Touch screen cover plate glass high in acid and alkali resistance

A technology of acid and alkali resistance and cover glass, which is applied in the field of glass production and can solve problems such as poor acid and alkali resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

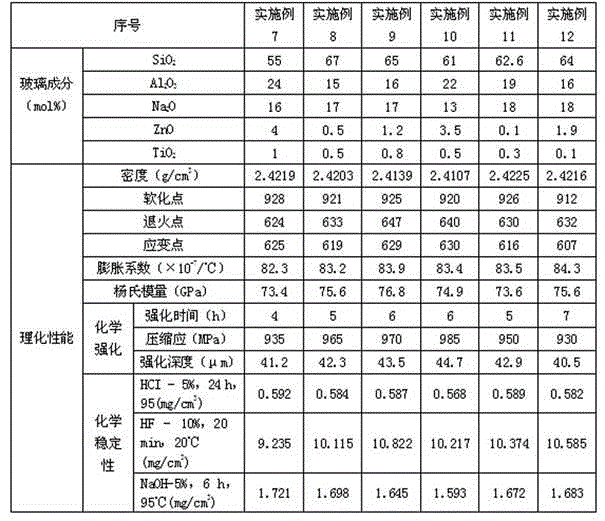

Examples

Embodiment Construction

[0011] A touch screen cover glass with strong acid and alkali resistance, the components in the glass components are calculated by weight percentage as follows:

[0012] SiO 2 55-67%,

[0013] Al 2 o 3 16-24%,

[0014] Na 2 O 13-18%,

[0015] ZnO 0.1-4%,

[0016] TiO 2 0.1-1%.

[0017] The SiO 2 The content is preferably 60-63%.

[0018] The Al 2 o 3 The content is preferably 18-22%.

[0019] The Na 2 The O content is preferably 14-17%.

[0020] The ZnO content is preferably 0.5-3.5%.

[0021] The TiO 2 The content is preferably 0.5-0.8%.

[0022] SiO 2 It is a component that constitutes the glass skeleton, SiO 2 Higher content, chemical resistance and mechanical strength will increase, high temperature viscosity of glass will increase, SiO 2 If it is too much, it will be difficult to obtain glass with long material properties. SiO 2 Low content is not easy to form glass, the strain point decreases, the expansion coefficient increases, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com