Ultra-thin electronic touch screen glass and processing technology thereof

A processing technology and touch screen technology, applied in the field of ultra-thin electronic touch screen glass and its processing technology, can solve the problems of reducing mechanical strength, reducing, and reducing the tempering effect, etc., and achieve the effect of reducing the impact, increasing the thermal decomposition temperature, and improving the effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

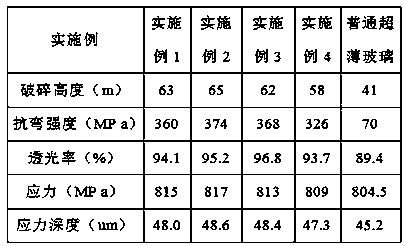

Embodiment 1

[0058] First prepare the raw materials, weigh silicon dioxide, aluminum oxide, the third additive and clarifying agent in proportion, and set aside; take zinc oxide, magnesium oxide, boron trioxide, zirconium dioxide, sodium oxide and lithium oxide in proportion , standby; take graphene oxide, sodium hydroxide, benzoyl peroxide, divinylbenzene, styrene in proportion, standby; take potassium nitrate, sodium nitrate, sodium nitrite, auxiliary agent and accelerator in proportion ,spare;

[0059] To prepare the molten salt treatment agent, first take graphene oxide, dissolve it in deionized water, disperse it ultrasonically for 1.5 hours, then dropwise add sodium hydroxide solution, adjust the pH to 9, stir at 25°C for 3 hours, filter, and wash twice with deionized water , dried at 70°C for 20h to obtain material A; then put material A into a beaker, add styrene, ultrasonically disperse for 1h, then add benzoyl peroxide and divinylbenzene, mix and stir well, and polymerize at 65°C...

Embodiment 2

[0065] First prepare the raw materials, weigh silicon dioxide, aluminum oxide, the third additive and clarifying agent in proportion, and set aside; take zinc oxide, magnesium oxide, boron trioxide, zirconium dioxide, sodium oxide and lithium oxide in proportion , standby; take graphene oxide, sodium hydroxide, benzoyl peroxide, divinylbenzene, styrene in proportion, standby; take potassium nitrate, sodium nitrate, sodium nitrite, auxiliary agent and accelerator in proportion ,spare;

[0066]To prepare the molten salt treatment agent, first take graphene oxide, dissolve in deionized water, ultrasonically disperse for 2 hours, then dropwise add sodium hydroxide solution, adjust the pH to 9, stir at 30 °C for 4 hours, filter, and wash 3 times with deionized water, Dry at 80°C for 22h to obtain material A; then put material A into a beaker, add styrene, ultrasonically disperse for 1.3h, then add benzoyl peroxide and divinylbenzene, mix and stir well, and polymerize at 70°C for 7h...

Embodiment 3

[0072] First prepare the raw materials, weigh silicon dioxide, aluminum oxide, the third additive and clarifying agent in proportion, and set aside; take zinc oxide, magnesium oxide, boron trioxide, zirconium dioxide, sodium oxide and lithium oxide in proportion , standby; take graphene oxide, sodium hydroxide, benzoyl peroxide, divinylbenzene, styrene in proportion, standby; take potassium nitrate, sodium nitrate, sodium nitrite, auxiliary agent and accelerator in proportion ,spare;

[0073] To prepare the molten salt treatment agent, first take graphene oxide, dissolve it in deionized water, disperse it ultrasonically for 2.5 hours, then dropwise add sodium hydroxide solution, adjust the pH to 10, stir at 35°C for 5 hours, filter, and wash with deionized water 3 times , dried at 90°C for 24 hours to obtain material A; then put material A into a beaker, add styrene, ultrasonically disperse for 1-1.5 hours, then add benzoyl peroxide and divinylbenzene, mix and stir evenly, 75 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com