Adjustable air compressing device for quenching cold air grate of glass toughening furnace

A glass tempering and adjustable technology, used in glass tempering, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of glass deformation, fast cooling, uneven glass cooling, etc., to prevent glass deformation, improve the tempering effect, Anti-deformation effect is remarkable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

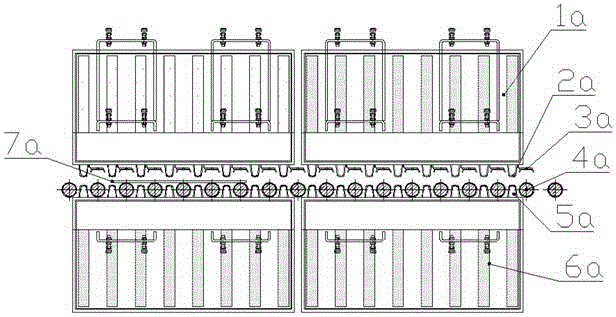

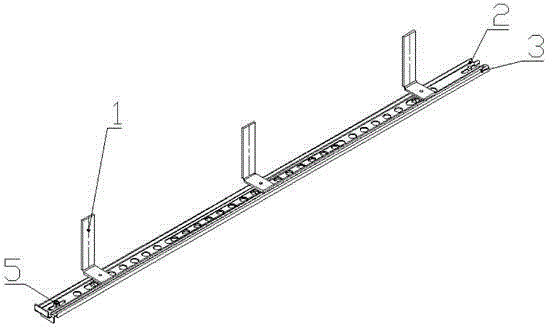

[0031] see Figure 3 ~ Figure 5 , the adjustable air pressure device for the quenching air grid of the glass tempering furnace of the present invention includes a mounting plate 1 and a pressure air mechanism, the air pressure mechanism is connected to the mounting plate 1, and the mounting plate 1 is connected to the air grid; wherein :

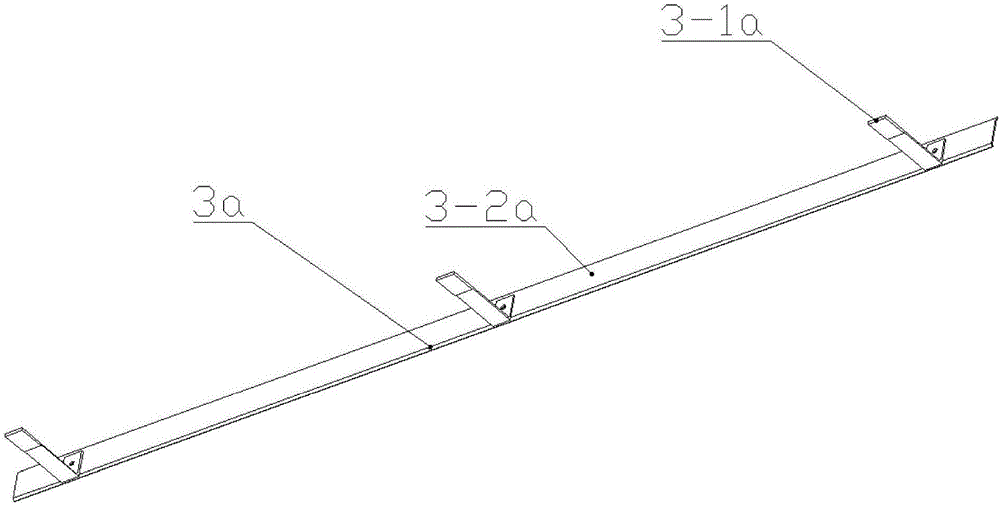

[0032] The air pressure mechanism includes an air pressure plate 3 and a first adjustment plate 2 stacked together. The plates 2 are connected together by an adjustable connection structure 5 that can move relatively in the length direction; the air pressure plate 3 is arranged with a plurality of first ventilation holes 3-3 along the length direction; the middle part of the first adjustment plate 2 There are first long ventilation holes 2-4, and first adjustment holes 2-3 are arranged at both ends.

[0033] see Figure 3 ~ Figure 6 , the adjustable connection structure includes a first connection slot 2-1 extending along the length direc...

Embodiment 2

[0038] see Figure 7 The difference between this embodiment and embodiment 1 is that the air pressure mechanism also includes a second adjustment plate 4; the second adjustment plate 4 is installed on the lower side of the first adjustment plate 2, and the first adjustment plate 2 Located on the upper side of the air pressure plate 3; the middle part of the second adjustment plate 4 is provided with a second adjustment hole 4-3 arranged along the length direction, and the arrangement spacing of the second adjustment holes 4-3 is the same as that on the air pressure plate 3. The first ventilation holes 3-3 are consistent with each other, and the two ends of the second adjusting plate 4 are provided with second adjusting long holes 4-4 extending along the length direction. The purpose of adopting the above structure is to adjust the ventilation volume in the middle of the air pressure mechanism, specifically, similar to the adjustment principle between the first adjustment plate...

Embodiment 3

[0042] see Figure 8 The difference between this embodiment and Embodiment 1 is that the air pressure mechanism also includes a third adjustment plate 6; the third adjustment plate 6 is installed on the lower side of the first adjustment plate 2, and the first adjustment plate 2 Located on the upper side of the air pressure plate 3; the third adjustment plate is provided with third adjustment holes 6-1 arranged along the length direction, and the arrangement spacing of the third adjustment holes 6-1 is the same as that of the first air pressure plate 3 A ventilation hole 3-3 is consistent. The purpose of adopting the above-mentioned structure is to uniformly adjust the ventilation volume on the entire length range of the air pressure mechanism. Specifically, by adjusting the positional relationship between the third adjustment plate 6 and the air pressure plate 3, the air pressure on the air pressure plate 3 can be changed. The degree of coincidence between all the first vent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com