A kind of composition for glass and aluminosilicate glass and its preparation method and application

A technology of aluminosilicate glass and composition, applied in semiconductor devices, photovoltaic power generation, electrical components, etc., to achieve high thermal expansion coefficient, good tempering effect, and high elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

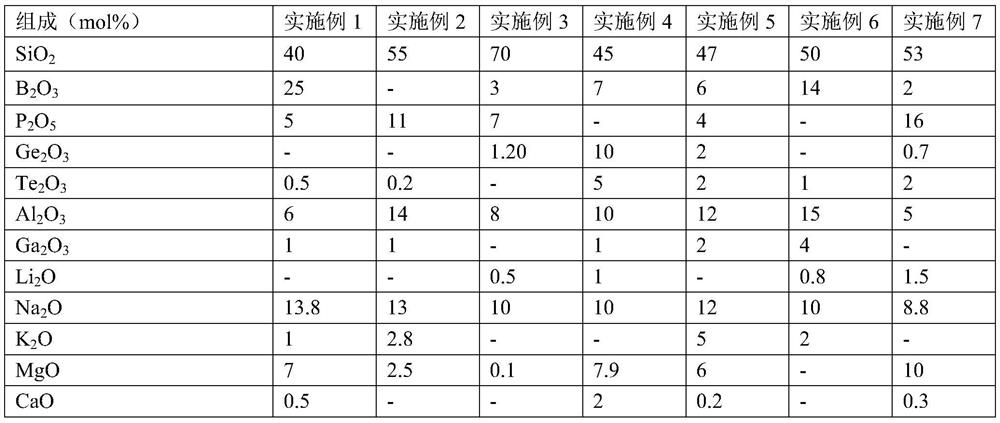

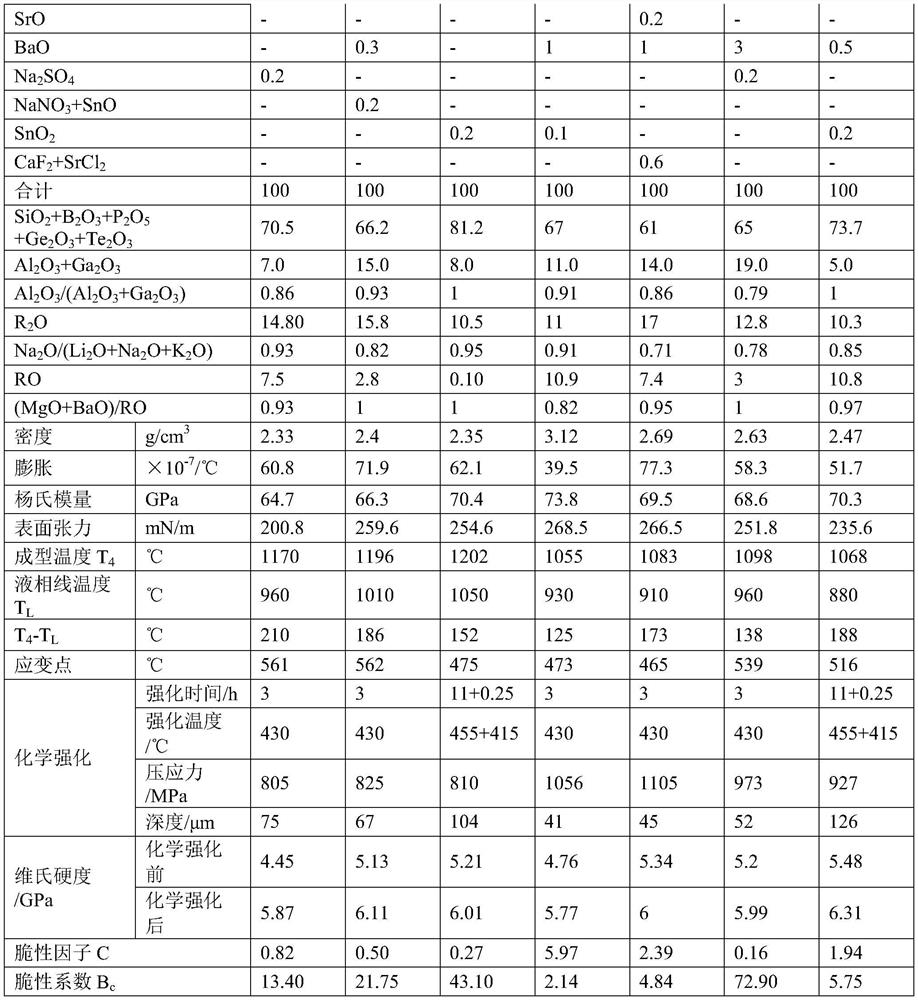

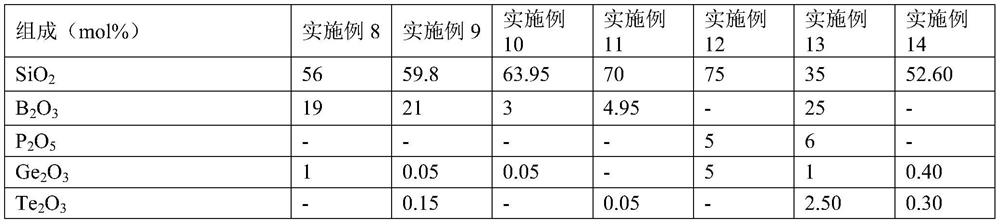

Embodiment 1-20

[0100] Weigh each component according to Table 1-3, mix well, pour the mixture into a platinum crucible, then heat in a 1450°C resistance furnace for 4 hours, and stir with a platinum rod to remove air bubbles. Pour the molten glass into a stainless steel cast iron mold to form a specified block glass product, then anneal the glass product in an annealing furnace for 2 hours, turn off the power and cool down to 25°C with the furnace. The glass product is cut, ground and polished, then cleaned with deionized water and dried to obtain a finished glass product with a thickness of 0.5mm. The various properties of each glass product were measured respectively, and the results are shown in Table 1-3, wherein, RO means alkaline earth metal oxide, R 2 O stands for Li 2 O+Na 2 O+K 2 O.

[0101] Among them, Example 3 and Example 7 are treated by secondary strengthening process (wherein, those skilled in the art should understand that the secondary chemical strengthening treatment me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com