Automatic cleaning system for penicillin bottle plugs

An automatic cleaning and vial stopper technology, applied in the field of vial cleaning, can solve the problems of small contact area between the cork and the cleaning solution, the inability to realize the cork, and the water content of the cork, etc., so as to improve the cleaning effect and reduce the water content. , the effect of improving the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

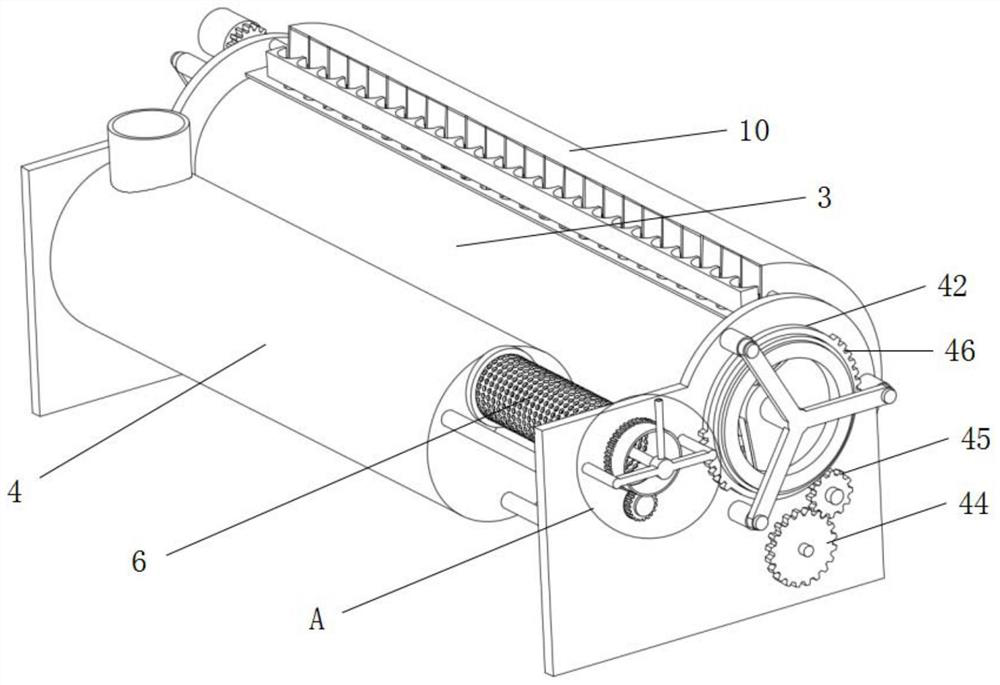

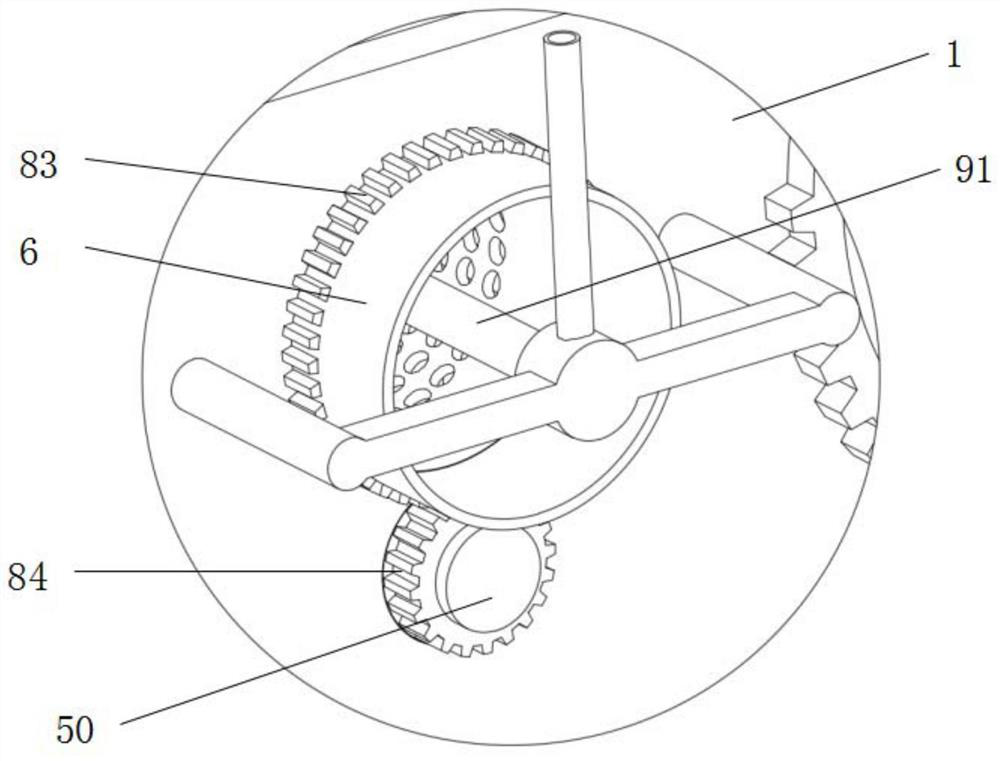

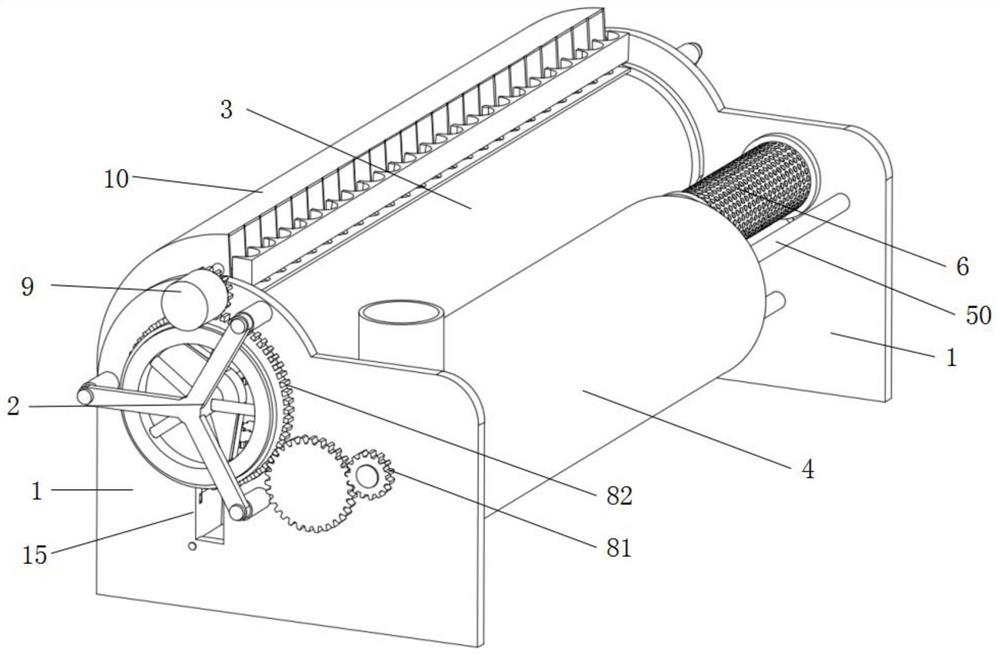

[0038] Such as Figure 1 to Figure 3 As shown, the present invention provides a kind of cillin bottle stopper automatic cleaning system, comprises the bracket 1 that is located in the cleaning box, the bracket 1 is provided with a mounting frame, the middle part of the mounting frame is provided with a pole 2, and the pole 2 is rotated with a Drum 3; Drum 3 is provided with a water-permeable mesh; Drum 3 is provided with a telescopic scrubbing mechanism that follows the rotation and telescopic movement of the drum 3, so as to clean the rows of vials entering the cleaning box through the telescopic scrubbing mechanism. Rotate and flip, and rotate and scrub the inside of the vial during the flipping process; the other side of the support 1 is provided with a net cylinder 4; the net cylinder 4 is a water-permeable cylindrical net structure; the rotation of the net cylinder 4 is provided with a spiral push roller 5 One end of the helical push roller 5 is provided with a driving ge...

Embodiment 2

