Substrate terminal cleaning apparatus and substrate terminal cleaning method

A cleaning device and cleaning technology, which are applied to the cleaning method using tools, the cleaning method using liquid, the cleaning method and the utensils, etc., can solve the problems of the elongation of stains, hinder the quality improvement and enlargement of the liquid crystal panel, etc., and achieve high precision Effect of cleaning action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

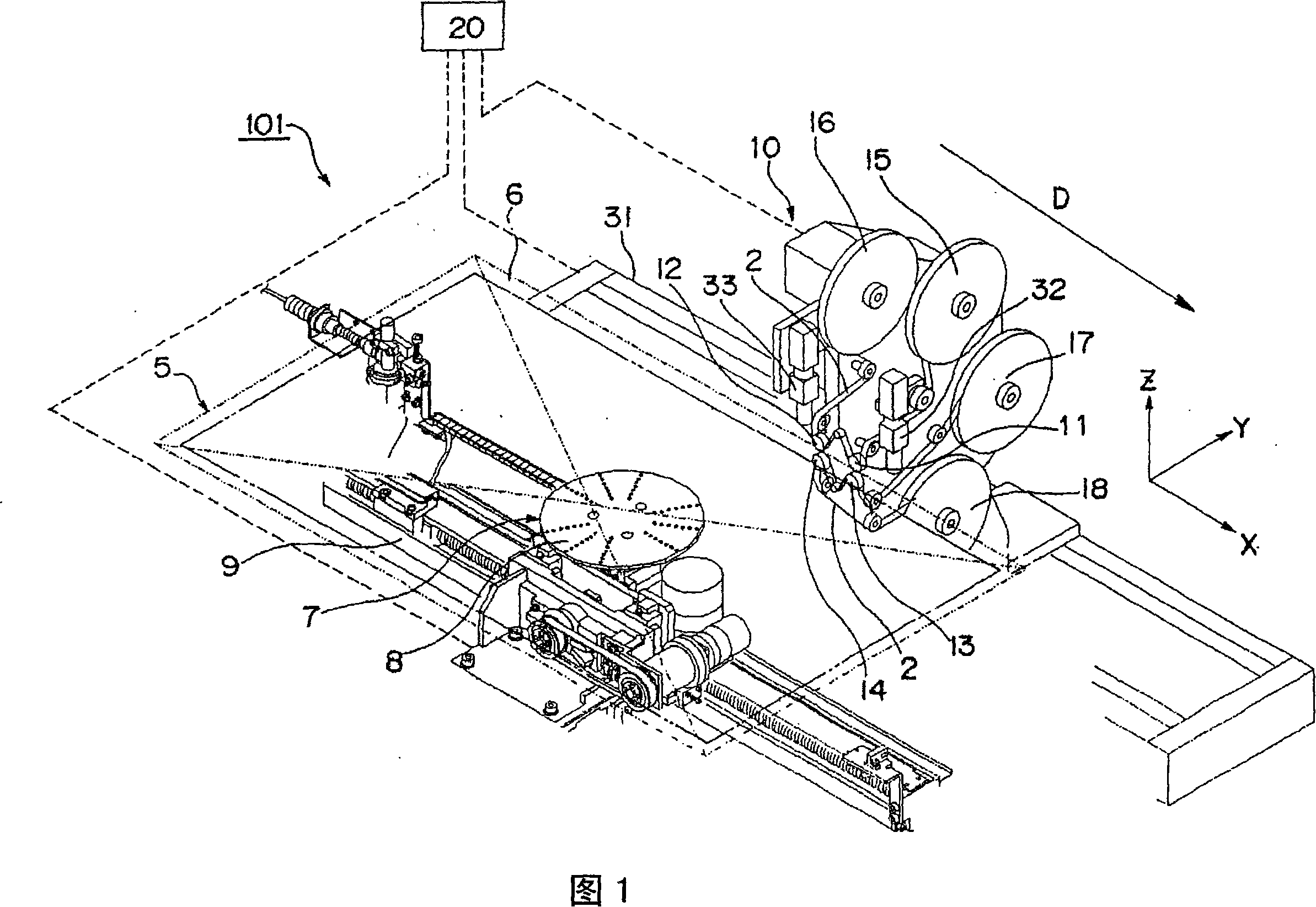

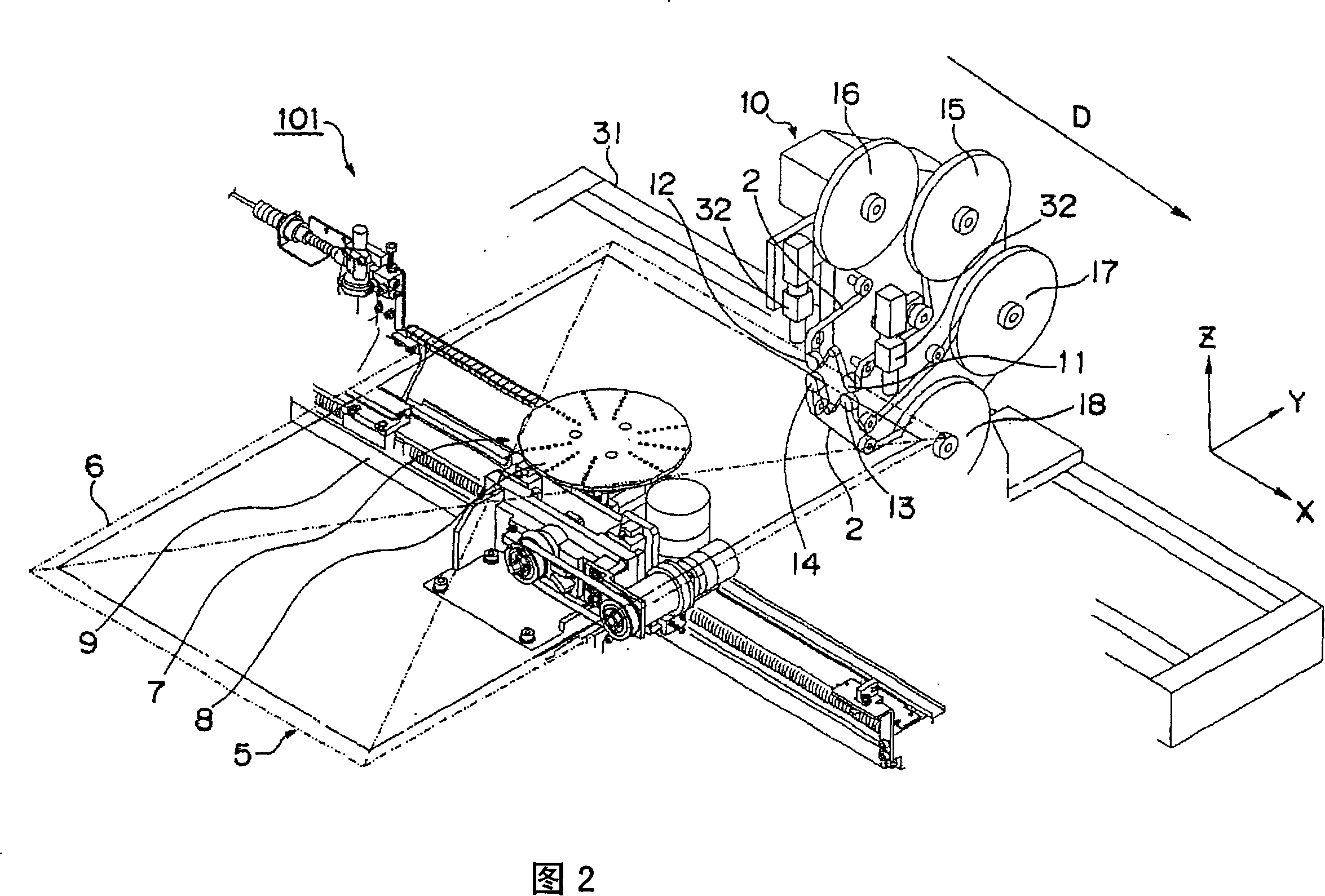

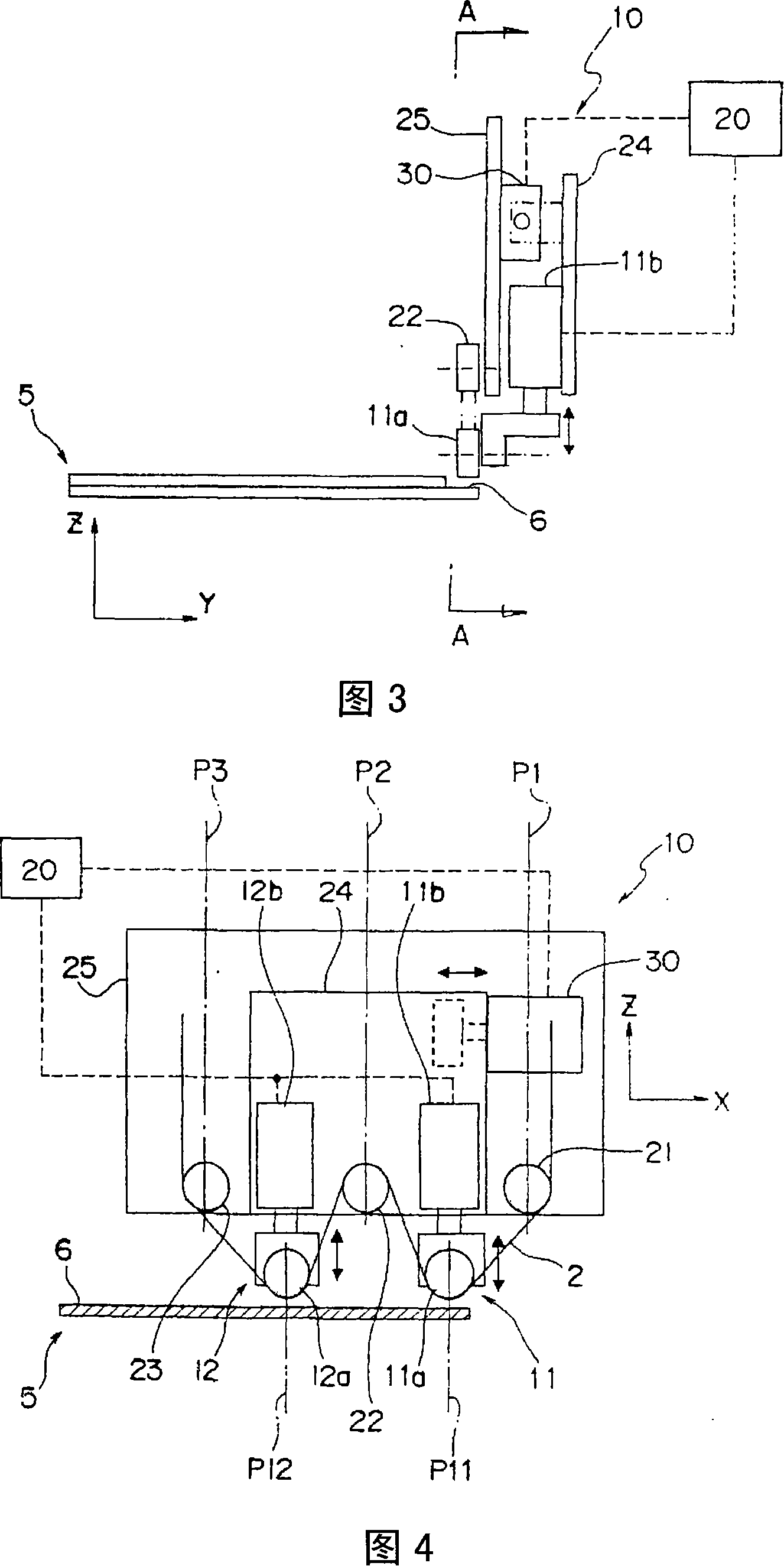

[0060] FIG. 1 is a schematic perspective view showing a main configuration of a terminal cleaning device 101 as an example of a substrate terminal cleaning device according to a first embodiment of the present invention. The terminal cleaning device 101 according to the