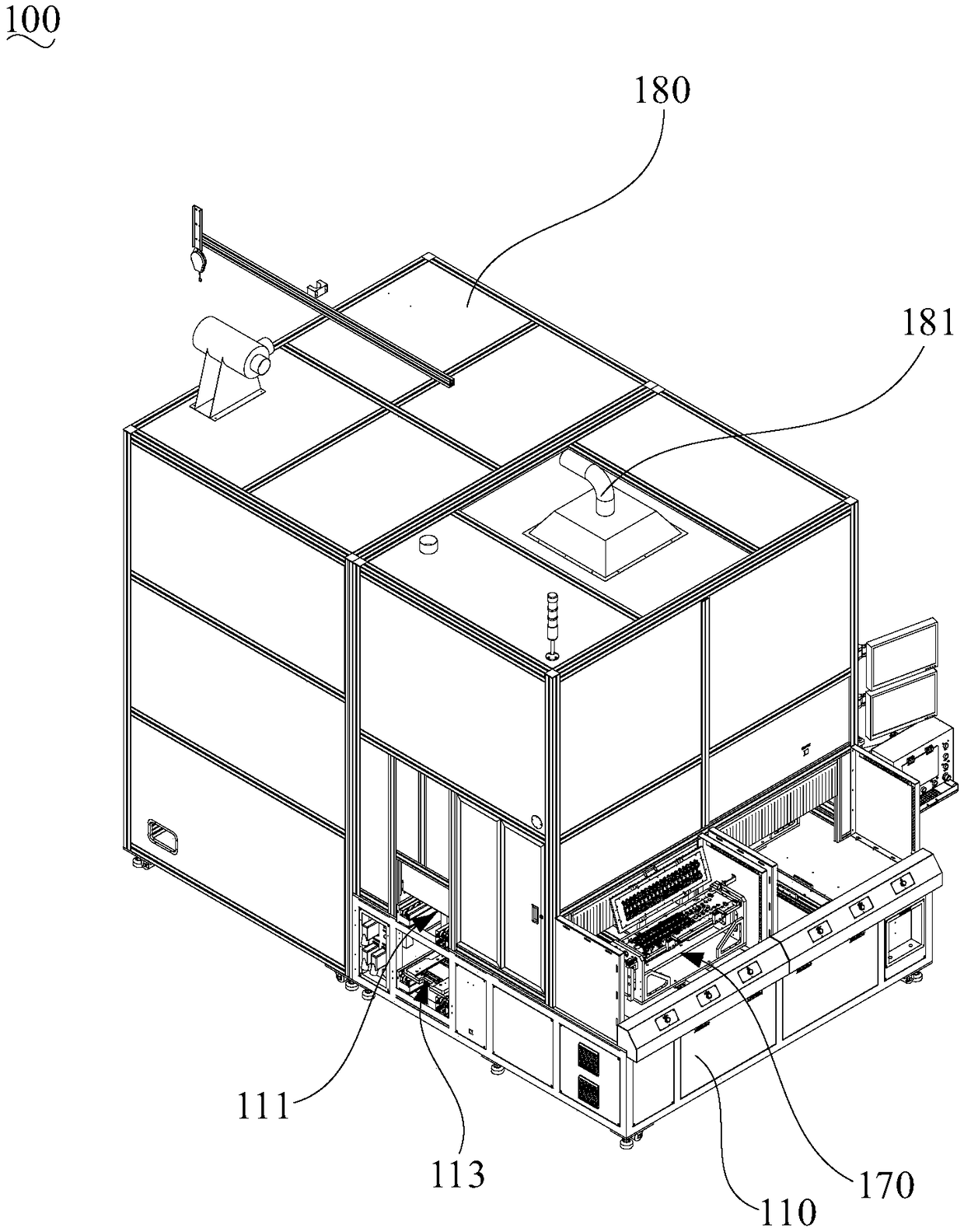

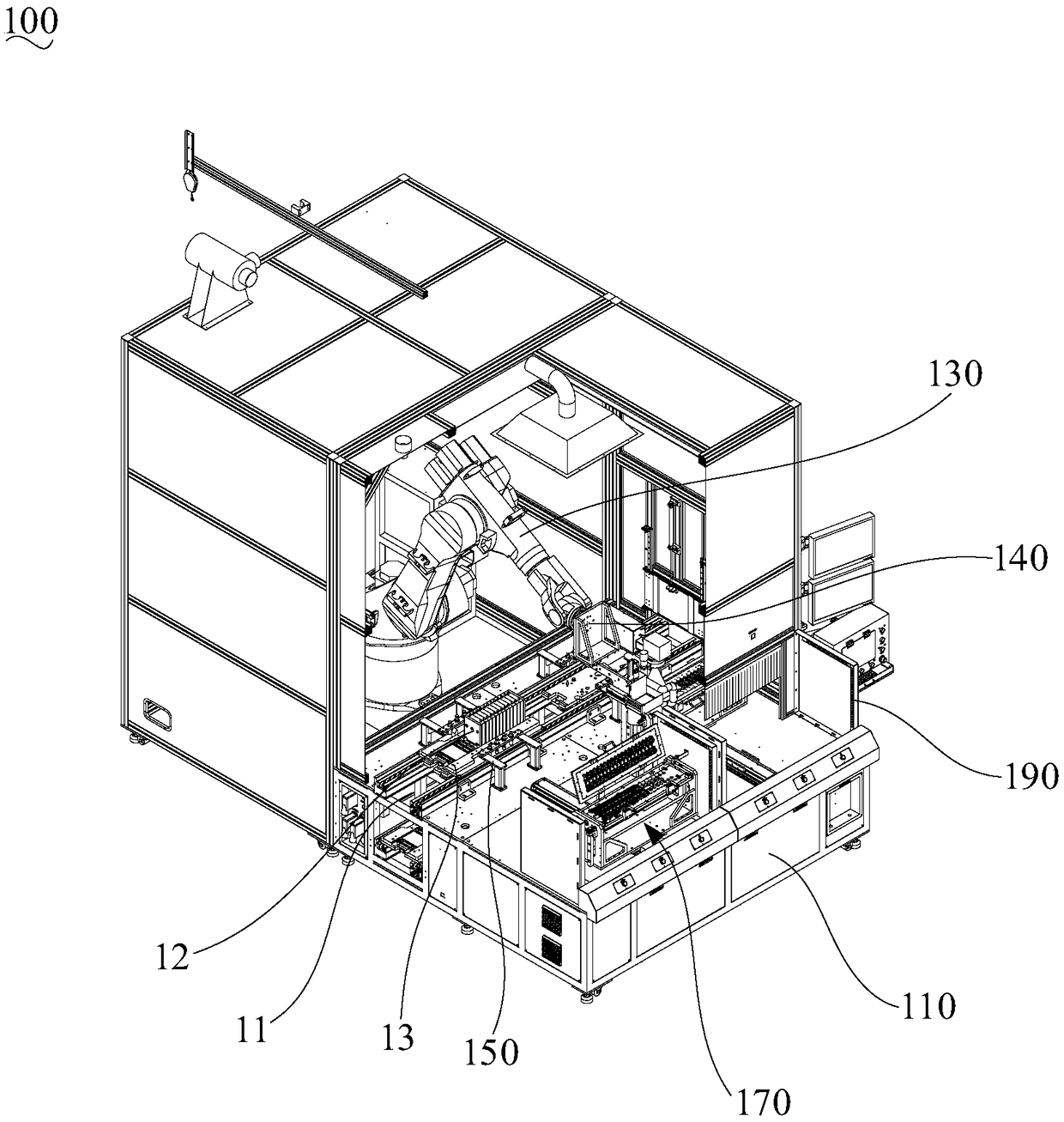

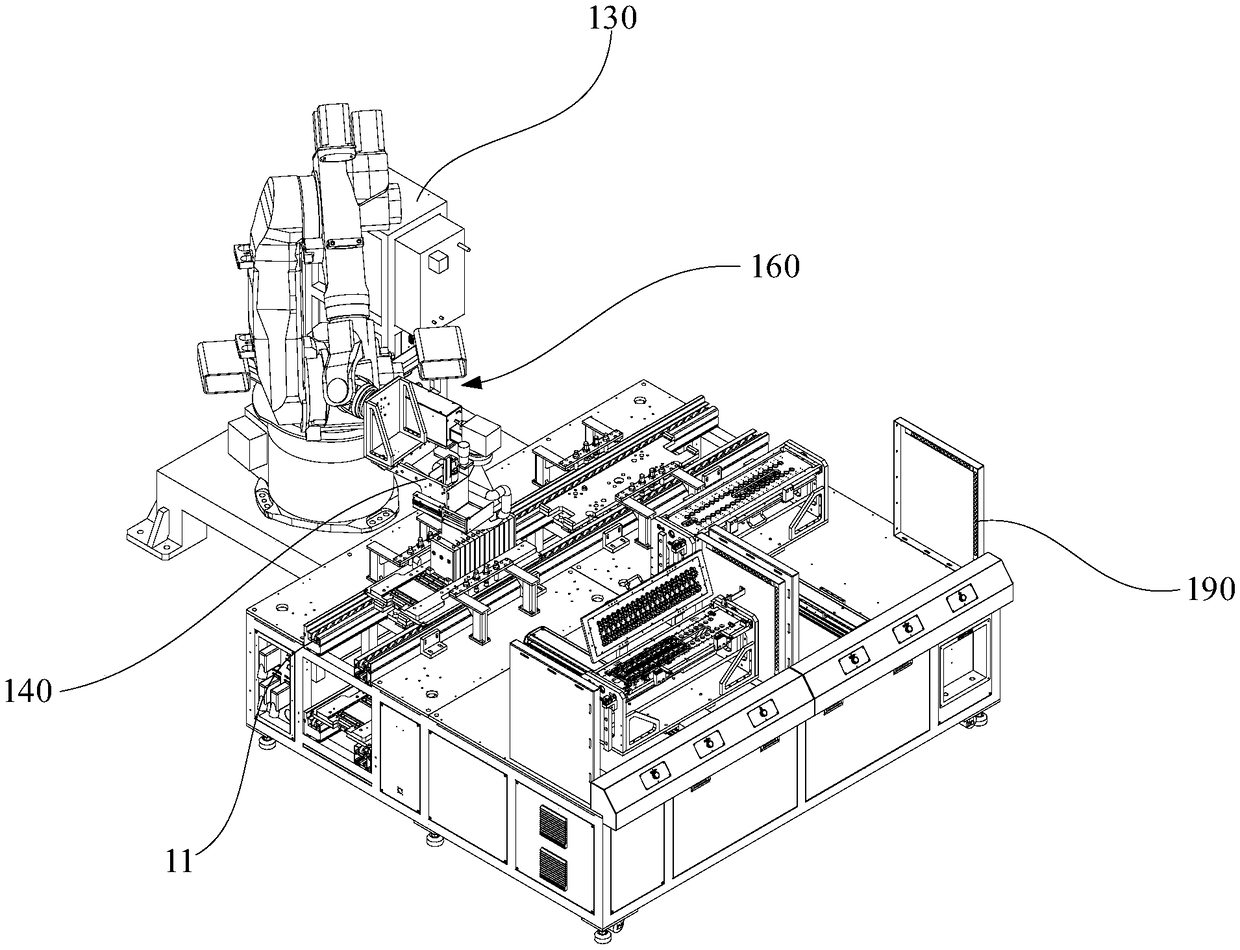

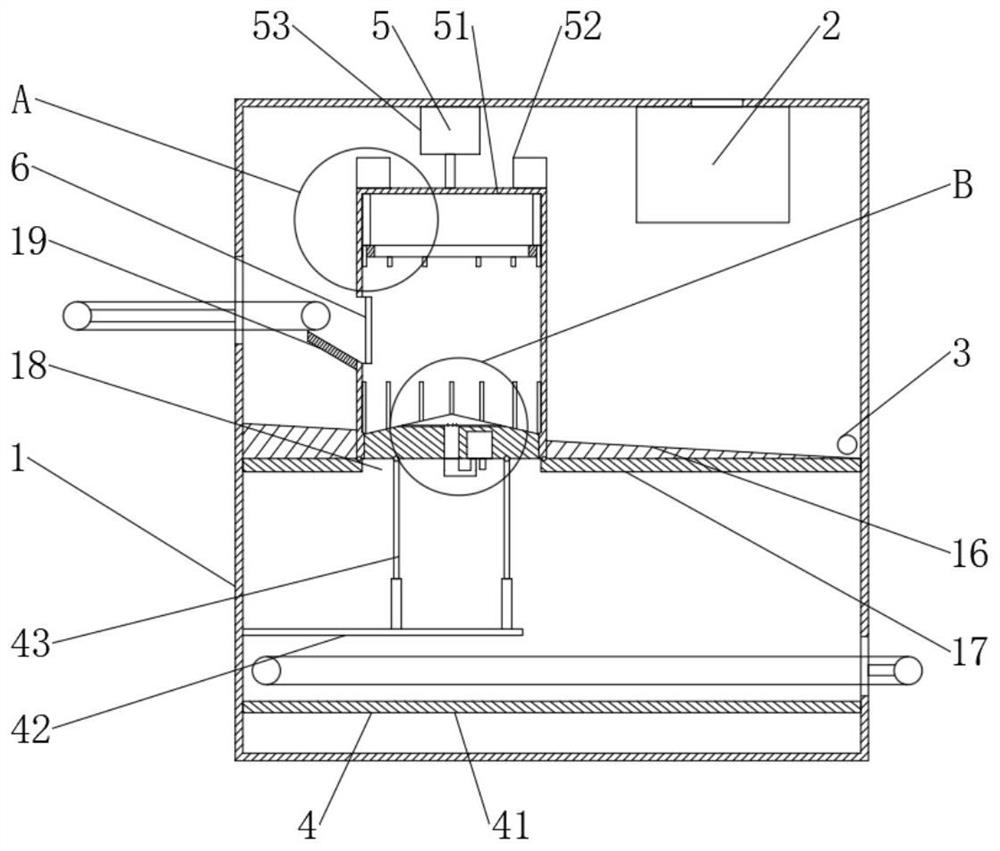

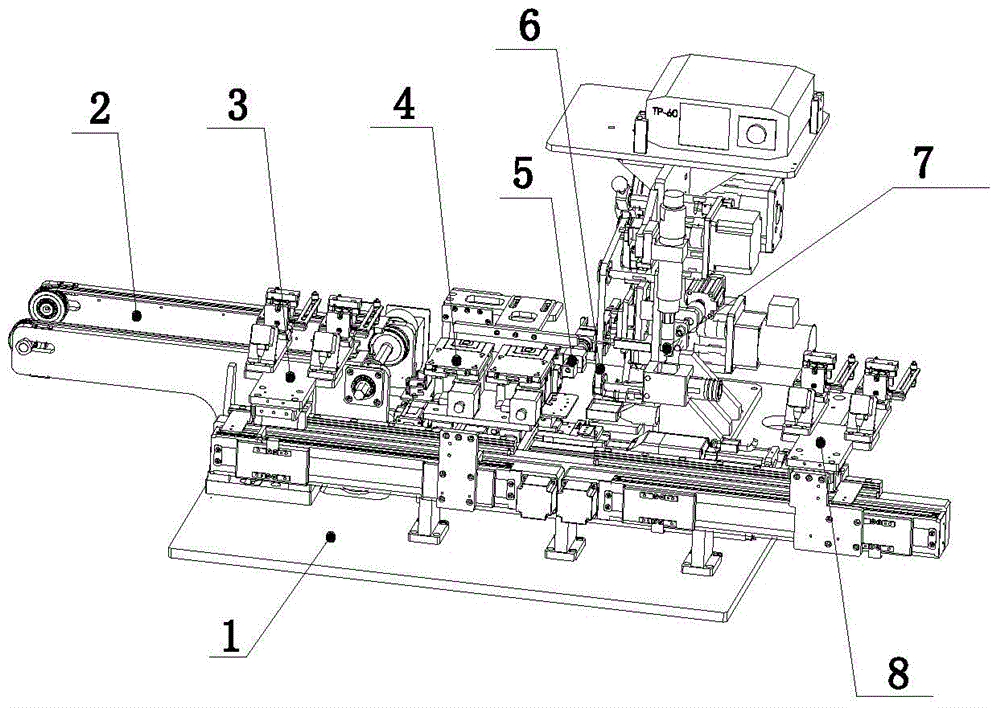

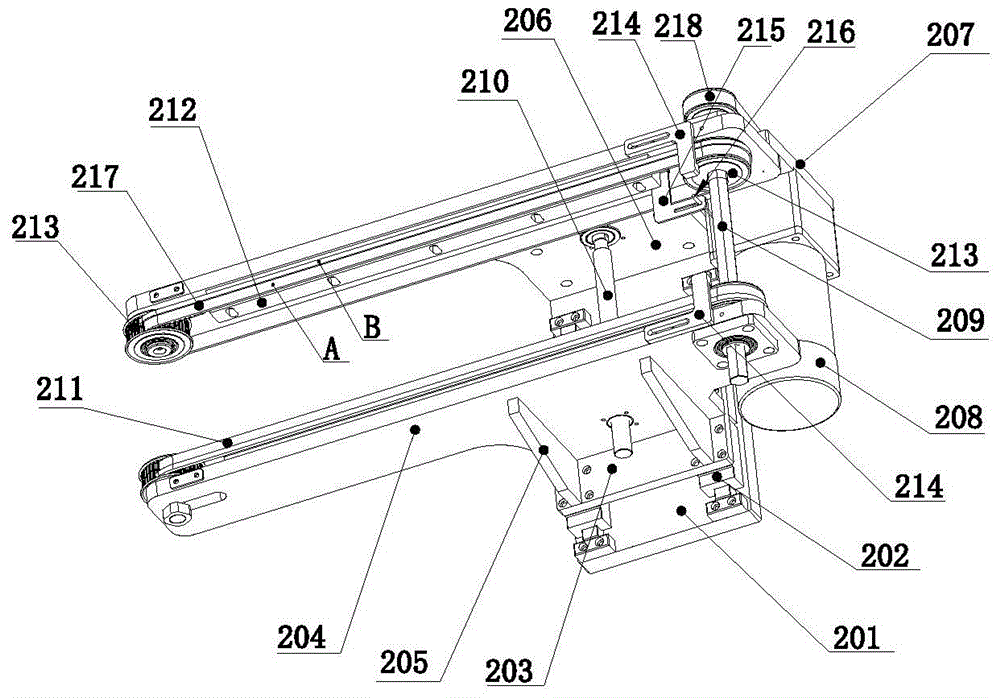

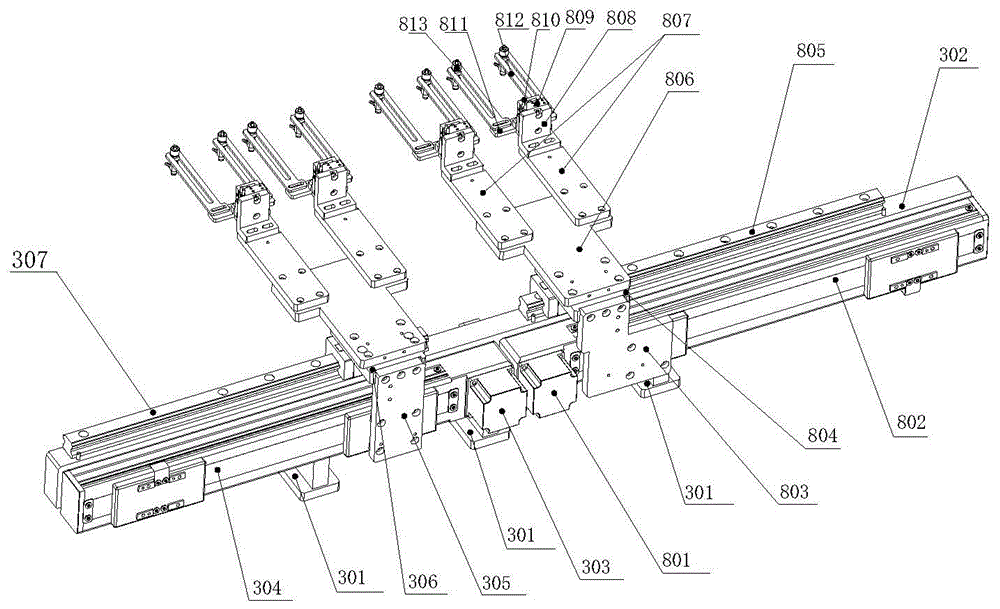

Fully-automatic LCD (Liquid Crystal Display) terminal cleaning machine

ActiveCN104550158AHigh precisionEasy to cleanFlexible article cleaningCleaning using toolsLiquid-crystal displayEngineering

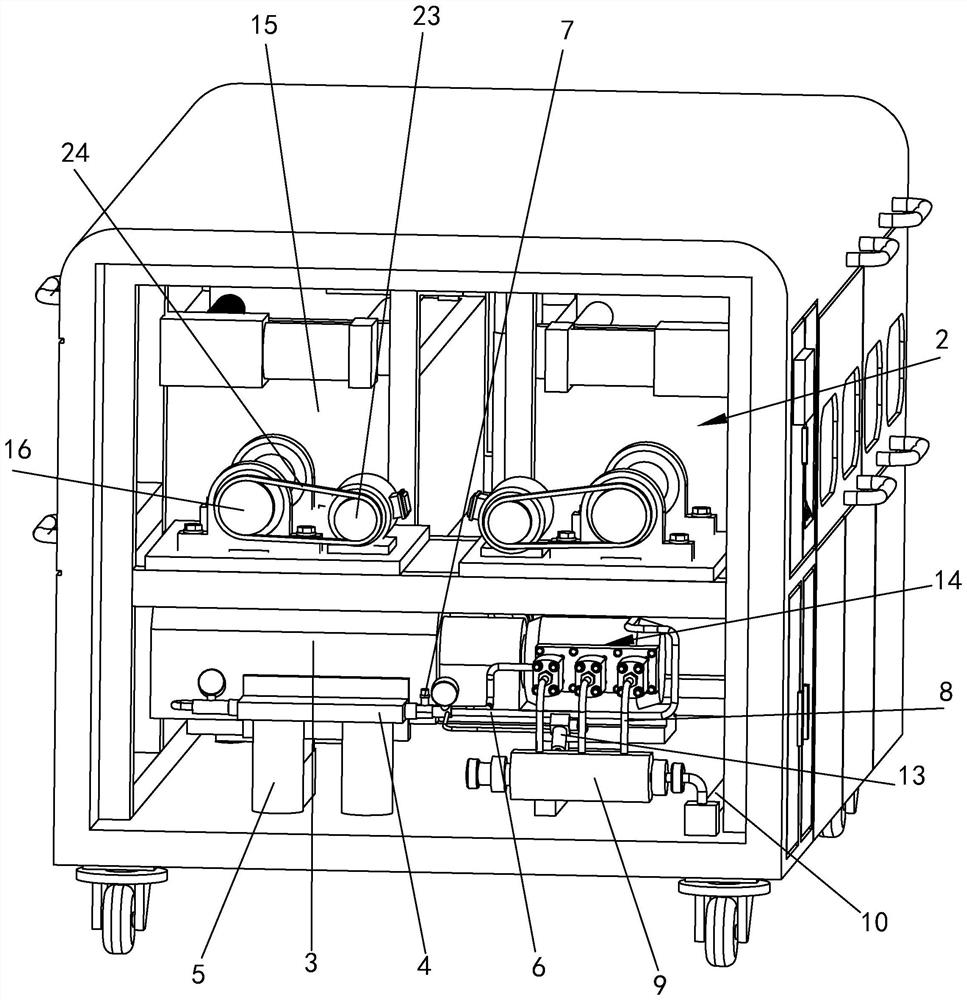

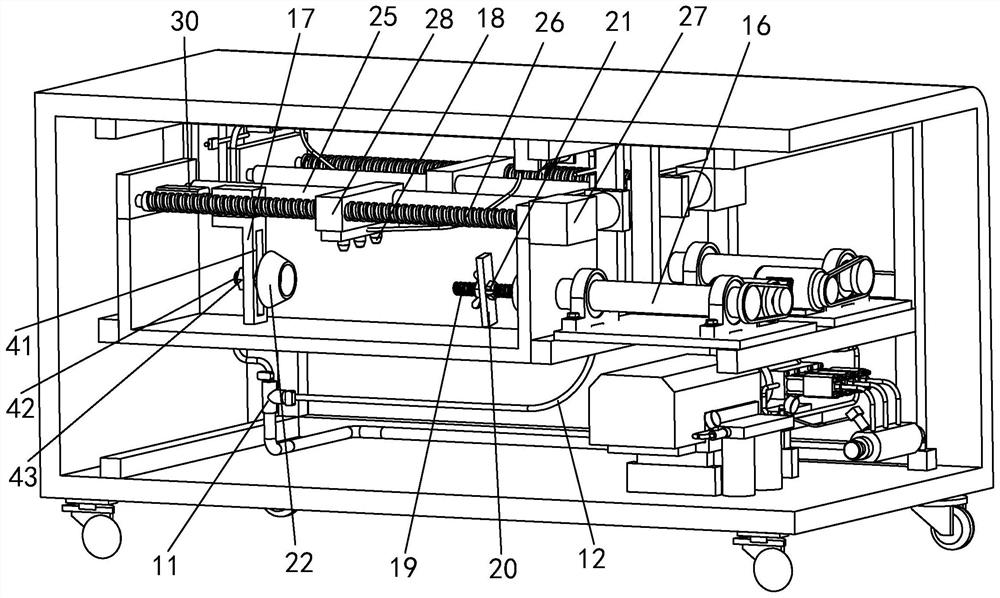

The invention discloses a fully-automatic LCD (Liquid Crystal Display) terminal cleaning machine. The fully-automatic LCD terminal cleaning machine comprises a table plate, a charging belt line device, a charging manipulator, a material transmission unit, a CCD (Charge Coupled Device) image pickup mechanism, a dustproof cloth cleaning mechanism, a plasma cleaning mechanism and a discharging manipulator, wherein the charging belt line device, the charging manipulator, the material transmission unit, the CCD image pickup mechanism, the dustproof cloth cleaning mechanism, the plasma cleaning mechanism and the discharging manipulator are sequentially mounted on the table plate. The fully-automatic LCD terminal cleaning machine has higher LCD terminal cleaning efficiency and accuracy, and increase of the production cost caused by manual operation and harm to the human health caused by chemicals are avoided.

