A flexible screen terminal cleaning mechanism

A cleaning mechanism and flexible screen technology, which is applied in the direction of cleaning flexible objects, cleaning methods and utensils, cleaning methods using tools, etc., can solve problems such as limited cleaning effect, improve adsorption force, improve installation stability, and improve integrity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

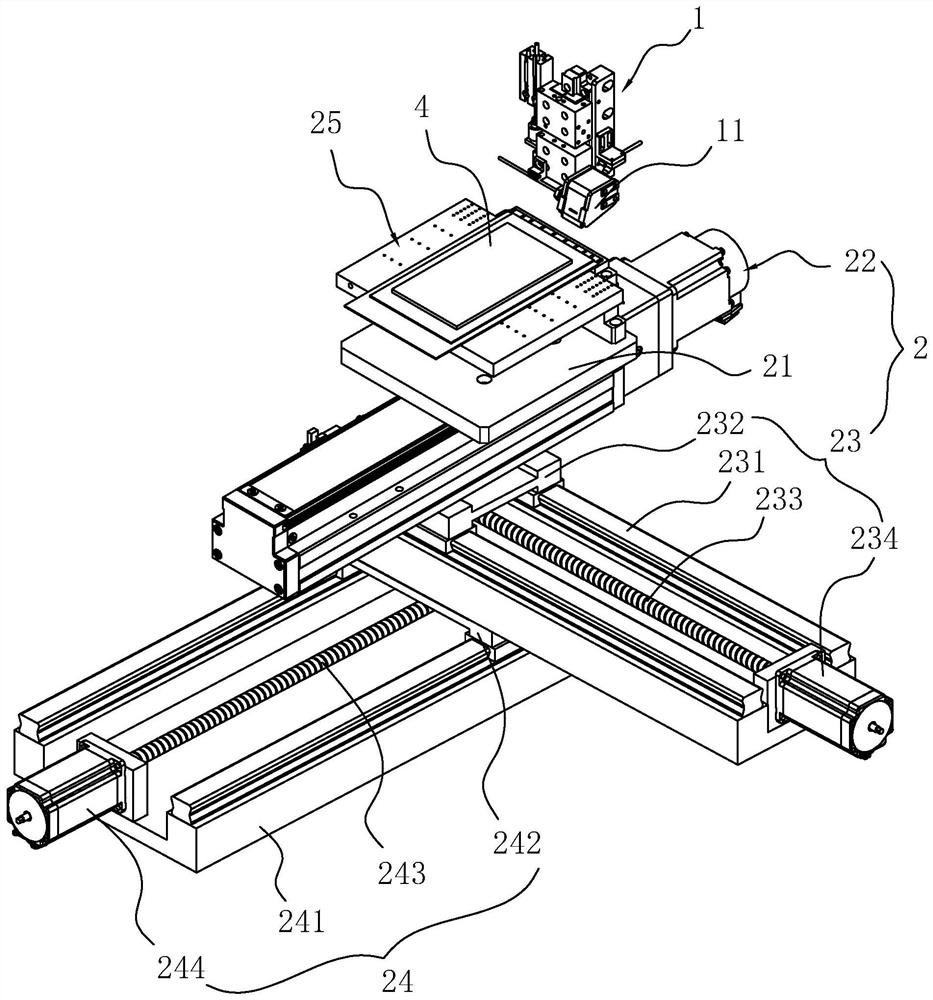

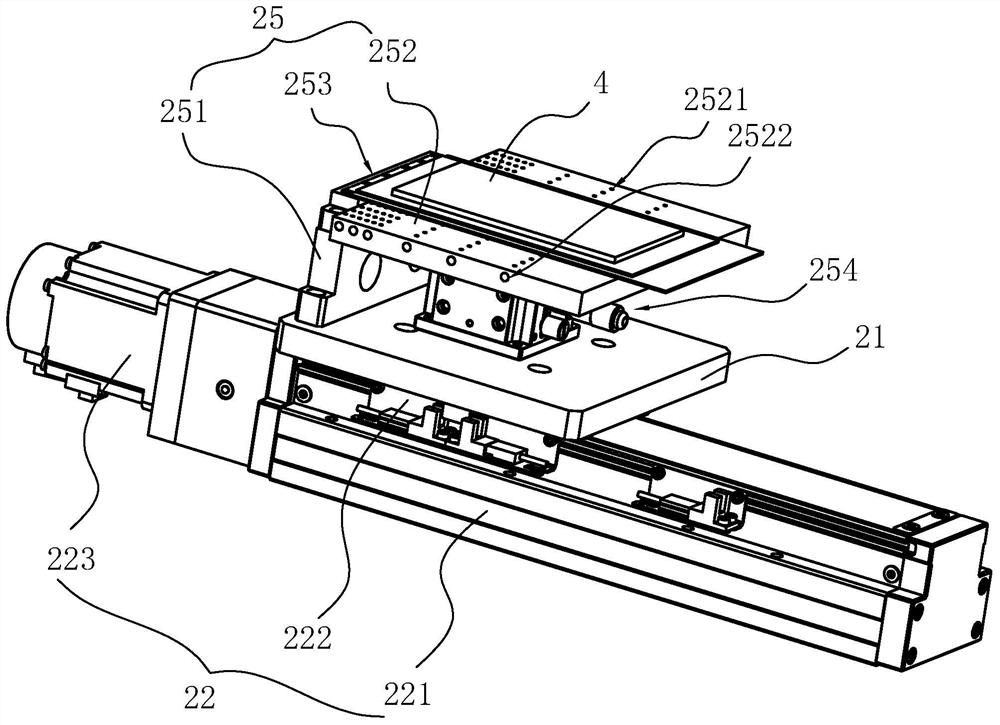

[0038] refer to figure 1 , The cleaning mechanism includes a cleaning chuck device 1 and a cleaning platform device 2 . The cleaning chuck device 1 is located above the cleaning platform device 2 and is equipped with a cleaning head 11 for cleaning the terminals of the flexible screen 4 . The cleaning platform device 2 includes a transfer platform mounting plate 21, on which a mounting assembly 25 for fixing the flexible screen 4 is provided, and at least under the transfer platform mounting plate 21 there is an assembly for driving the transfer platform mounting plate 21 along the The first linear module 22 that continuously slides back and forth in the length direction of the installed flexible screen 4 terminals, and the second linear module used to drive the transfer platform mounting plate 21 to reciprocate and intermittently move along the horizontal arrangement direction of the flexible screen 4 terminals twenty three.

