A special wiping chuck device for a terminal cleaning machine

A cleaning head and cleaning machine technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems such as debugging difficulties, achieve good practical application value, reasonable design, and fast suspension adjustment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

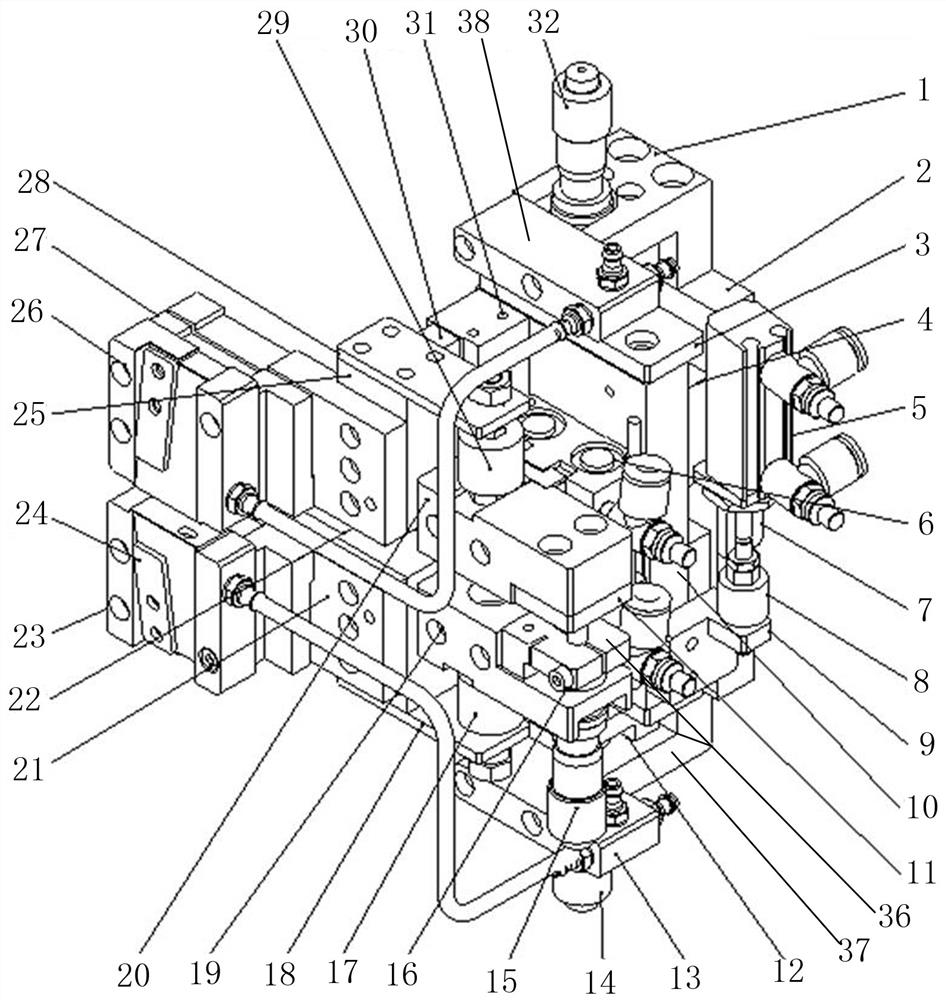

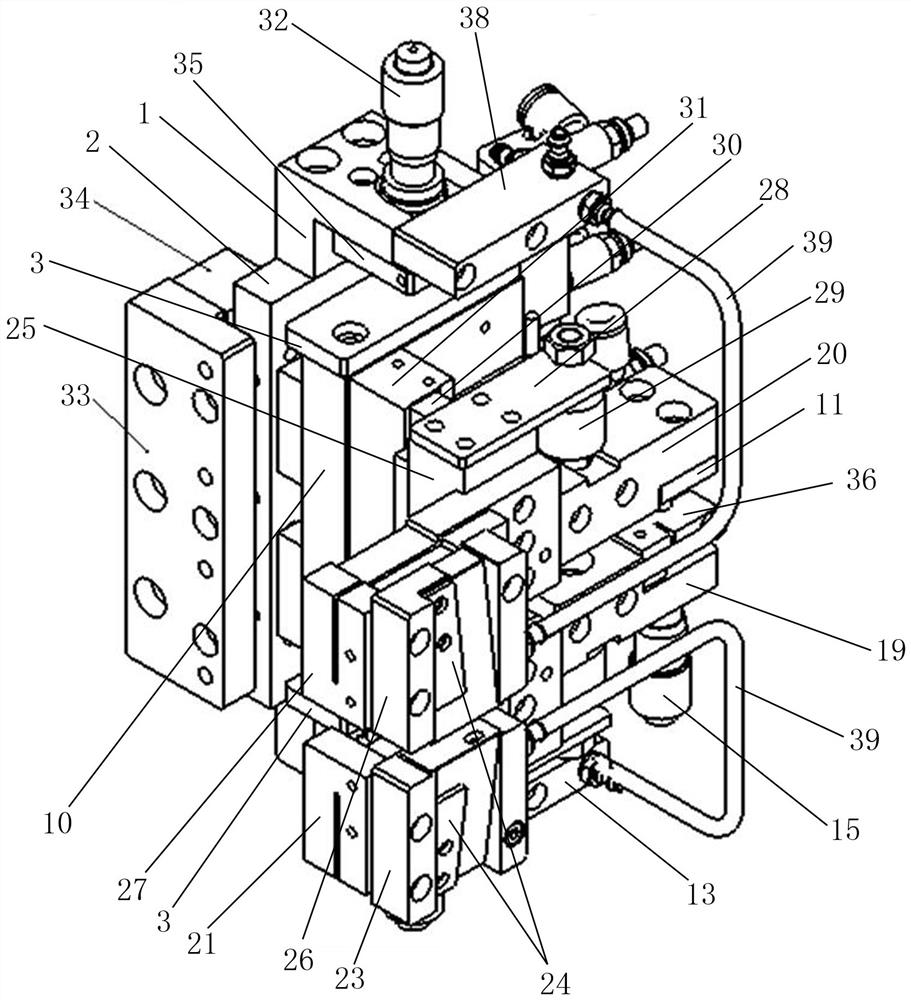

[0026] A special wiping chuck device for a terminal cleaning machine, such as figure 1 , 2 As shown, it includes the cleaning headrest I2, the back of the cleaning headrest I2 is fixed on the cleaning headrest II34, and the cleaning headrest II34 is fixed on the washing machine equipment. The flatness adjustment block 33 is installed on the side of the cleaning headrest II 34, and the flatness adjustment block 33 adjusts the cleaning headrest I2 through screws, that is, fine-tunes the lateral displacement of the cleaning headrest I2.

[0027] like figure 1 , 2 As shown, the front of the cleaning head support part I2 is movably installed with the cleaning head fixture seat II10 through the guide rail I4, and the top and bottom of the cleaning head fixture seat II10 are respectively equipped with guide rail stoppers 3. The side of the cleani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com