Owner:SHENZHEN LIANDE AUTOMATION EQUIP

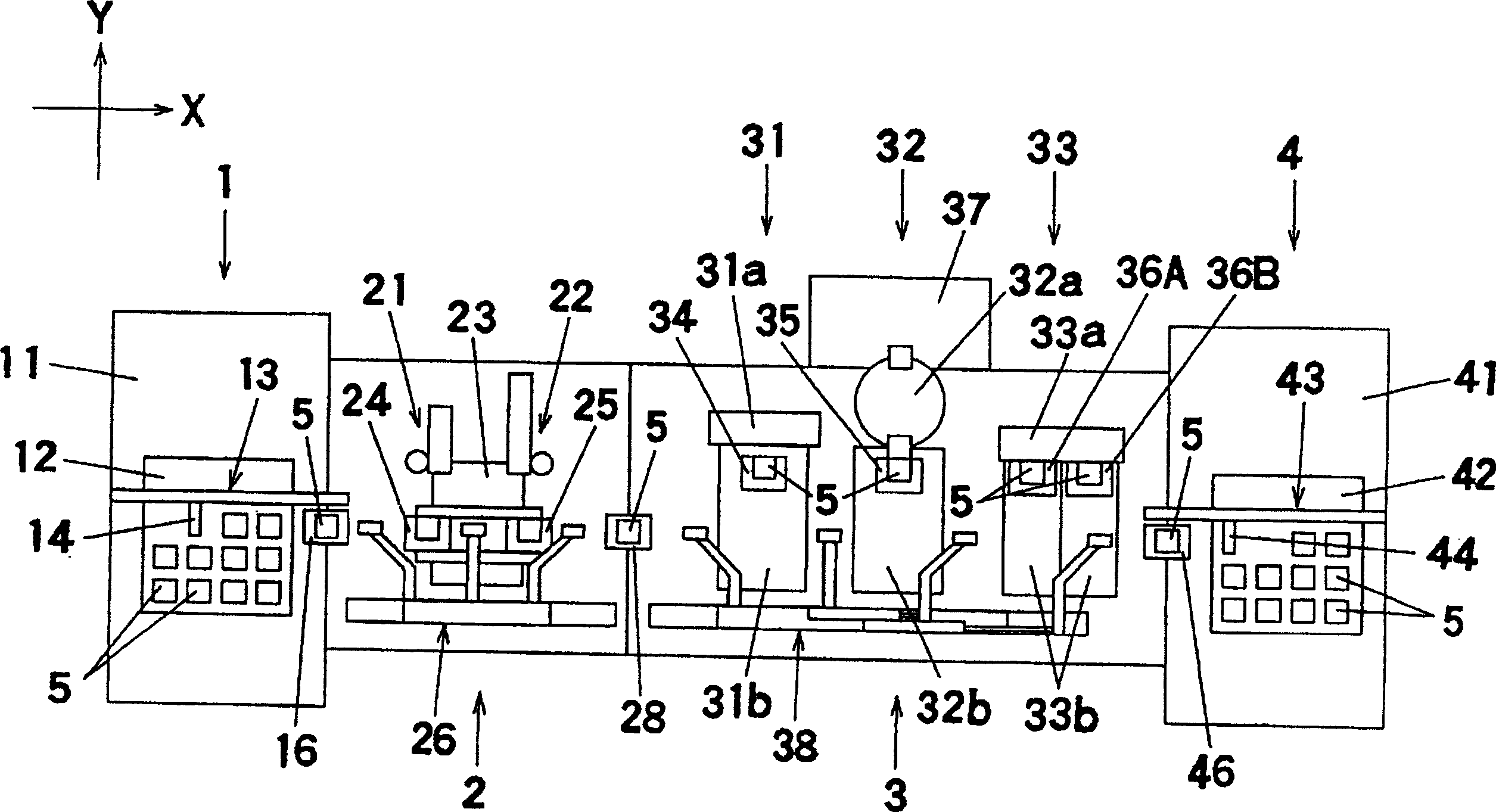

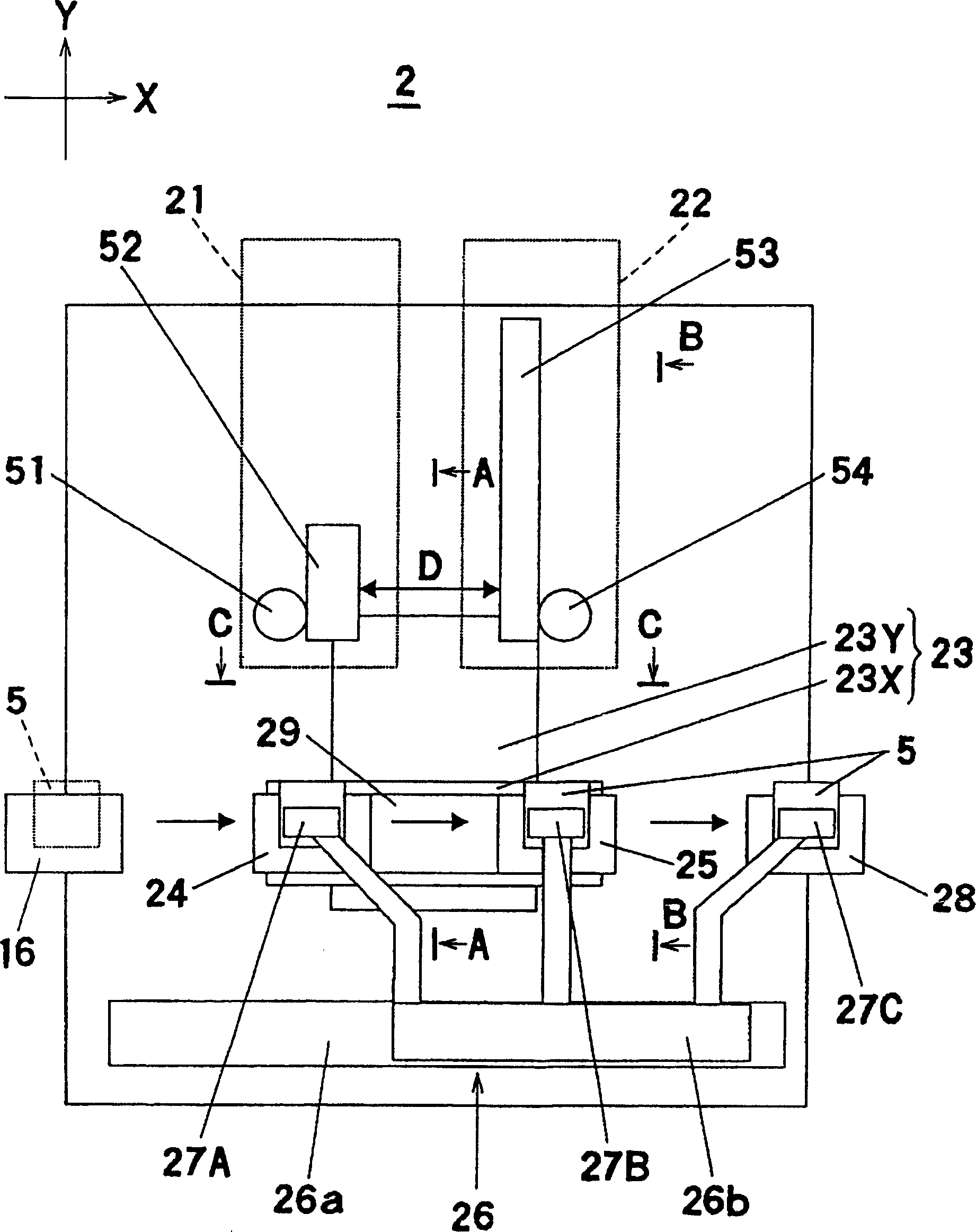

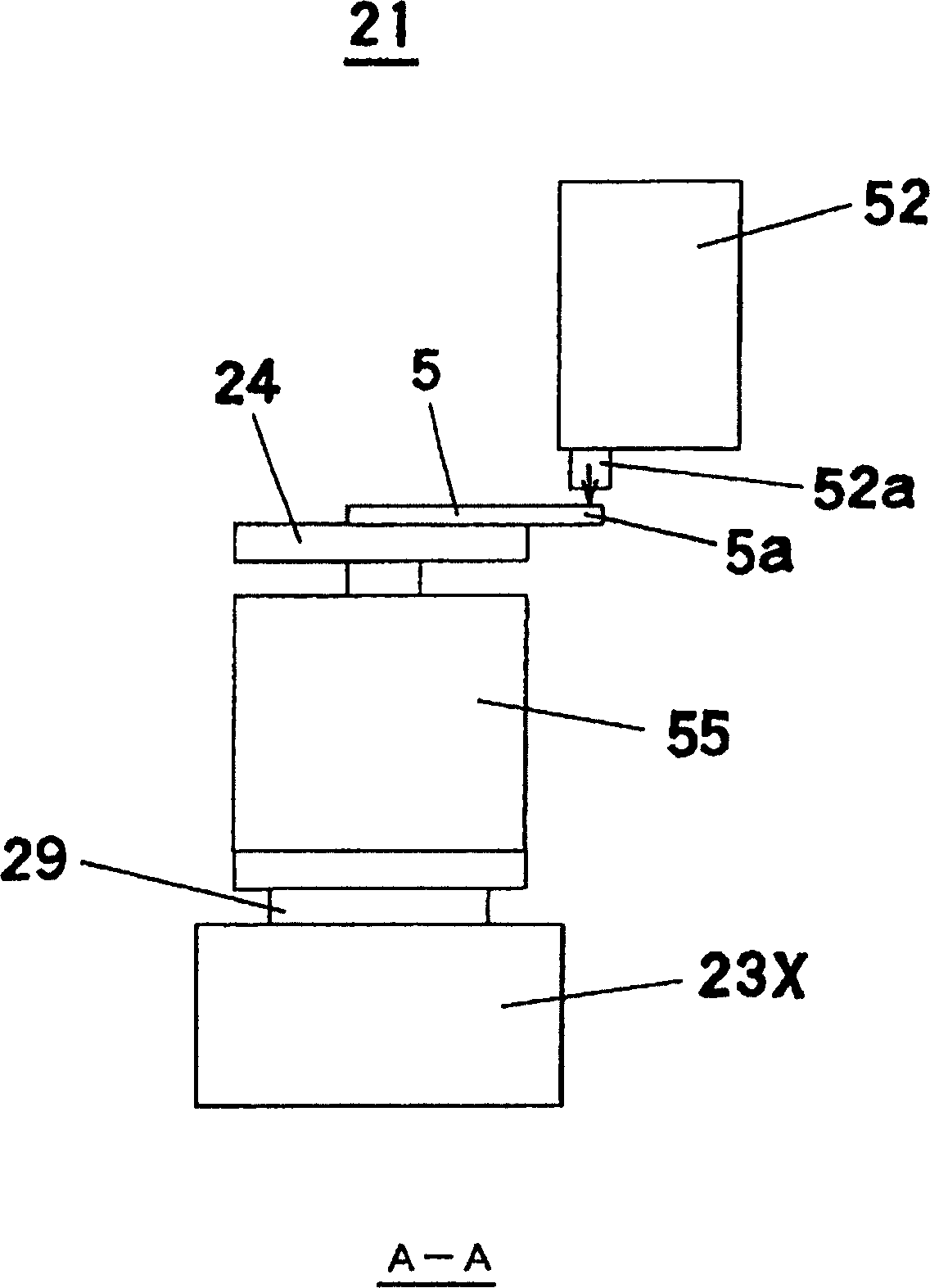

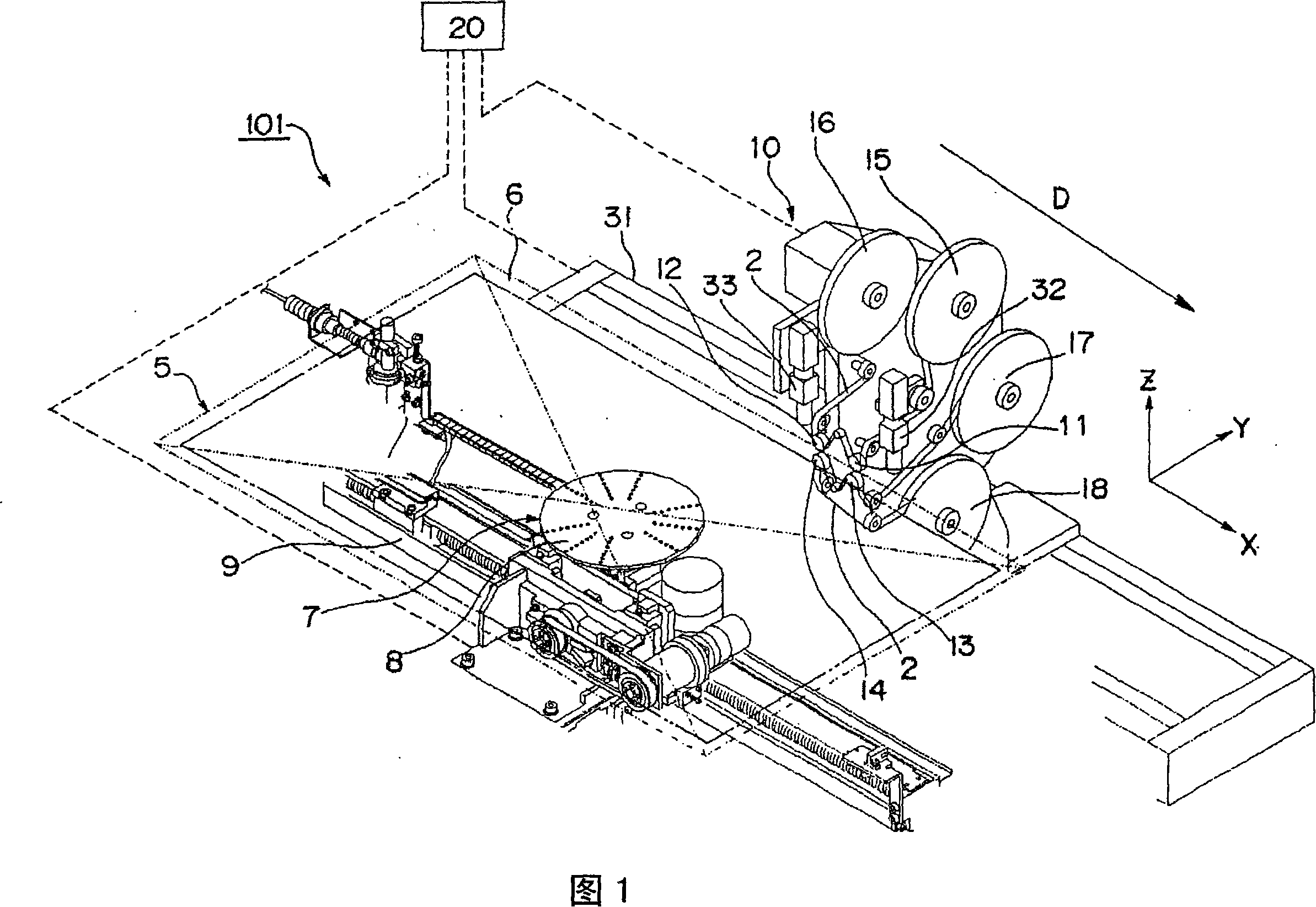

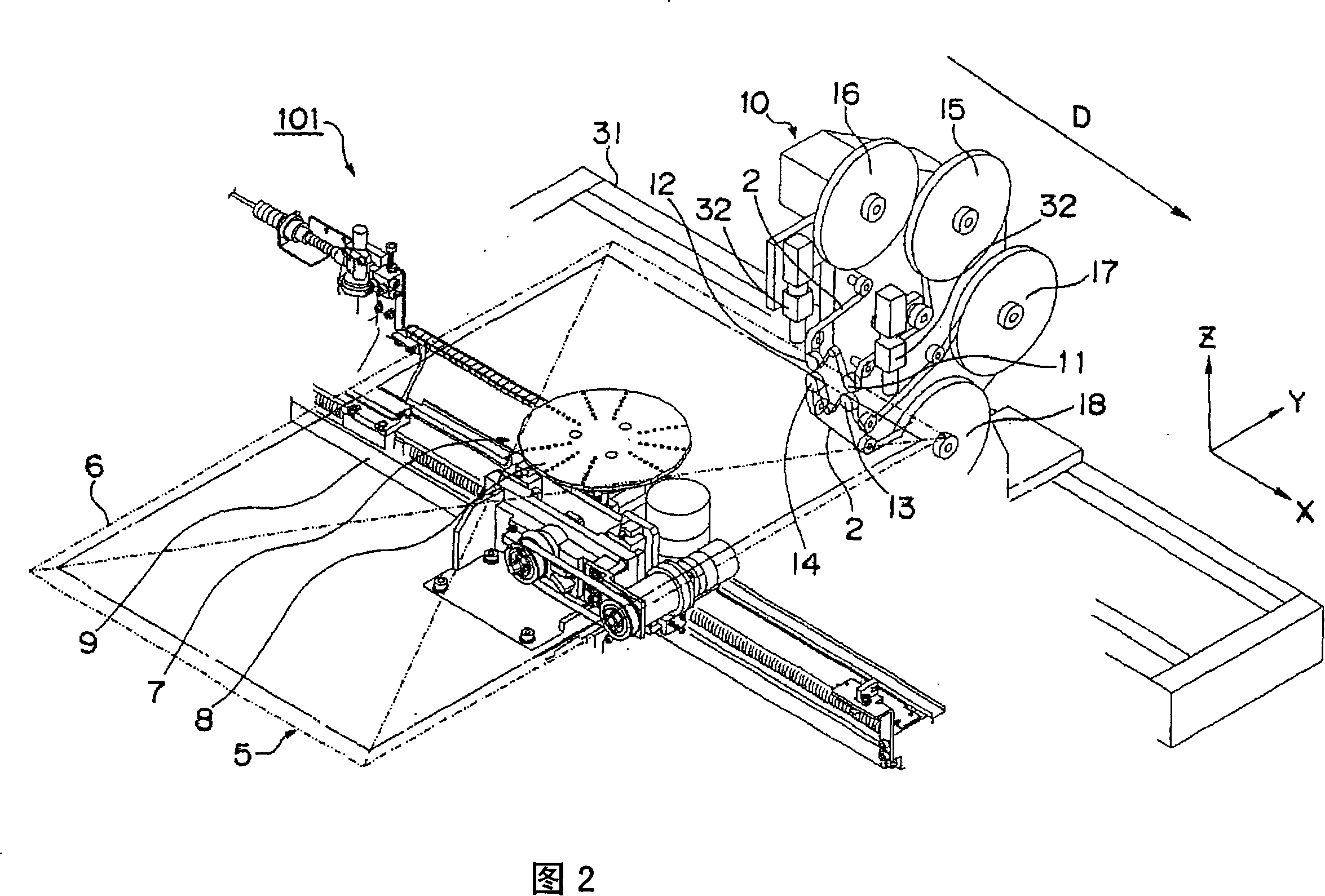

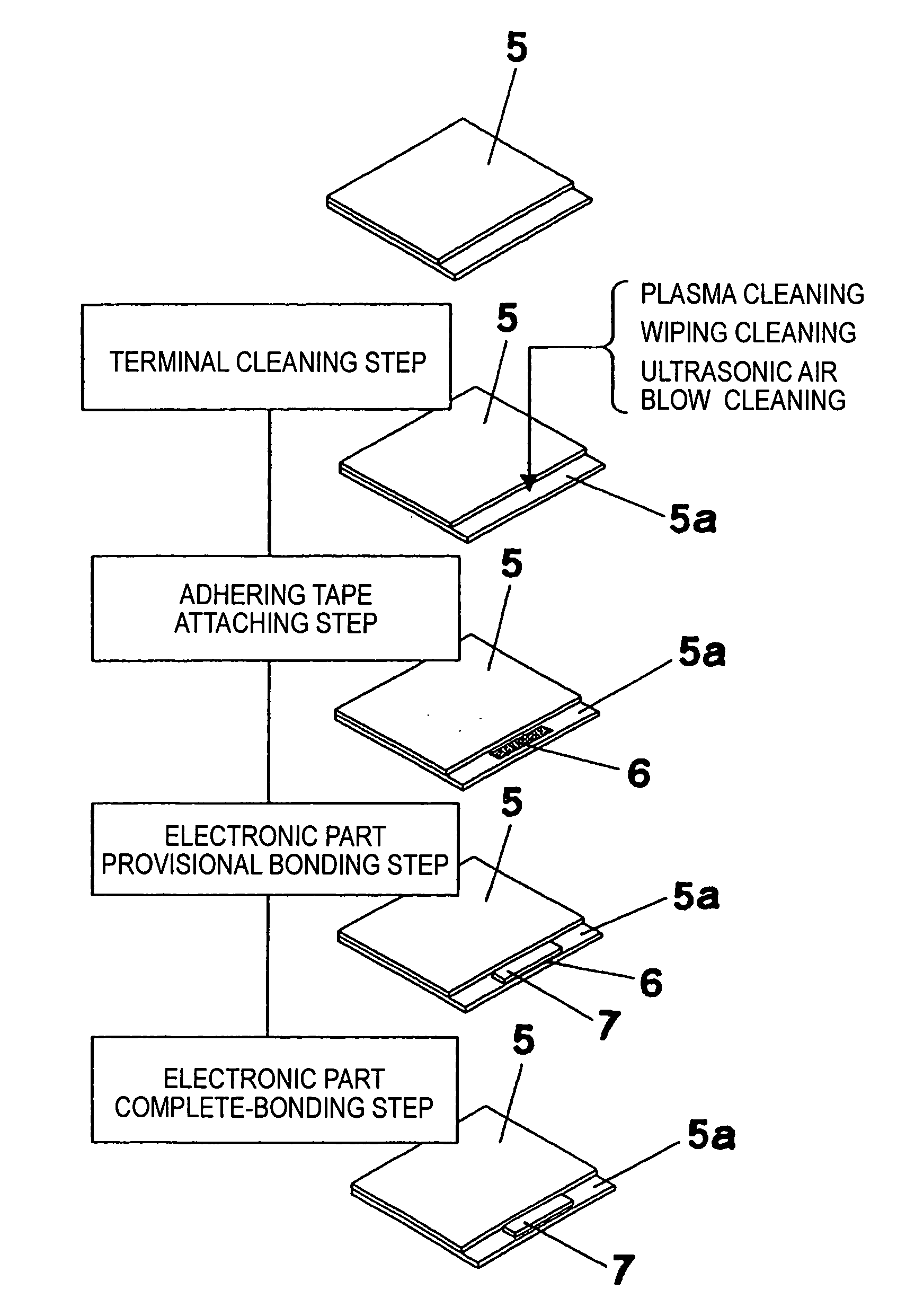

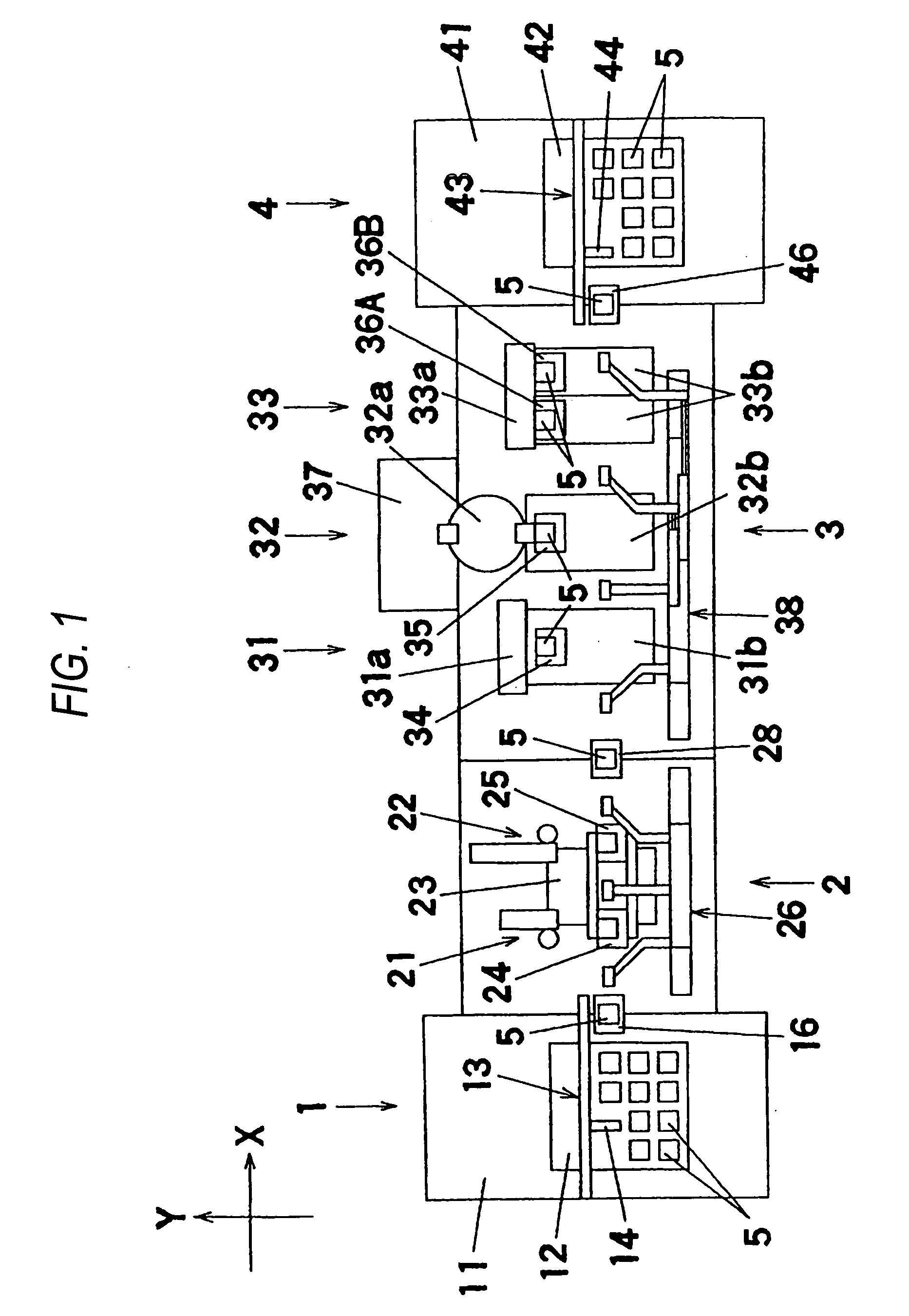

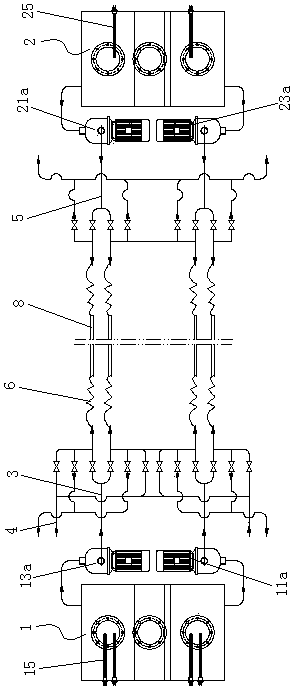

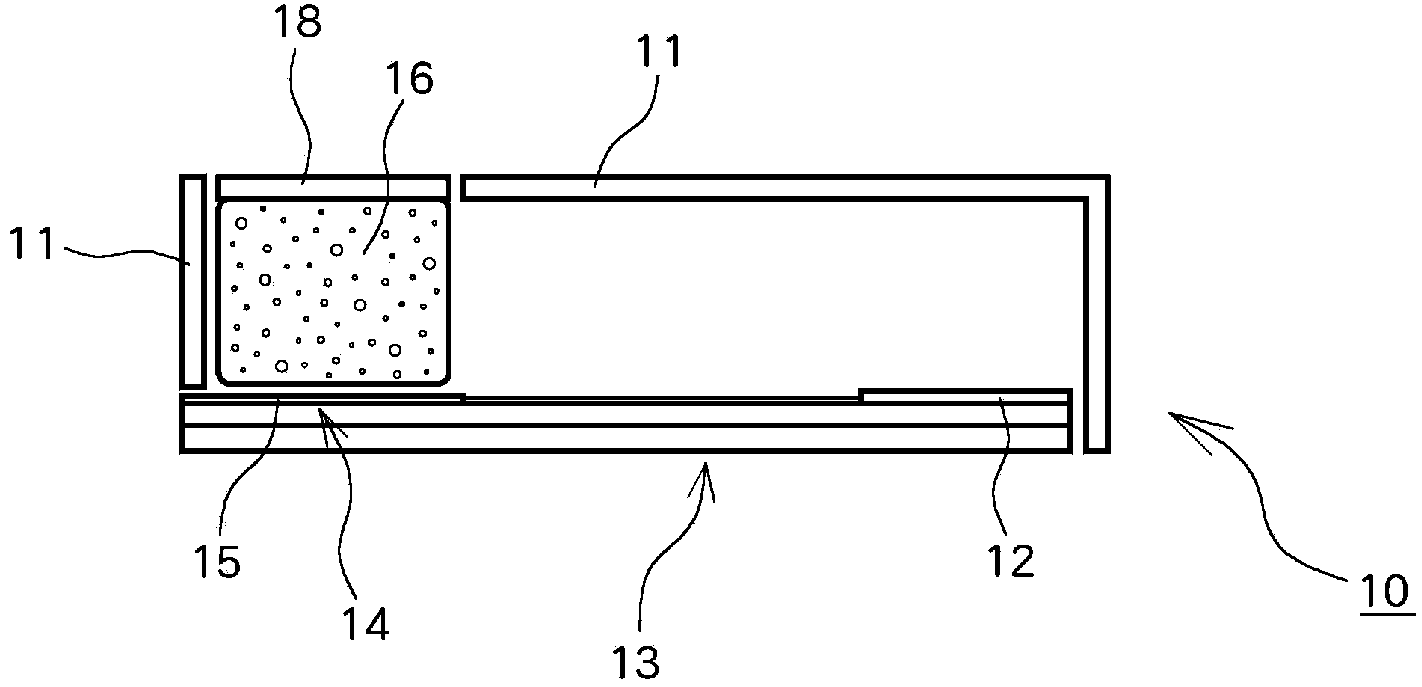

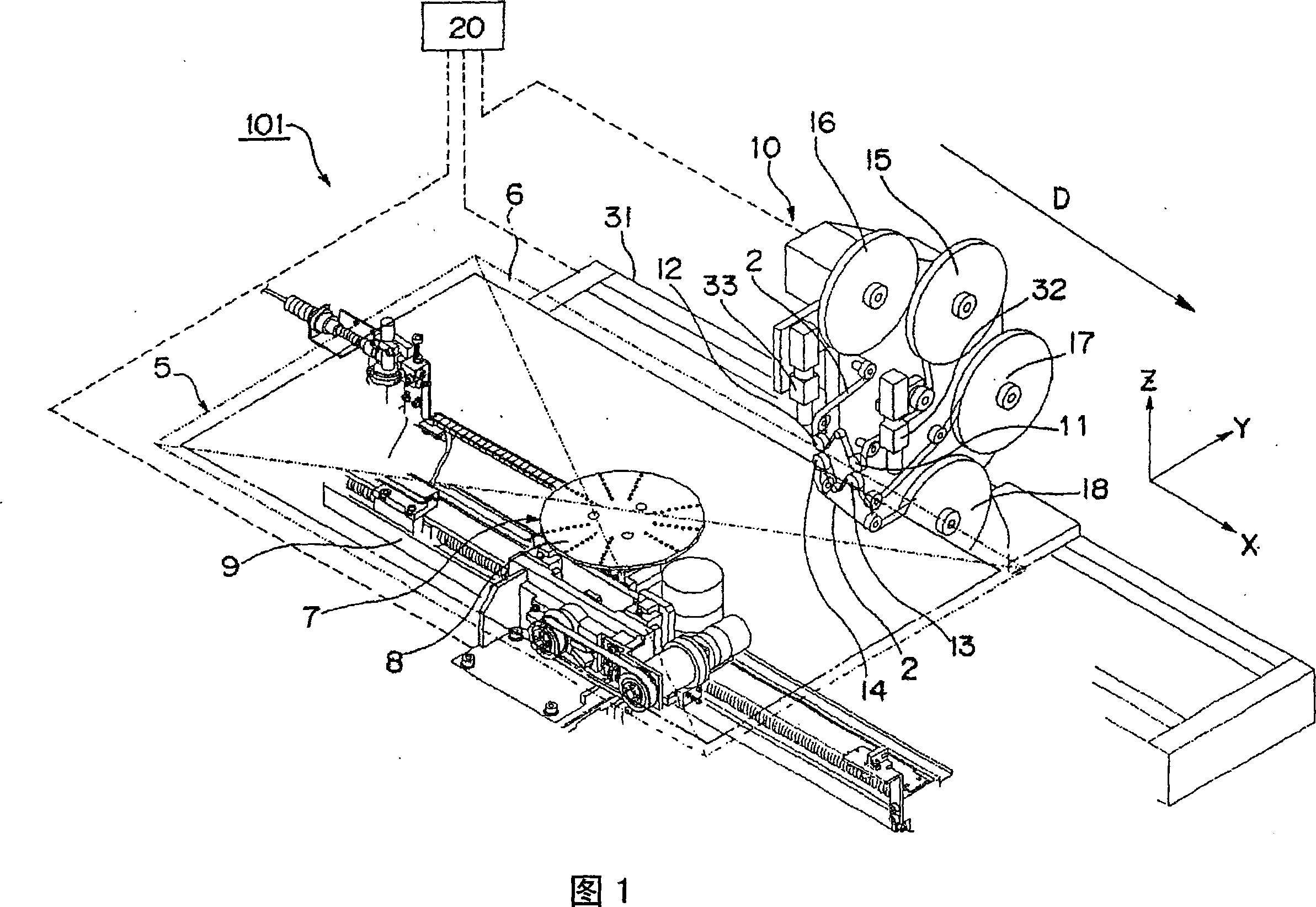

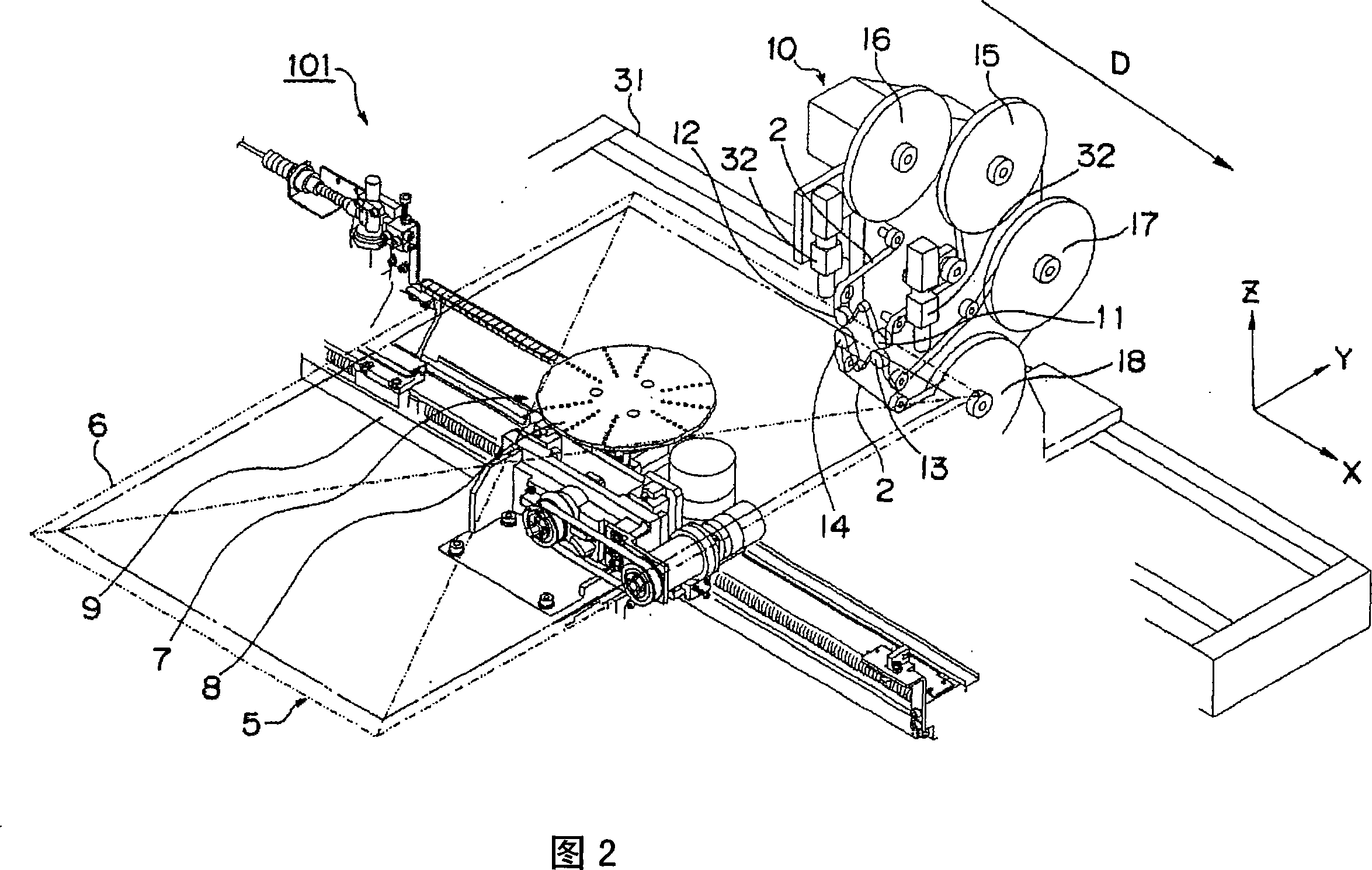

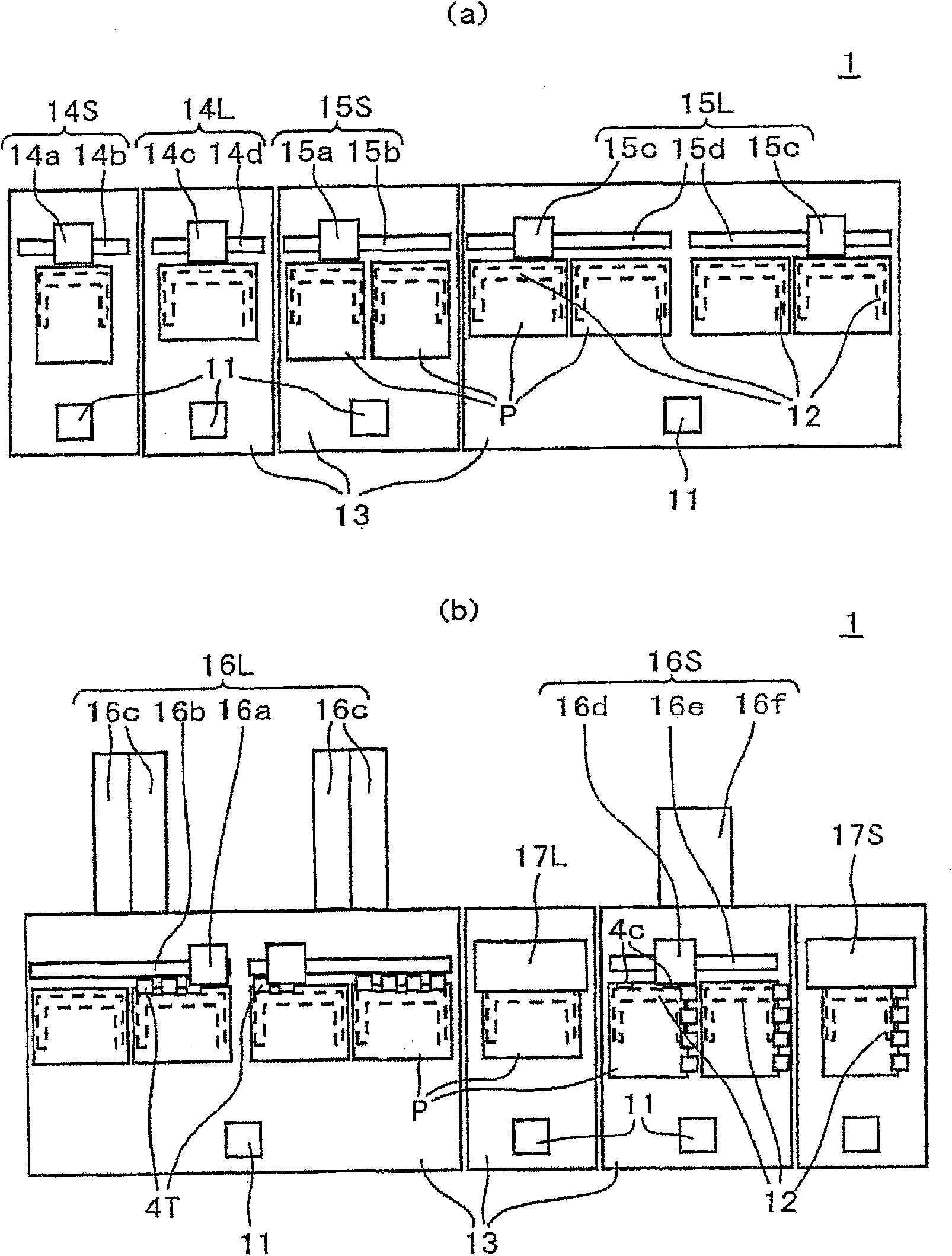

Assembling apparatus, assembling method and terminal cleaning apparatus

ActiveCN1601715AShorten the time periodPrinted circuit assemblingSemiconductor/solid-state device manufacturingEngineeringTransfer mechanism

