Self-cleaning ultrasonic water purifier

An ultrasonic and self-cleaning technology, applied in chemical instruments and methods, filtration separation, separation methods, etc., can solve the problem of inconvenient use of filter elements, ensure cleaning, improve cleaning efficiency, and avoid the trouble of cleaning filter elements or replacing filter elements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

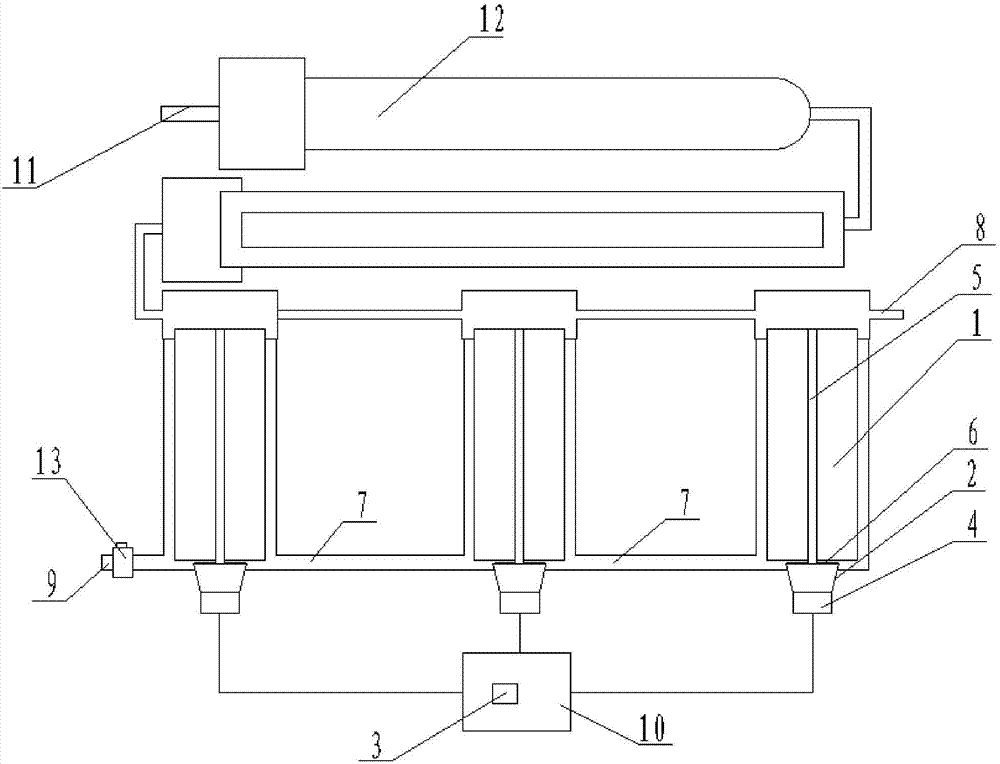

Embodiment 1

[0016] The self-cleaning ultrasonic water purifier includes three filter devices 1, which are connected sequentially through pipe fittings 7 and arranged horizontally, with a water inlet 8 above the right end of the filter device 1 on the right, and below the left end of the filter device 1 on the left A sewage outlet 9 is provided, and a water outlet device 12 connected to the filter device 9 is provided above the filter device 9. The water outlet device 12 is provided with a water outlet 11, and the filter device 1 is provided with an ultrasonic cleaning device 2. The ultrasonic cleaning device 2 includes an ultrasonic cleaning device. The vibration head 4 and the cleaning rod 5 connected with the ultrasonic vibration head 4 , the vibration of the ultrasonic vibration head 4 drives the vibration of the cleaning rod 5 , and the cleaning rod 5 is arranged in the filter device 1 .

[0017] The ultrasonic cleaning device 2 is arranged below the filter device 1, and the cleaning r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com