Carbon fiber three-dimensional fabric automatic weaving machine

A technology of three-dimensional fabrics and carbon fibers, which is applied in looms, textiles, textiles and papermaking, etc., can solve the problems of not having the function of automatic integral yarn pressing, and achieve the effects of reducing wear, improving success rate, and ensuring accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The present invention will be further described in detail below in combination with specific embodiments.

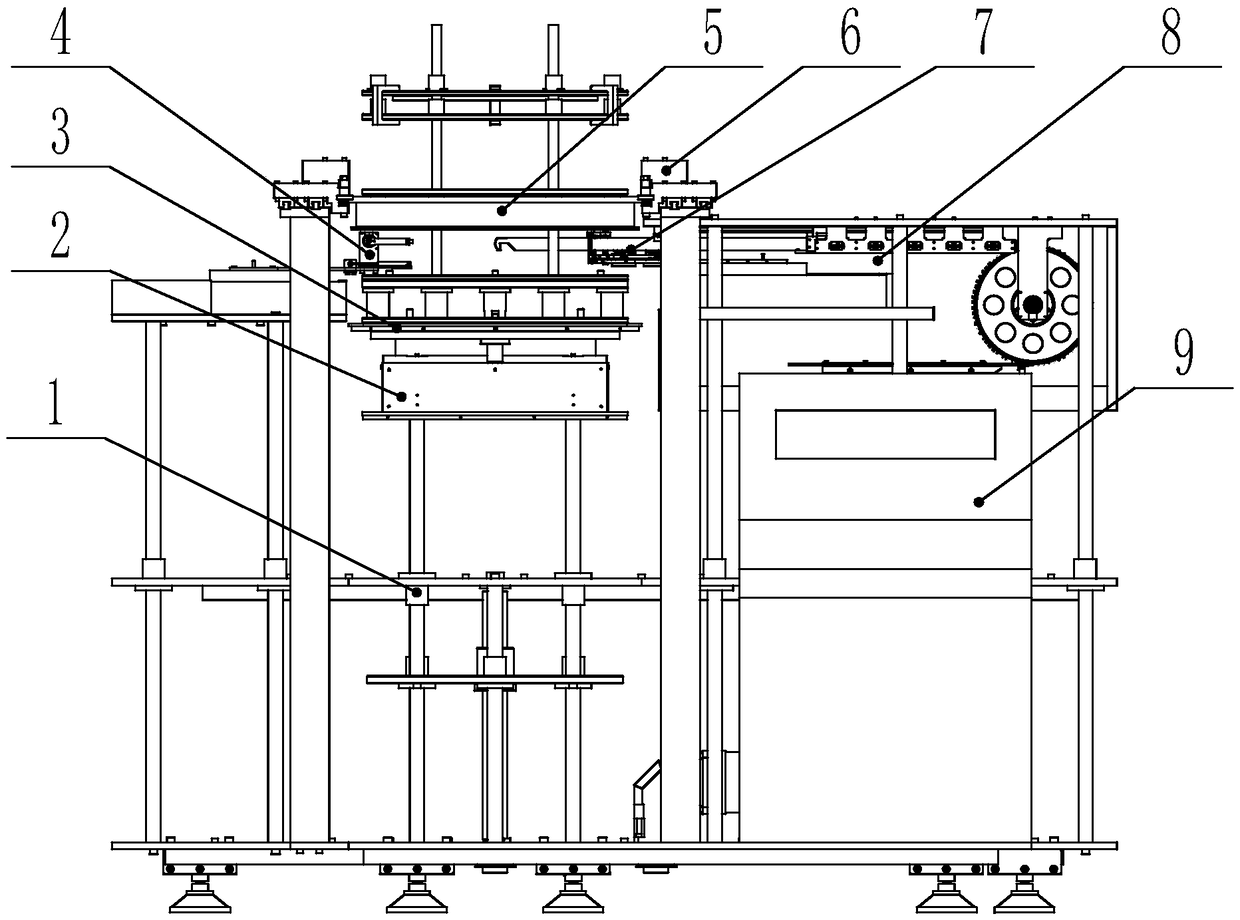

[0070] like Figure 1 to Figure 10 As shown, a carbon fiber three-dimensional fabric automatic knitting machine includes a lifting table 1, a translational table 2, a rotary table 3, a weft delivery mechanism 4, a tooling 5, a translational slide table 6, a weft insertion mechanism 7, and a weft insertion mechanism. Workbench 8 and electrical control cabinet 9;

