Blast furnace hot slag microcrystalline glass and preparation method thereof

A technology for hot slag and glass-ceramic, which is applied in the field of blast furnace hot slag and glass-ceramic and its preparation, and can solve the problems of poor durability, general quenching and tempering effect, and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

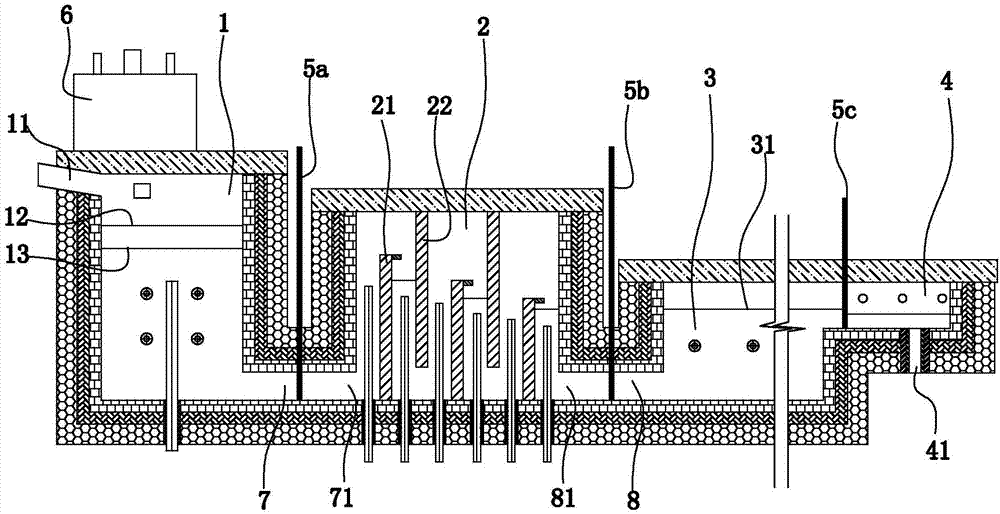

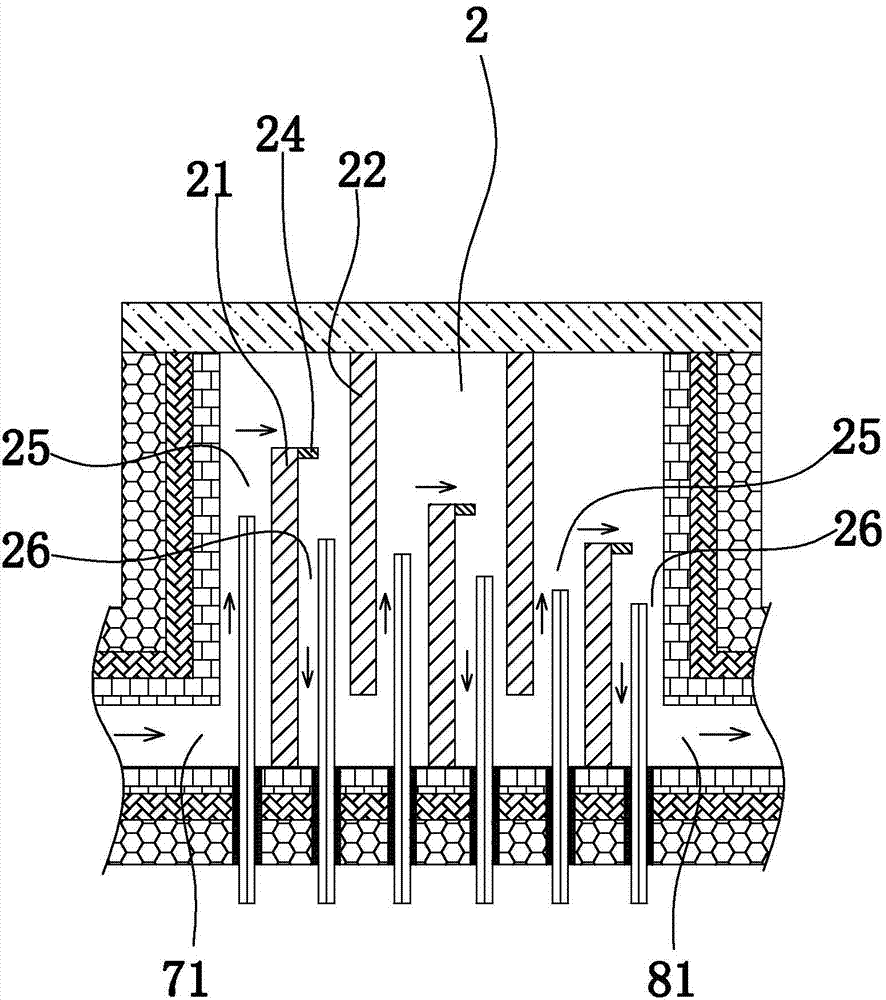

Method used

Image

Examples

Embodiment 1

[0049] Example 1: A blast furnace hot slag glass-ceramics, the raw material of the blast furnace hot slag glass-ceramics is composed of the following components in mass percentage: liquid blast furnace slag is 53%, fly ash is 24%, Lithium carbonate is 5%, sodium carbonate is 4.5%, sodium fluorosilicate is 4%, zirconium oxide is 2%, titanium dioxide is 3%, arsenic trioxide is 0.2%, antimony oxide is 0.2%, and phosphorus pentoxide is 2%. Cesium oxide is 0.1% and colorant is 2%. (HYPERLI of Zirconia

[0050] The fly ash contains the following components by mass percentage: SiO 2 46-48%, Al 2 O 3 27-28%, TiO 2 1-1.5%, FeO is 5-6%, CaO is 4-4.5%, MgO is 0.5-1%, K 2 O is 1-1.5%, Na 2 O is 0.3-0.6%, MnO is 0.01-0.1%, P 2 O 3 0.1-0.5%, SO 3 It is 1-1.5%. The loss on ignition of fly ash is less than 10%.

[0051] The colorant is ceria, cobalt tetroxide or copper oxide. If the coloring agent is cerium oxide, the color of the glass-ceramic obtained is beige. When the bright blue colorant ...

Embodiment 2

[0070] Embodiment 2: Refer to Embodiment 1 for the specific structure of the slag furnace in this embodiment.

