Calcium, magnesium, aluminum and silicon building float glass ceramic channel and method for applying same

A technology of glass-ceramics and forehearth, which is applied in the direction of glass production and feeding trough, can solve the problems of local crystallization, easy generation of streaks, erosion of refractory materials, etc., so as to improve product quality and yield, and prevent local crystallization , improve the effect of clarification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

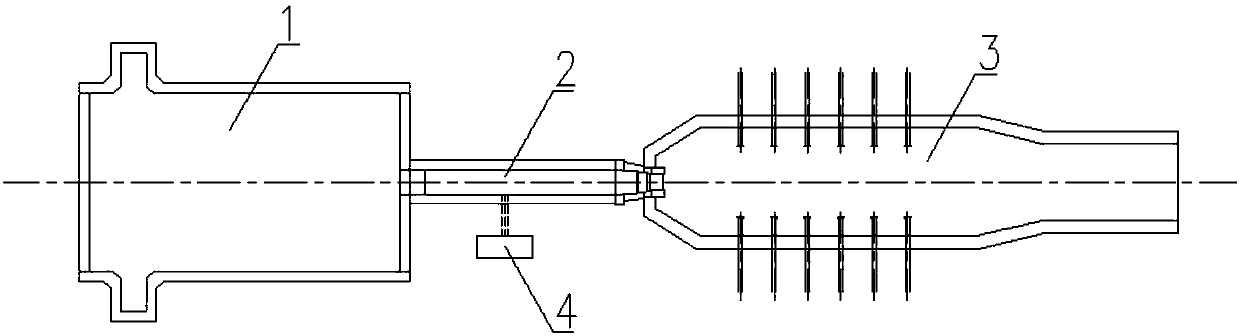

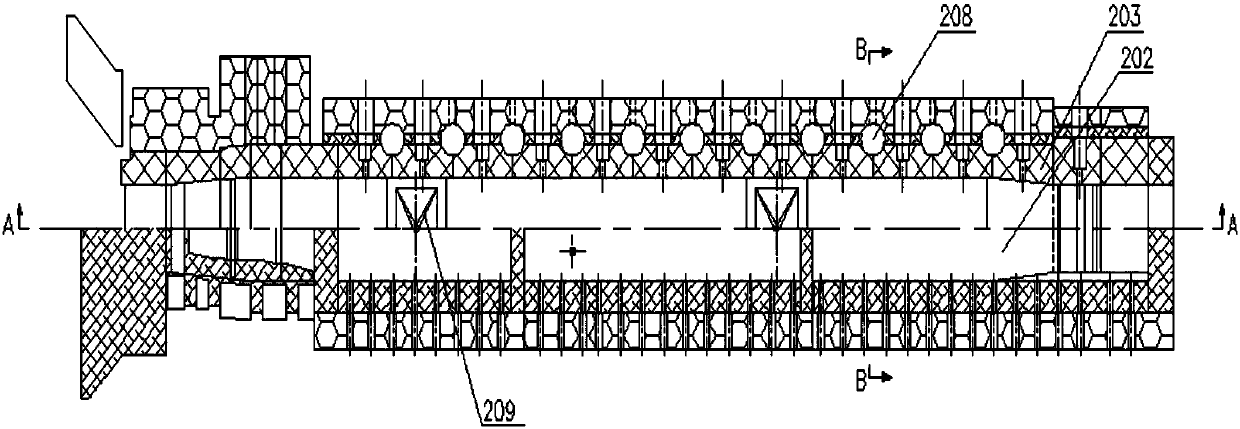

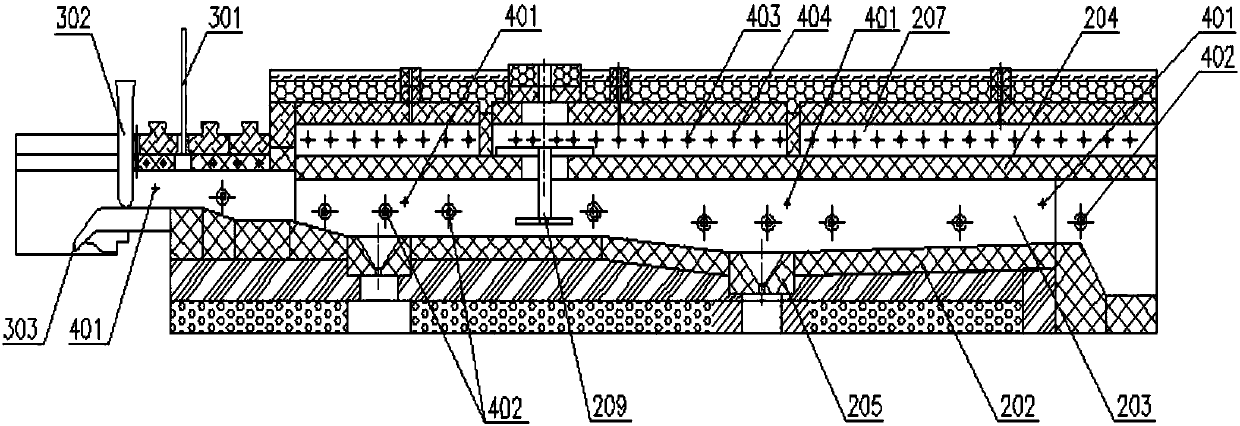

[0026] The present invention relates to a calcium-magnesium-aluminum-silicon architectural float glass-ceramic forehearth. The forehearth 2 is connected between the output end of the melting furnace 1 and the input end of the tin tank 3 as a flow channel for glass liquid, and includes a pool wall 203, a pool The bottom 202 and the cover plate 204 constitute the main body of the channel for the flow of molten glass and the external heat preservation shell. The setting avoids the uncontrollable speed of the molten glass when it initially enters the main body of the forehearth. When the molten glass rises to the uppermost end along the ascending channel, it enters the main body of the forehearth in the form of overflow, and the flow speed of the molten glass can be controlled by the flow rate. Perform precise control to avoid the generation of unqualified waste. The tail of the material channel 2 is provided with a flow gate 302. The flow gate 302 is provided with a heating elemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com