Composite clarifying used in production technology of contact screen cover plate glass

A composite clarifier and cover glass technology, which is applied in the field of glass clarifiers, can solve problems such as large economic burden, unfavorable environmental protection, and high price, and achieve the effects of promoting clarification, low cost, and reducing glass density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

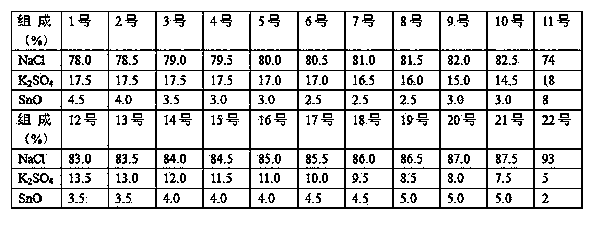

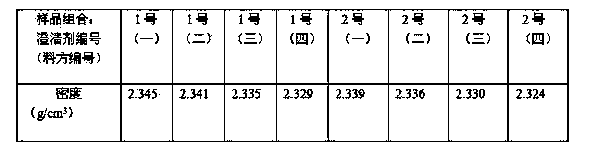

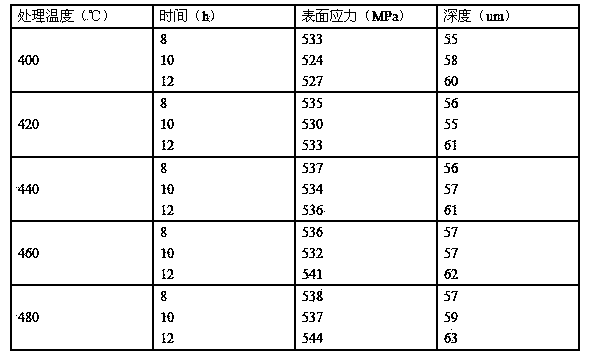

[0009] A compound clarifier used in the production process of touch screen cover glass, used to eliminate bubbles in molten glass, it is important that NaCl is used as the main material in the clarifier formula components, supplemented by SnO and K 2 SO 4 , wherein, the weight percent content of above component is:

[0010] NaCl 74~93%,

[0011] SnO 2~8%,

[0012] K 2 SO 4 5~18%.

[0013] The NaCl, SnO, K 2 SO 4 The dosage form is powder.

[0014] The particle size range of the NaCl is 80-350 mesh.

[0015] The particle size range of the SnO is 100-400 mesh.

[0016] The K 2 SO 4 The particle size range is 100-330 mesh.

[0017] In specific implementation, the composition of the touch screen cover glass used to verify the effect of this clarifying agent (not including the clarifying agent part) is:

[0018] SiO 2 65.7%,

[0019] al 2 o 3 14.5%,

[0020] B 2 o 3 3%,

[0021] KO 2 2.8%,

[0022] NaO 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Surface stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com