[0071] A blast furnace hot molten slag glass-ceramic, the raw material of the blast furnace hot molten slag glass-ceramic is composed of the following components by mass percentage: liquid blast furnace slag is 55%, fly ash is 23%, and lithium carbonate is 4 %, sodium carbonate is 6%, sodium fluorosilicate is 3.5%, zirconium oxide is 3%, titanium dioxide is 3%, arsenic trioxide is 0.16%, antimony oxide is 0.2%, phosphorus pentoxide is 2%, and cesium oxide is 0.1 %, the colorant is 0.04%.

[0072] The fly ash contains the following components by mass percentage: SiO 2 46-48%, Al 2 O 3 27-28%, TiO 2 1-1.5%, FeO is 5-6%, CaO is 4-4.5%, MgO is 0.5-1%, K 2 O is 1-1.5%, Na 2 O is 0.3-0.6%, MnO is 0.01-0.1%, P 2 O 3 0.1-0.5%, SO 3 It is 1-1.5%. The loss on ignition of fly ash is less than 10%.

[0073] The colorant is composed of cadmium sulfide and selenium with a mass ratio of...

Embodiment 3

[0088] Embodiment 3: Refer to Embodiment 1 for the specific structure of the slag furnace in this embodiment.

[0089] A blast furnace hot slag glass-ceramic. The raw material of the blast furnace hot slag glass-ceramic is composed of the following components in mass percentage: liquid blast furnace slag is 59%, fly ash is 17%, and lithium carbonate is 4 %, sodium carbonate is 5.5%, sodium fluorosilicate is 4%, zirconium oxide is 5%, titanium dioxide is 3%, arsenic trioxide is 0.3%, antimony oxide is 0.2%, phosphorus pentoxide is 1%, and cesium oxide is 0.15 %, the colorant is 0.85%.

[0090] The fly ash contains the following components by mass percentage: SiO 2 46-48%, Al 2 O 3 27-28%, TiO 2 1-1.5%, FeO is 5-6%, CaO is 4-4.5%, MgO is 0.5-1%, K 2 O is 1-1.5%, Na 2 O is 0.3-0.6%, MnO is 0.01-0.1%, P 2 O 3 0.1-0.5%, SO 3 It is 1-1.5%. The loss on ignition of fly ash is less than 10%.

[0091] The colorant is composed of cobalt tetroxide and nickel oxide with a mass ratio of 1:3. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| wear coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com