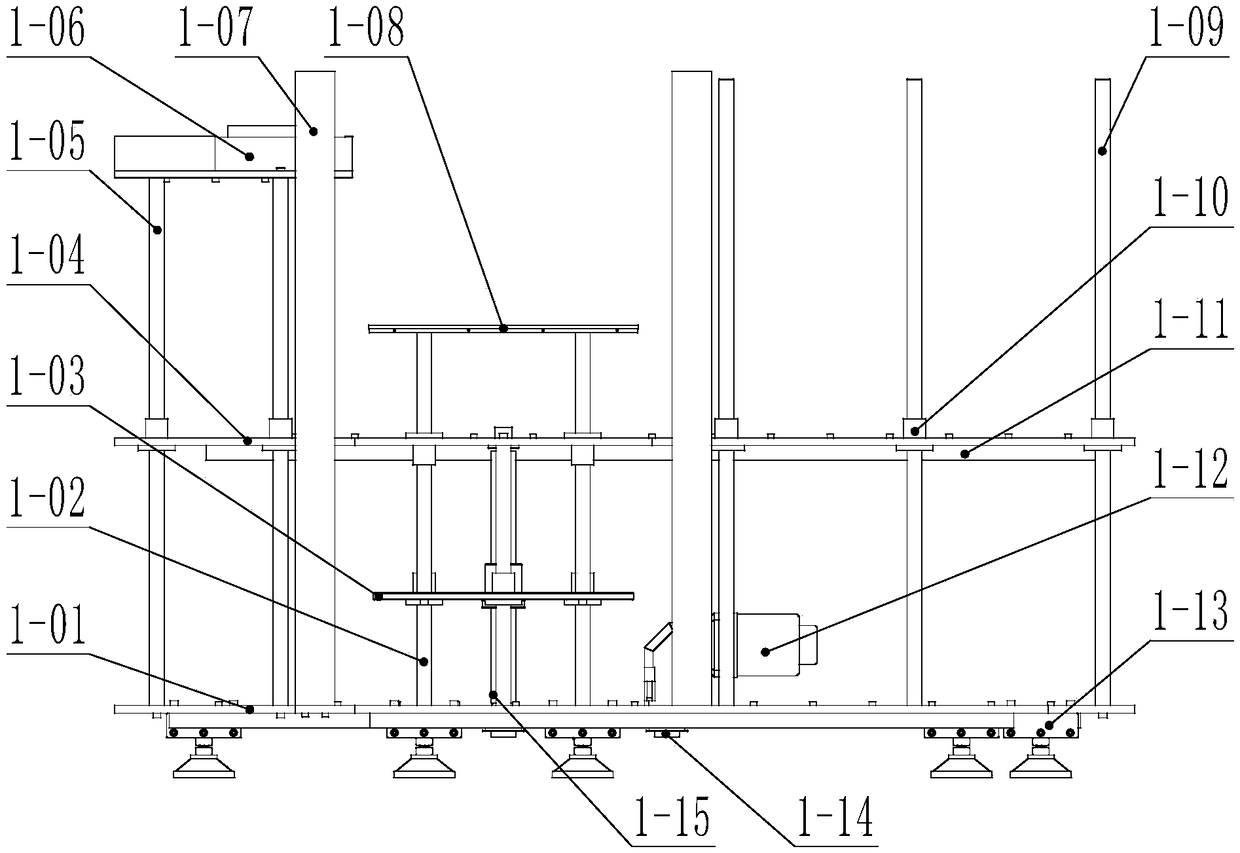

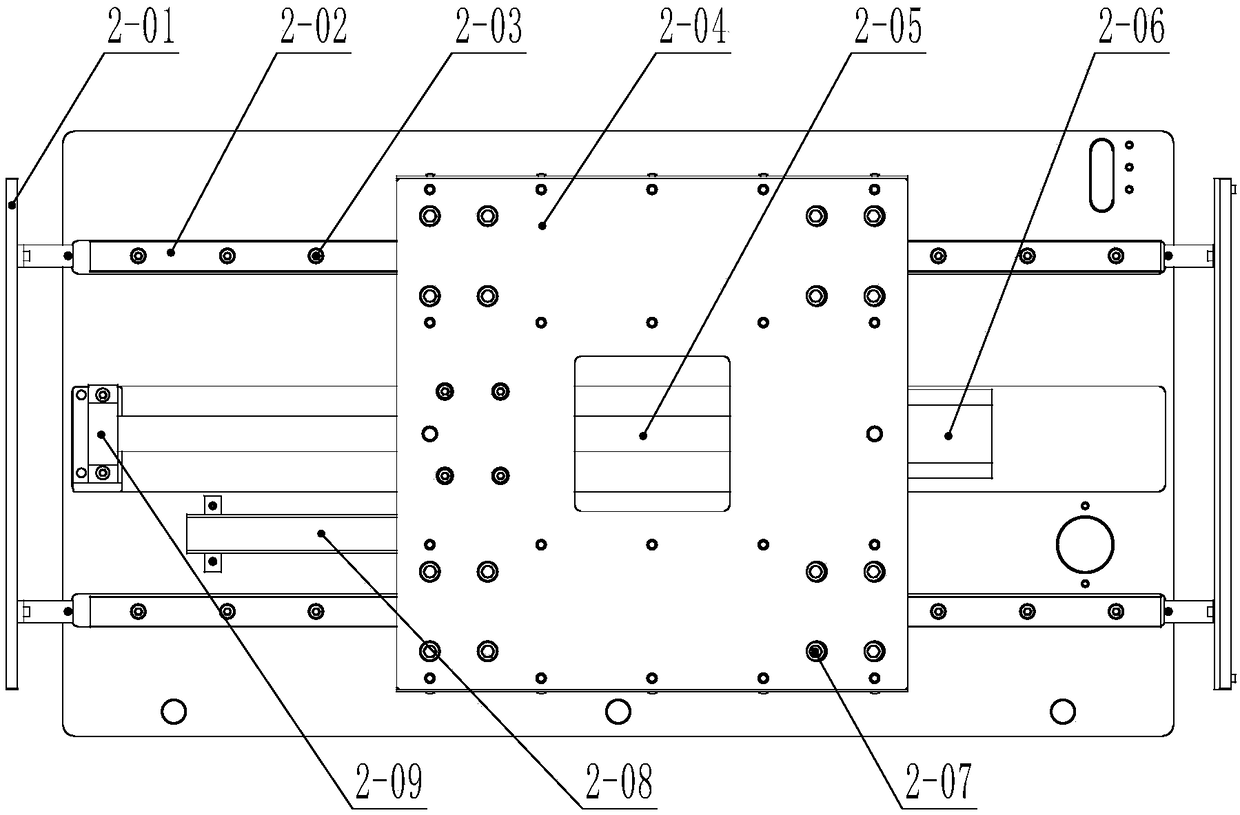

[0071] like figure 1 As shown, the weft transfer linear module 1-06 on the right side of the lifting workbench 1 is positioned and installed with the weft transfer mechanism 4, the columns 1-07 on both sides of the middle part are respectively positioned and installed with a translation slide table 6, and the upper moving plate 1-08 is positioned on the Install the translation workbench 2, position and install the rotation workbench 3 on the translation workbench moving plate 2-04, locate and install th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com