Ion exchange molten salt composition, and tempered cover plate glass and tempering method thereof

A technology of ion exchange and cover glass, which is applied in glass tempering, glass manufacturing equipment, manufacturing tools, etc. It can solve the problems of poor comprehensive performance of tempered cover glass, achieve improved tempering effect, speed up tempering, and prevent volatilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0044] According to a specific embodiment of the present invention, the tempering method of the cover glass includes:

[0045] (1) Stir the weighed ion-exchange molten salt composition evenly into a tempering furnace, heat to 300-450°C, and after fully melting, introduce 0.1- 1 part by weight of alumina powder, then fully stirred, and left to stand for 6-24h.

[0046] (2) Polish all the surfaces and corners of the cover glass to be tempered to prevent the glass from bursting due to temperature difference. Put the cleaned cover glass to be tempered into an annealing furnace and slowly heat it to 200-300°C.

[0047] (3) Quickly transfer the cover glass to be tempered to the tempering furnace, fix it on the bracket in the tempering furnace, and turn on the ultrasonic wave. The cover glass to be tempered is subjected to ion exchange at 300-450° C. for 2-5 hours.

[0048] (4) Take the cover glass out of the ion-exchange molten salt, put it in an annealing furnace at 200-300°C, cl...

Embodiment 1

[0061] (1) Configuration of ion exchange molten salt composition

[0062] According to the composition of Table 2, 2000 g of the ion exchange molten salt composition was prepared, and the mixture was fully stirred to make it evenly mixed.

[0063] (2) Tempered

[0064] Weigh 2000g of the ion-exchange molten salt composition, stir it evenly, put it into a tempering furnace, heat it to 400°C and fully melt it, introduce 20g of alumina powder into the molten salt solution, stir it fully, and let it stand for 10 hours.

[0065] Polish and clean the surface and corners of the cover glass to be tempered. Put the cleaned cover glass to be tempered into an annealing furnace, preheat the cover glass at a heating rate of 10°C / min, preheat to 300°C and keep at a constant temperature for 30min.

[0066] Then transfer the cover glass to the tempering furnace, fix it on the bracket in the tempering furnace, and carry out ion exchange at 350°C for 3 hours. This process is carried out under...

Embodiment 2-20

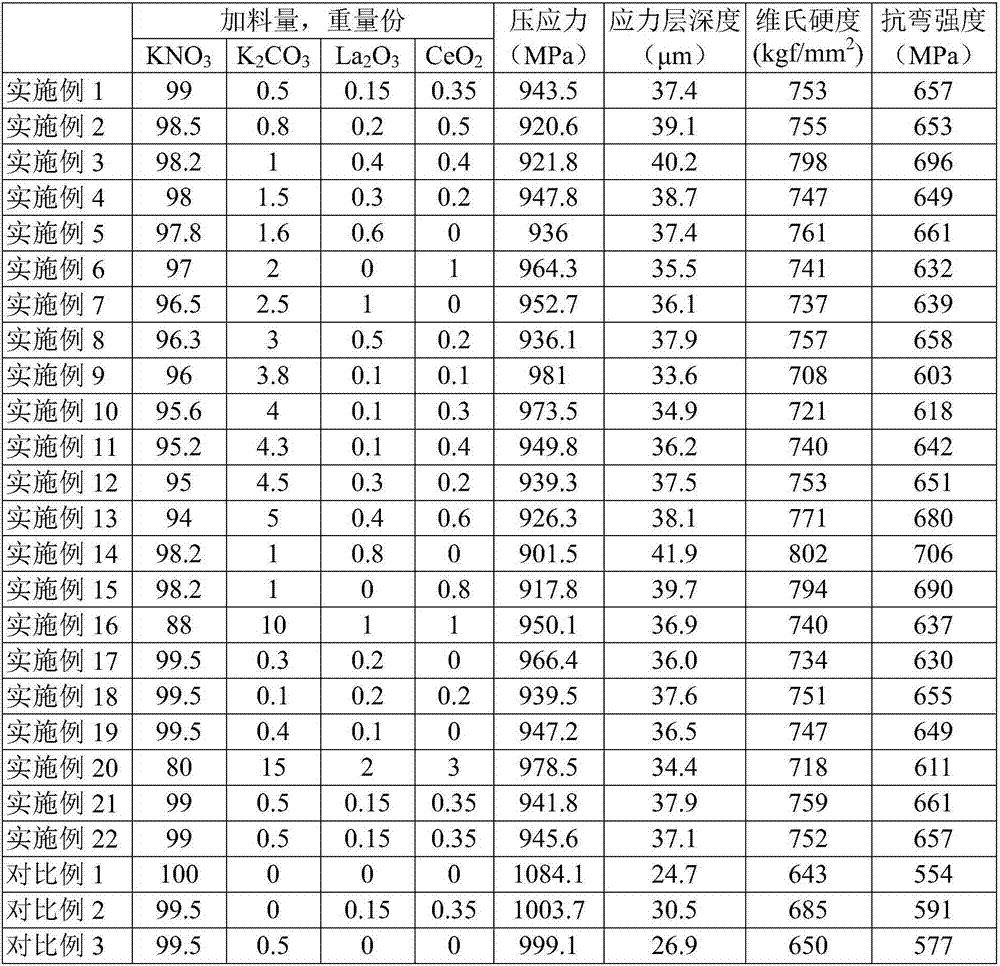

[0070] According to the method of Example 1, the difference is that according to the composition and preparation conditions in Table 2, ion-exchange molten salt compositions were respectively prepared to obtain a tempered cover glass.

[0071] The mechanical properties of the obtained tempered cover glass were measured, and the results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com