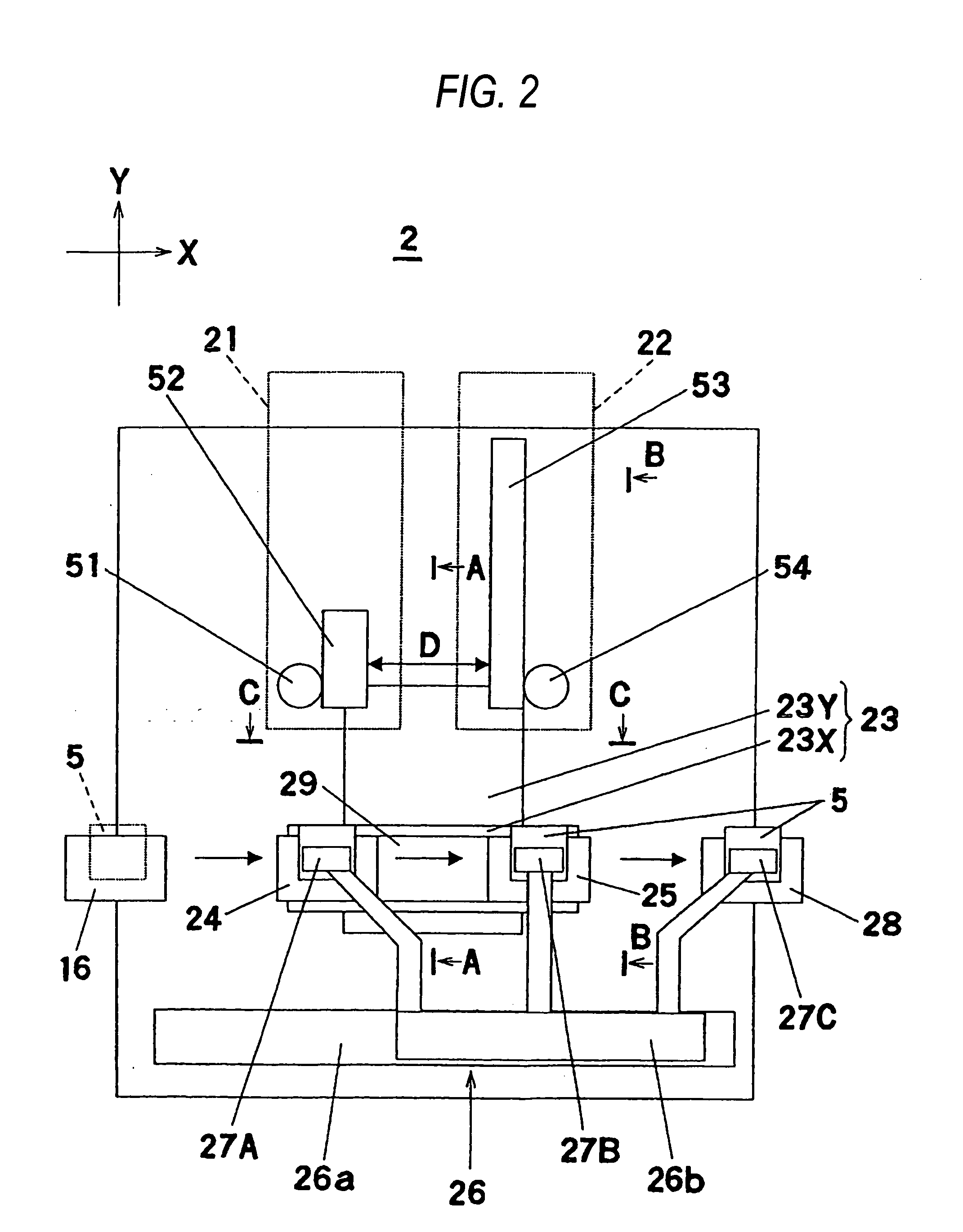

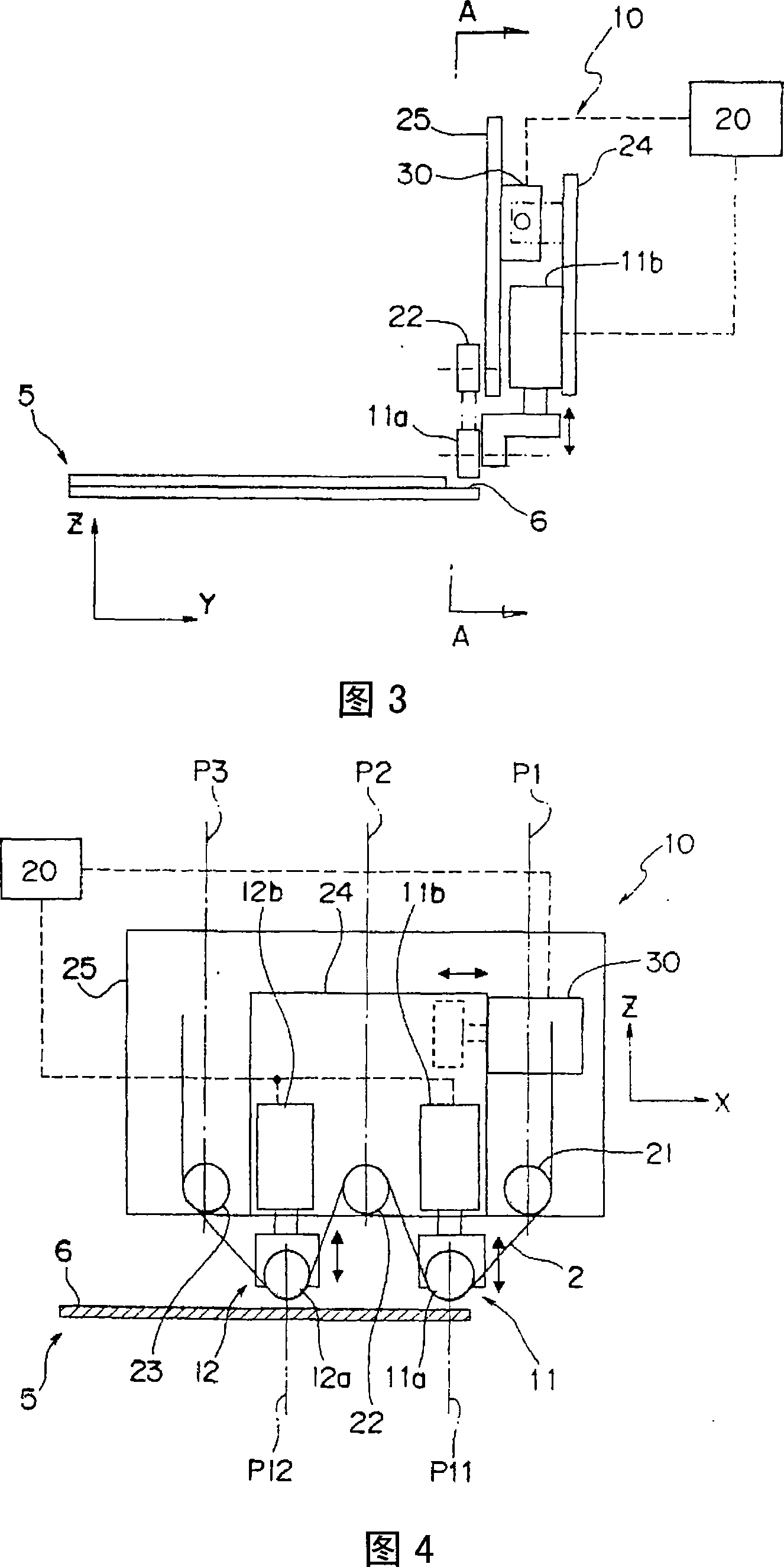

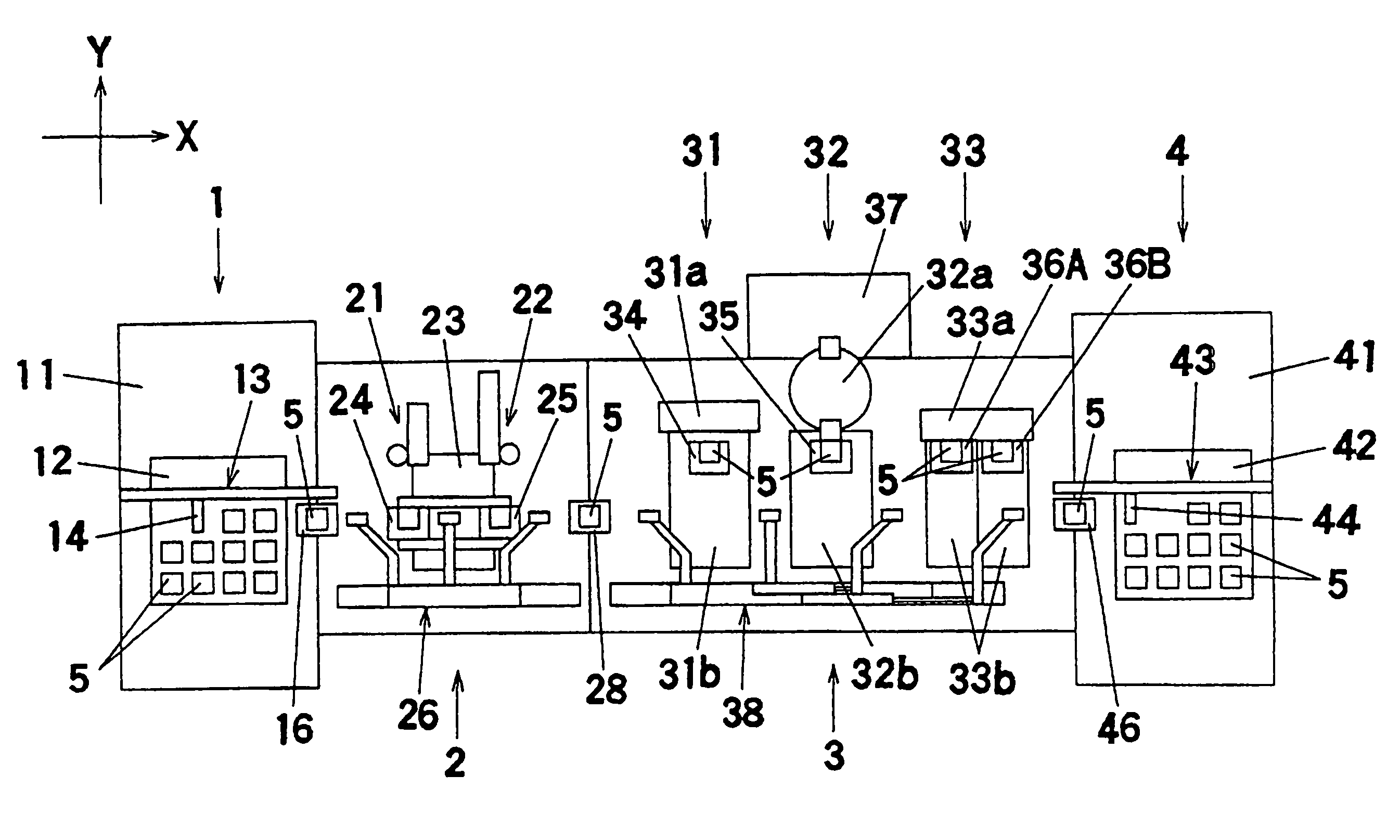

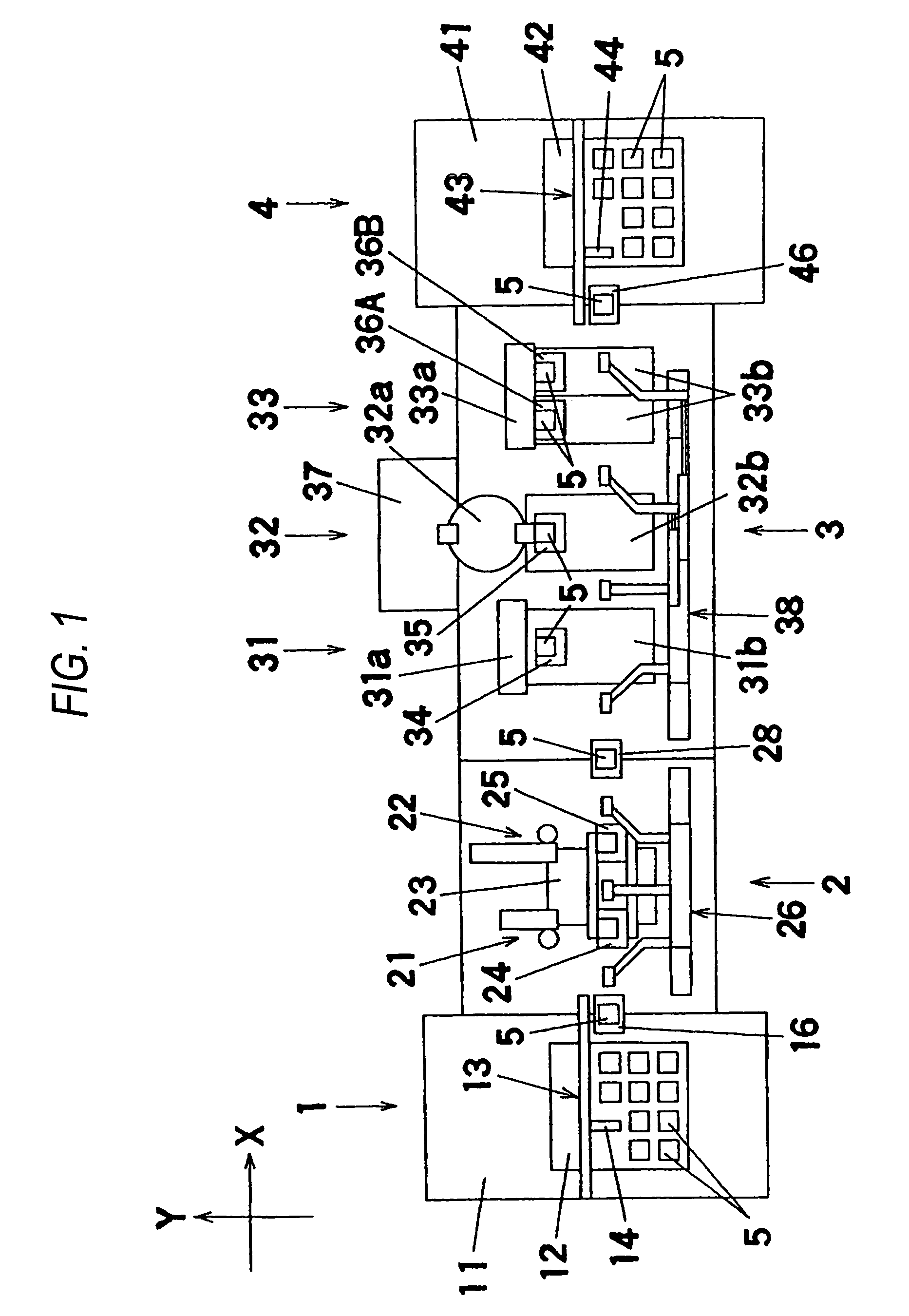

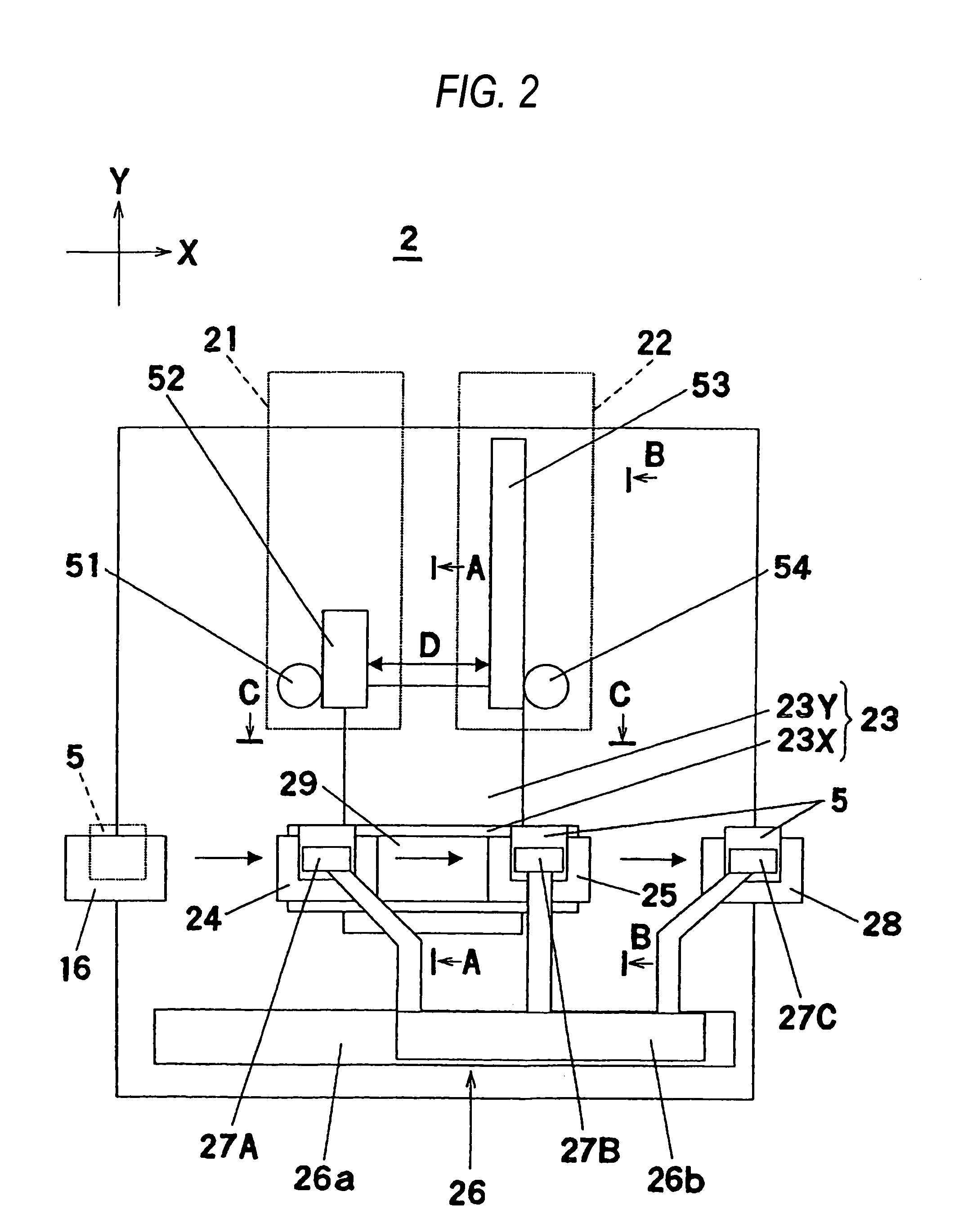

A terminal cleaning apparatus integrated to an assembling apparatus for integrating a display panel by bonding an electronic part to an externally connecting terminal of a substrate in which substrates 5 respectively held by a first substrate holding portion 24 and a second substrate holding portion 25 moved by an XY table mechanism 23 are made to pass through a first cleaning portion 21 and a second cleaning portion 22 having different cleaning means to simultaneously clean and the substrate which is not cleaned is carried in and the substrate 5 is transferred between the substrate holding portions and the substrate 5 which has been cleaned is carried out simultaneously by a first substrate transferring mechanism 26. Thereby, an operational efficiency of a step of cleaning an externally connecting terminal can be improved by making substrate carrying operation efficient.

Owner:PANASONIC CORP

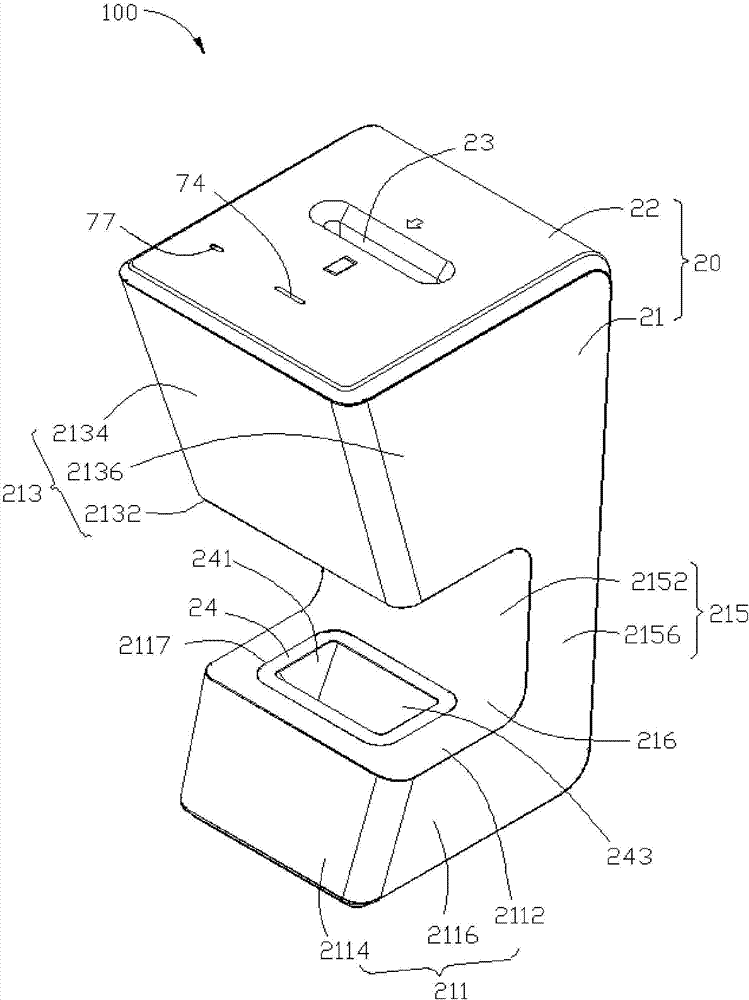

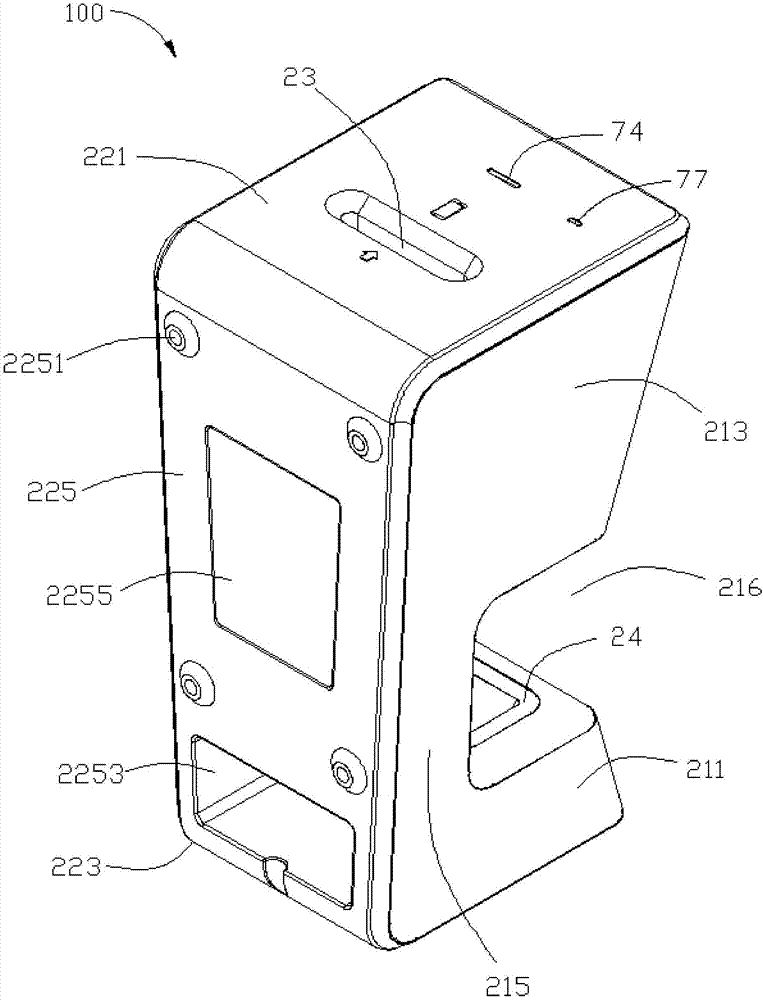

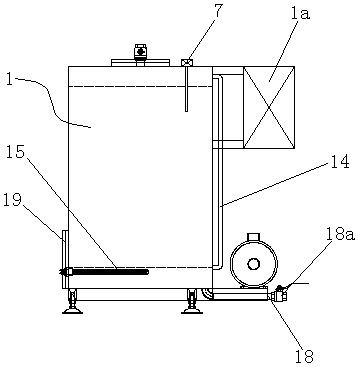

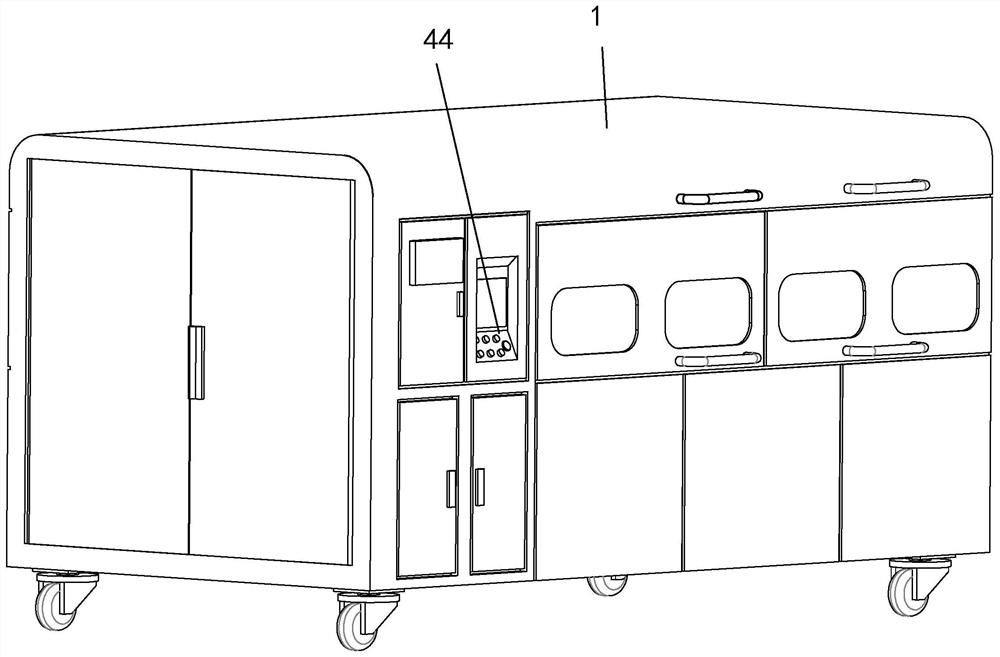

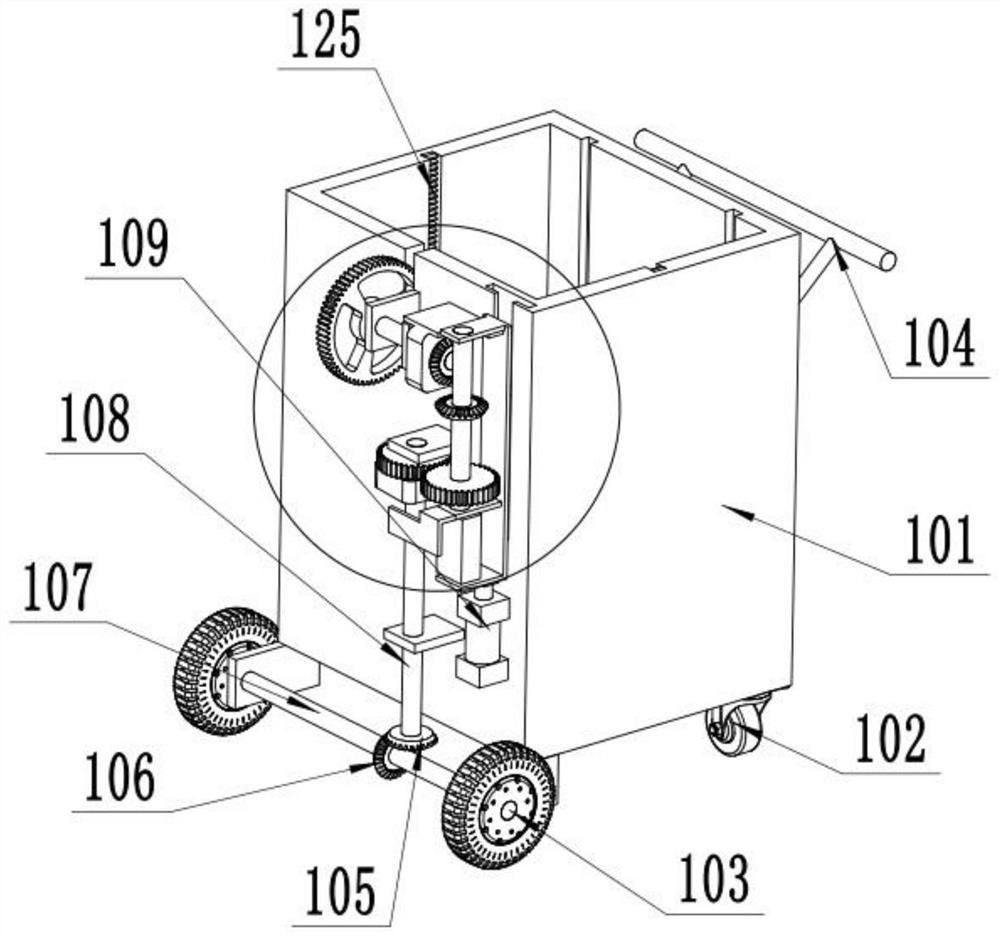

Mobile terminal cleaning device

PendingCN107971263AEasy to useHigh degree of automationDrying gas arrangementsCleaning using toolsComputer terminalEngineering

