Ultra-thin glass chemical tempering equipment and tempering method

A technology of chemical tempering and ultra-thin glass, which is applied in glass tempering, glass manufacturing equipment, glass production, etc., can solve the problem of reducing the performance and yield of ultra-thin glass products, polluting chemical tempering molten salt, watermarks, water marks and rust To avoid problems such as streaks, achieve the effects of preventing coloring ion pollution, uniform chemical tempering, and improving performance and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

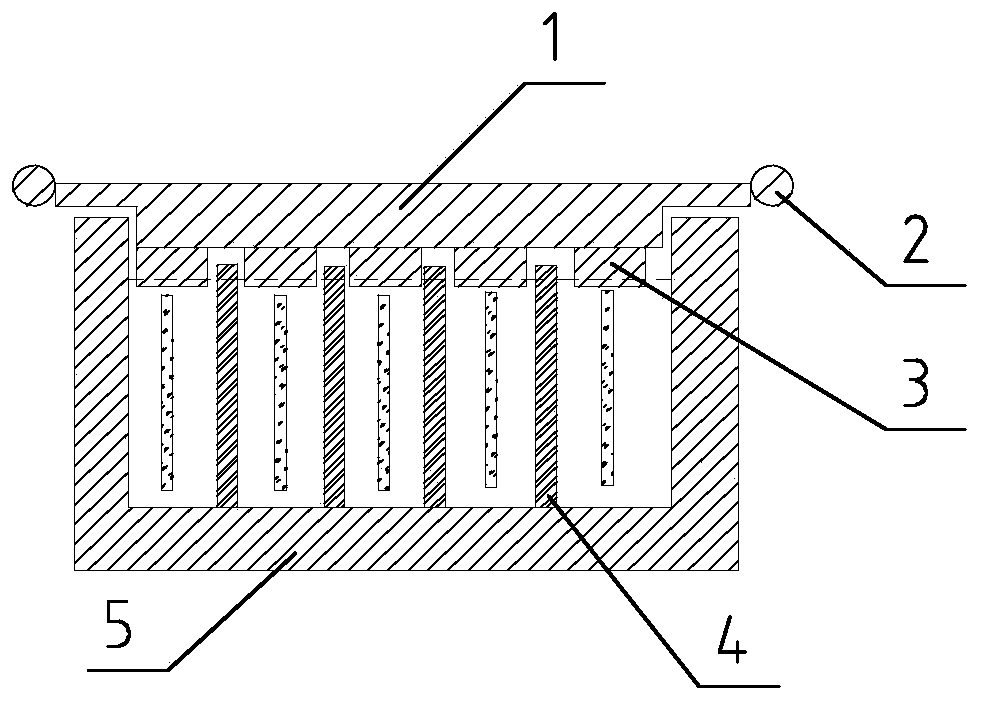

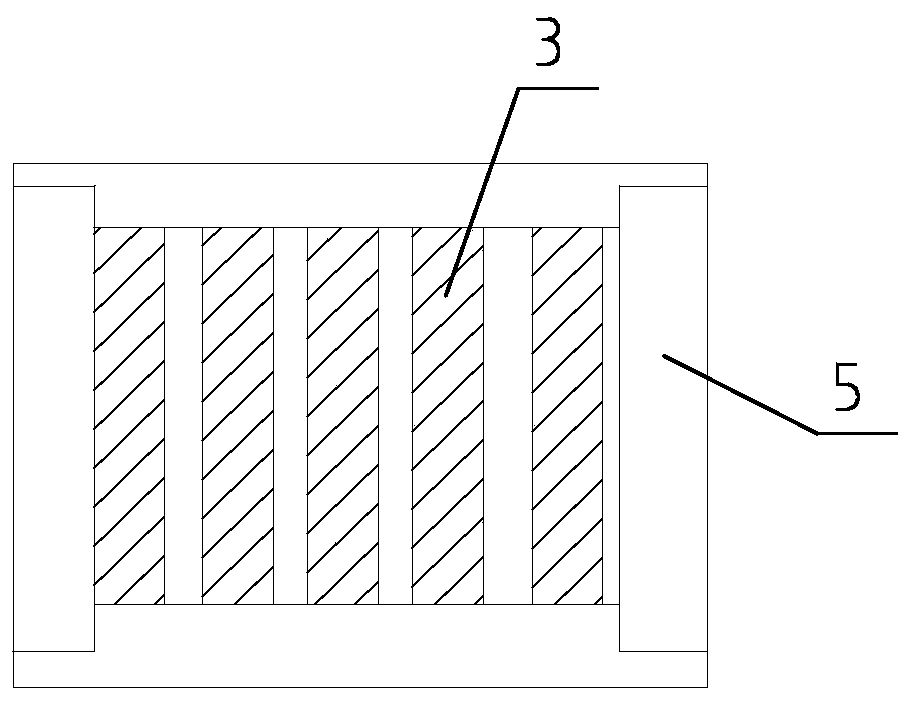

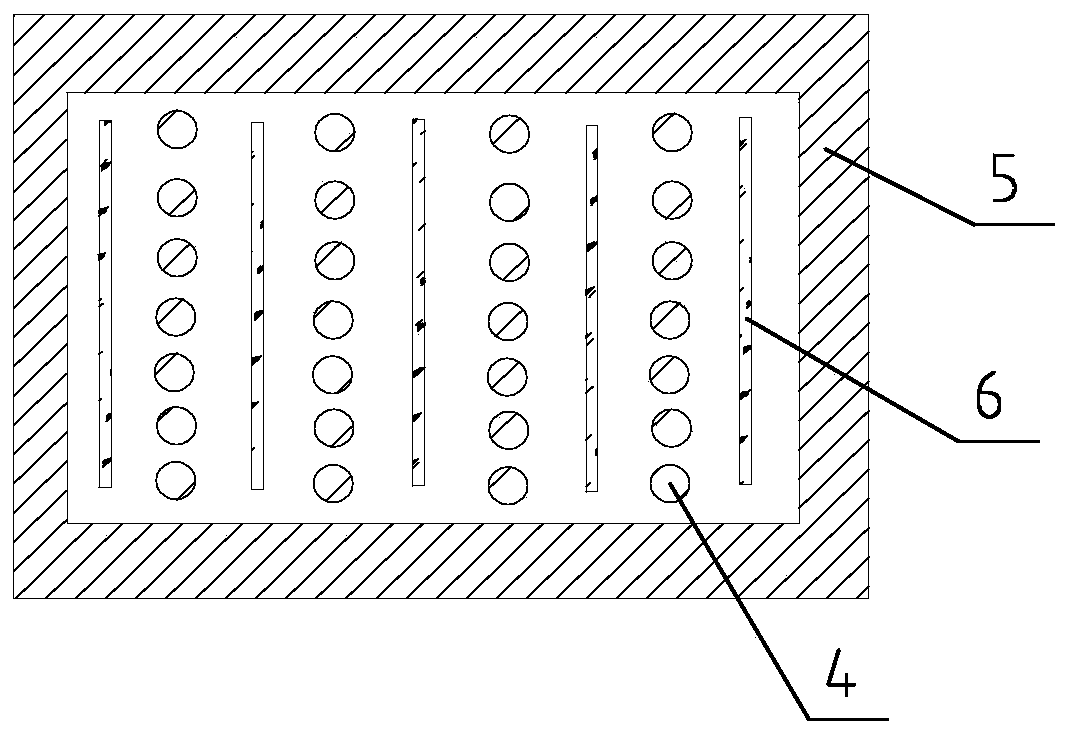

[0038] Such as Figure 1-Figure 3 As shown, an ultra-thin glass chemical tempering equipment includes a tempering tank cover 1, a gripper 2, a glass-ceramic piece 3, a tank frame 4, and a chemically toughened outer tank 5, and grippers are provided at both ends of the tempering tank cover 1 2. The lower end of the toughened tank cover 1 is provided with a boss, and a plurality of glass-ceramics 3 are arranged on the raised platform, and the toughened tank cover 1 is placed at the upper end of the chemically toughened outer tank 5 .

[0039] A plurality of tank frames 4 are arranged at the inner bottom of the chemically toughened outer tank 5 .

[0040] The side of the boss is attached to the inner wall of the chemically toughened outer tank 5 .

[0041] The height of the top of the frame 4 is higher than that of the bottom of the glass-ceramic piece 3 .

[0042] The glass-ceramic part 3 is made of lithium-aluminum-silicon glass-ceramics, which has high temperature resistance...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com