Precision mirror frame based on a flexible hinge

A reflective mirror frame and flexible hinge technology, which is applied in installation, optics, instruments, etc., can solve the problems that the light path is easily affected by external factors such as vibration and temperature, the technical requirements of optical mechanical engineers are high, and the adjustment accuracy of the mirror frame is difficult to grasp. , to achieve the effects of wide application space, reduced adjustment difficulty, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

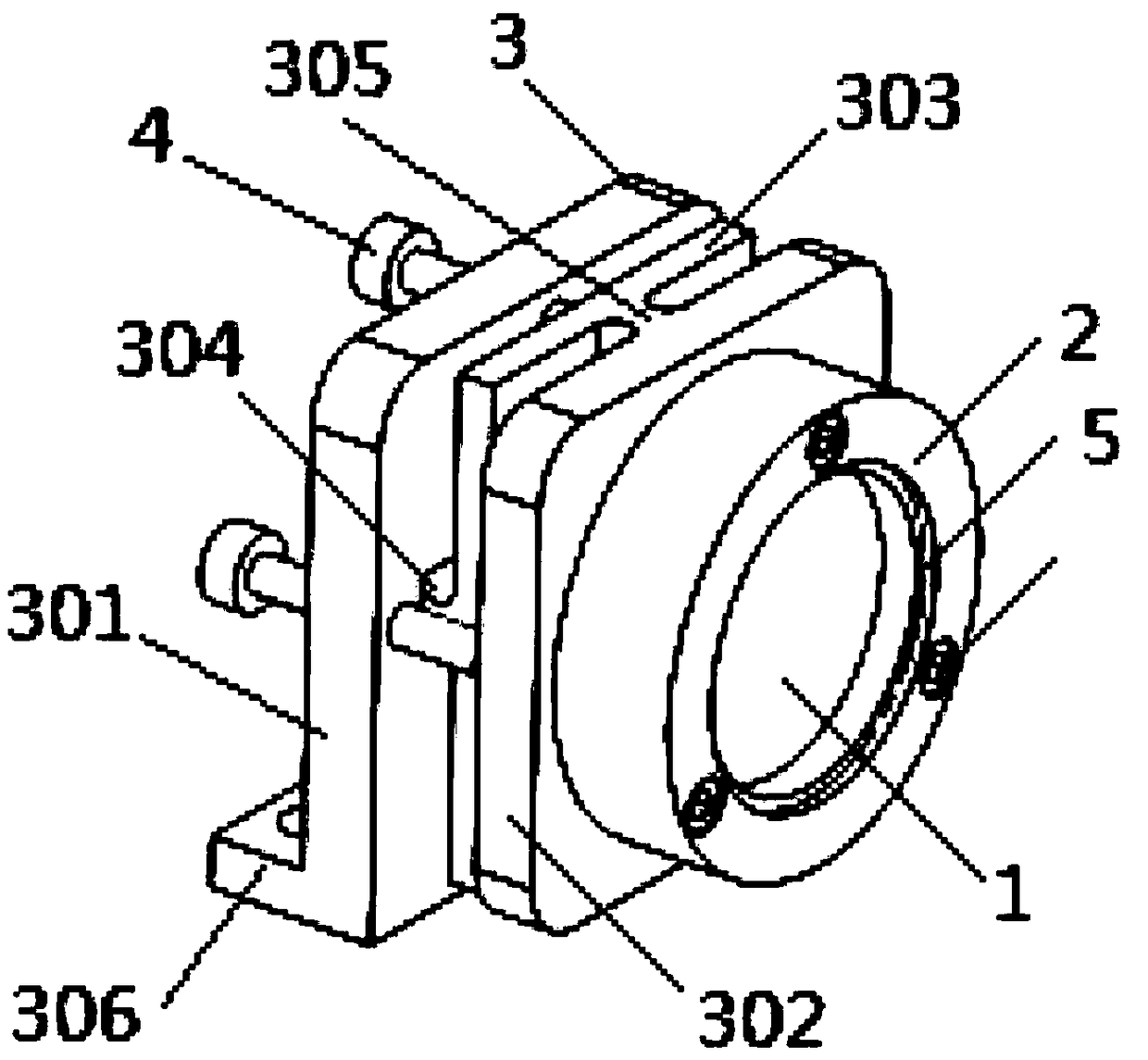

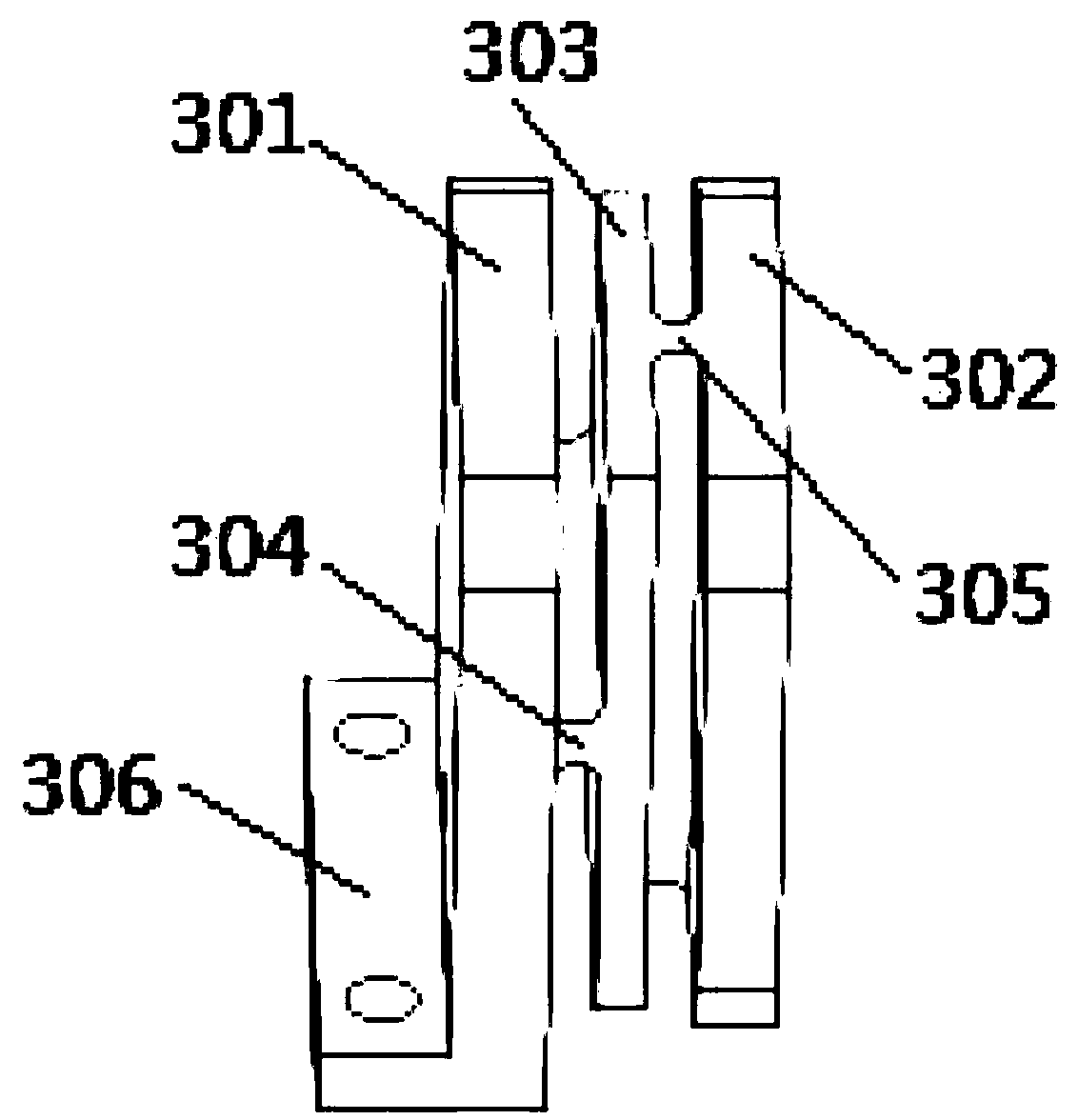

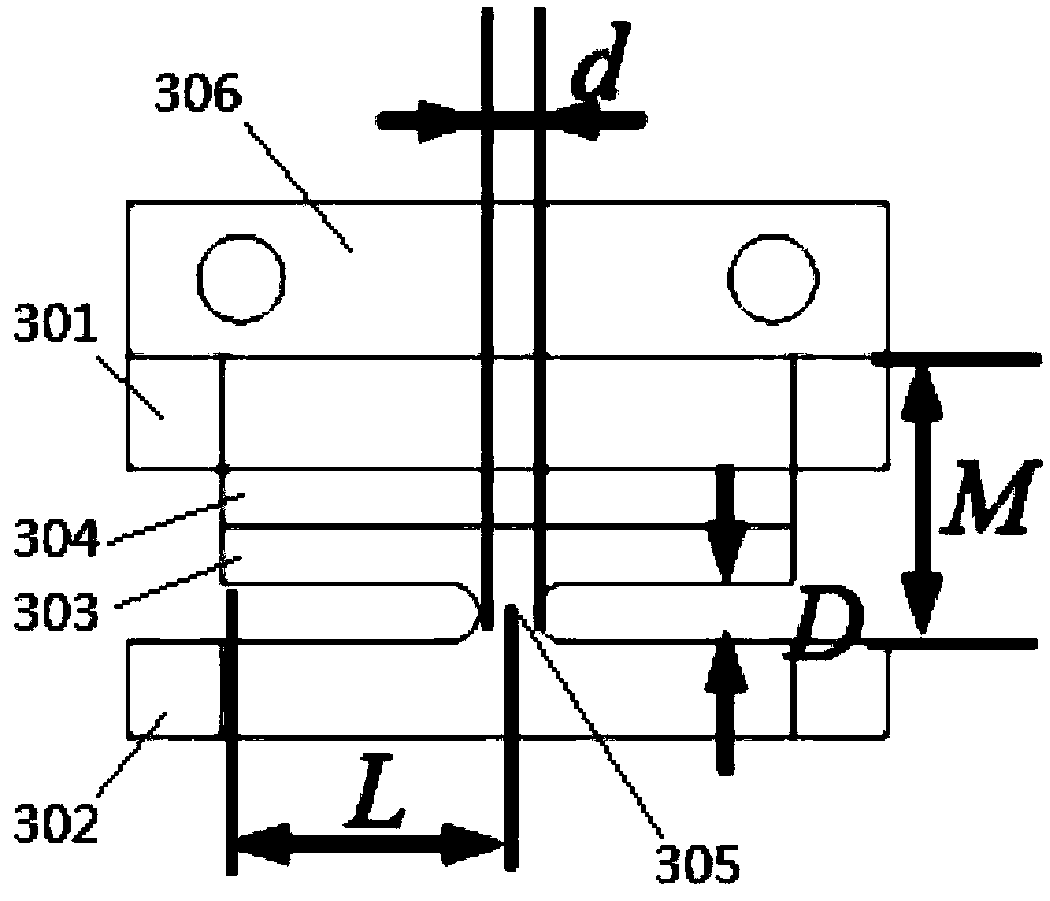

[0025] as attached Figure 1-5 As shown, a precision mirror frame based on a flexible hinge includes a mirror 1, a mirror holder 2 for installing the mirror 1, a base 3 for supporting the mirror holder 2, and a mirror 1 for adjusting the angle The adjustment unit 4, the base 3 includes a fixed plate 301, an adjustable plate 302 and a connecting plate 303 arranged between the fixed plate 301 and the adjusting plate 302, the fixed plate 301 and the connecting plate 303 are connected by a first hinge 304, and the adjustment The plate 302 and the connecting plate 303 are connected by a second hinge 305. The fixing plate 301 is provided with an adjusting unit 4 for adjusting the angle between the fixing plate 301 and the adjusting plate 302. The adjusting plate 302 is fixedly installed on one side away from the connecting plate 303. There is a mirror holder 2 on which a reflector 1 is installed; the thickness d of the first hinge 304 and the second hinge 305 ranges from 1 to 10 mm,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com