Aluminosilicate glass and preparation method thereof, and touch screen glass cover plate

The technology of aluminosilicate glass and glass cover plate is applied in the preparation of aluminosilicate glass and the field of touch screen glass cover plate. To achieve the effect of reducing density, reducing expansion coefficient and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

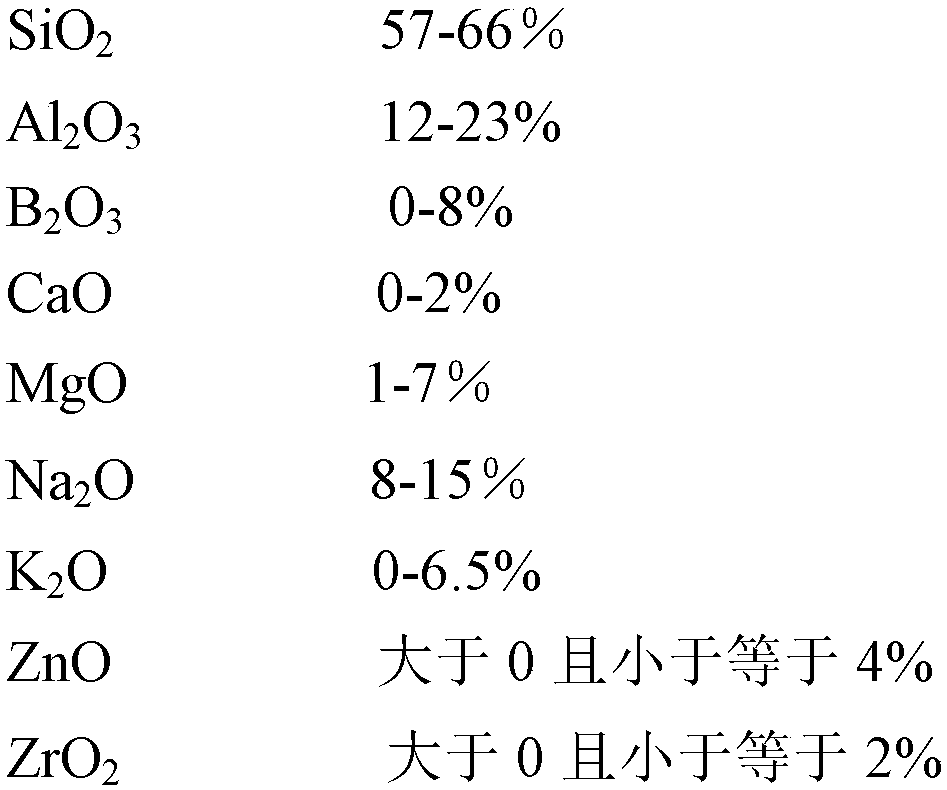

Method used

Image

Examples

Embodiment 12

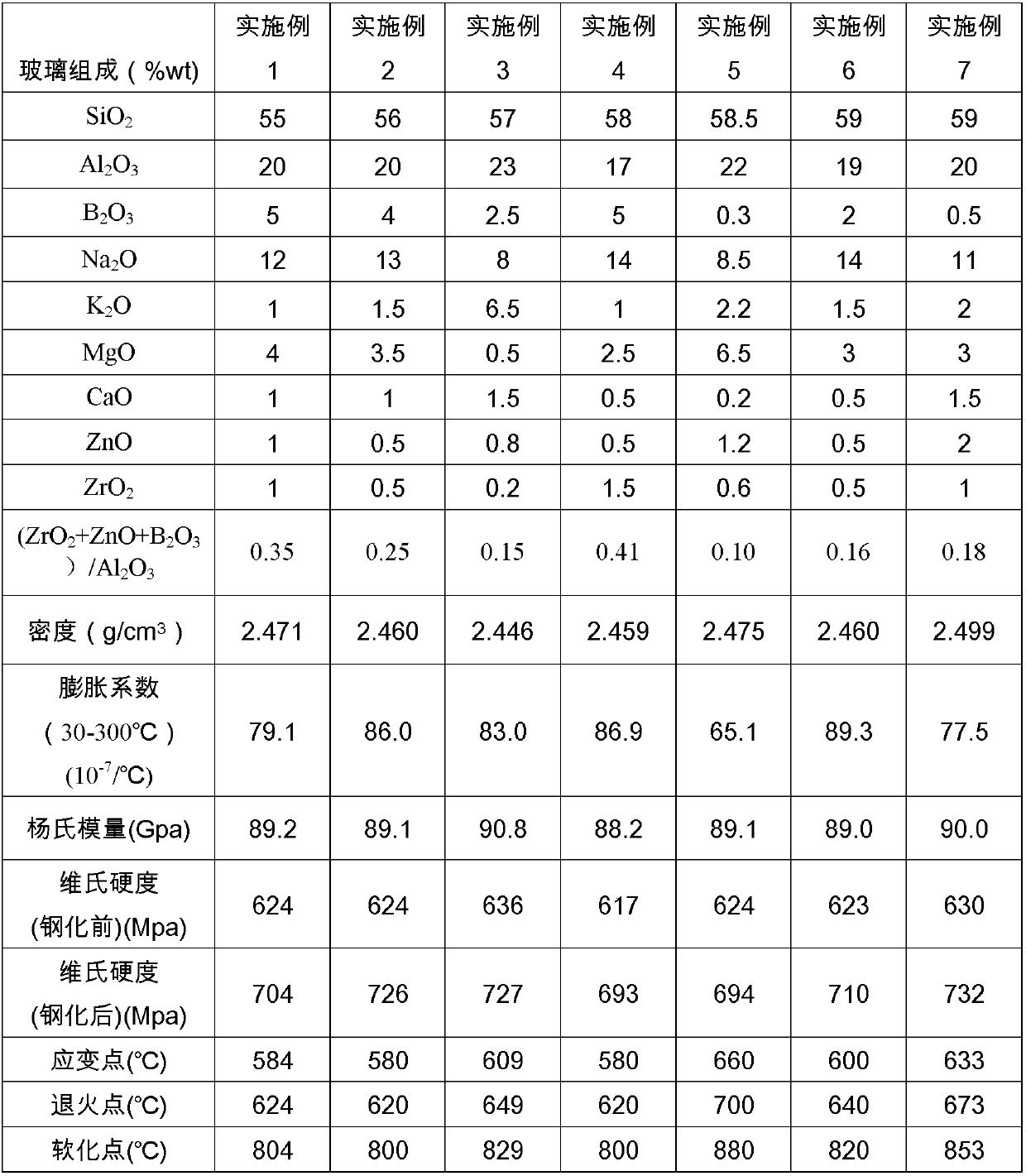

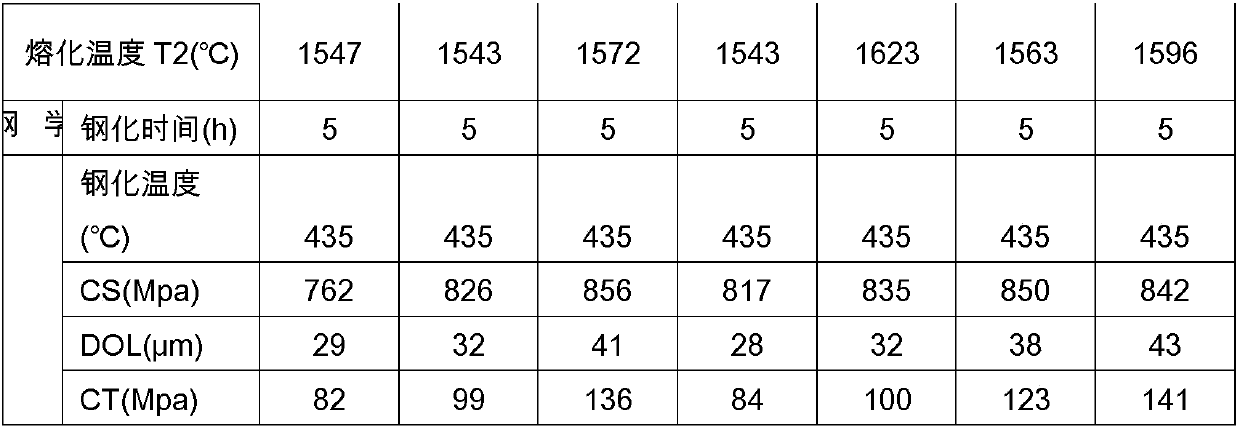

[0085] The data comparison of embodiment 12 and embodiment 5, 8 and 14 shows that 0.15≤(ZrO 2 +ZnO+B 2 o 3 ) / Al 2 o 3 ≤0.37, it can further improve the Young's modulus, thermal stability and chemical strengthening effect of the glass, and the self-explosion of the glass sheet does not occur during the chemical tempering process.

[0086] Compared with the data of Comparative Example 1, it can be known that Example 12 contains B 2 o 3 The aluminosilicate glass has a lower linear expansion coefficient of 84.5×10 -7 / ℃, while the linear expansion coefficient of Comparative Example 1 is 95×10 -7 / °C, the lower coefficient of linear expansion ensures the dimensional stability of the cover glass during high-temperature chemical tempering, and prevents the cover glass from exploding and breaking due to excessive volume expansion-shrinkage.

[0087] Compared with the data of Comparative Examples 2, 3 and 4, it can be seen that Example 12 contains ZnO and ZrO 2 The boroaluminos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com