Rock wool product and method for preparing mineral wool by tempering silica sand and albite

A technology of cotton products and albite, which is applied in the field of mineral wool preparation, can solve the problems of polluting flue gas, wasting water resources, unfavorable environmental protection and comprehensive utilization of resources, and achieves an obvious effect of tempering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to explain the technical solutions of the embodiments of the present invention more clearly, the following will briefly introduce the embodiments. Obviously, the following describes some embodiments of the present invention. For those of ordinary skill in the art, it is not necessary to be creative. Under the premise of labor, other essentially identical solutions can also be obtained according to these embodiments.

[0020] The embodiment of the present invention provides a rock mineral wool product, which is composed of the following components in parts by mass: SiO 2 35-50 copies, Al 2 O 3 10-17 parts, CaO 18-27 parts, MgO 1-5 parts, MnO 4-14 parts, TFe 1-2 parts, K 2 O 1-3 parts, Na 2 O 0-2 copies.

[0021] Further, it is composed of the following components in parts by mass: SiO 2 37-47 copies, Al 2 O 3 12-15 parts, CaO 20-25 parts, MgO 2-5 parts, MnO7-10 parts, TFe 1-2 parts, K 2 O 1-2 parts, Na 2 O 0-1 parts.

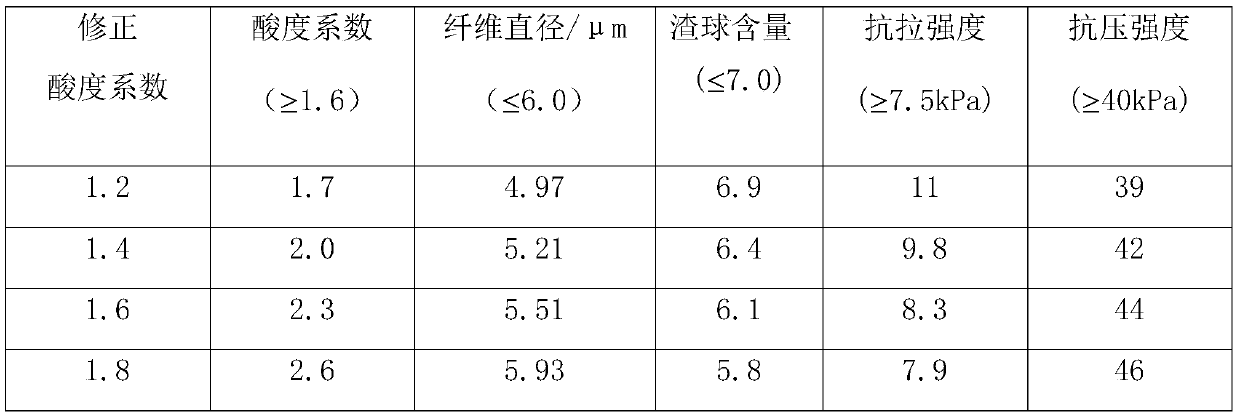

[0022] Further, the modified acidity coefficie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com