Glass, chemically strengthened glass, production method of glass, production method of chemically strengthened glass, display device cover glass and display device

A technology for strengthening glass and display devices, which is applied in the fields of instruments, electrical digital data processing, digital data processing components, etc., can solve the problems that the display device cannot be well protected, the chemical strengthening effect needs to be improved, etc., and achieves high elastic modulus. And chemical strengthening effect, high flexural strength, high refractive index effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

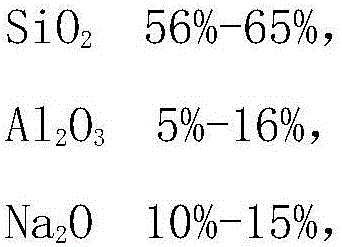

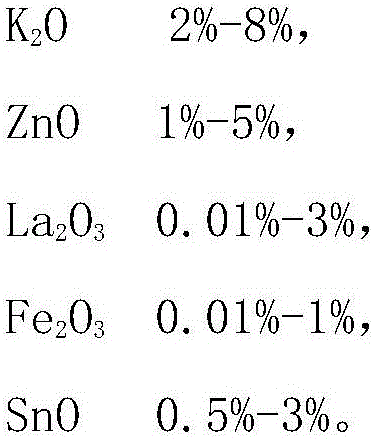

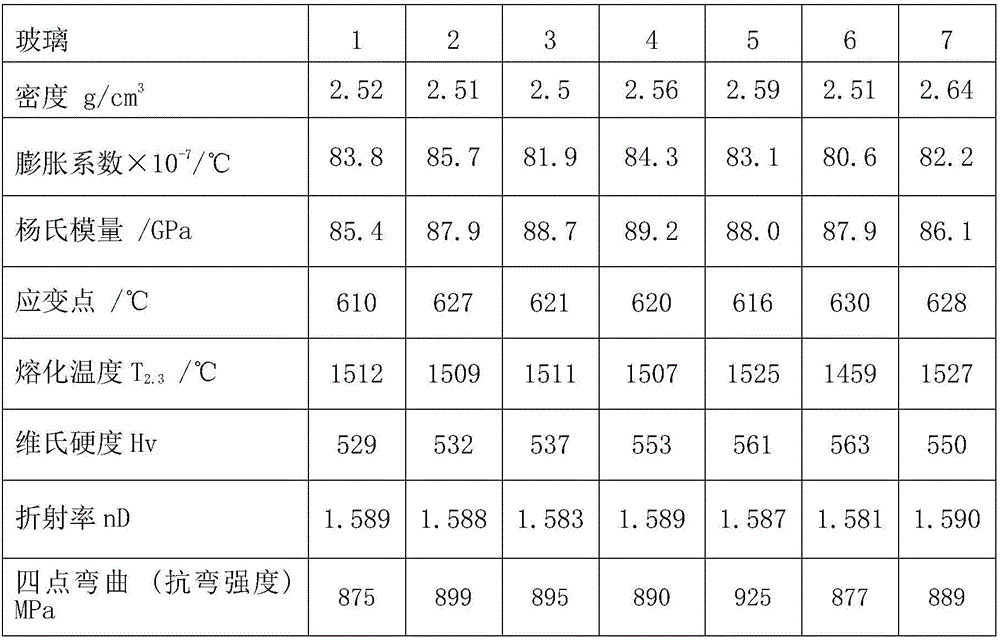

[0037] Convert and weigh the corresponding raw materials according to the mass percentage of the following components: SiO 2 60%, Al 2 o 3 11%, Na 2 O 15%, K 2 O5.5%, ZnO 4%, La 2 o 3 1.5%, Fe 2 o 3 1%, SnO 2%;

[0038] Mix the weighed glass raw materials evenly to form a glass mixture, pour the above glass mixture into a crucible, place the crucible containing the glass mixture in a high-temperature furnace for melting, set the melting temperature to 1450°C, and melt the glass mixture Finally, the molten glass was obtained, and the above molten glass was incubated and homogenized at 1450°C for 4 hours. In order to make the glass components uniform, a platinum rod was used to stir the molten glass during the heat preservation period. The bubbles in the molten glass escaped and each part of the molten glass was stirred by stirring. The components are evenly distributed. The above-mentioned molten glass is poured into a preheated stainless steel cast iron mold and so...

Embodiment 2

[0040] Convert and weigh the corresponding raw materials according to the mass percentage of the following components: SiO 2 57%, Al 2 o 3 16%, Na 2 O 11%, K 2 O7.7%, ZnO 3%, La 2 o 3 2%, Fe 2 o 3 0.8%, SnO 2.5%;

[0041] In Example 2, the raw materials were prepared according to the above formula, and the test sample of Example 2, namely No. 2 glass, was prepared by the method of Example 1; wherein, the melting temperature was 1500° C., and the homogenization time was 6 hours.

Embodiment 3

[0043] Convert and weigh the corresponding raw materials according to the mass percentage of the following components: SiO 2 58%, Al 2 o 3 14%, Na 2 O 14%, K 2 O7%, ZnO 3.5%, La 2 o 3 1%, Fe 2 o 3 0.5%, SnO 2%;

[0044]In Example 3, the raw materials were prepared according to the above formula, and the test sample of Example 3, namely No. 3 glass, was prepared by the method of Example 1; wherein, the melting temperature was 1550° C., and the heat preservation and homogenization time was 8 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| strain point | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com