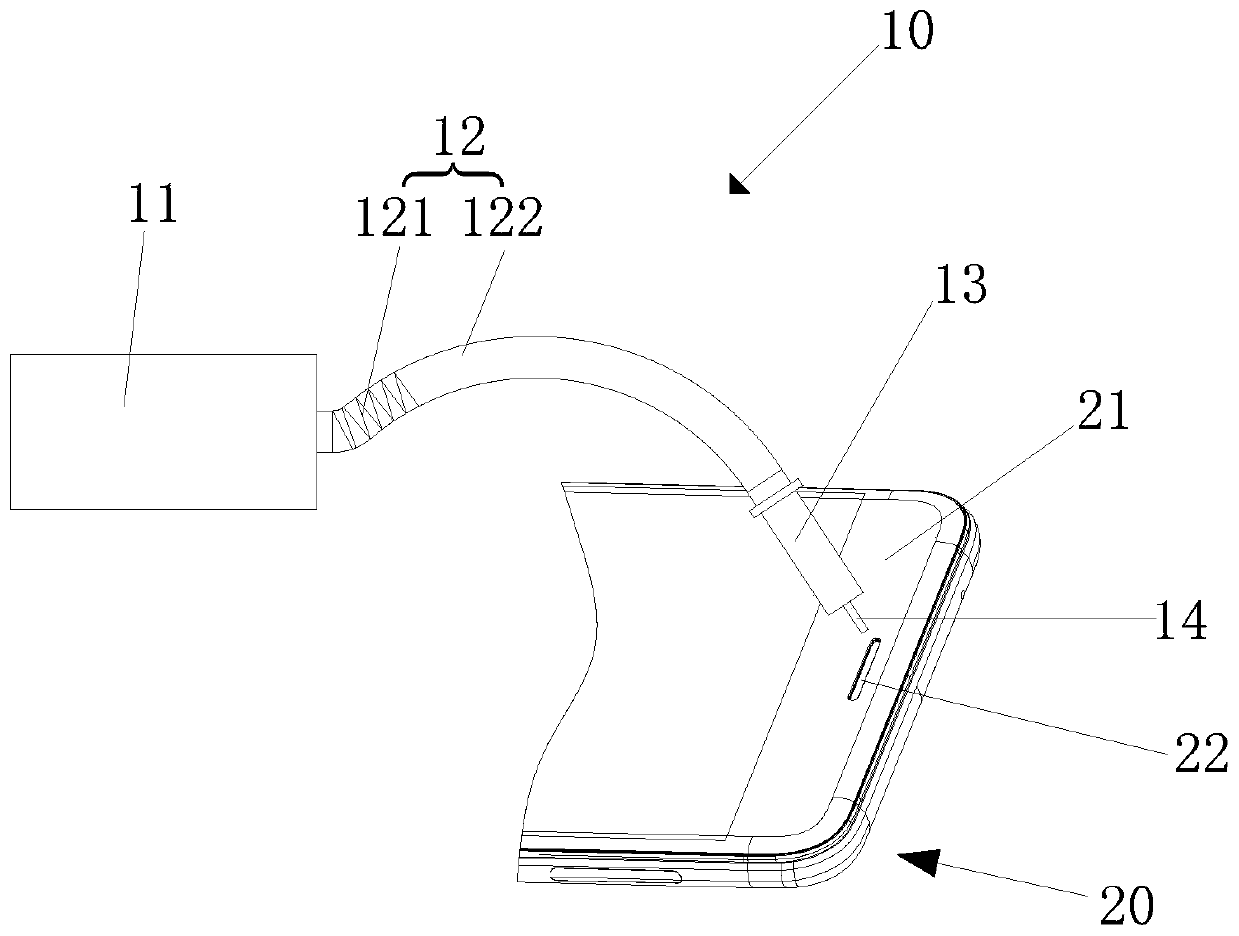

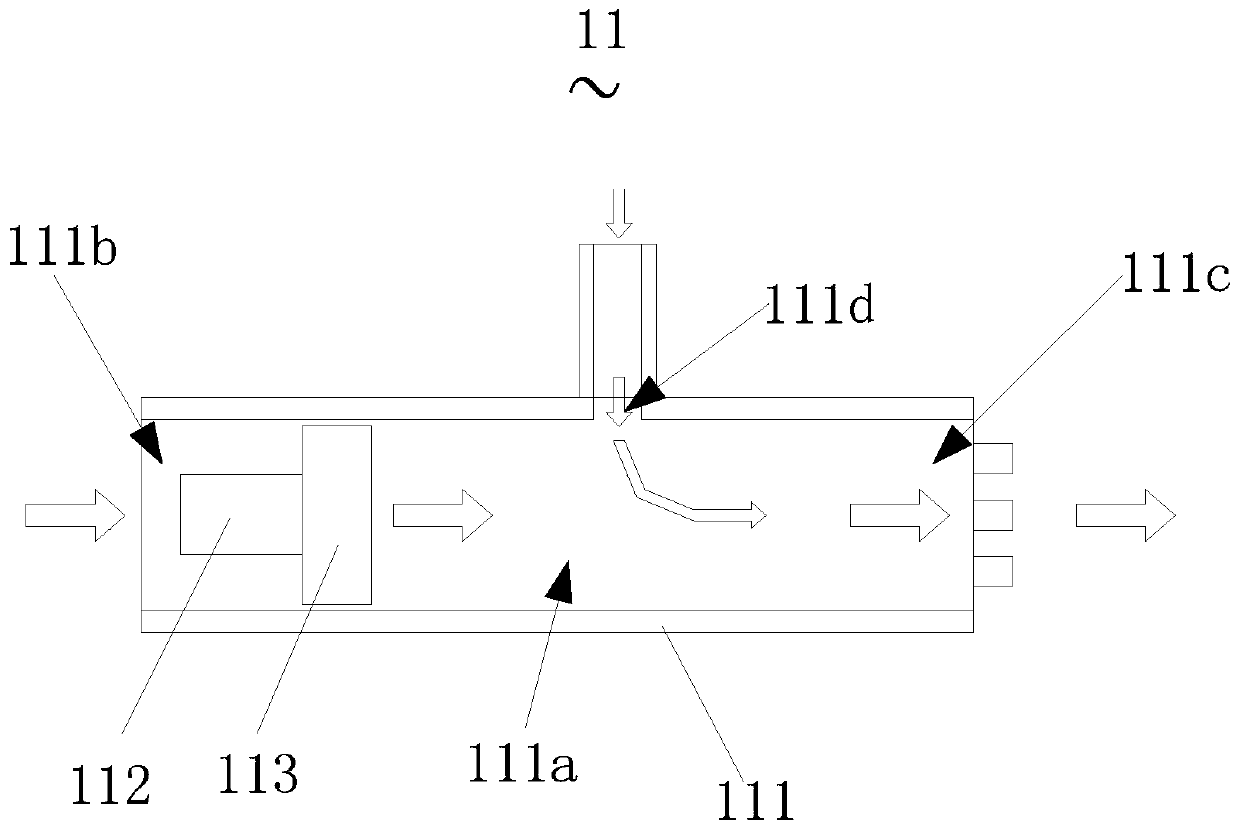

The invention provides a mobile terminal cleaning device. A shell, a guiding mechanism, a cleaning and disinfecting mechanism and a controller electrically connected to the guiding mechanism and the cleaning and disinfecting mechanism are included; a cleaning area is arranged in the shell; a feeding port is formed in one end of the cleaning area; a discharging port is formed in the other end of the cleaning area; the guiding mechanism comprises an inlet guiding piece arranged at the position of the feeding port and an outlet guiding piece arranged at the position of the discharging port; the cleaning and disinfecting mechanism is arranged in the shell and between the inlet guiding piece and the outlet guiding piece; a mobile terminal is inserted in the feeding port; the controller controlsthe guiding mechanism to drive the mobile terminal to pass through the cleaning area; and the controller controls the cleaning and disinfecting mechanism to perform cleaning and disinfecting on the mobile terminal.

Owner:深圳市极峰创新有限公司

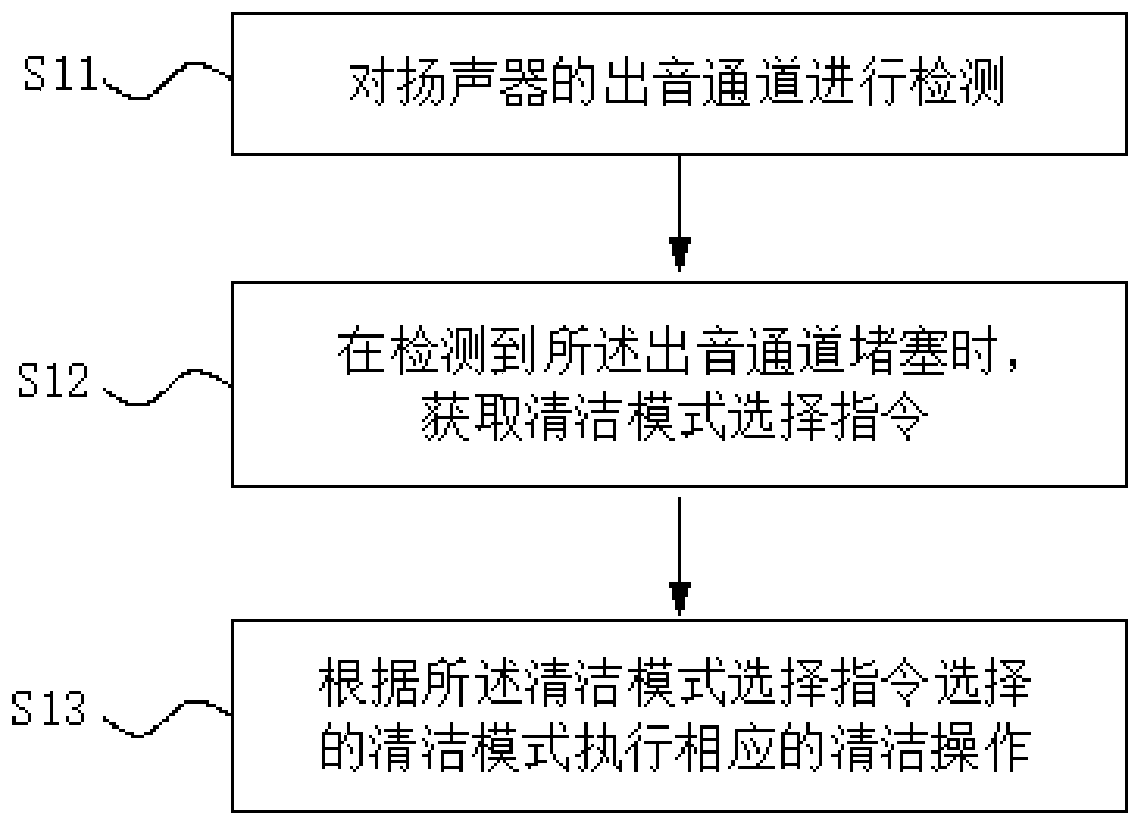

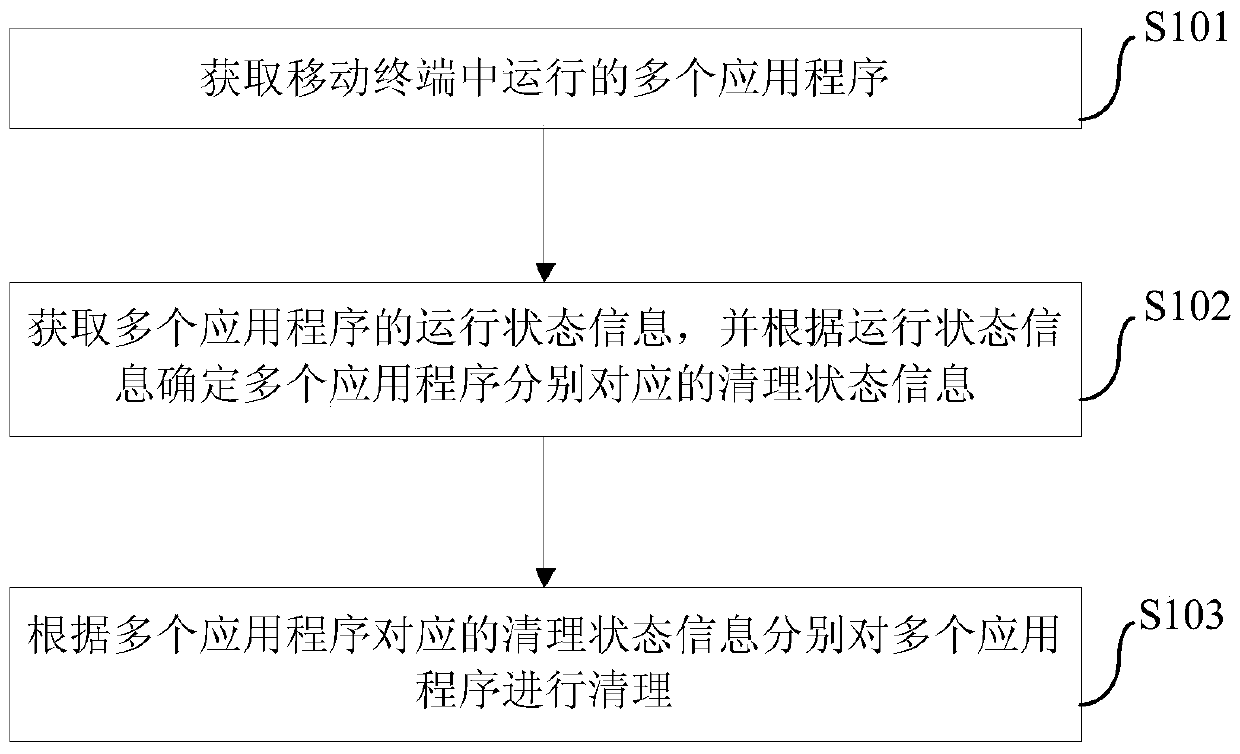

Method for processing terminal cleaning process, mobile terminal and readable storage medium

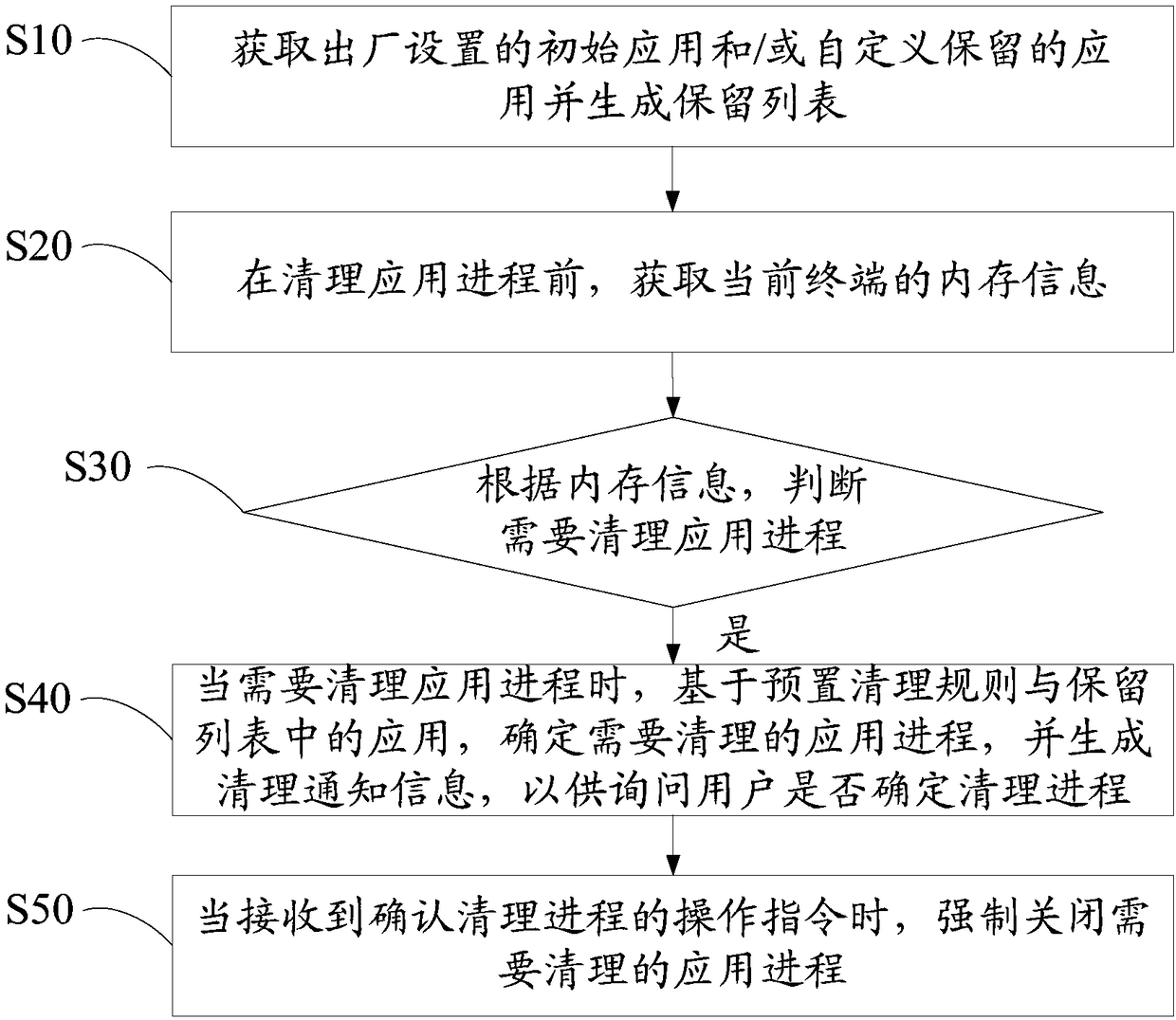

PendingCN108519916AImprove experienceGuaranteed smoothnessProgram initiation/switchingResource allocationComputer terminalTerminal cleaning

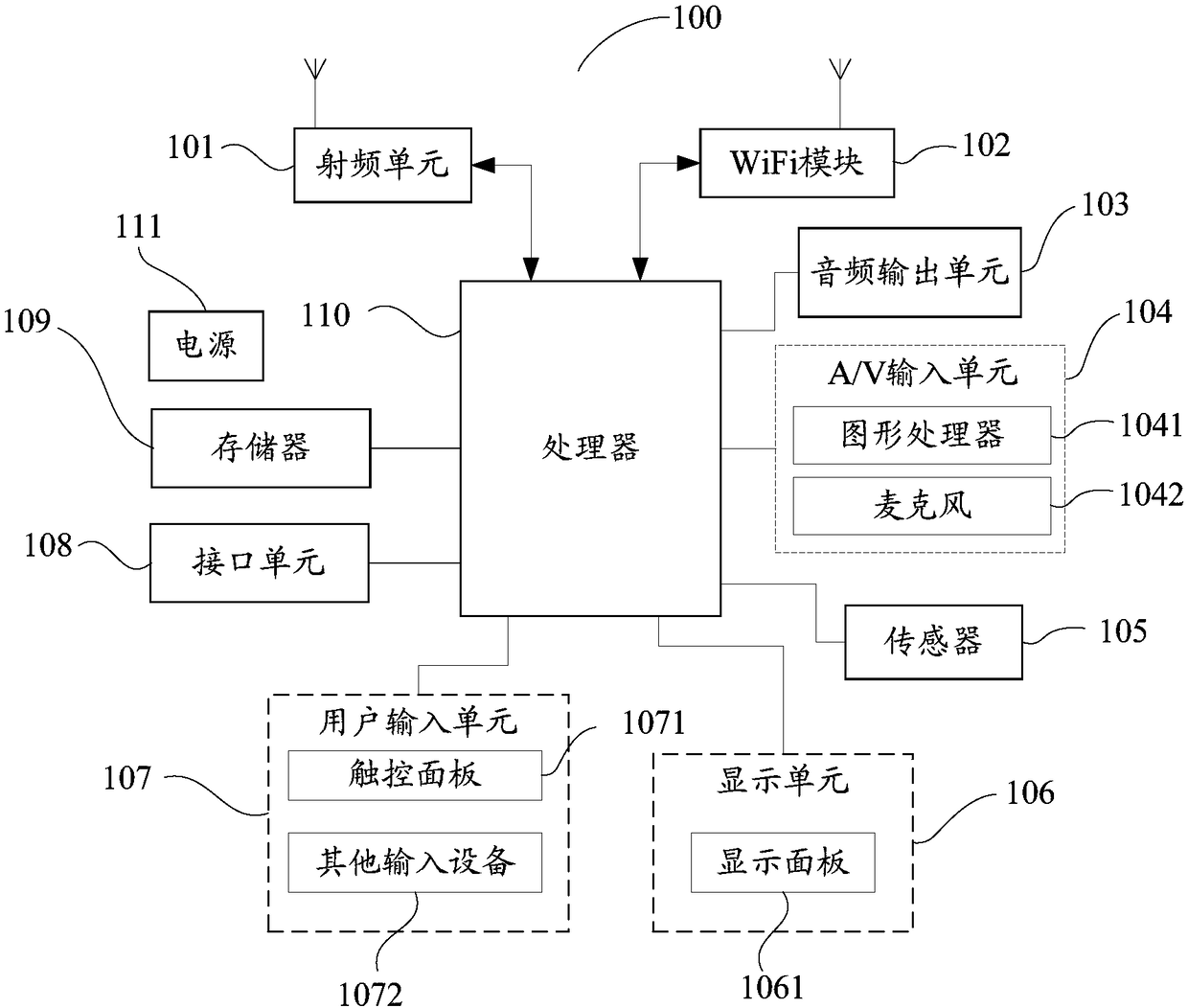

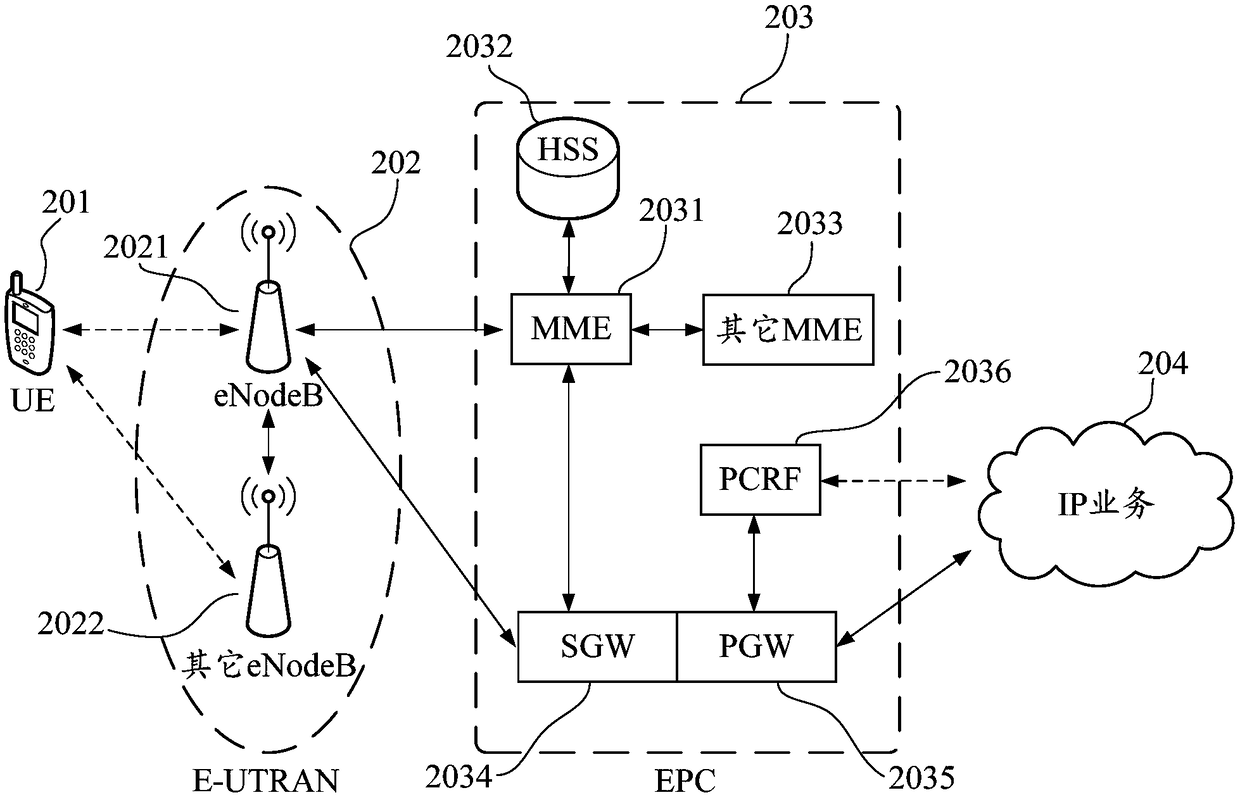

The invention discloses a method for processing a terminal cleaning progress. The method comprises the following steps that factory-set initial applications and / or customizedly reserved applicationsare obtained and a reservation list is generated; before cleaning an application progress, memory information of a current terminal is obtained; according to the memory information, it is judged whether or not the application progress needs to be cleaned; if yes, on the basis of a preset cleaning rule and application in the reservation list, the to-be-cleaned application progress is determined, cleaning notification information is generated, so that it can be queried whether or not a user determines to clean the progress; when an operation instruction that the cleaning progress is determined is received, the to-be-cleaned application progress is forcibly switched off. The invention further discloses a mobile terminal and a readable storage medium. The processing method, mobile terminal andreadable storage medium of the terminal cleaning progress have the advantages that it can be achieved that the application progress unreasonably taking up memory resources are released, thereby ensuring the fluency and cruising ability of the terminal running, and the operations of the user are reduced, thereby improving the use experience of the user.

Owner:NUBIA TECHNOLOGY CO LTD

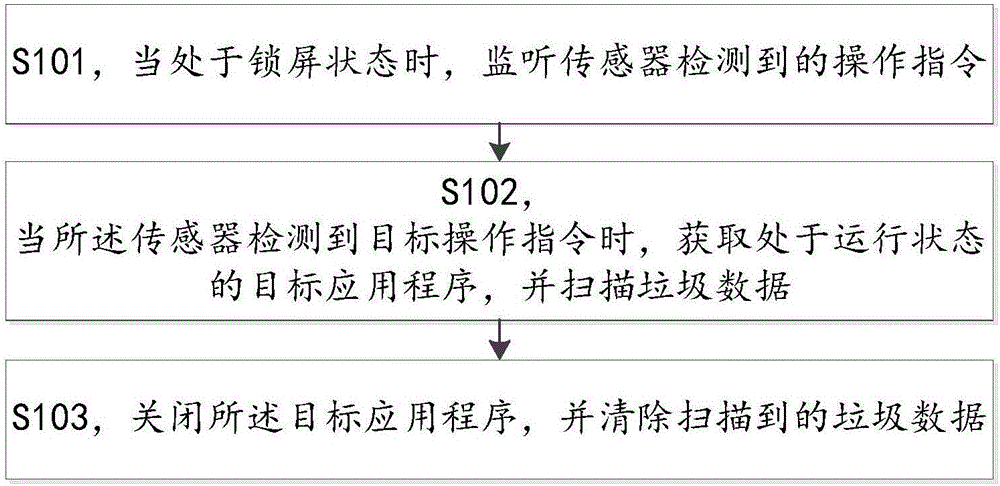

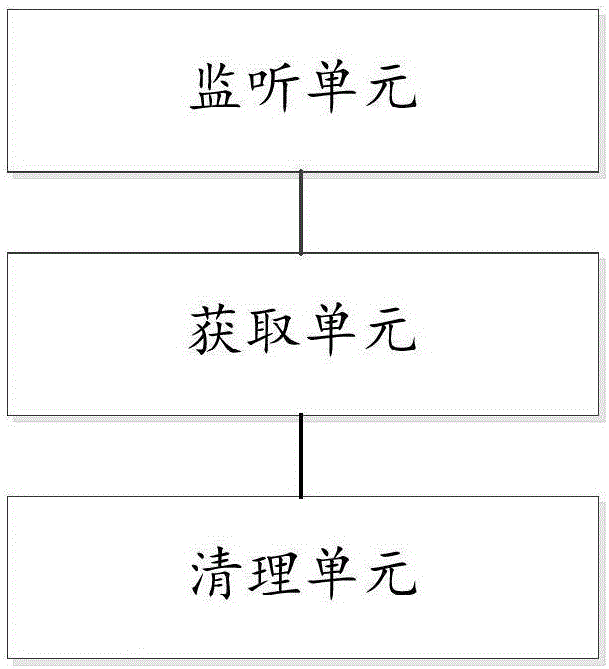

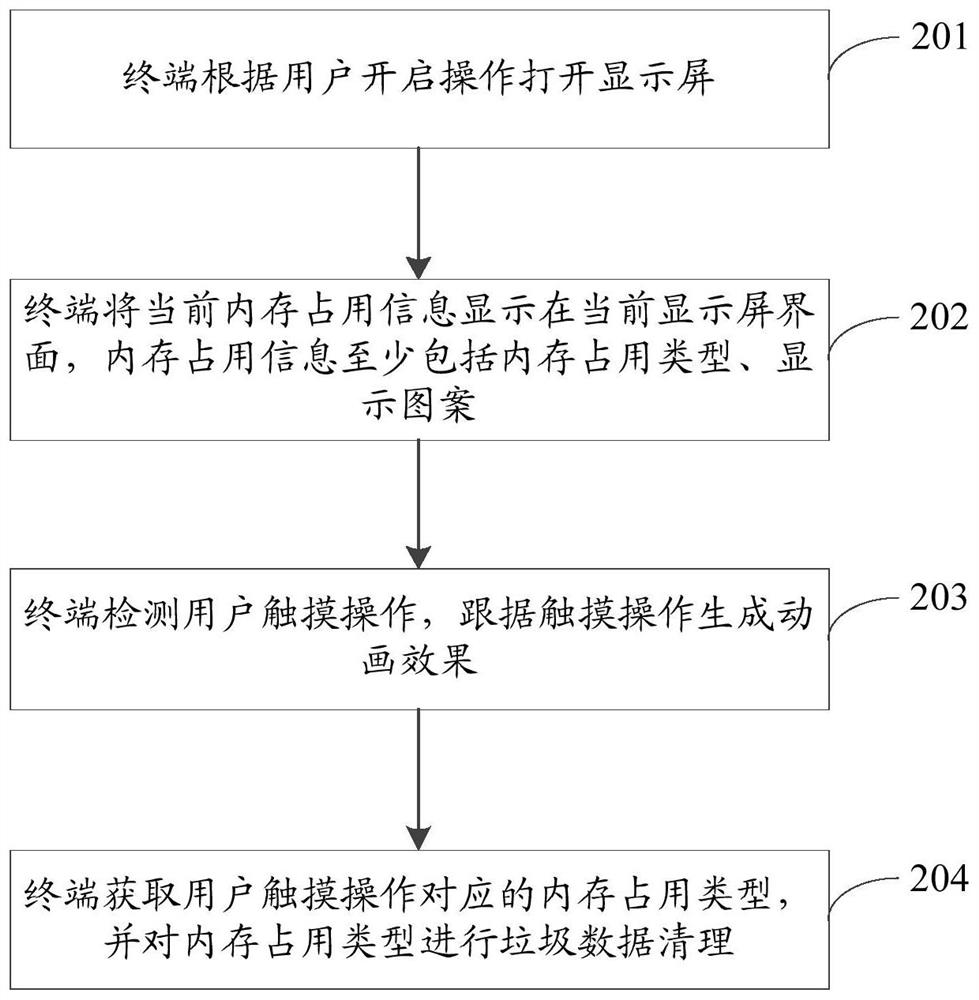

Cleaning method of mobile terminal and mobile terminal

InactiveCN106406694ASimplify cumbersome operationsSpecial data processing applicationsInput/output processes for data processingComputer terminalCleaning methods

The embodiment of the invention provides a cleaning method of a mobile terminal and the mobile terminal. In one aspect, the terminal cleaning method provided by the invention comprises the following steps: when the mobile terminal is in a lock screen state, monitoring an operation instruction detected by a sensor; when the sensor detects a target operation instruction, acquiring a target application program in a running state, and scanning trash data; and closing the target application program, and cleaning the scanned trash data. According to the cleaning method, cleaning operation of the mobile terminal can be enabled based on a preset operation instruction when the mobile terminal is in a lock screen state. Therefore, due to the cleaning method, cleaning operation of a user can be simplified.

