Stainless steel finish pipe inner wall cleaning equipment and cleaning method thereof

A technology for cleaning equipment and stainless steel, used in cleaning methods and utensils, metal processing equipment, chemical instruments and methods, etc., can solve problems such as large damage, difficult finished product quality, harsh working environment, etc., to improve cleaning efficiency and high degree of automation , the effect of reducing the operator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

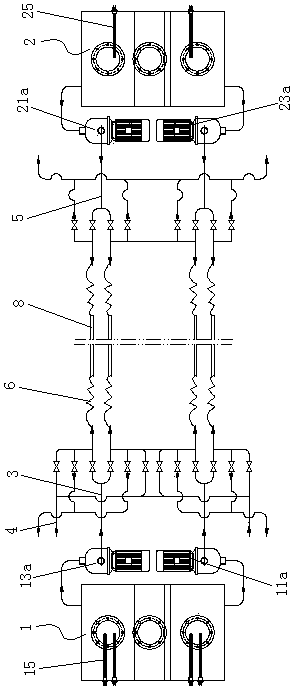

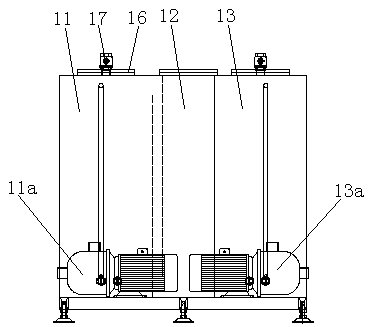

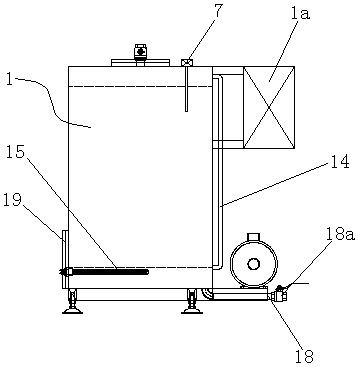

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0034] like Figure 1 to Figure 5 Shown is the structural representation of the present invention,

[0035] The reference signs are: main cleaning machine 1, main electric control box 1a, main cleaning agent tank 11, main cleaning agent pump 11a, main oil separation tank 12, main clean water tank 13, main clean water pump 13a, main liquid level sensor 14. Main heating rod 15, main inspection port 16, main breathing valve 17, main drain pipe 18, main drain valve 18a, main slag cleaning port 19, mobile cleaning machine 2, mobile terminal electric control box 2a, mobile terminal cleaning Agent tank 21, cleaning agent pump 21a at the mobile end, oil separation tank 22 at the mobile end, clean water tank 23 at the mobile end, clean water pump 23a at the mobile end, liquid level sensor 24 at the mobile end, heating rod 25 at the mobile end, mainten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com