A dynamic voltage-stabilized nickel screen cleaning machine

A cleaning machine, nickel mesh technology, applied in printing machines, general parts of printing machinery, printing and other directions, can solve the problems of photosensitive glue, changes in water pressure, and increase the work intensity of staff

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following description is only a preferred embodiment of the present invention, and the protection scope is not limited to this embodiment. All technical solutions that belong to the idea of the present invention should belong to the protection scope of the present invention. At the same time, it should be pointed out that, for those skilled in the art, some improvements and modifications without departing from the principle of the present invention should also be regarded as the protection scope of the present invention.

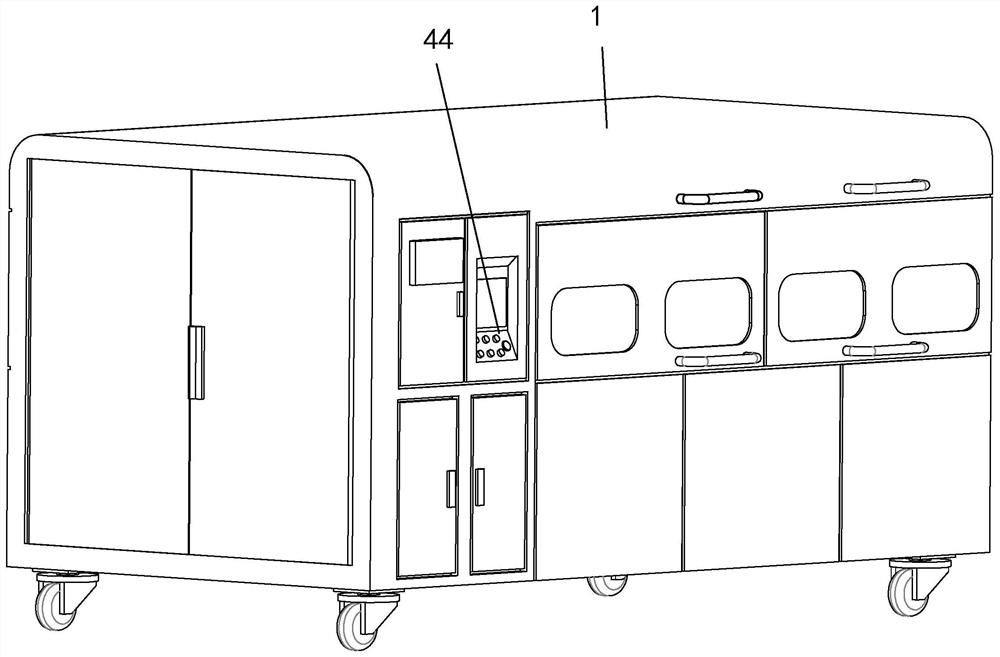

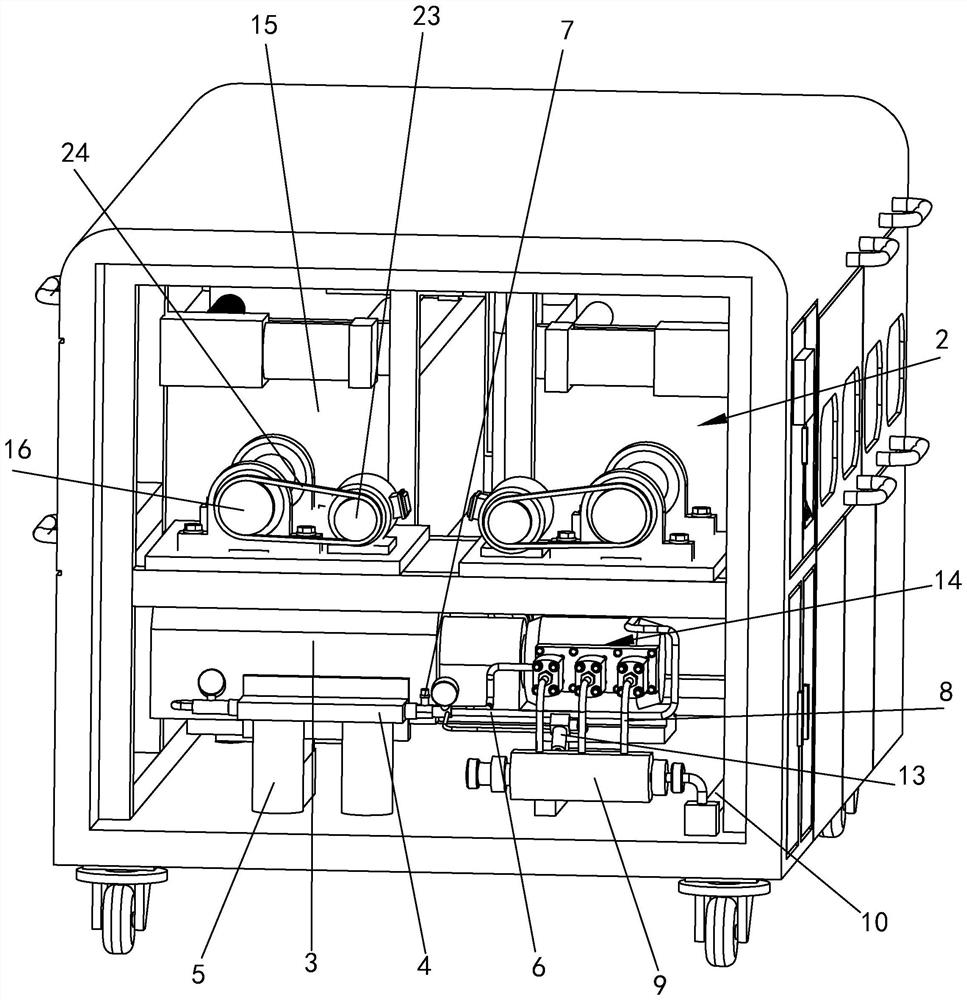

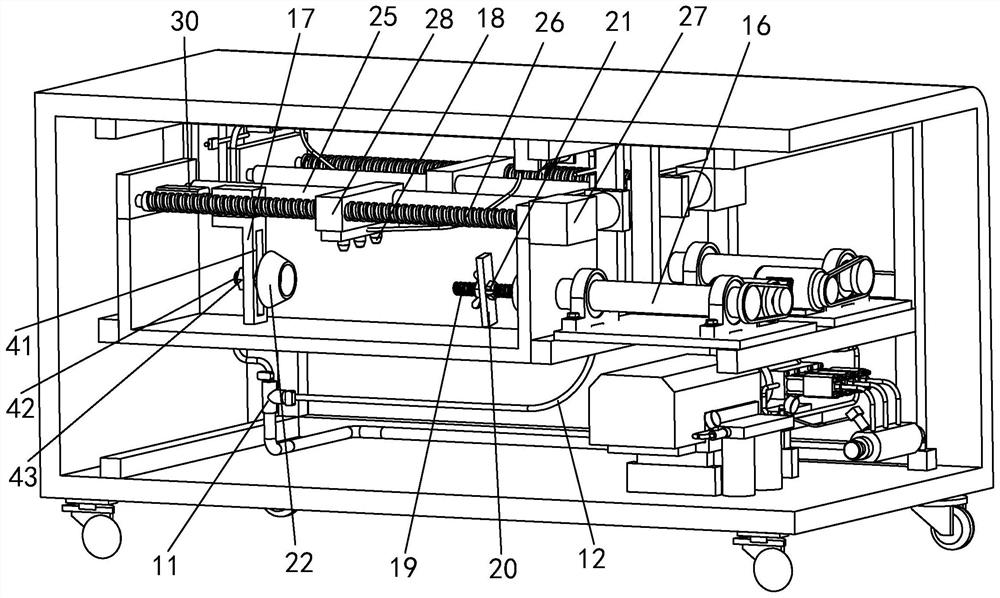

[0023] See Figures 1 to 4, a kind of nickel mesh cleaning machine with dynamic voltage regulation, comprising a casing 1 and a cleaning component 2 arranged in one side of the casing 1 for cleaning the nickel mesh, and also comprising a cleaning component 2 arranged in the casing 1 and connected with the cleaning Component 2 is oppositely arranged to remove the end head cleaning component, the pressure control component arranged inside the casi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com