Owner:SHENZHEN TINNO WIRELESS TECH

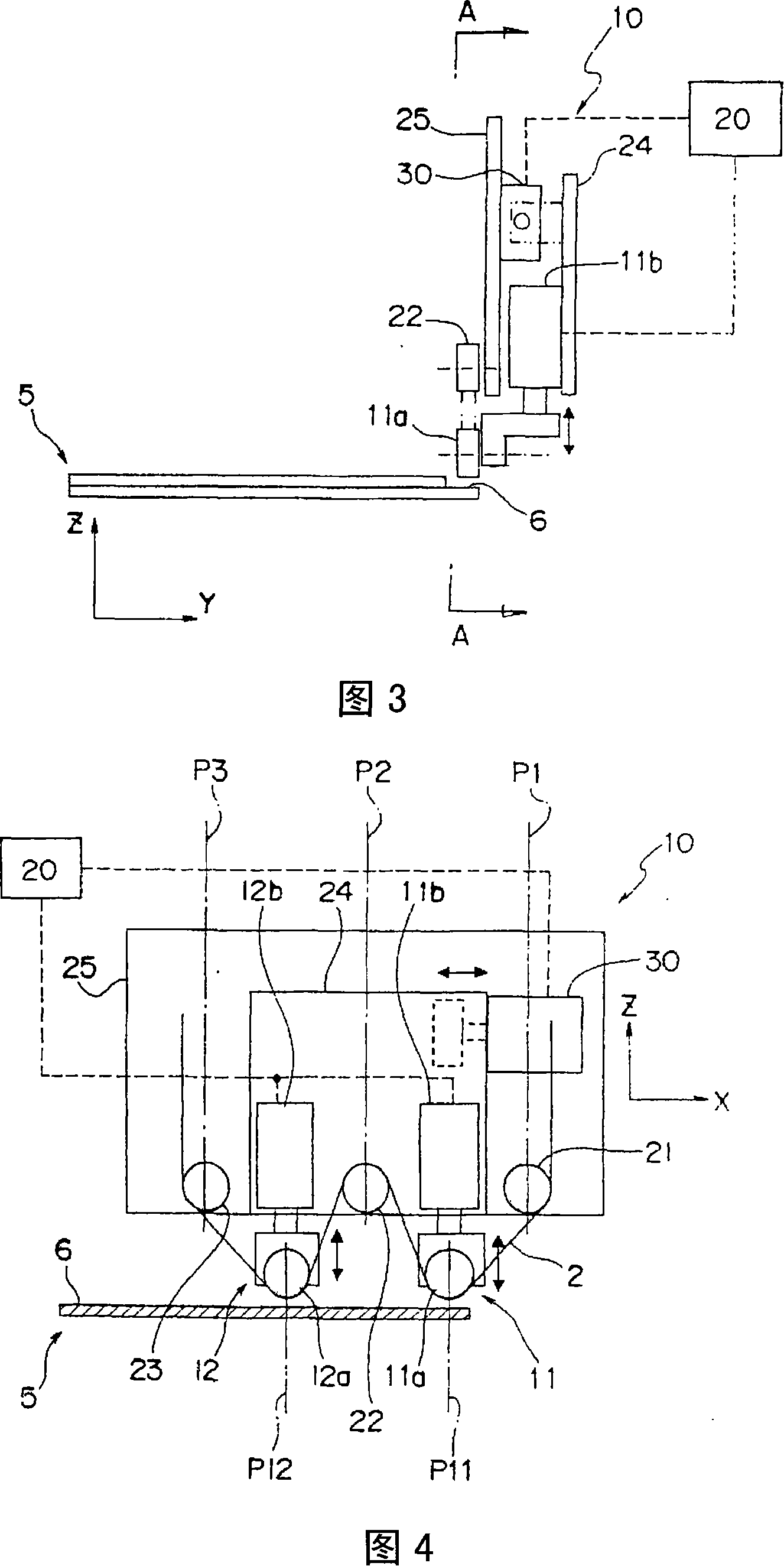

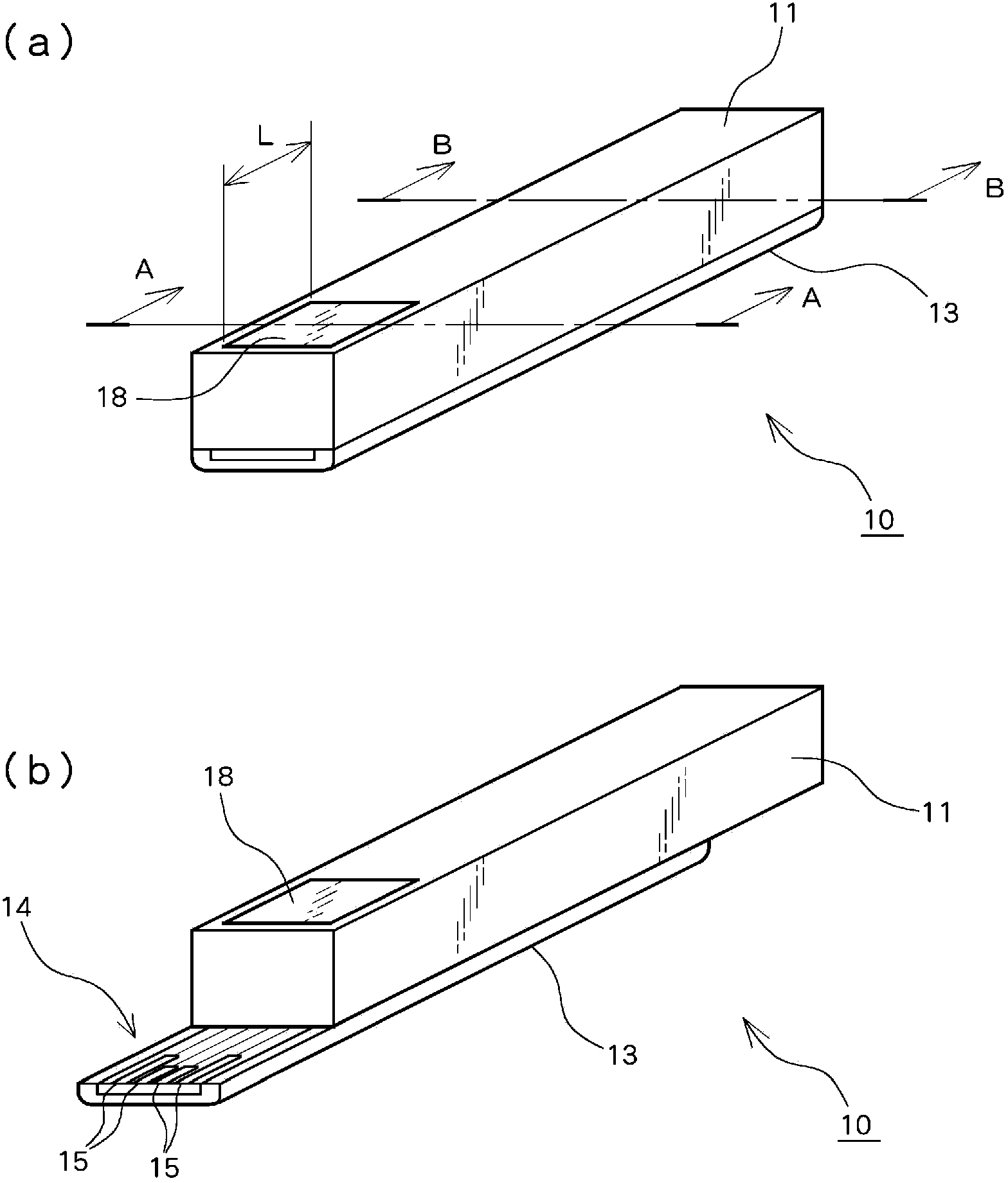

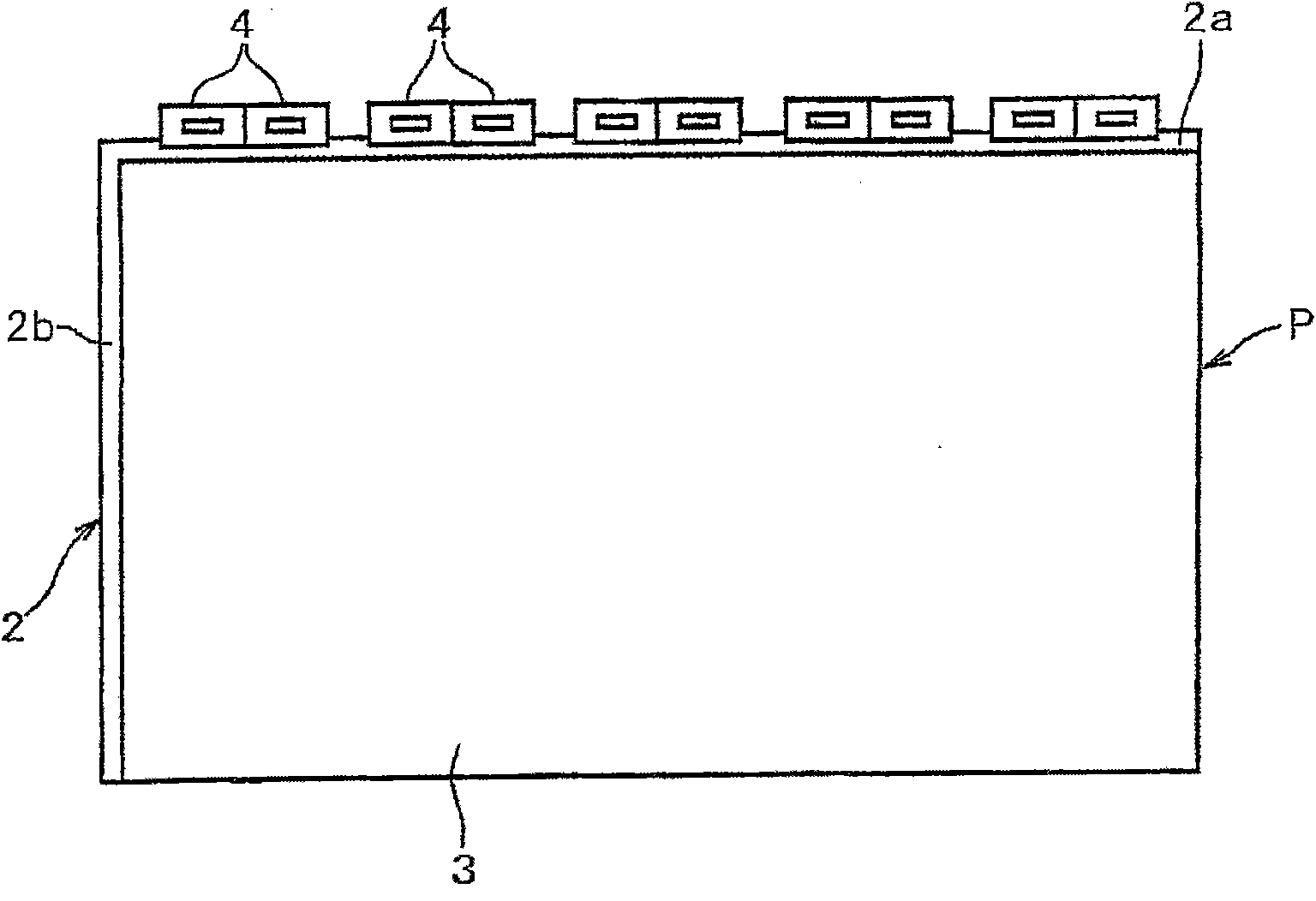

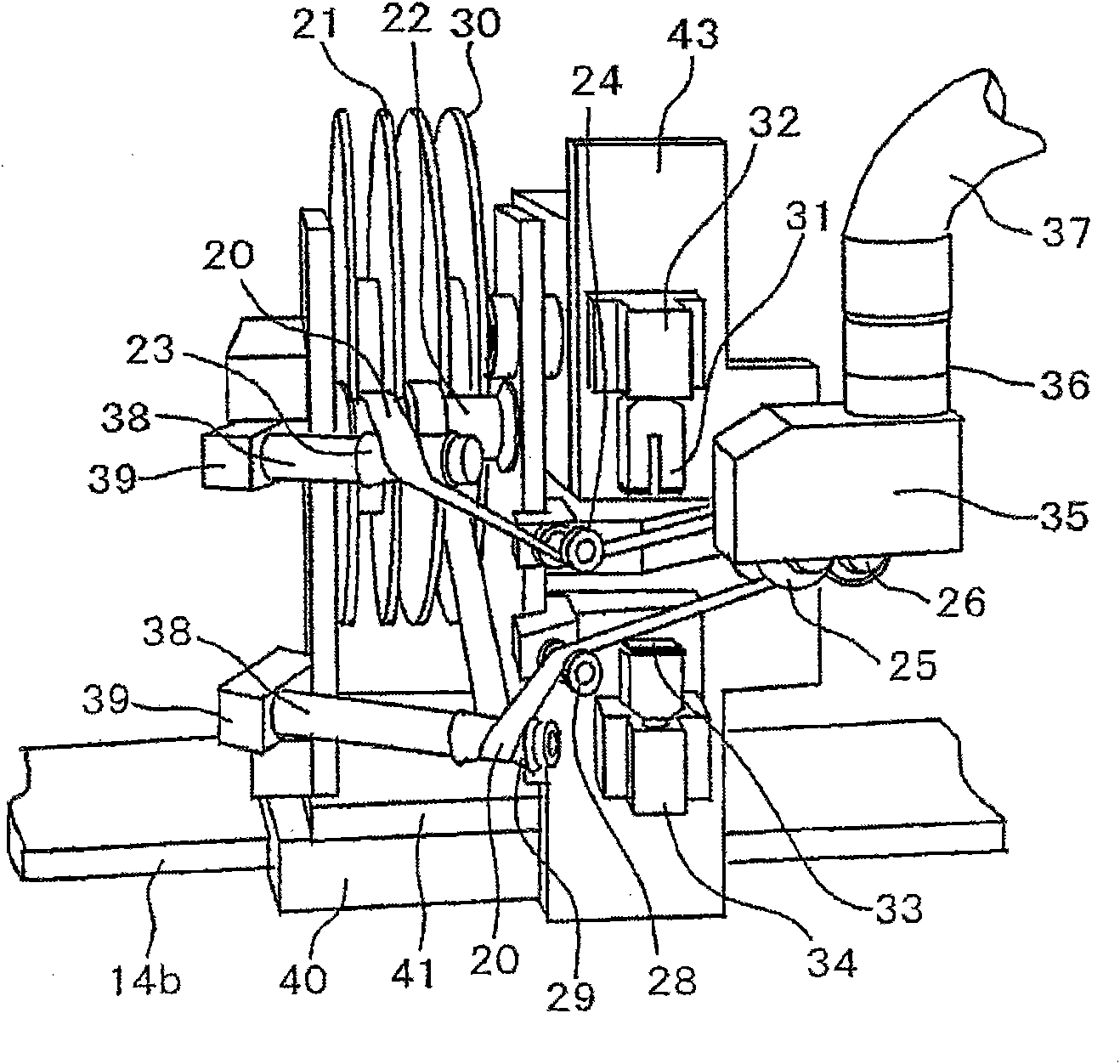

Substrate terminal cleaning apparatus and substrate terminal cleaning method

ActiveCN101151104AHigh precisionSemiconductor/solid-state device manufacturingCleaning using toolsEngineeringCleaning methods

A substrate terminal cleaning apparatus which performs cleaning of a terminal section of a substrate by having a cleaning member abut to the terminal section. The substrate terminal cleaning apparatus is provided with a first supporting section for supporting the cleaning member at a first position; a second supporting section for supporting the cleaning member at a second position; a cleaning head section for applying pressure to a part of the cleaning member, which is being supported between the first position and the second position, by having the part of the cleaning member abut to the terminal section of the substrate; a supporting section moving apparatus for integrally moving the first supporting section and the second supporting section in a direction along the terminal section; and a cleaning head moving apparatus for moving the cleaning head section in the direction along the terminal section, at a second moving speed different from a first moving speed at which the supporting section moving apparatus moves the first supporting section and the second supporting section.

Owner:PANASONIC CORP

Assembling apparatus, assembling method and terminal cleaning apparatus

ActiveUS20050066522A1Shorten cycle timeEasy to operatePrinted circuit assemblingLamination ancillary operationsEngineeringTransfer mechanism

A terminal cleaning apparatus integrated to an assembling apparatus for integrating a display panel by bonding an electronic part to an externally connecting terminal of a substrate in which substrates 5 respectively held by a first substrate holding portion 24 and a second substrate holding portion 25 moved by an XY table mechanism 23 are made to pass through a first cleaning portion 21 and a second cleaning portion 22 having different cleaning means to simultaneously clean and the substrate which is not cleaned is carried in and the substrate 5 is transferred between the substrate holding portions and the substrate 5 which has been cleaned is carried out simultaneously by a first substrate transferring mechanism 26. Thereby, an operational efficiency of a step of cleaning an externally connecting terminal can be improved by making substrate carrying operation efficient.

Owner:PANASONIC CORP

Base plate cleaning device

ActiveCN104465332AReduce water consumptionReduce manufacturing costSemiconductor/solid-state device manufacturingWater storageTerminal cleaning

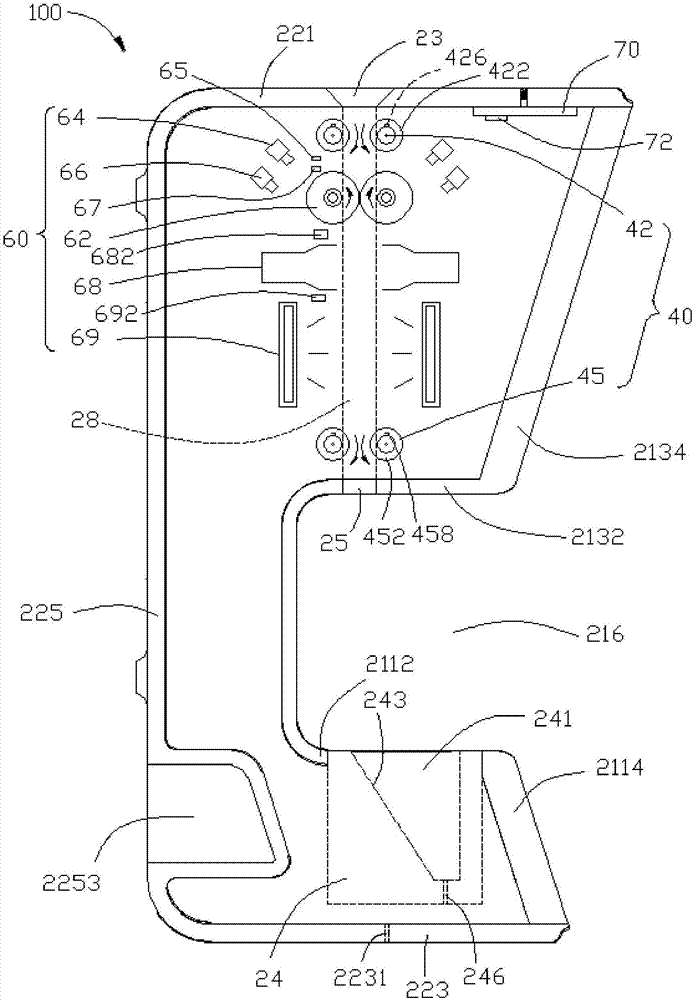

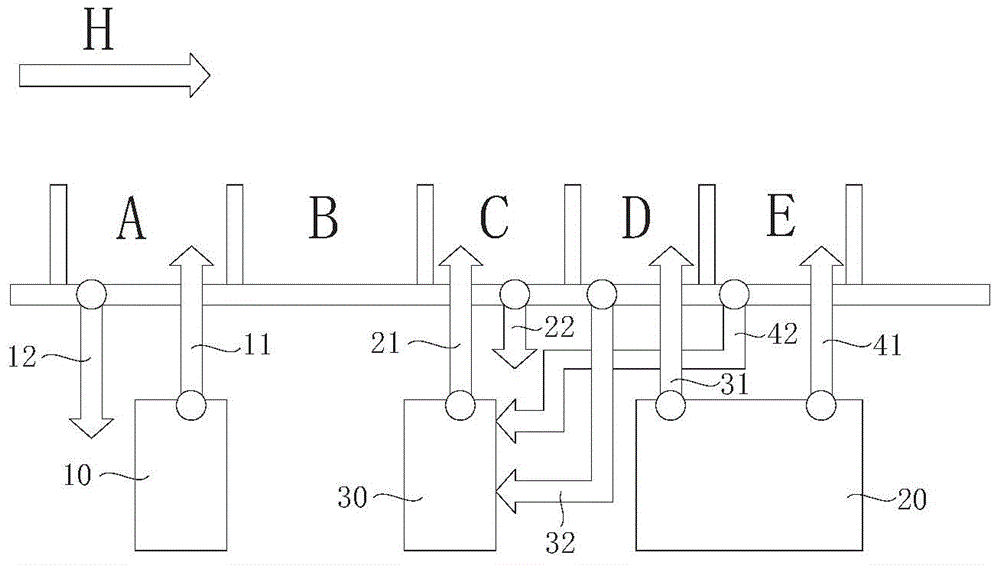

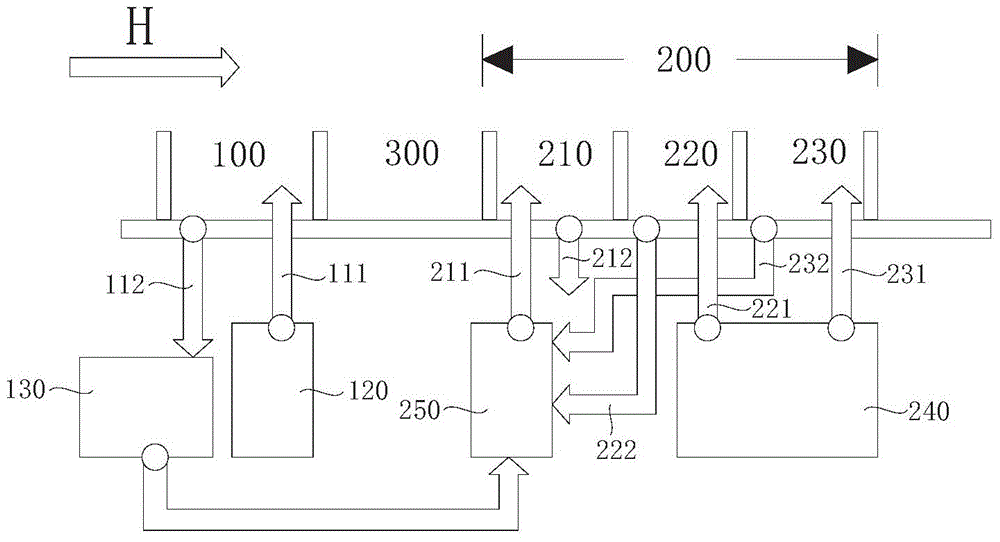

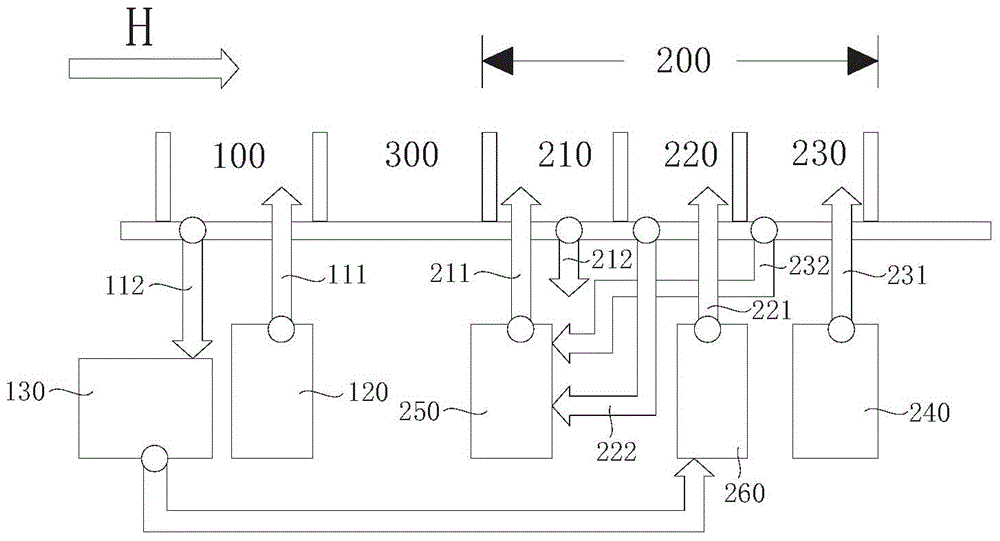

The invention discloses a base plate cleaning device. The base plate cleaning device comprises a before-photoetching cleaning region (100) and an after-photoetching cleaning region (200). The before-photoetching cleaning region (100) comprises a water supply pipe and a waste discharge pipe. The water supply pipe of the before-photoetching cleaning region (100) is communicated with a first water storage device (120). The after-photoetching cleaning region (200) comprises a primary cleaning region (210), an intermediate cleaning region (220) and a terminal cleaning region (230), wherein the primary cleaning region (210), the intermediate cleaning region (220) and the terminal cleaning region (230) are sequentially and adjacently connected. The primary cleaning region (210), the intermediate cleaning region (220) and the terminal cleaning region (230) each comprise a water supply pipe and a waste discharge pipe. The water supply pipe (221) and the water supply pipe (231) of the terminal cleaning region (230) are communicated with a second water storage device (240). The water supply pipe (211) is communicated with a second recoverer (250), the waste discharge pipe (222) and the waste discharge pipe (232) are communicated with the second recoverer (250), and the second recoverer (250) are communicated with the waste discharge pipe (112). By the adoption of the base plate cleaning device, water generated after a base plate is cleaned in the before-photoetching cleaning region is recovered, the pure water consumption is reduced, and therefore production cost is reduced.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

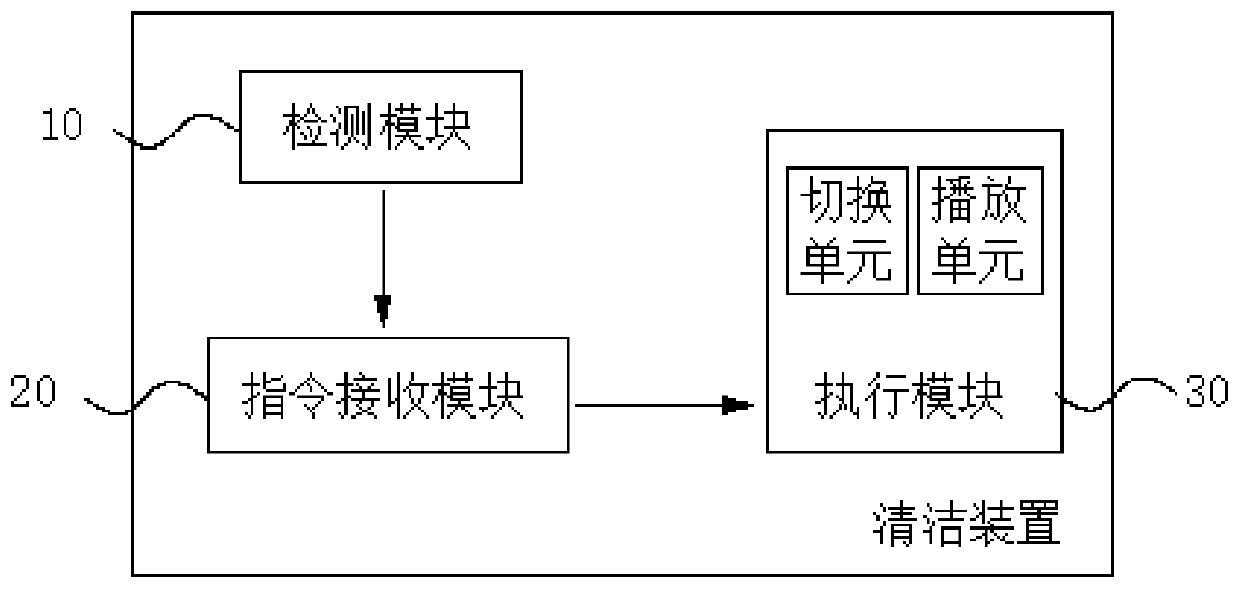

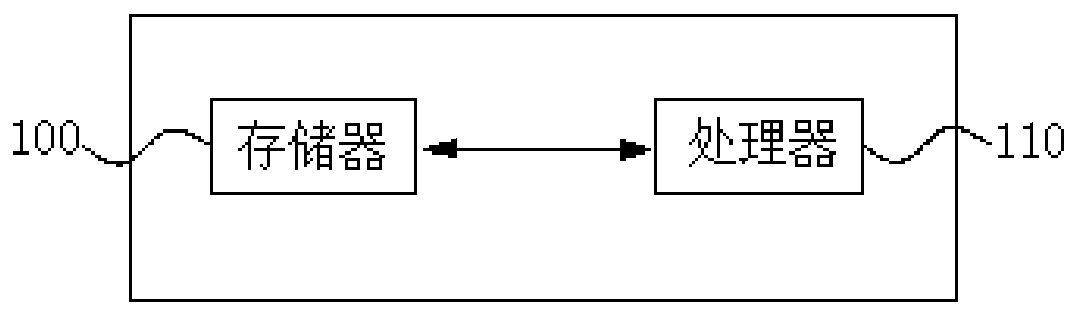

Cleaning method and device and terminal

PendingCN110691302ASolve the volume downSolve abnormal problems such as poor sound qualitySignal processingDispersed particle filtrationEngineeringLoudspeaker

Owner:SHENZHEN TRANSSION HLDG CO LTD

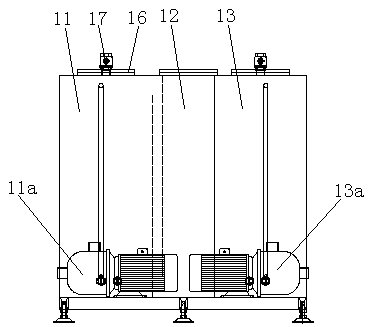

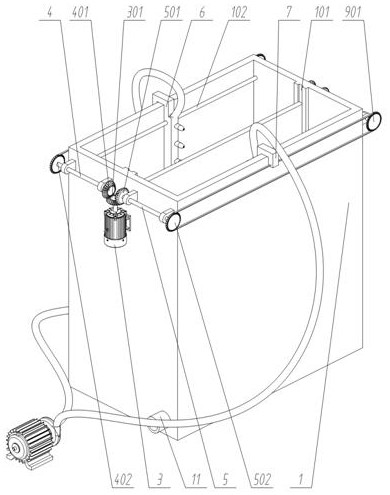

Stainless steel finish pipe inner wall cleaning equipment and cleaning method thereof

PendingCN108015065AClean thoroughlyAvoid effluxHollow article cleaningWork cleaning devicesWater basedMobile end

The invention discloses stainless steel finish pipe inner wall cleaning equipment. A main control computer controls and is connected with a main electric cabinet of a main cleaning machine and a mobile terminal electric cabinet of a mobile cleaning machine, wherein a main cleaning agent groove, a main oil separation groove and a main clear water groove are formed in the main cleaning machine; a main liquid level sensor is arranged on the main cleaning machine; a main cleaning agent groove and a main clear water groove are respectively connected with a main cleaning pipe by virtue of a main cleaning agent pump and a main clear water pump; and the main cleaning pipe is connected with a scavenging pipe; a mobile terminal cleaning agent groove, a mobile terminal oil separation groove and a mobile terminal clear water groove are formed in the mobile cleaning machine; a mobile terminal liquid level sensor is arranged on the mobile cleaning machine, and the mobile terminal cleaning agent groove and the mobile terminal clear water groove are respectively connected with a mobile terminal cleaning pipe by virtue of a mobile terminal cleaning agent pump and a mobile terminal clear water pump;and quick flexible pipes are arranged on a main cleaning pipe and a mobile terminal cleaning pipe, and the main cleaning agent groove and the mobile terminal cleaning agent groove respectively contain a water-based type environment-friendly cleaning agent. A cleaning method of the equipment comprises the following steps: cleaning with the cleaning agent, washing, and carrying out purging and airdrying. The equipment disclosed by the invention has the advantages of simple structure, high cleaning efficiency and good quality.

Owner:宁波东鼎特种管业有限公司

Electronic device

The invention provides an electronic device, and a user can select whether to clean a terminal for connection or not. The electronic device comprises a cover component, a terminal component, and a terminal cleaning component. The terminal component is provided with a terminal portion on an end, and the terminal portion can move between a position contained in the cover component and a position exposed outside the cover component. The terminal cleaning component is configured on a side of the cover component, and can move between a position contacting the terminal and a position of retreating on a moving path of the terminal portion.

