Lead-acid storage battery brass terminal cleaning device

A lead-acid battery and cleaning device technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of insufficient cleaning and laboriousness, and achieve shortening cleaning time, thorough cleaning, and simplification. Effects of cleaning steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

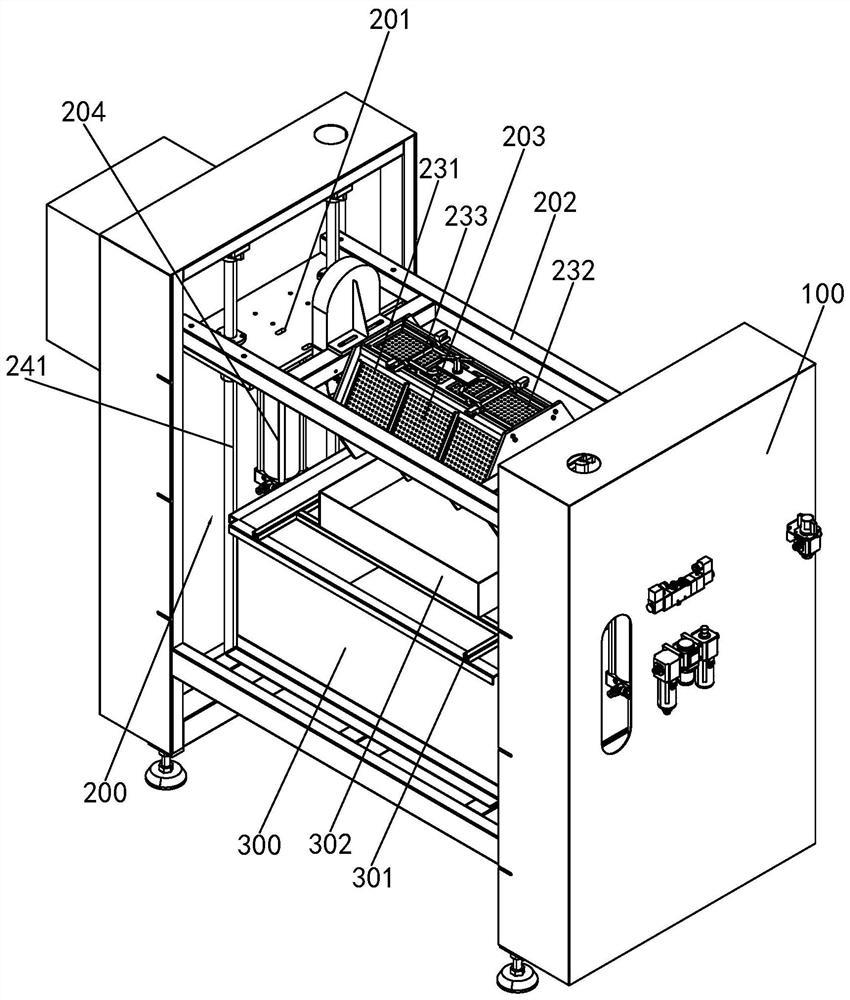

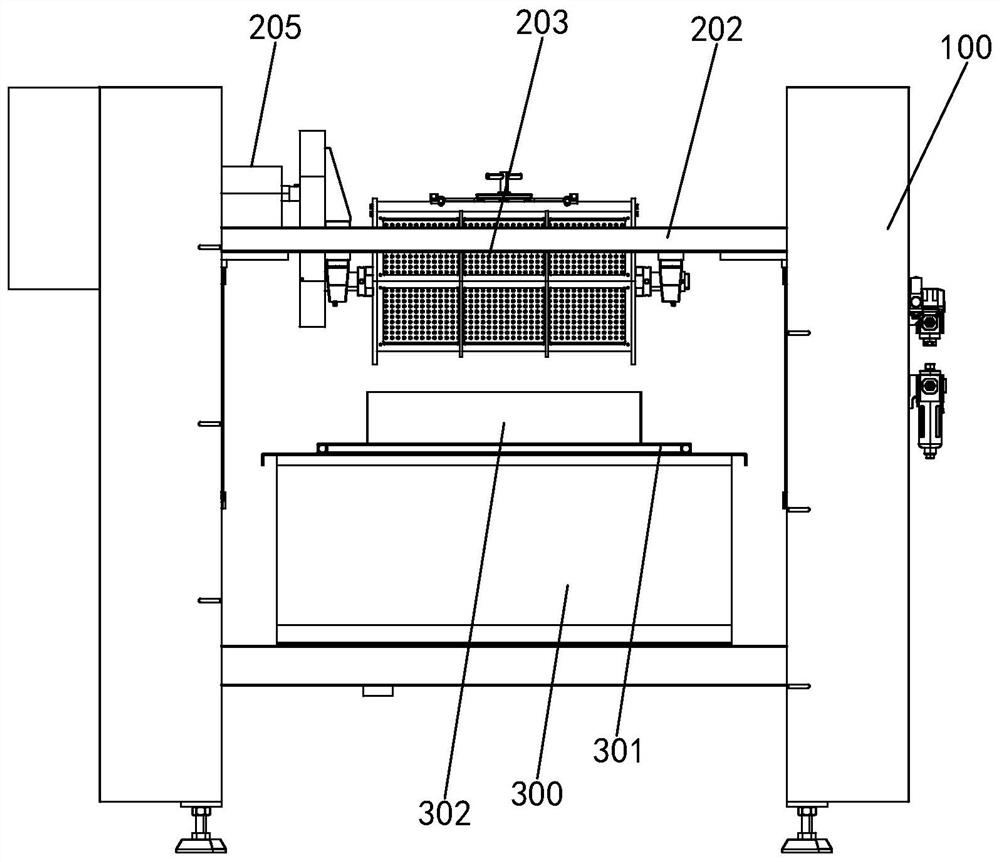

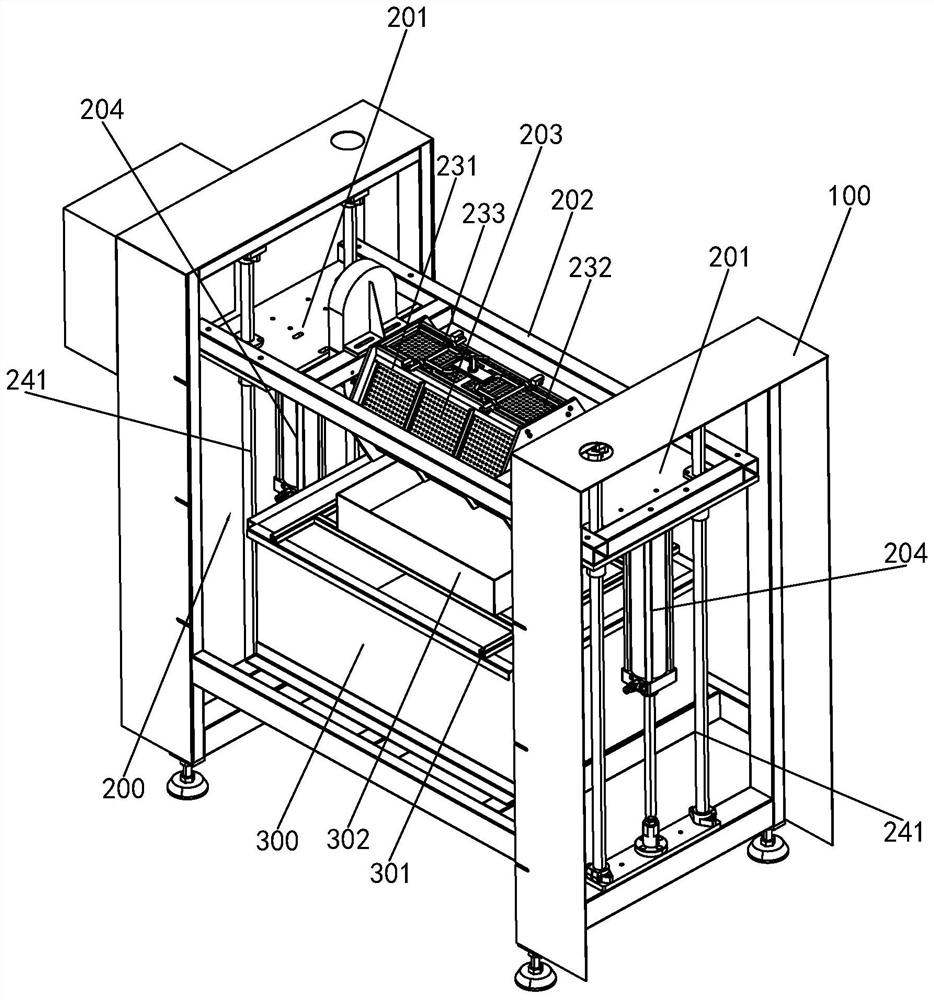

[0029] Example: see Figure 1-5 , a lead-acid battery brass terminal cleaning device, including a Z-axis lifting mechanism 200 and an oil pool 300; the oil pool 300 is used to hold kerosene, and the brass terminals are washed with kerosene;

[0030] The Z-axis lifting mechanism 200 includes two horizontally oppositely arranged lifting plates 201, and a linear drive mechanism acts on the two lifting plates 201 respectively. Specifically, the linear drive mechanism includes a lifting cylinder 204 and two vertically opposite guide rods. 241, the two ends of the lifting plate 201 are slidably connected to the guide rod 241 along the vertical direction through linear bearings, the guide rod 241 adopts a chrome-plated hard guide rod to cooperate with the guiding function, and the active end of the lifting cylinder 204 is fixed on the bottom of the lifting plate 201, The lifting plate 201 is driven by the lifting cylinder 204 to move up and down; the cleaning device also includes a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com