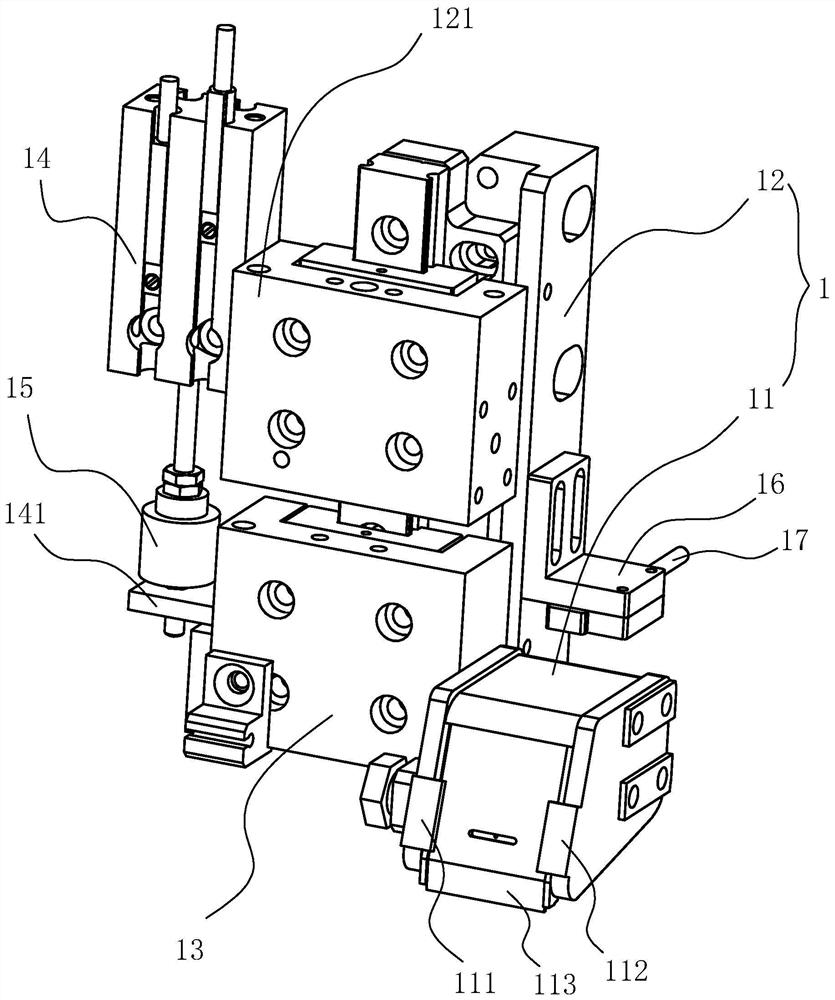

[0039] refer to figure 1 , 2 , in this embodi...

Embodiment 2

[0049] refer to Figure 4 The difference between embodiment 2 and embodiment 1 is that: the top wall of the entire platform is provided with a limit mechanism 3 for limiting the movement of the flexible screen 4 .

[0050] Limiting mechanism 3 comprises two cover plates 31, and two cover plates 31 are respectively hinged on the two side edges perpendicular to vacuum platform 252 top wall and cleaning pressing platform 253, and two cover plates 31 are close to one side of vacuum platform 252 top walls Both are provided with a flexible layer 32, and in this embodiment, the flexible layer 32 can be made of silica gel. The flexible layer 32 is bonded to the cover plate 31, and the cover plate 31 is folded over the vacuum platform 252 and parallel to the top wall of the vacuum platform 252, and the flexible layer 32 is pressed against the flexible screen 4 to partially deform and adhere to the surface contour of the flexible screen 4. Together, the part of the flexible layer 32 ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com