Owner:BUFFALO CORP LTD

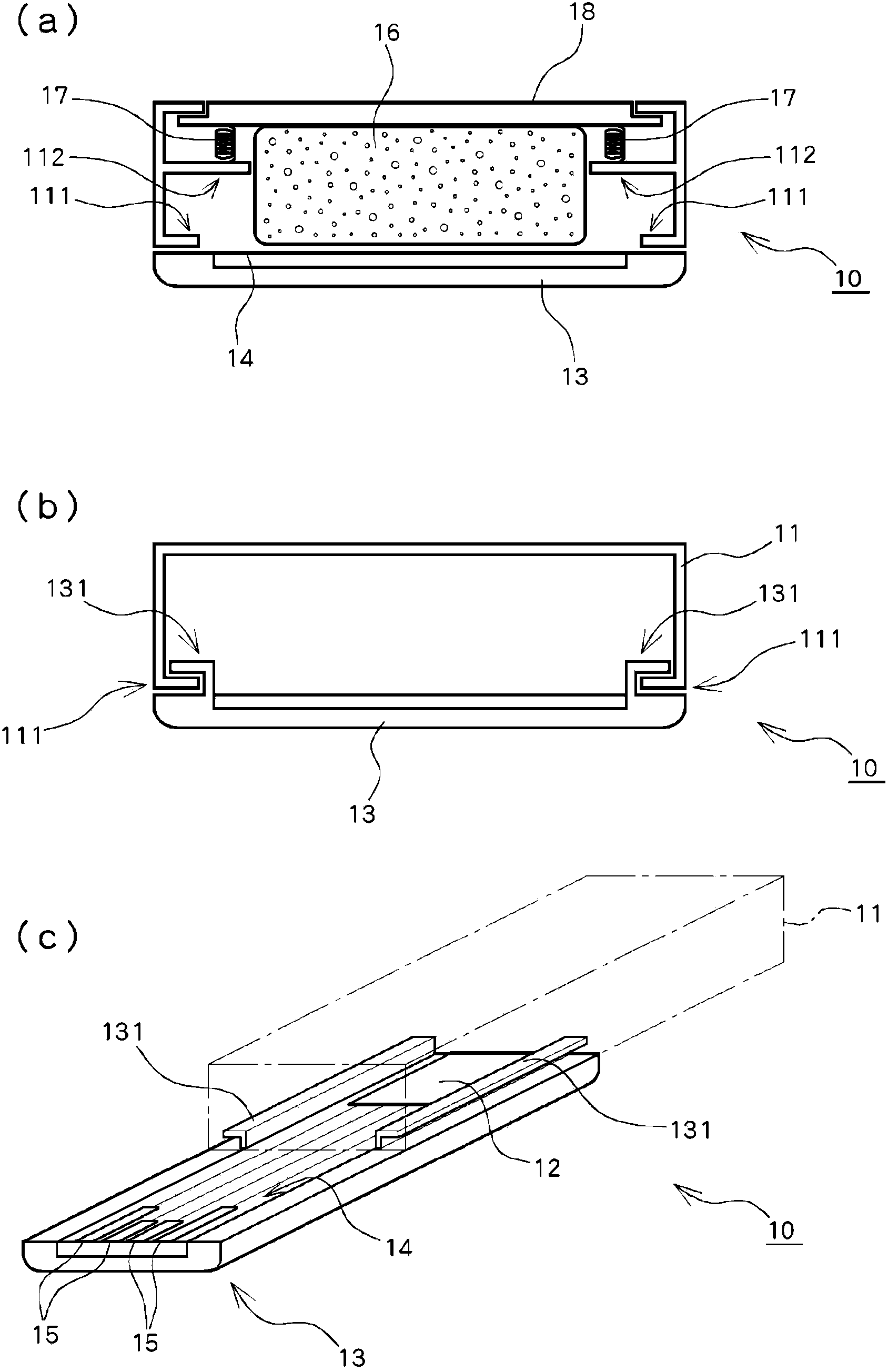

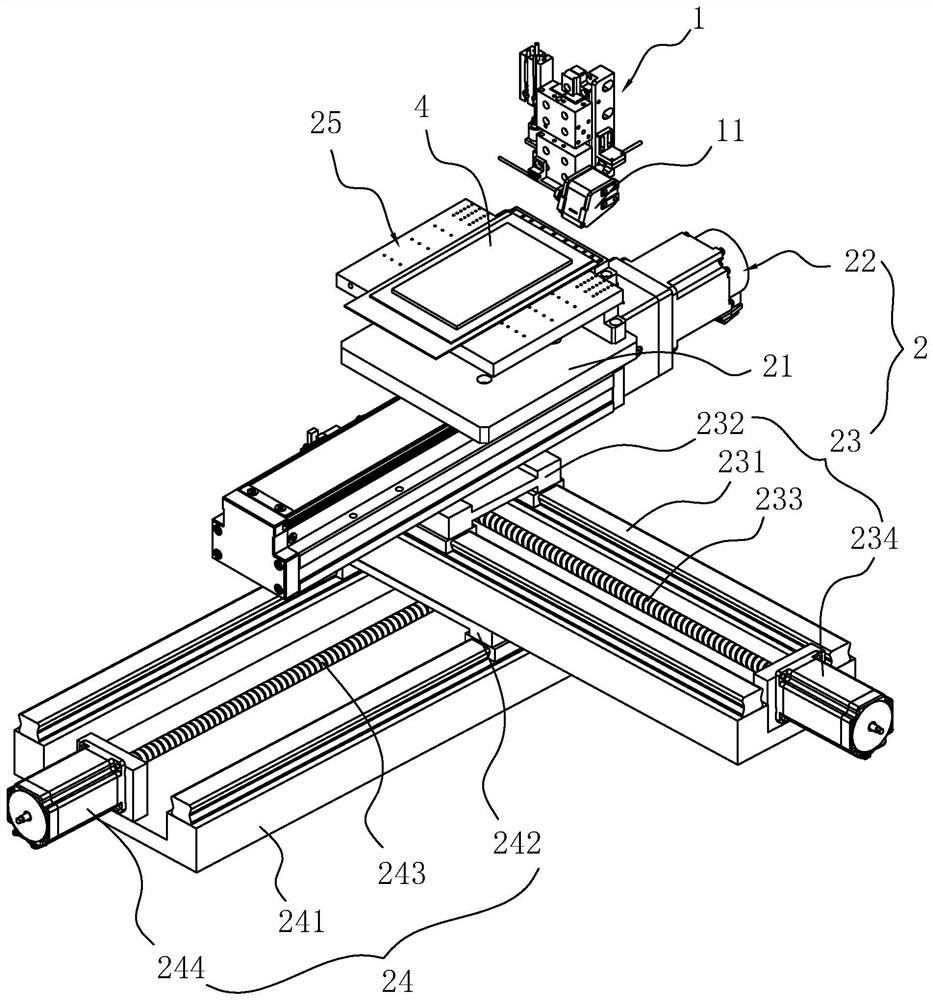

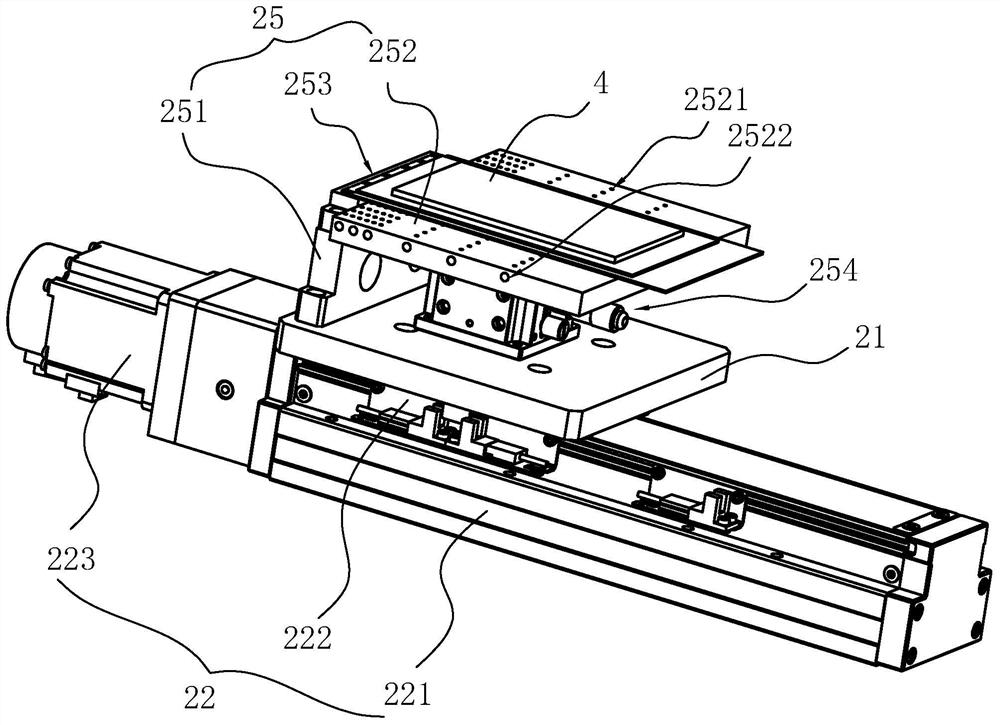

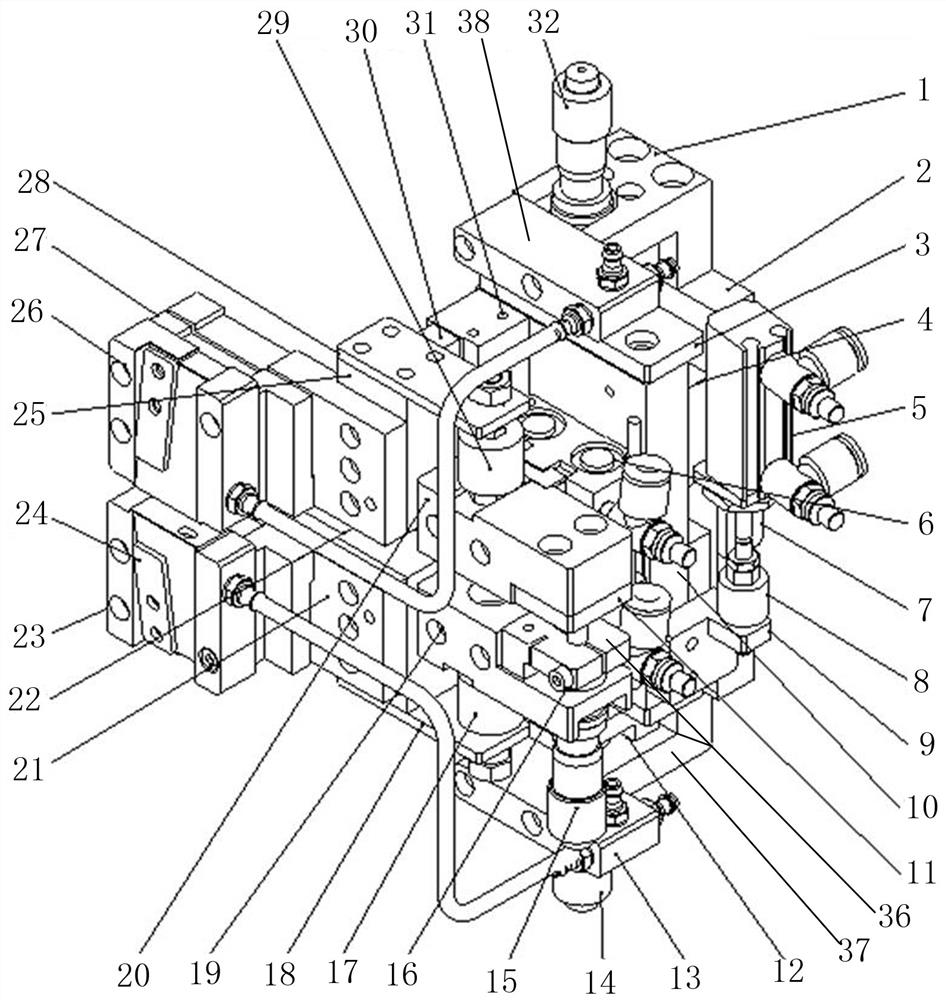

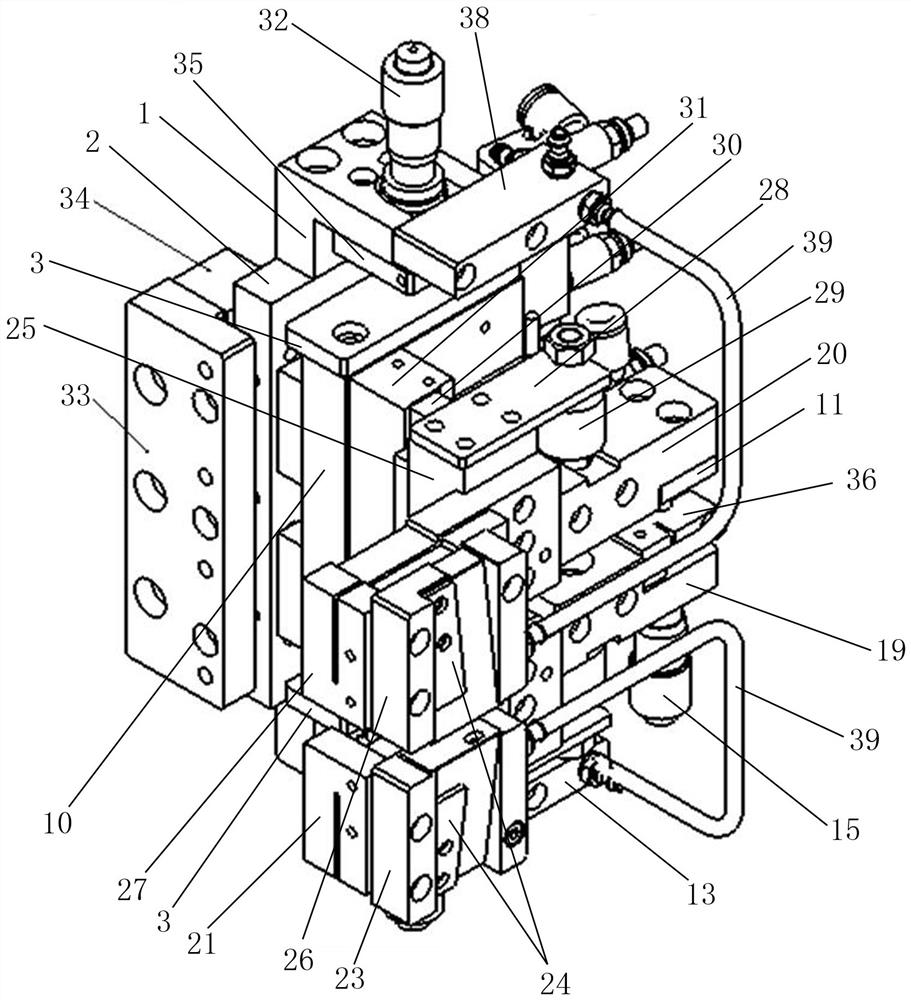

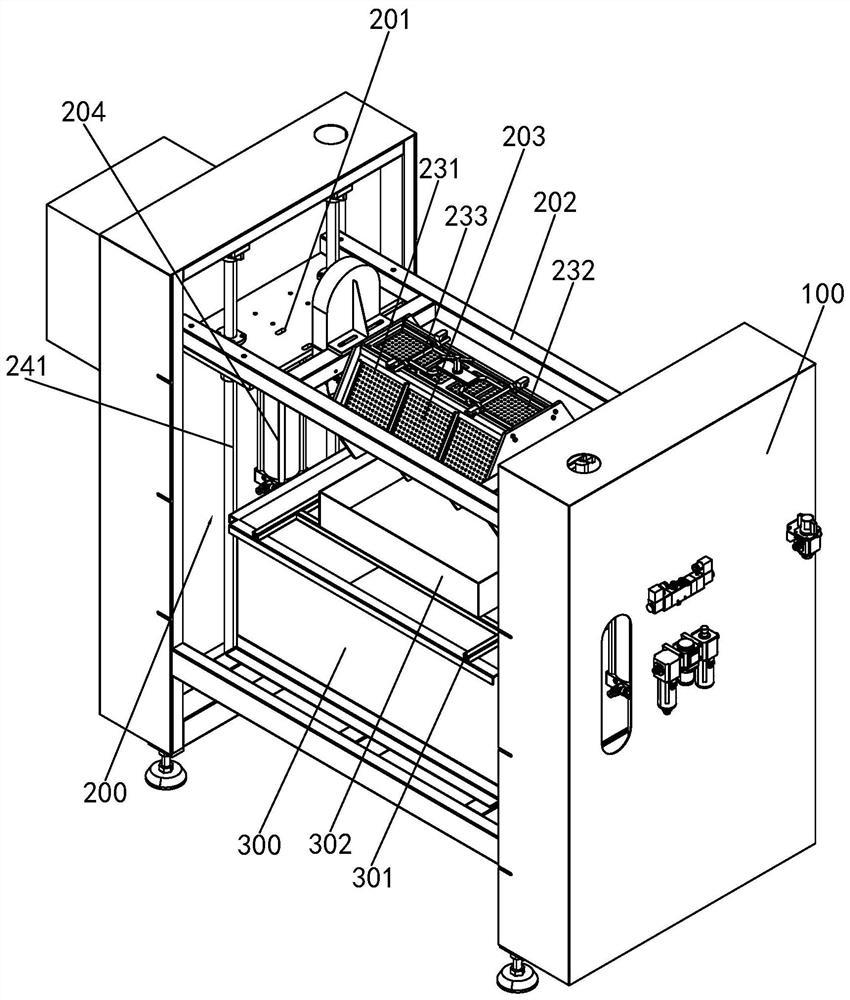

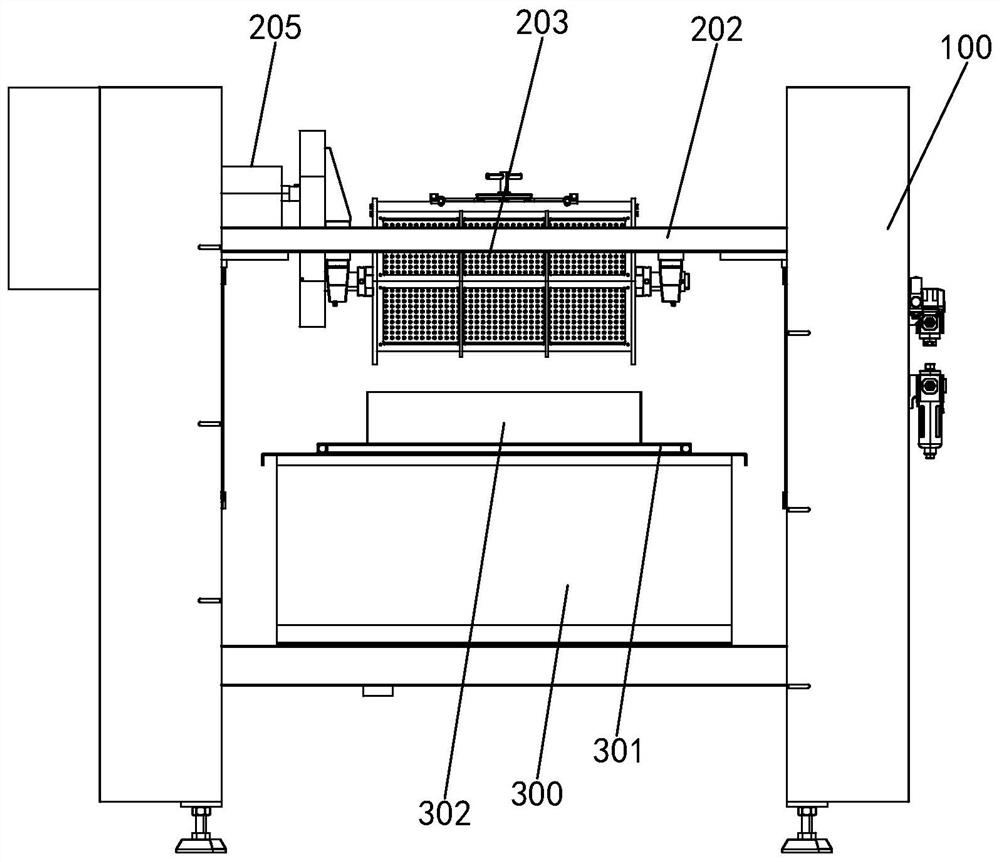

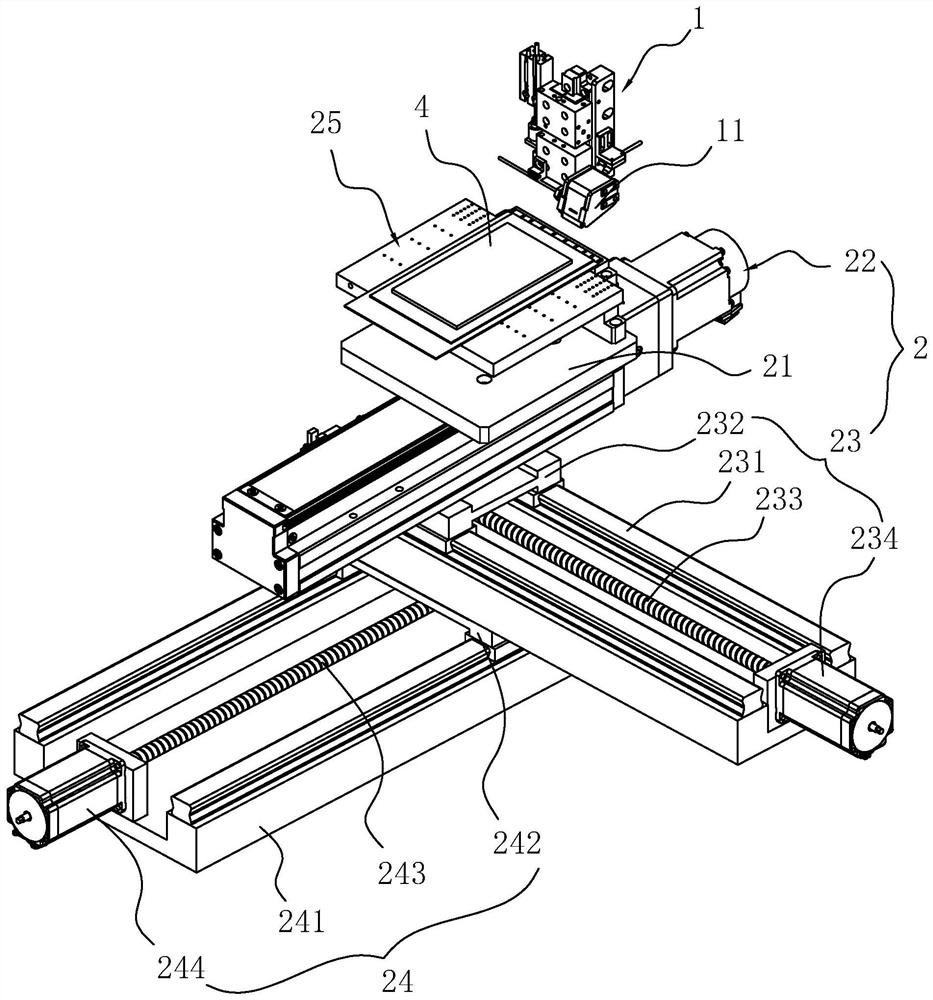

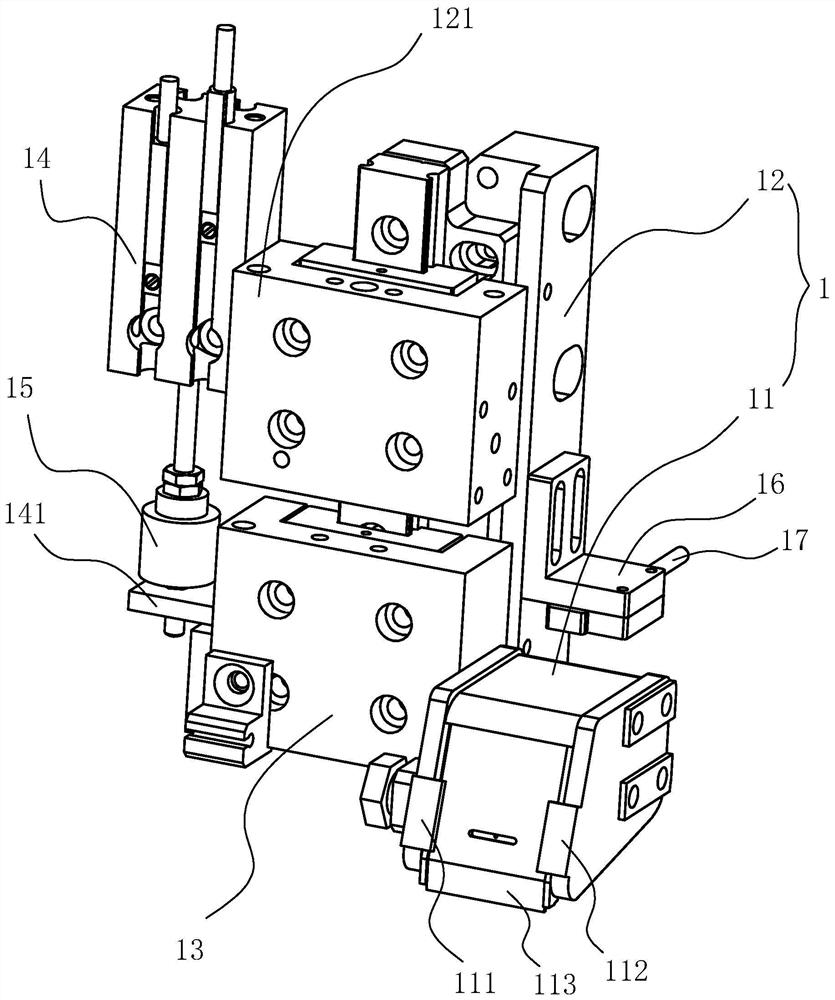

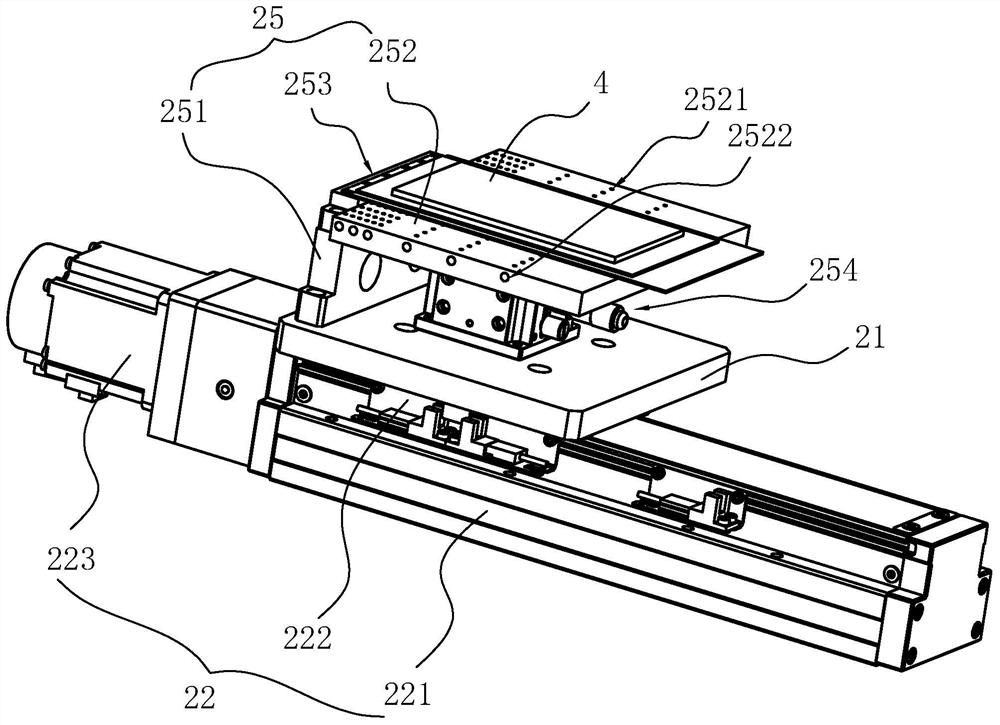

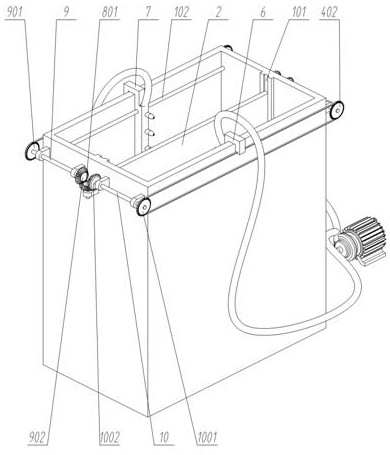

Flexible screen terminal cleaning mechanism

ActiveCN112893372AImprove integrityAvoid bendingFlexible article cleaningCleaning using toolsMechanical engineeringTerminal cleaning

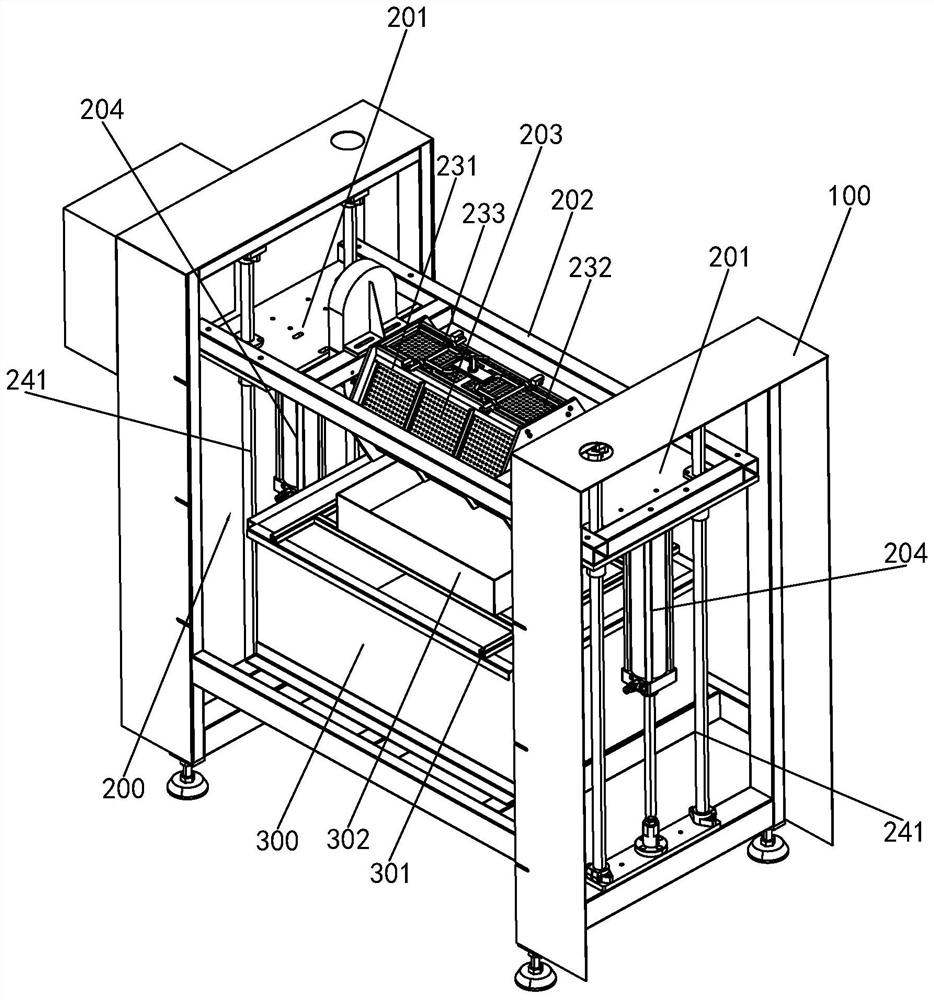

The invention relates to a flexible screen terminal cleaning mechanism. The mechanism comprises a cleaning chuck device used for cleaning flexible screen terminals and a cleaning platform device. The cleaning platform device comprises a switching platform mounting plate, a first linear module and a second linear module, and a mounting assembly used for fixing a flexible screen is arranged on the switching platform mounting plate. The first linear module is used for driving the switching platform mounting plate to reciprocate in the length direction of the flexible screen terminals, and the second linear module is used for driving the switching platform mounting plate to intermittently move in the arrangement direction of the flexible screen terminals. When the flexible screen terminals are cleaned, the flexible screen is firstly fixed to the switching platform mounting plate, the switching platform mounting plate drives the flexible screen to move back and forth below the cleaning chuck device through the first linear module, and after the cleaning chuck device cleans the terminal back and forth at least once, the second linear module drives the switching platform mounting plate to be vertically translated for a certain distance, so that the cleaning chuck device cleans the terminals in the direction perpendicular to the arrangement direction of the terminals. The flexible screen terminal cleaning mechanism has the effect of improving the integrity of the terminals.

