Cog bonding machine terminal cleaning pressure head mechanism

A technology of bonding machine and pressure head, applied in the direction of cleaning flexible objects, cleaning methods and utensils, workpiece clamping devices, etc., can solve the problems of reducing equipment working efficiency, inability to guarantee product quality, inconvenient adjustment of parallelism, etc., and achieve structural Simple, time-saving, easy-to-adjust effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

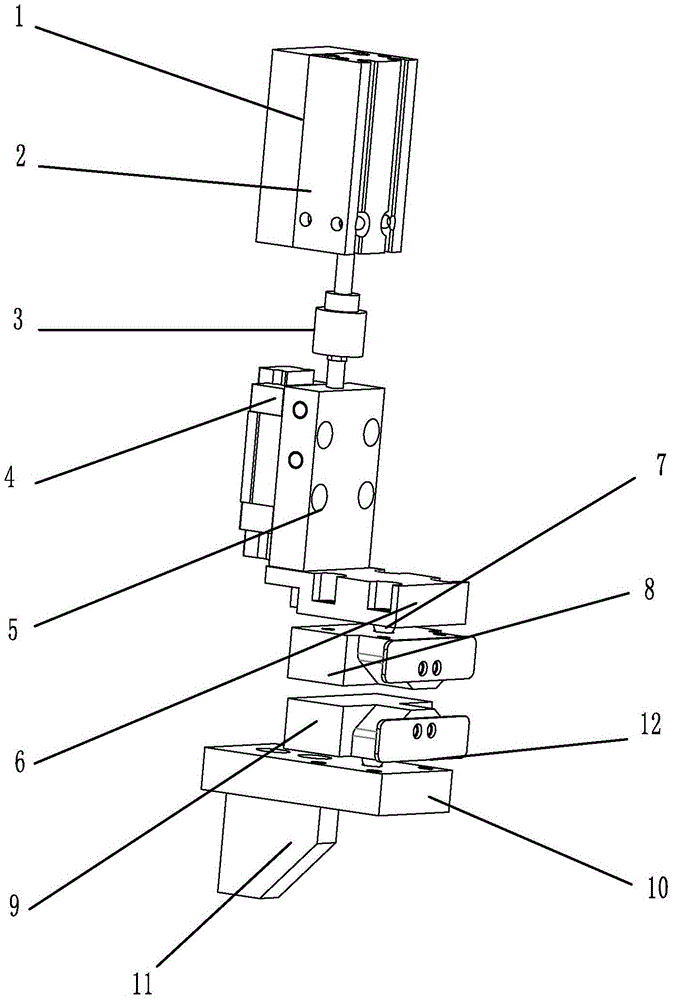

[0008] The connection process of the device of the present invention, such as figure 1 The shown cylinder 2 is fixed on the top of the machine tool body plate 1, the floating joint 3 is connected to the bottom of the cylinder, the middle plate 5 under the floating joint 3, the guide rail slider 4 is installed under the middle plate 5, and the connecting plate 6 is fixed on the bottom surface of the middle plate 5 , The connecting plate 6 is connected to the pressure head 8 by bolts, and a steel ball 7 is installed between the two parts, so that the upper part of the pressure head is assembled. The lower part first fixes the supporting plate 10 on the rib plate 11 of the machine tool body, the supporting plate 10 is connected with the back supporting plate 9 through bolts, and a steel ball 7 is installed between the back supporting plate 9 and the supporting plate 10, and the pressure head and the back supporting plate Guide piece 12 is housed respectively on the plate, and who...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com