[0040] Such as Figure 1 to Figure 4 As shown, in conjunction with the technical scheme of embodiment 1, in the present embodiment, one end of net tube 4 is provided with feed opening, and the other end of net tube 4 is provided with discharge port, and discharge port is communicated with net 6 of getting rid of; 5 is provided with a spiral push blade 7, so that the spiral push roller 5 drives the spiral push blade 7 to push the bottle stopper from the discharge port into the throwing net 6, so that the bottle stopper is pushed on the net tube 4 by the spiral push blade 7 It moves inside and out, and relies on the screw push blade 7 to press the cork into the cleaning solution for cleaning, so as to reduce the problem of unclean cleaning caused by the cork floating on the surface of the cleaning solution due to buoyancy, and effectively improve the dehumidification efficiency of the cork .

[0041] Specifically, rotation is provided with air pipe 91 in mesh cylinder 4, and on...

Embodiment 3

[0044] Such as Figure 5 to Figure 12 As shown, in conjunction with the technical scheme of embodiment 2, in the present embodiment, one side of rotating drum 3 is provided with a row of arc-shaped guide grooves 10, and the bottom of rotating drum 3 is provided with a baffle plate 11 for making the vials linearly move into the cleaning box One end of baffle plate 11 is provided with intermittent opening and closing assembly, and opening and closing assembly carries out intermittently opening baffle plate 11 by rotating drum 3, so that institute telescoping scrubbing mechanism drives the vial from the opening baffle plate under the rotation of rotating drum 3. The plate 11 enters into the arc-shaped guide groove 10, so that the end of the vial can be close to the inner wall of the arc-shaped guide groove 10 and rotate around the pole 2, so as to limit the position of the vial so that it can be placed completely The telescopic scrubbing mechanism does not have the problem of det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com