Owner:SHENZHEN COMWIN AUTOMATION TECH

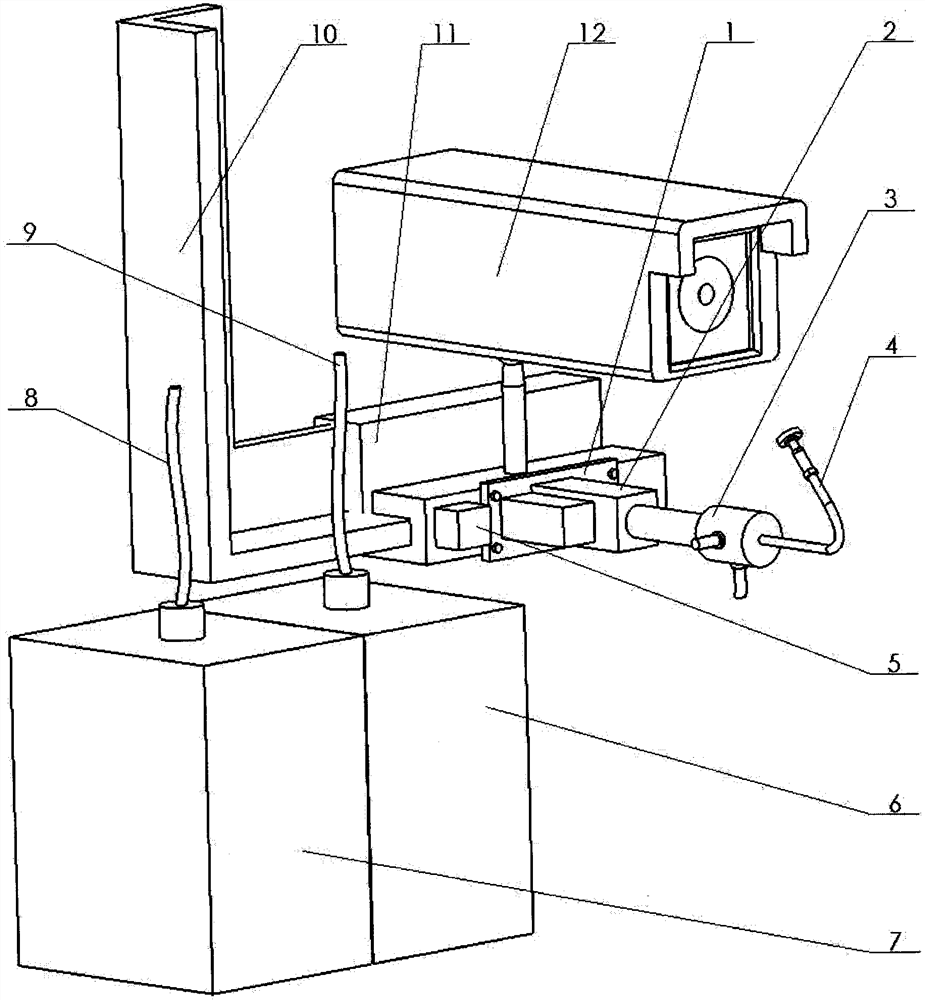

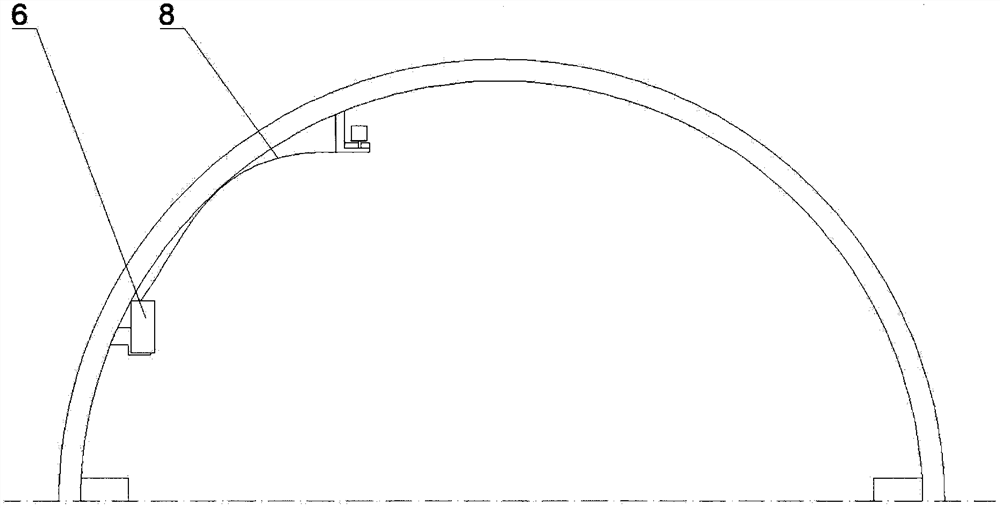

Tunnel camera self-feedback cleaning device and method

PendingCN113770145AGuaranteed cleanlinessNo human intervention requiredNeural architecturesCleaning using liquidsControl engineeringStructural engineering

The invention discloses a tunnel camera self-feedback cleaning device and method, and belongs to the technical field of camera cleaning. The tunnel camera self-feedback cleaning device comprises a flange plate, a telescopic mechanism, a connector, a cleaning nozzle, a water supply hose, a terminal controller and a water tank; the flange plate is connected with the telescopic mechanism, the connector connects the telescopic mechanism, the water supply hose and the cleaning nozzle, and the water supply hose is led out of the water tank. According to the tunnel camera self-feedback cleaning device, whether cleaning is needed or not is judged through recognition of a monitored image, and automatic cleaning is achieved through a terminal cleaning device; the telescopic mechanism can prevent a camera from being shielded by the cleaning device in a non-cleaning state; and the device can be installed on most gun-shaped cameras at present, and modification of existing monitoring equipment is facilitated. In general, the cleaning efficiency, the safety and the real-time performance are improved, the cleaning frequency can be adjusted according to the lens pollution degree, and the definition of the monitored image is guaranteed.

Owner:陕西高速电子工程有限公司

A dynamic voltage-stabilized nickel screen cleaning machine

The invention discloses a dynamic voltage-stabilized nickel mesh cleaning machine, which includes a casing and a cleaning assembly arranged on one side of the casing for cleaning the nickel mesh, and also includes a removal device arranged in the casing and opposite to the cleaning assembly. The end cleaning component, the pressure control component installed inside the casing to dynamically adjust the pressure, and the drive motor 1 set inside the casing to drive the pressure control component work. There is also a support frame inside the casing and the support frame is set There are multiple water purifiers, the hose 1 is provided with a pressure sensor 1, and one end of the pressure control component is connected to a water collecting tube through a steel pipe, and one end of the water collecting tube is fixed with a hard tube and one end of the hard tube is fixed with a T-shaped shunt tube. The pressure sensor 2 is fixed on the water cylinder, which can not only remove the ends of the nickel mesh, but also clean the nickel mesh. Not only that, the nickel mesh cleaning machine can also perform dynamic water pressure control to ensure that the nickel mesh is cleaned The water pressure is in a stable state to ensure the cleaning effect.

Owner:杭州易染数码科技有限公司

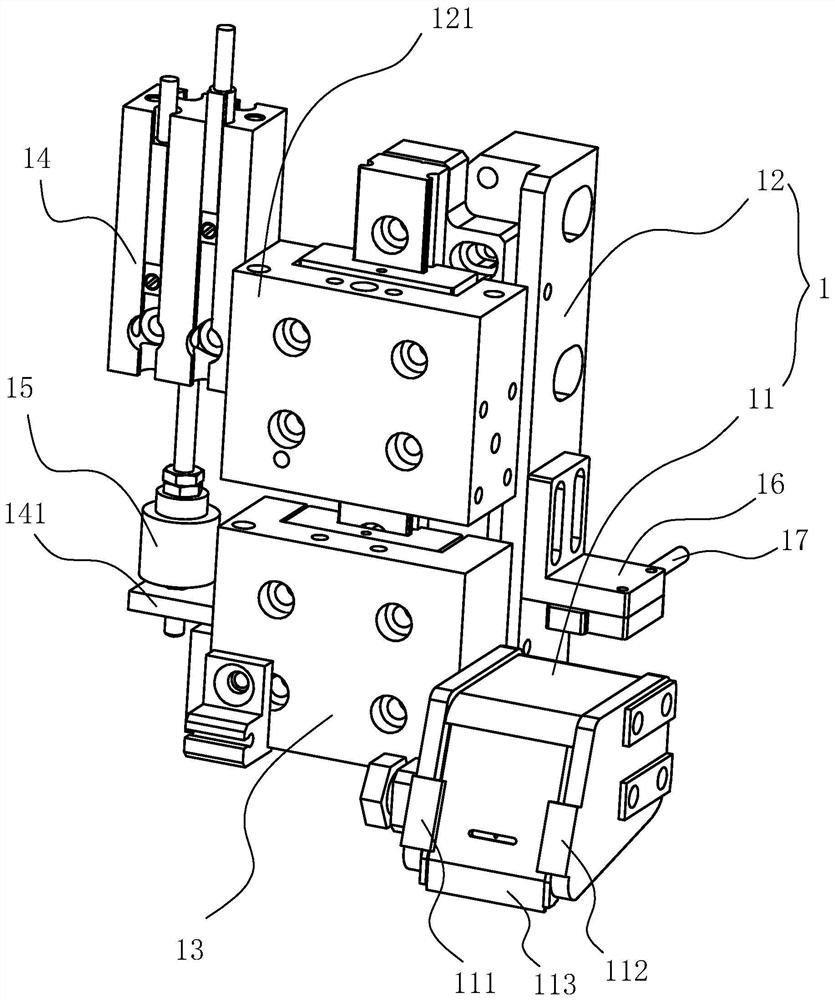

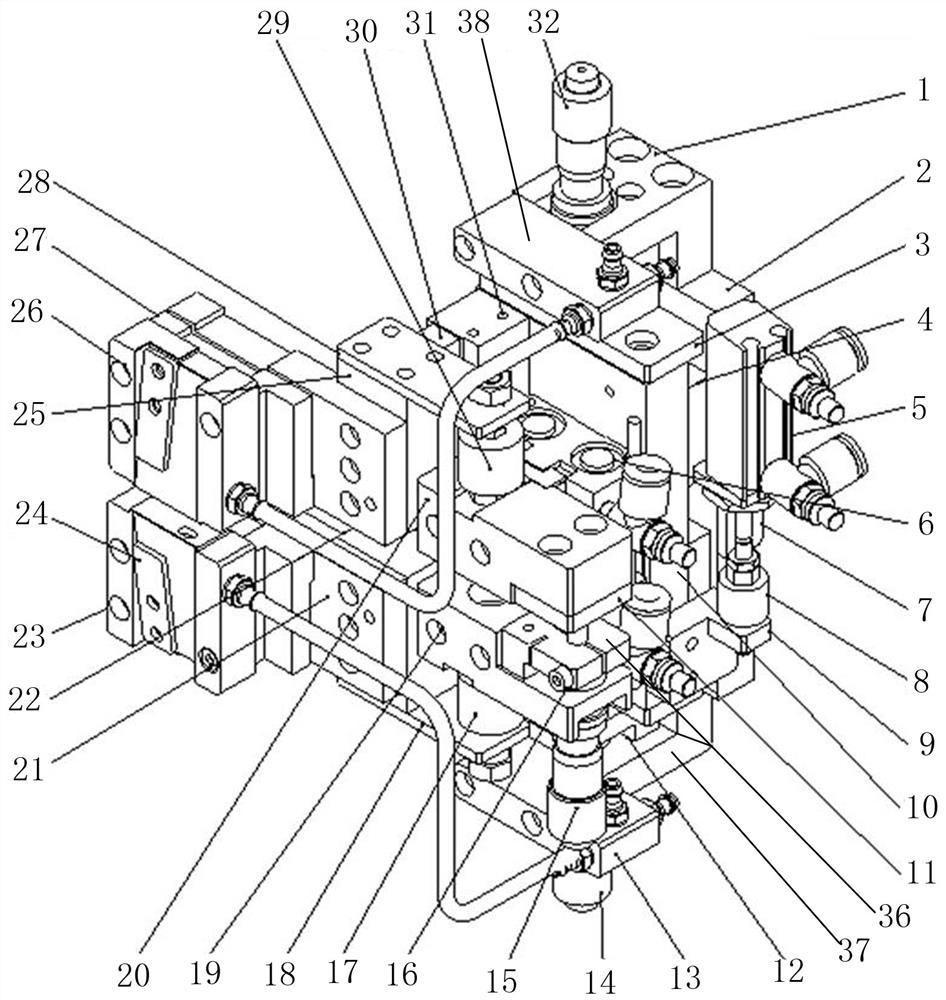

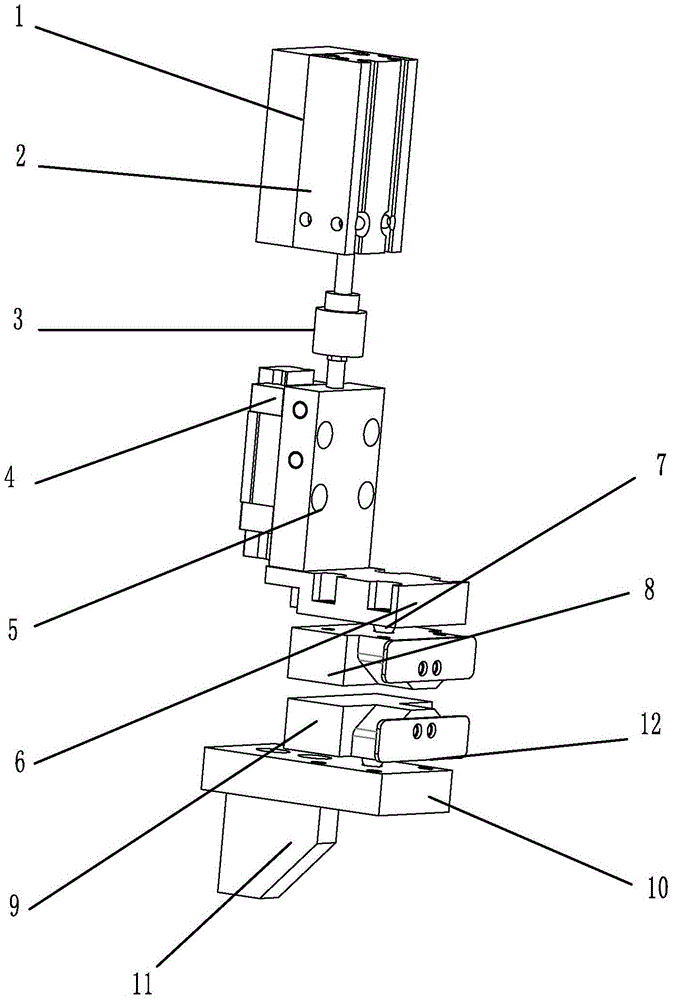

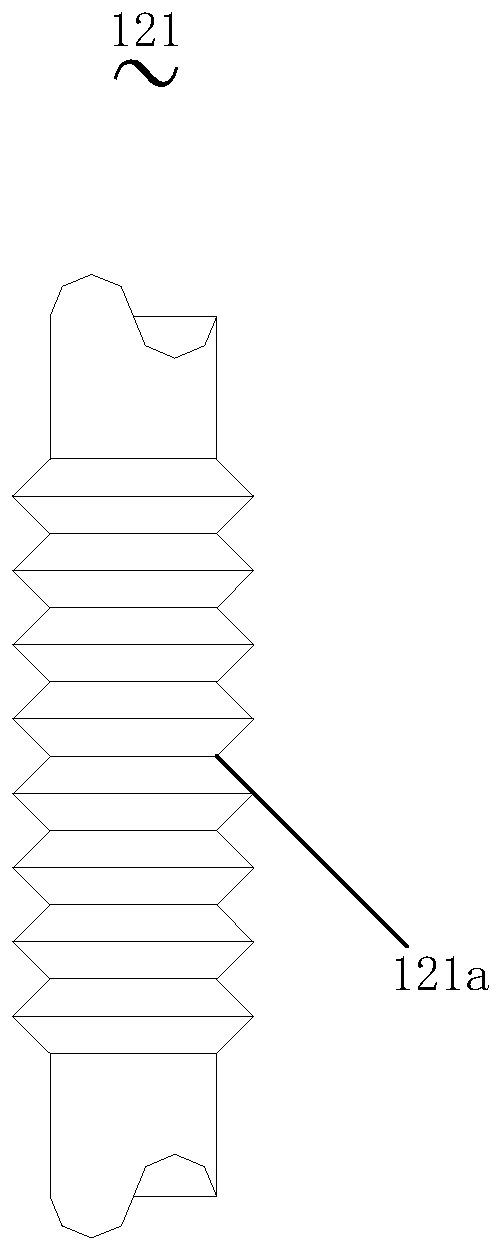

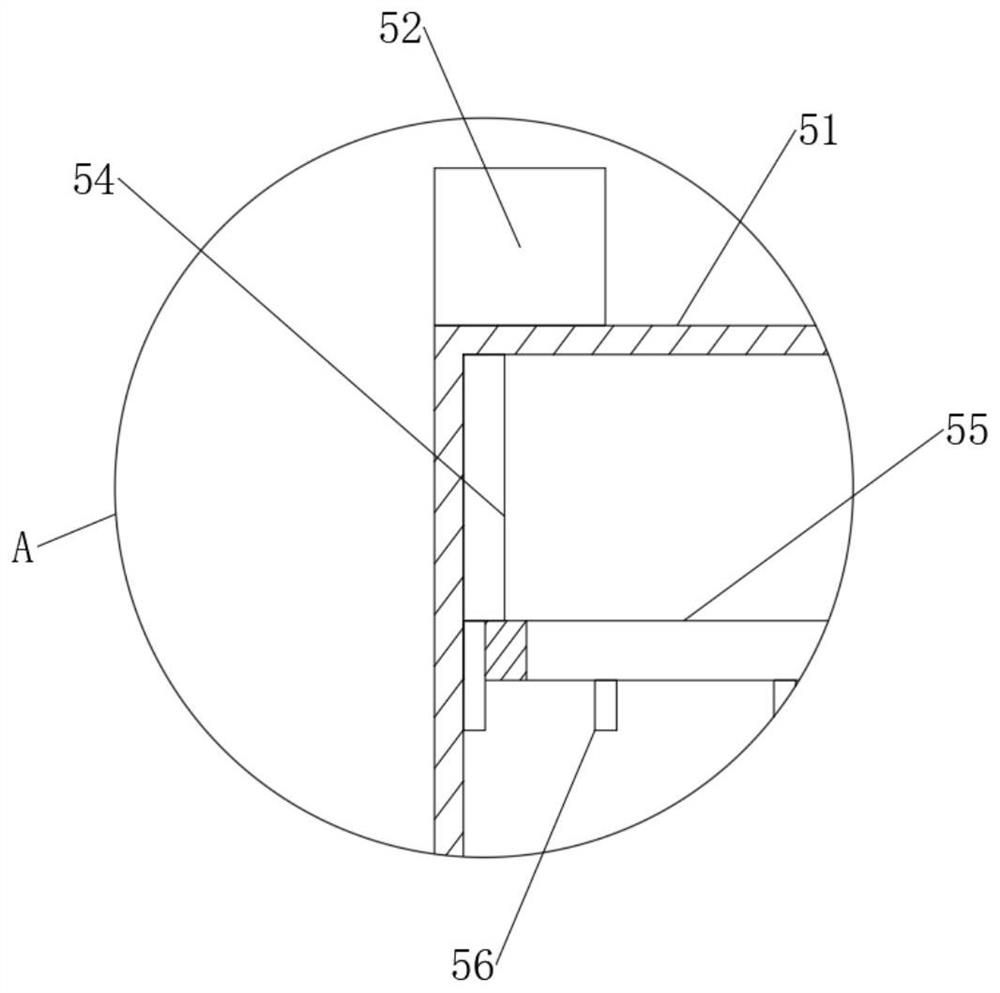

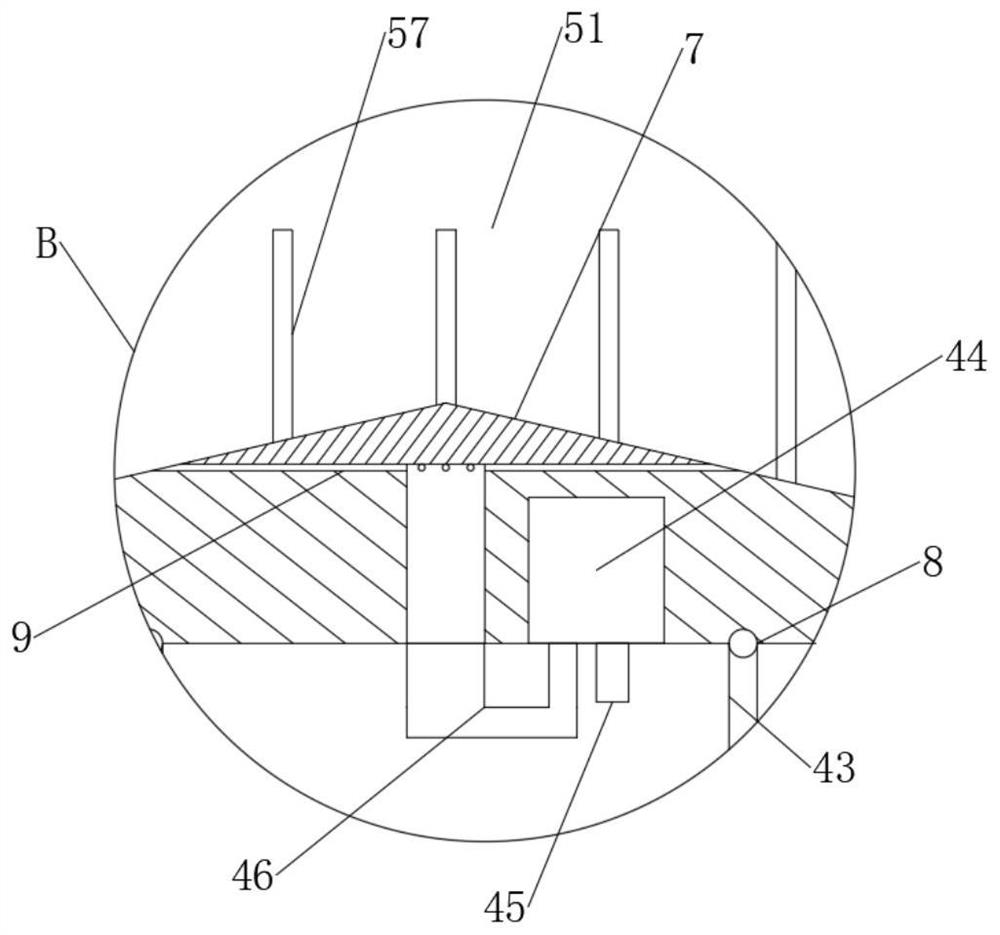

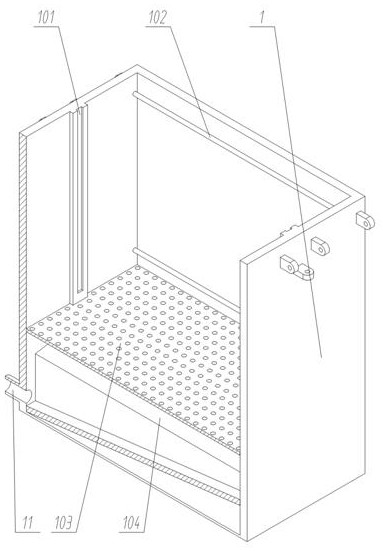

Special wiping chuck device for terminal cleaning machine

The invention discloses a special wiping chuck device for a terminal cleaning machine. The special wiping chuck device for the terminal cleaning machine comprises a cleaning head leaning piece I (2), wherein the front surface of the cleaning head leaning piece I (2) is movably provided with a cleaning head fixing piece seat II (10) through a guide rail I (4), the side surface of the cleaning head leaning piece I (2) is fixedly provided with an air cylinder (5) through a self-weight air cylinder fixing piece (7), and the end part of a telescopic rod of the air cylinder (5) is provided with a floating joint I (8); and the floating joint I (8) is connected with a self-weight connecting piece (9) located at the bottom of the side surface of the cleaning head fixing piece seat II (10). The special wiping chuck device for the terminal cleaning machine is reasonable in design, increases the production efficiency, reduces the product damage, expands the product application range, and has a great practical application value.

Owner:TAIYUAN FENGHUA INFORMATION EQUIP

A special wiping chuck device for a terminal cleaning machine

The invention discloses a special wiping chuck device for a terminal cleaning machine, which includes a cleaning head rest I (2), and the front of the cleaning head rest I (2) is movably installed with a cleaning head firmware seat II ( 10), the side of the cleaning headrest I (2) is fixedly installed with the cylinder (5) through the self-weight cylinder firmware (7), and the end of the telescopic rod of the cylinder (5) is installed with a floating joint I (8), and the floating The joint I (8) is connected with the self-weight connecting piece (9) located at the bottom of the side of the cleaning head firmware seat II (10). The invention has reasonable design, improves production efficiency, reduces product damage, expands the range of applied products, and has good practical application value.

Owner:TAIYUAN FENGHUA INFORMATION EQUIP

Substrate terminal cleaning apparatus and substrate terminal cleaning method

ActiveCN101151104BHigh precisionSemiconductor/solid-state device manufacturingCleaning using toolsCleaning methodsEngineering

A substrate terminal cleaning apparatus which performs cleaning of a terminal section of a substrate by having a cleaning member abut to the terminal section. The substrate terminal cleaning apparatus is provided with a first supporting section for supporting the cleaning member at a first position; a second supporting section for supporting the cleaning member at a second position; a cleaning head section for applying pressure to a part of the cleaning member, which is being supported between the first position and the second position, by having the part of the cleaning member abut to the terminal section of the substrate; a supporting section moving apparatus for integrally moving the first supporting section and the second supporting section in a direction along the terminal section; and a cleaning head moving apparatus for moving the cleaning head section in the direction along the terminal section, at a second moving speed different from a first moving speed at which the supporting section moving apparatus moves the first supporting section and the second supporting section.

Owner:PANASONIC CORP

Assembling apparatus, assembling method and terminal cleaning apparatus

ActiveUS7501038B2Easy to cleanShorten cycle timePrinted circuit assemblingLamination ancillary operationsEngineeringTransfer mechanism

A terminal cleaning apparatus integrated to an assembling apparatus for integrating a display panel by bonding an electronic part to an externally connecting terminal of a substrate in which substrates 5 respectively held by a first substrate holding portion 24 and a second substrate holding portion 25 moved by an XY table mechanism 23 are made to pass through a first cleaning portion 21 and a second cleaning portion 22 having different cleaning means to simultaneously clean and the substrate which is not cleaned is carried in and the substrate 5 is transferred between the substrate holding portions and the substrate 5 which has been cleaned is carried out simultaneously by a first substrate transferring mechanism 26. Thereby, an operational efficiency of a step of cleaning an externally connecting terminal can be improved by making substrate carrying operation efficient.

Owner:PANASONIC CORP

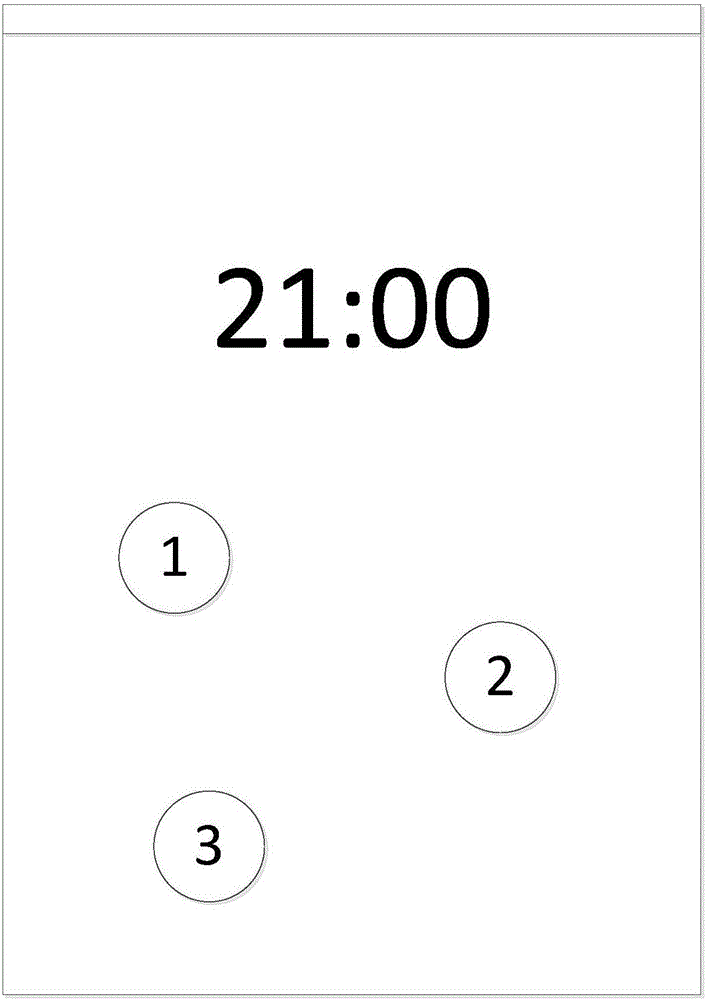

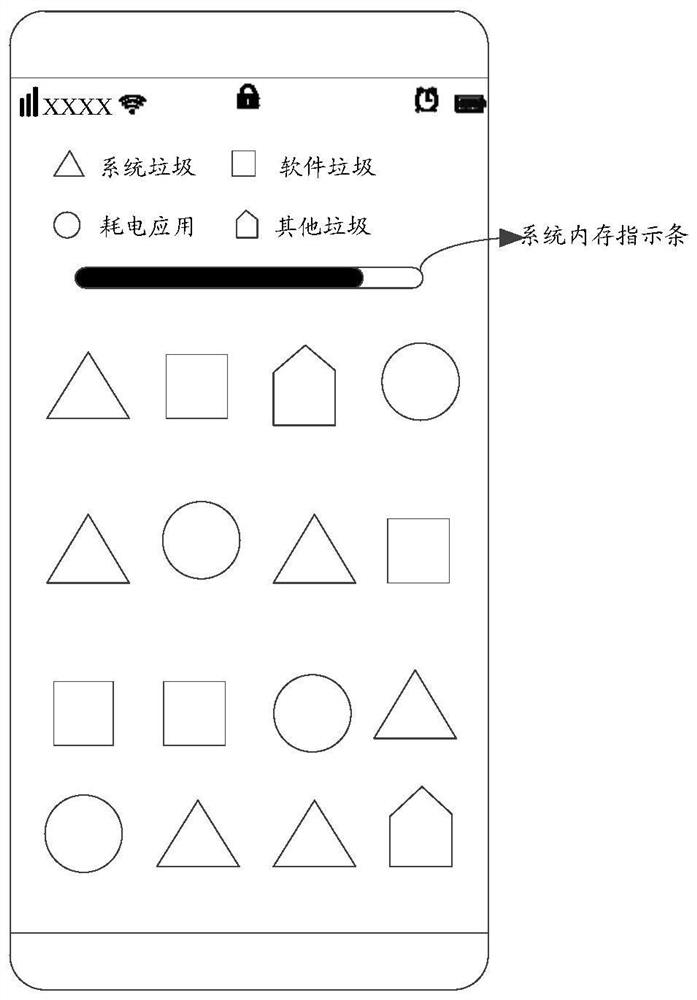

A memory cleaning method, device, storage medium and terminal

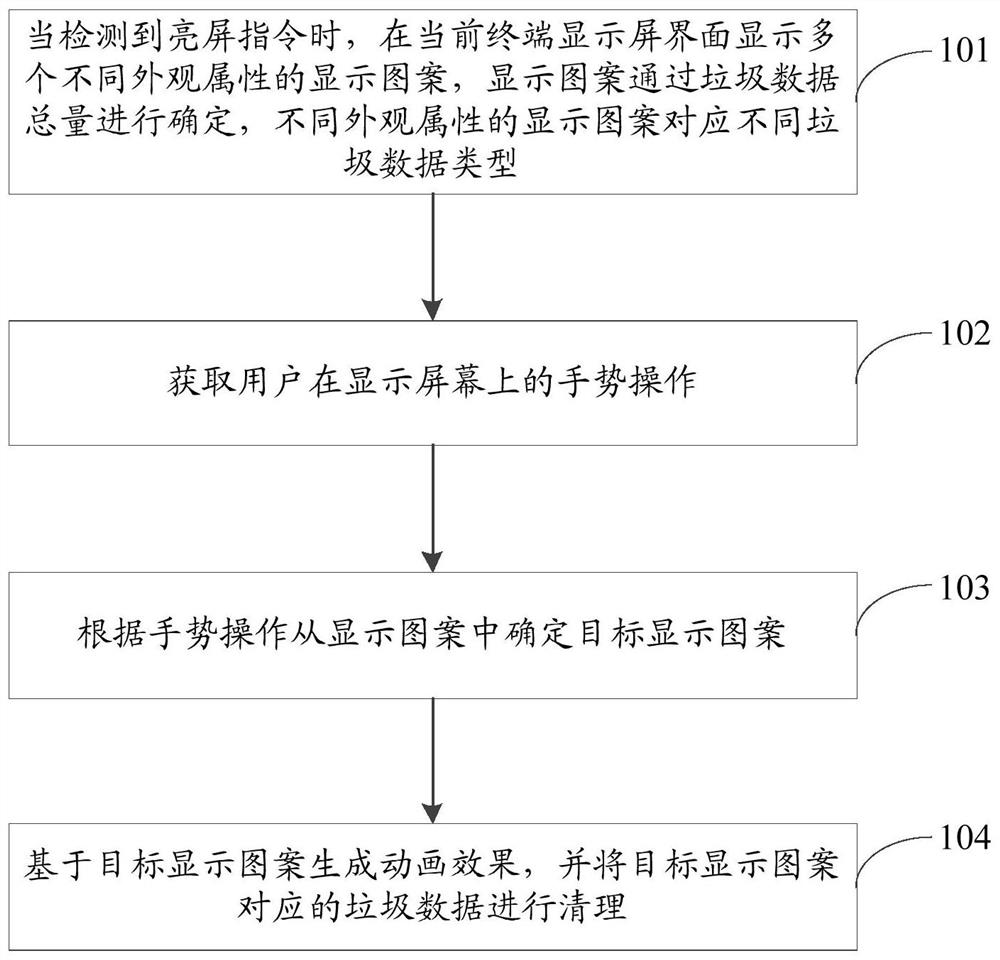

ActiveCN111240574BImprove cleaning efficiencyInput/output processes for data processingComputer hardwareData class

The embodiment of the present application discloses a memory cleaning method, device, storage medium and terminal. The memory cleaning method includes: when a bright screen instruction is detected, displaying a plurality of display patterns with different appearance attributes on the current terminal display screen interface, the display patterns are determined by the total amount of garbage data, and the display patterns of different appearance attributes correspond to different Garbage data type; acquire the user's gesture operation on the display screen; determine the target display pattern from the display pattern according to the gesture operation; generate an animation effect based on the target display pattern, and perform garbage data corresponding to the target display pattern clean up. The embodiment of the present application triggers the terminal to clear the garbage data in the memory through the interactive mode of game elimination, so that the user can maintain a sense of pleasure and accomplishment while cleaning the garbage data in the terminal, and can effectively improve the efficiency of cleaning garbage data in the terminal memory.

