Tempering method of 2-mm glass

A glass and transmission direction technology, applied in glass tempering, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of easy deformation, thin thickness, affecting the appearance and performance of glass, and achieve good tempering effect and avoid deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

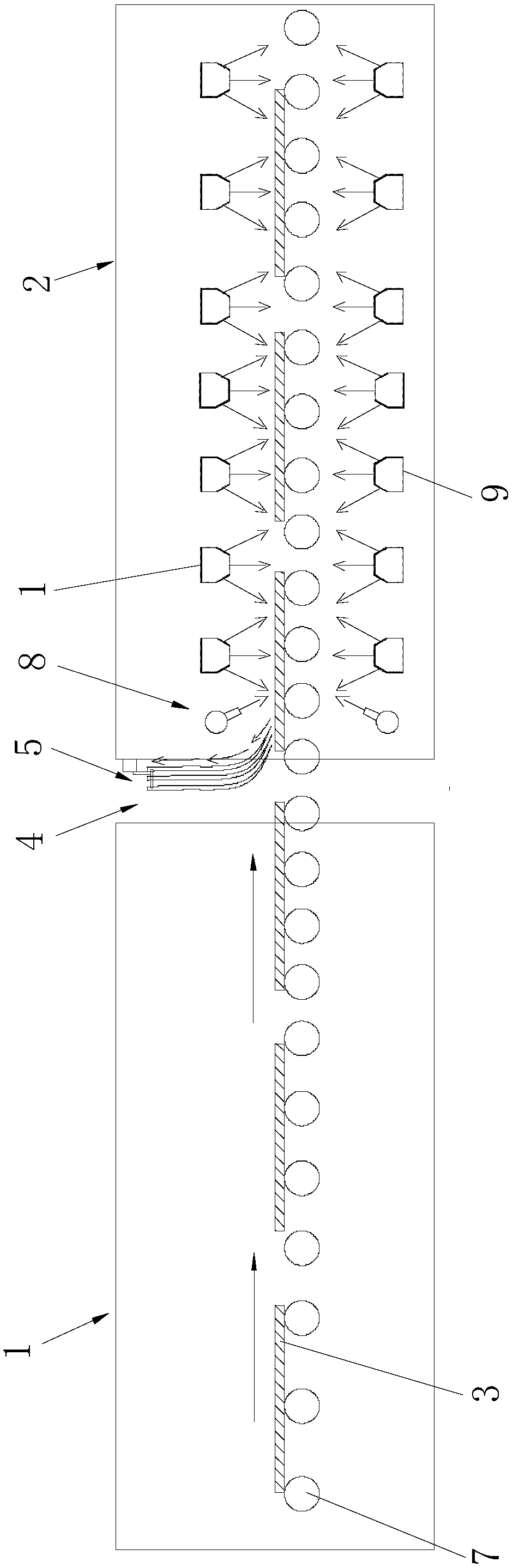

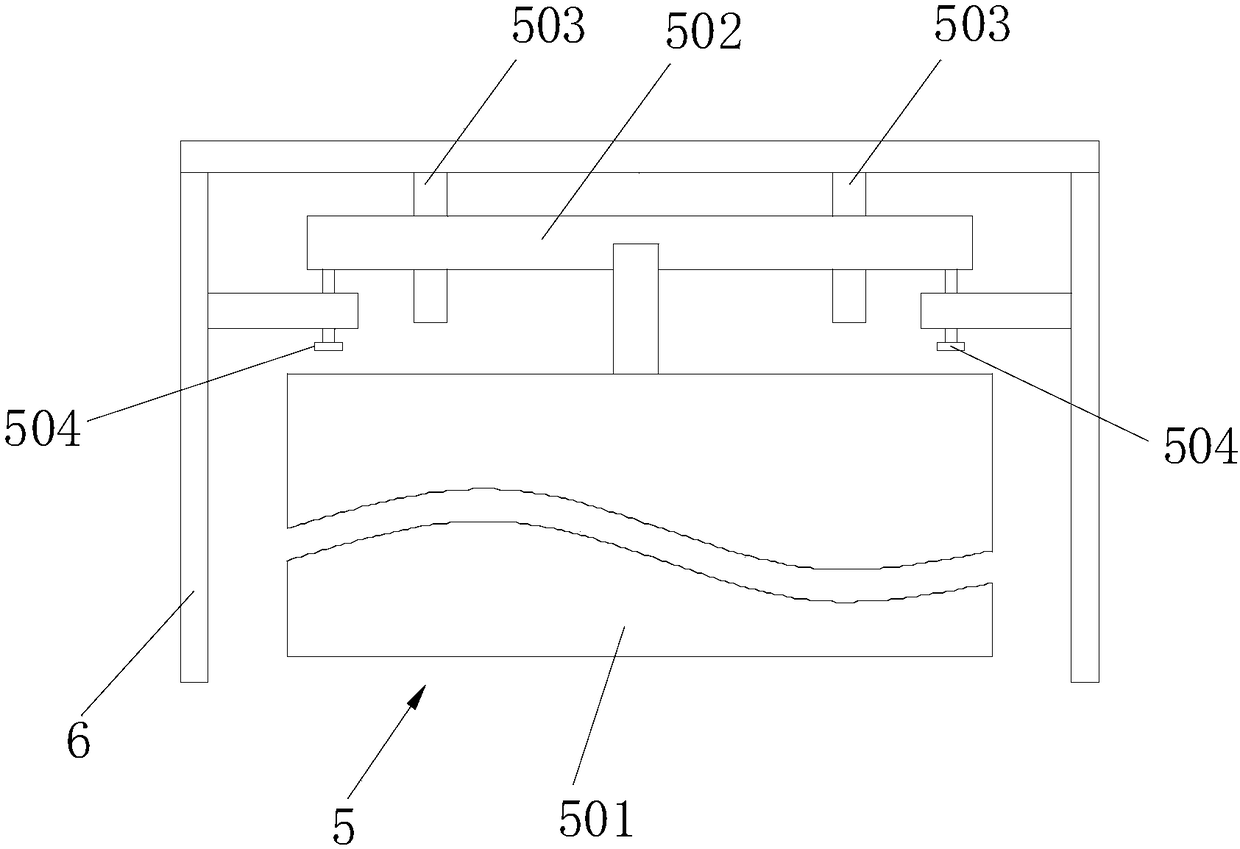

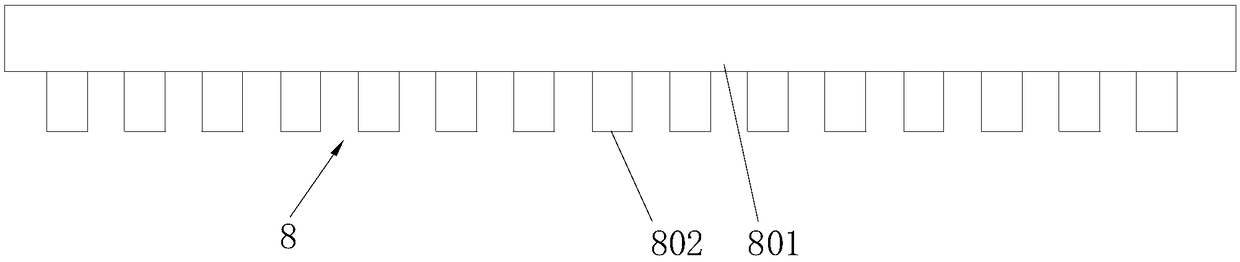

[0038] Such as Figure 1 to Figure 4 Shown, a kind of toughening method of 2mm glass comprises the steps:

[0039] step 1:

[0040] The glass 3 is placed on the transmission roller 7 in the heating zone 1 to pass through multiple heating zones of the heating zone 1 at a constant speed to heat up, and the upper surface and the lower surface of the glass 3 are heated simultaneously by the heating wire. The temperature rise curve of the glass 3 is as follows :

[0041] S1: 0 ~ 30s from room temperature to 300 ℃;

[0042] S2: Continue to heat up to 350 or 360°C for 30-55s;

[0043] S3: 55~75s continue to heat up to 400 or 420°C;

[0044] S4: Continue to heat up to 550°C for 75-90s;

[0045] S5: Continue to heat up to 630°C for 90-100s;

[0046] S6: Maintain the temperature at 630°C for 100-105s;

[0047] The heating zone 1 has a plurality of heating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com