first embodiment is made by contacting a cleaning cloth as an example of a cleaning member with an edge or the like on the surface of a substrate for a flat display panel such as a liquid crystal display device (liquid crystal panel) or a plasma display panel (PDP). A device for cleaning by contacting and wiping the terminal part (or the surface of the terminal part or the area where the terminal part is arranged) formed at the terminal. In addition, in this specification, the so-called "cleaning" refers to removing stains adhering to the object by washing or sweeping, including, for example, wet cleaning using a cleaning cloth soaked in an organic solvent or the like, or cleaning without using a solvent. Two t...

no. 2 approach

[0114] In addition, this invention is not limited to the said embodiment, It can implement in other various forms. For example, FIG. 10 is a schematic explanatory diagram showing a partial structure of a cleaning unit 110 included in a terminal cleaning device according to a second embodiment of the present invention.

[0115] As shown in FIG. 10 , in the cleaning unit 110, there is a twisting mechanism 120 that reverses the front and back of the cleaning cloth 2 so that the cleaning cloth 2 that is in contact with the terminal portion 6 of the substrate 5 by the first cleaning head 111 The abutting surface and the abutting surface of the cleaning cloth 2 abutting against the terminal portion 6 by the second cleaning head 112 are reversed from each other, and have a different structure from the cleaning unit 10 of the first embodiment in this point. .

[0116] Specifically, as shown in FIG. 10 , the constituent parts of the cleaning unit 110 on the upper side have: four rolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com