Owner:深圳市正粤知识产权服务有限公司

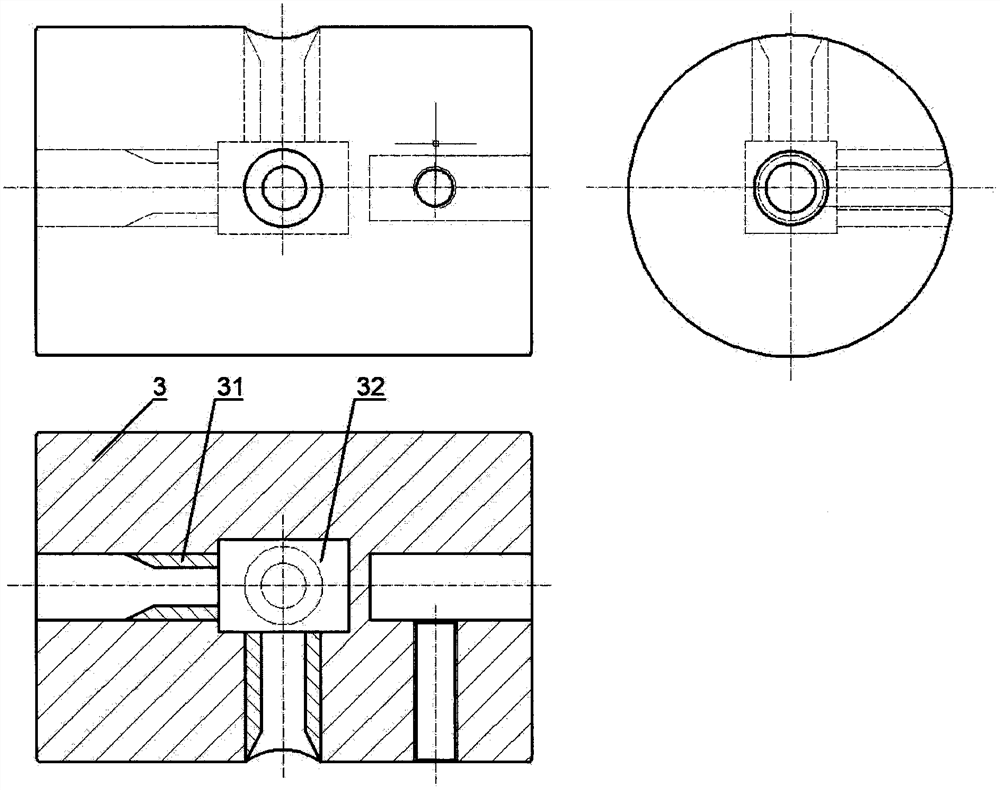

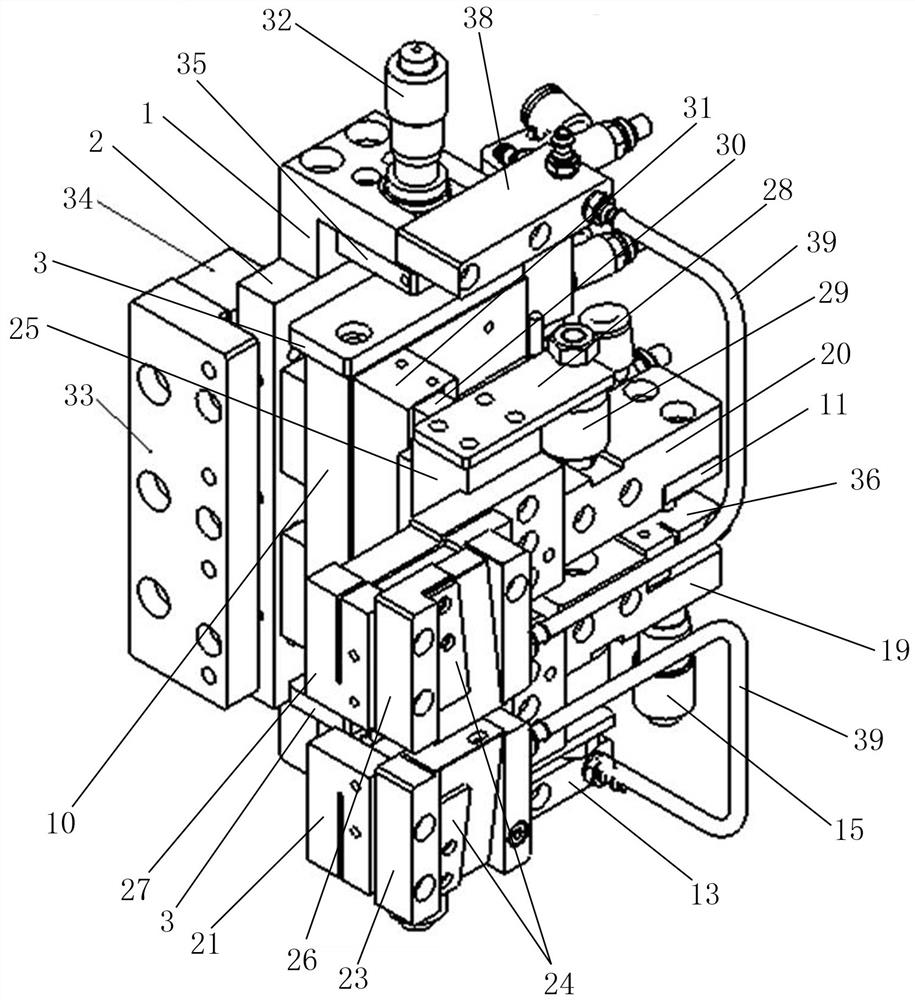

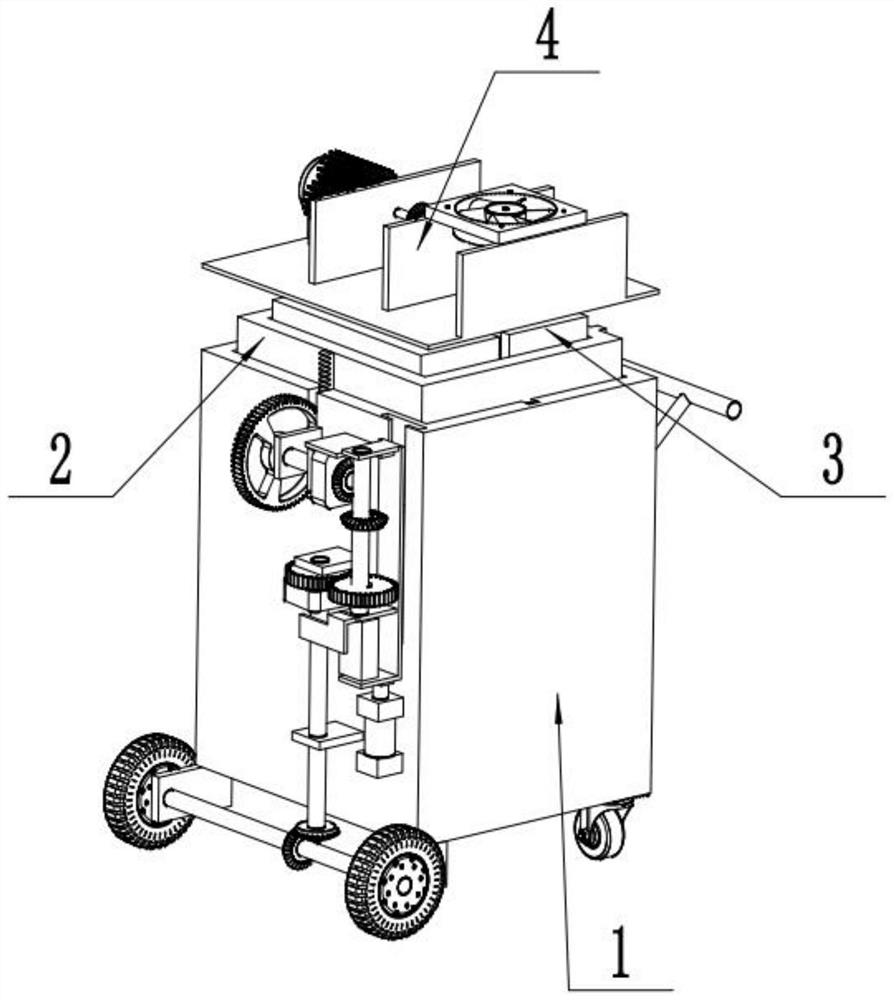

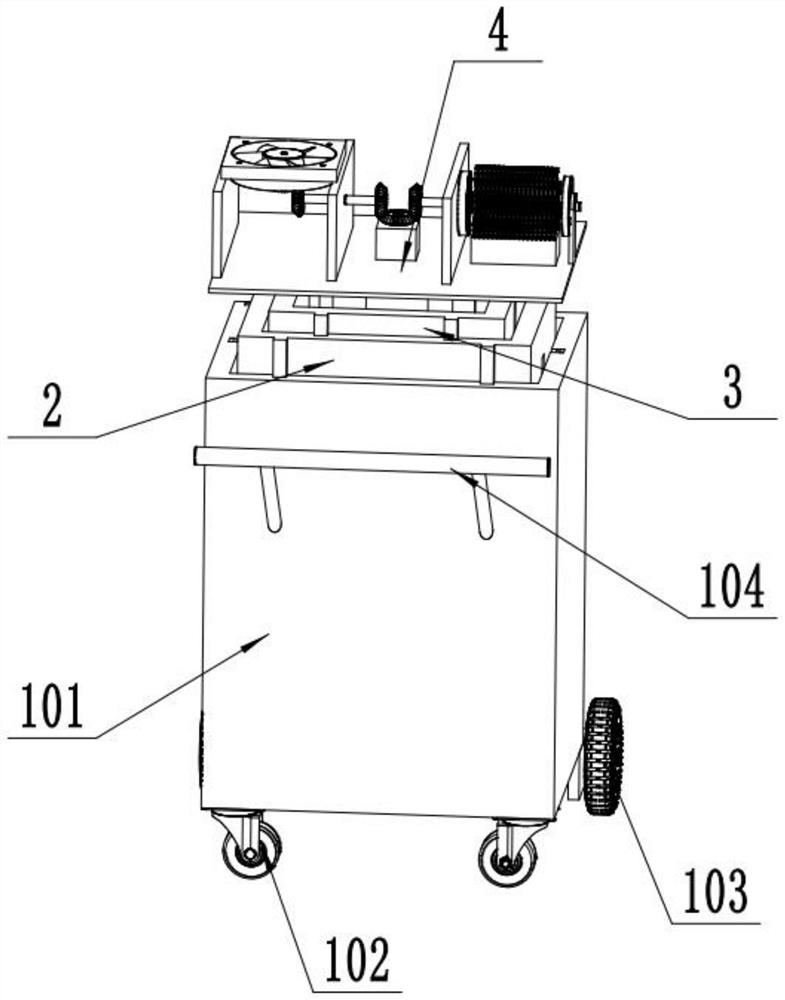

Cog bonding machine terminal cleaning pressure head mechanism

ActiveCN104148350BSimple structureEasy to adjustWork holdersFlexible article cleaningSteel ballEngineering

A pressure head mechanism for terminal cleaning of COG (chip on glass) binding machine comprises an upper pressure head 8 and a lower back-up plate 9. During operation, glass to be cleaned is pressed in the middle of the upper pressure head 8 and the lower back-up plate 9 during operation which are respectively fixedly connected to an upper pressurizing and driving unit and a lower fixing and supporting unit in a bolt binding manner, and steel balls 7 are respectively nested between the upper pressure head 8 and the upper pressurizing and driving unit as well as between the back-up plate 9 and the top supporting part of the supporting unit. The pressure head can be adjusted by the aid of rotation of the steel balls, so that the pressure head mechanism has the advantages of simple structure, convenience in adjustment, saved time, high efficiency and the like; through simple adjustment, the pressure head and the back-up plate can be guaranteed to be in a parallel state, and damage to the glass can be prevented on the premise that the cleaned glass is positioned.

Owner:DALIAN YISHENGDA INTELLIGENT TECH

Fpd panel mounting device and mounting method thereof

The present invention provides a technique, wherein the wiping performance of used cross grain fabric is sustained for improving the wiping performance in terminal cleaning of an FPD display substrate, and furthermore the longitudinal wire or cross wire that forms the ultra-thin fiber fabric of a cleaning strip does not cling on comb teeth shaped projections of a substrate terminal thereby preventing foreign matter. An FPD panel mounting device which is provided with a device which causes the relative movement of the cleaning strip and the substrate and causes the cleaning strip to slide and contact relatively to the substrate in a preset width for cleaning for cleaning is provided with the following components: an upper contact component which wipes a terminal part of substrate end that performs component mounting with the cleaning strip; and a lower contact component which wipes the back surface of the substrate end, wherein the cleaning strip is obliquely configured relatively to the substrate end.

Owner:HITACHI HIGH-TECH CORP

Battery cleaning device

ActiveCN108941133AImprove processing efficiencyCleaning processes and apparatusElectrical batteryAssembly line

The invention relates to a battery cleaning device which comprises a machine frame, a limiting mechanism, a movable supporting part and a cleaning part. The machine frame is provided with a feeding channel, and a feeding assembly line for conveying battery modules can penetrate in the feeding channel. When a battery clamp to which the battery modules are fixed is conveyed to a post terminal cleaning station along with the feeding assembly line, the limiting mechanism is switched to a limiting state. At the moment, the battery clamp is stopped to stay in the post terminal cleaning station, andthe feeding assembly line continues to be operated. Further, the movable supporting part drives the cleaning part to move to the post terminal cleaning station, and therefore post terminals of the battery modules are cleaned. After cleaning is completed, the limiting mechanism is switched to an unlimiting state. At the moment, the cleaned battery modules continue to be moved to a next working procedure along with the feeding assembly line. Since the battery modules do not need to be manually carried in the battery module cleaning process, the machining efficiency is effectively improved.

Owner:深圳市大族锂电智能装备有限公司

Lead-acid storage battery brass terminal cleaning device

PendingCN112893285ASimplify cleaning stepsShorten cleaning timeCleaning using liquidsMetallurgyStructural engineering

The invention discloses a lead-acid storage battery brass terminal cleaning device which comprises a Z-axis lifting mechanism and an oil pool. The Z-axis lifting mechanism comprises two lifting plates which are horizontally and oppositely arranged, a linear driving mechanism acts on each of the two lifting plates, the lifting plates are driven by the linear driving mechanisms to move in the vertical direction, a roller frame is installed between the two lifting plates, a hollowed-out area is formed in the middle of the roller frame, the roller frame is rotatably connected with a roller assembly, the roller assembly is horizontally arranged in the hollowed-out area, a rotating mechanism is installed at the side, corresponding to the roller assembly, of one of the two lifting plates, and the rotating mechanism is rotatably connected with the roller assembly. According to the automatic brass terminal cleaning device, scraps in a brass terminal are cleaned in a rolling washing manner, the cleaning steps can be simplified, the cleaning time can be effectively shortened, and cleaning is more thorough.

Owner:JIANGSU LEOCH BATTERY

Mobile terminal cleaning device and cleaning method thereof

The invention discloses a cleaning device for a mobile terminal. The cleaning device comprises a suction device, a guiding pipe, a handle and a cleaning head which are sequentially connected. The guiding pipe, the handle and the cleaning head communicate with one another, so that when the cleaning head is inserted into a hole or groove of the mobile terminal, the suction device sucks away dirt in the hole or groove through the guiding pipe, the handle and the cleaning head. The invention further discloses a cleaning method for the mobile terminal. In this way, the cleaning device and method can effectively remove dirt in the hole or groove of the mobile terminal, and thus normal use of the mobile terminal is guaranteed.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

A flexible screen terminal cleaning mechanism

ActiveCN112893372BImprove integrityAvoid bendingFlexible article cleaningCleaning using toolsMechanical engineeringTerminal cleaning

The application relates to a flexible screen terminal cleaning mechanism, which includes a cleaning chuck device and a cleaning platform device for cleaning flexible screen terminals. The cleaning platform device includes an adapter platform mounting plate, a first linear module and a second linear module. The installation board of the transfer platform is provided with installation components for fixing the flexible screen. The first linear module is used to drive the transfer platform installation board to reciprocate along the length direction of the terminal of the flexible screen. The second linear module is used to drive The mounting plate of the transfer platform moves intermittently along the terminal arrangement direction of the flexible screen. When cleaning the terminal of the flexible screen, the flexible screen is first fixed on the mounting plate of the transfer platform, and the mounting plate of the transfer platform drives the flexible screen to move back and forth under the cleaning chuck device through the first linear module. After the head device cleans the terminals back and forth at least once, the second linear module drives the mounting plate of the transfer platform to translate vertically for a certain distance, so that the cleaning chuck device can clean the terminals along the direction perpendicular to the arrangement of the terminals. This application has the function of improving the terminal completeness effect.

Owner:SHENZHEN COMWIN AUTOMATION TECH

Multi-stage low-temperature drying device for full-automatic terminal cleaning machine

PendingCN114184030ACannot be taken out continuouslyContinuityDrying solid materials without heatDrying machine combinationsCold airEngineering

The invention provides a multi-stage low-temperature drying device for a full-automatic terminal cleaning machine, and belongs to the field of drying devices. The multi-stage low-temperature drying device for the full-automatic terminal cleaning machine comprises an outer side protection box body, a first electric exhaust fan is fixedly connected to the top inner wall of the outer side protection box body, a conveying device is arranged on the rear surface of the outer side protection box body, and a spin-drying device is fixedly arranged on the top inner wall of the outer side protection box body. By designing the air drying device, the terminal can be further air-dried, continuity is achieved, the situation that the terminal cannot be continuously taken out is avoided, by designing the spin-drying device, the terminal is spin-dried through centrifugal force, meanwhile, the terminal can be relatively fixed, the air nozzle is made to be more efficient when blowing air to the terminal, and the service life of the terminal is prolonged. By designing the spin-drying device and combining the spin-drying device with the air-drying device, gas with waste heat can be utilized, and cold air is used firstly, so that the purpose of saving energy is achieved.

Owner:江西宏均光电有限公司

Operating room air conditioner terminal cleaning device

InactiveCN113996577ASolve the problem that you need to climb on the air conditioner to clean the air conditionerReduce the burden onDrying gas arrangementsCleaning using toolsEngineeringTerminal cleaning

The invention discloses an operating room air conditioner terminal cleaning device, which relates to the technical field of air conditioner maintenance equipment. The operating room air conditioner terminal cleaning device comprises a power assembly used for providing power, a transmission assembly used for transmitting power is arranged in the power assembly, and a regulation and control assembly is arranged in the transmission assembly; and a cleaning assembly used for cleaning and blow-drying the air conditioner terminal is arranged on the regulation and control assembly, the power assembly comprises a moving unit and a power unit, the power unit comprises a power mechanism and an adjusting mechanism, the regulation and control assembly comprises a regulation and control box and a switching unit, and the cleaning assembly comprises a cleaning unit, a blow-drying unit and a supporting plate. The transmission assembly drives the supporting plate to lift through the switching unit, and the supporting plate drives the cleaning unit and the blow-drying unit to lift. The cleaning assembly can be driven to ascend and descend through the power assembly and the regulation and control assembly, the problem that people need to climb to the air conditioner to clean the air conditioner is solved, and the safety of cleaning personnel is guaranteed.

Owner:李宁

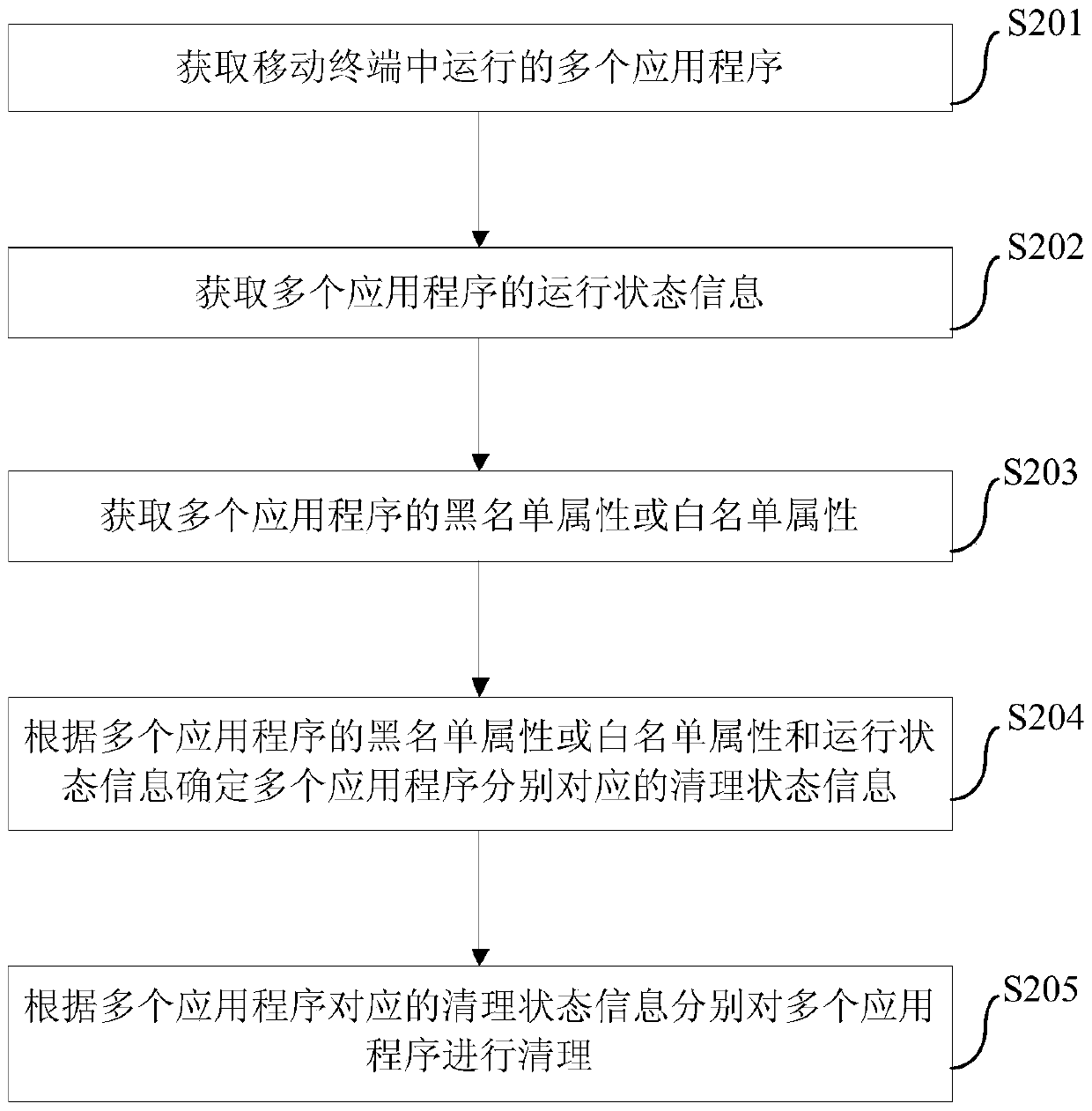

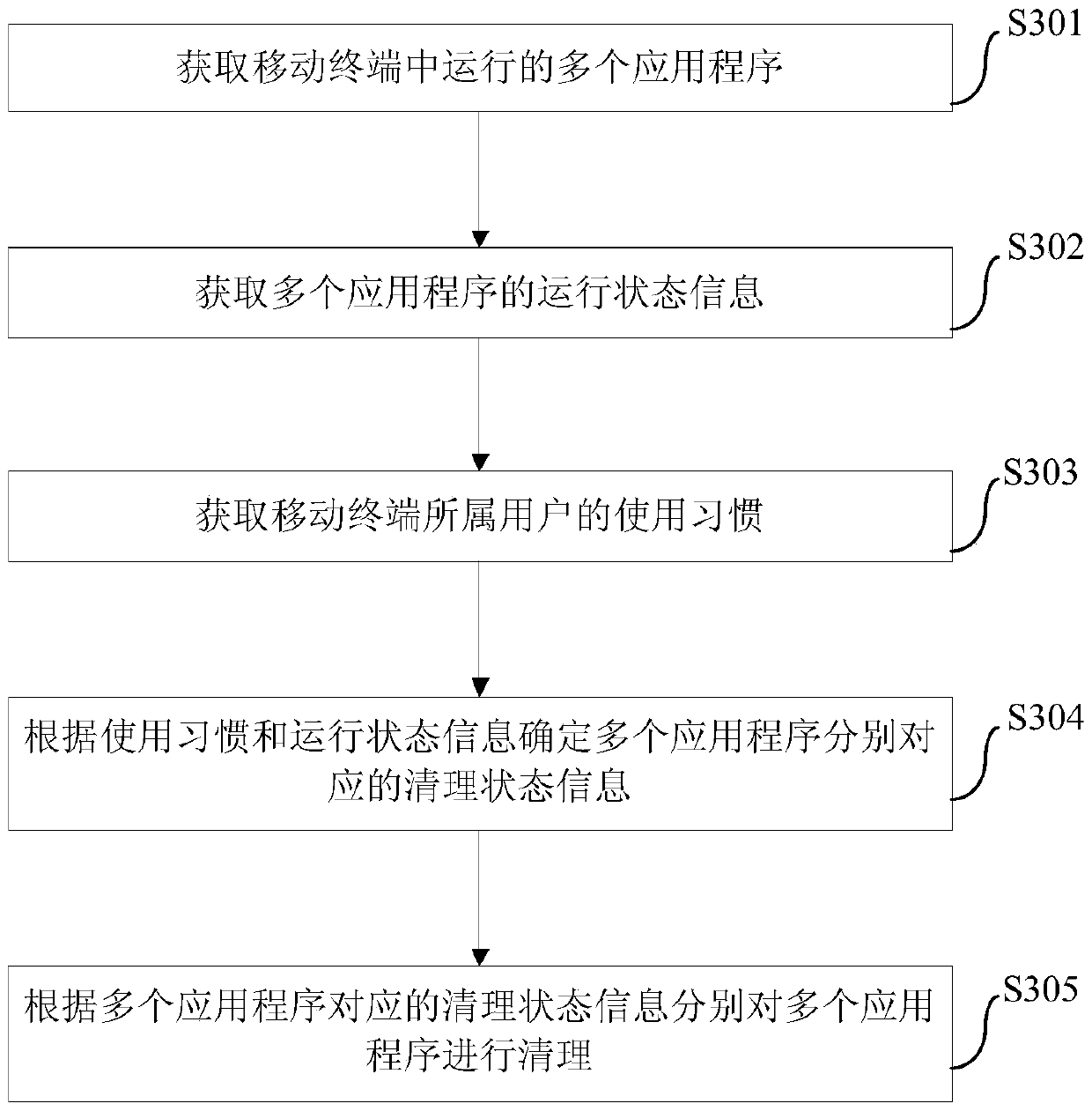

Application program cleaning method and device in mobile terminal and mobile terminal

ActiveCN104298549BImprove operational efficiencyEasy to cleanMultiprogramming arrangementsTerminal equipmentMultiple applications

Owner:BEIJING KINGSOFT INTERNET SECURITY SOFTWARE CO LTD

Automatic lcd terminal cleaning machine

ActiveCN104550158BHigh precisionEasy to cleanFlexible article cleaningCleaning using toolsLiquid-crystal displayEngineering

The invention discloses a fully-automatic LCD (Liquid Crystal Display) terminal cleaning machine. The fully-automatic LCD terminal cleaning machine comprises a table plate, a charging belt line device, a charging manipulator, a material transmission unit, a CCD (Charge Coupled Device) image pickup mechanism, a dustproof cloth cleaning mechanism, a plasma cleaning mechanism and a discharging manipulator, wherein the charging belt line device, the charging manipulator, the material transmission unit, the CCD image pickup mechanism, the dustproof cloth cleaning mechanism, the plasma cleaning mechanism and the discharging manipulator are sequentially mounted on the table plate. The fully-automatic LCD terminal cleaning machine has higher LCD terminal cleaning efficiency and accuracy, and increase of the production cost caused by manual operation and harm to the human health caused by chemicals are avoided.

Owner:SHENZHEN LIANDE AUTOMATION EQUIP

Terminal cleaning device for annealing and pickling line of hot-rolled nickel-based alloy stainless steel medium plate

InactiveCN112547652AImprove rotational stabilityImplement Guided MovementCleaning using liquidsDrive shaftSS - Stainless steel

The invention discloses a terminal cleaning device for an annealing and pickling line of a hot-rolled nickel-based alloy stainless steel medium plate, relates to the technical field of cleaning devices, and solves the problems that an existing cleaning device cleans stains on the surface through a brush, the brush cannot effectively clean the stains and pickling solutions on the surface of the stainless steel plate in the cleaning process, the cleaning efficiency is low, and the cleaning effect is poor. The terminal cleaning device comprises a device shell, and the left side of the device shell is rotationally connected with a group of left transmission shaft; the left side of the device shell is rotationally connected with a group of right transmission shaft; the right side of the deviceshell is rotationally connected with a set of connecting shaft; the right side of the device shell is rotationally connected with a group of right driven shaft; and the right side of the device shellis rotationally connected with a group of left driven shaft. According to the terminal cleaning device, through movement of a left side water spraying device and a right side water spraying device atthe two sides, the steel plate is cleaned, the cleaning efficiency and the cleaning effect are improved, and used sewage is rapidly drained through a drainage cavity.

Owner:武文青

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com