Patents

Literature

137results about How to "Simple smelting process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ni-Cr-Fe alloy and its production process

InactiveCN1847440ASave resourcesOptimize the smelting processBlast furnace detailsRecycling and recovery technologiesGranularityManganese

The present invention is Ni-Cr-Fe alloy and its production process. The Ni-Cr-Fe alloy contains Ni 1.5-6.0 wt%, Cr 3.0-21.0 wt%, Si 0.6-2.0 wt% and Mn 0.3-0.8 wt%, except Fe, and can meet the requirement for use as material smelting stainless steel. The production process includes the following steps: producing Ni-Cr agglomerate with industrial Ni-Cr waste, Ni-Cr ore powder of granularity smaller than 10 mm, flux, coke and water and through pelletizing, sintering and sieving; and smelting with the Ni-Cr agglomerate, Ni-Cr ore of granularity greater than 10 mm, flux and coke in a blast furnace. The present invention has sang in resource and environment friendship.

Owner:DONGDA CASTING WUJIANG

Method for producing steel plate of petroleum storage tank by using direct quenching process

The invention discloses a method for producing a steel plate of a petroleum storage tank by using a direct quenching process. The invention provides a chemical composition of special petroleum storage tank steel and adopts a direct quenching process. The method comprises the following steps of: heating a steel blank to 1100 to 1280 DEG C, rolling into a steel plate in re-crystallization and non-recrystallization stages; carrying out on-line quenching operation under the conditions that the temperature of the steel plate is between 780 DEG C and 900 DEG C, the average cooling rate ranges from 25 DEG C / s to 60 DEG C / s, the cooling terminal temperature is less than or equal to 350 DEG C, and performing off-line tempering on the steel plate subjected to quenching. Compared with the conventional high-energy-consumption hardening process based on the combination of off-line tempering and tempering, the method provided by the invention has the advantages of short production flow and low energy consumption and the prepared steel plate has good general mechanical properties and high heat input welding property. The yield strength of the steel plate is more than 490 MPa and the tensile strength of the steel plate is more than 610 MPa. In case of high heat input welding (less than or equal to 400 KJ / cm), a welding heat affected zone maintains excellent low-temperature toughness, and the mean value of work done by impact at -20 DEG C is more than 50 J.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD +1

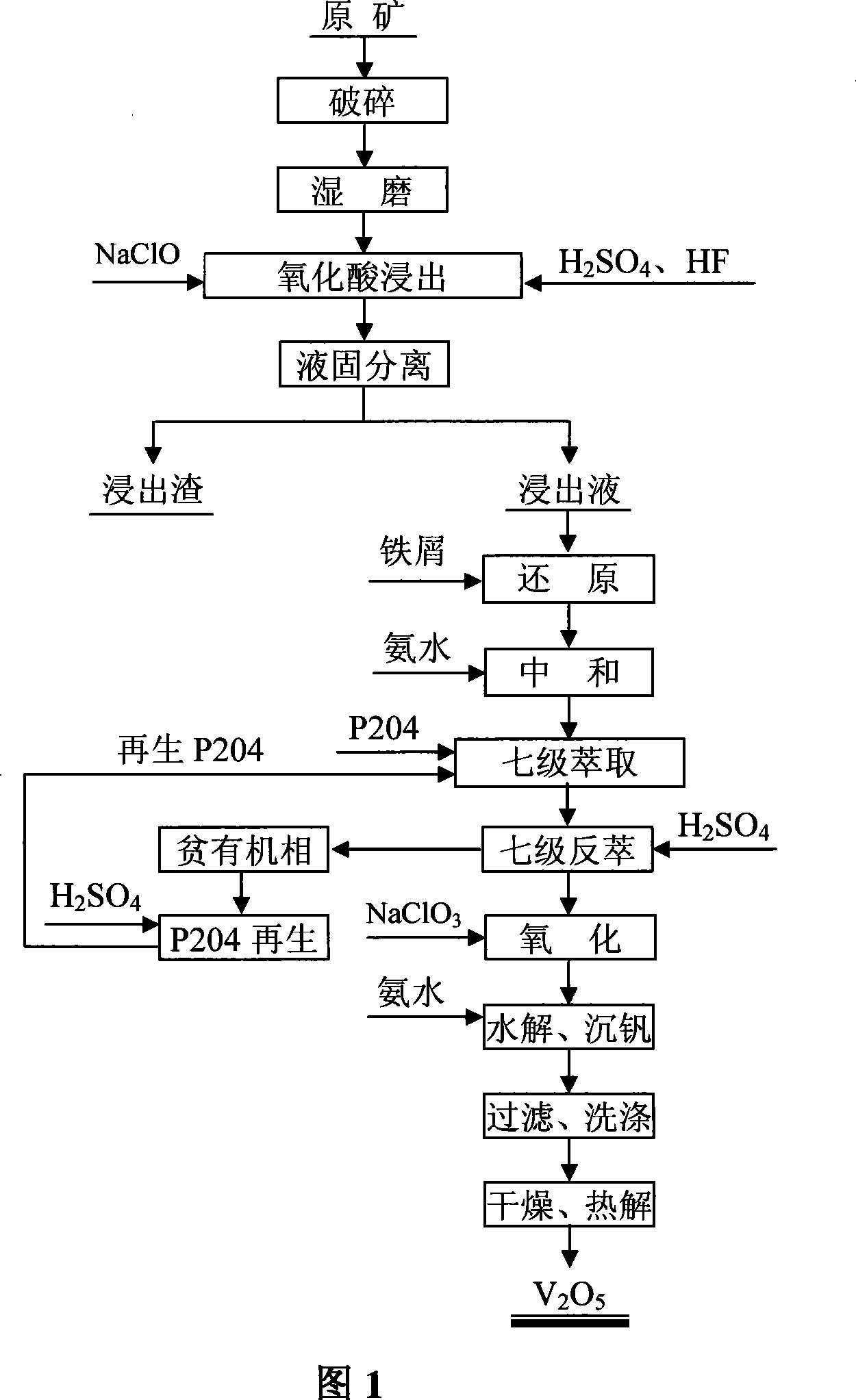

Method for coproducing vanadium pentoxide from vanadium-containing stone coal ore and fluorite

InactiveCN101239740ASolve the problem of leaching and extracting vanadiumSimplification of smelting processVanadium oxidesSulfateChemical combination

The present invention provides a preparing method of vanadic oxide by coal mine containing vanadium and fluorite. The invention belongs to vanadic hydrometallurgy technology, especially a melting technique of directly lixiviating and separating vanadium from coal mine containing vanadium. Acylvanadium sulfate is prepared by mixing coal mine containing vanadium, fluorite mine and sulphuric acid, then pumped in the reactive tank, further chemical combination and dissolving, acylvanadium sulfate enters in solution, qualified vanadic oxide is prepared. The invention adopts whole wet to process coal mine containing vanadium,recovering and utilizing vanadium, the method has a simple process, strength process, high metal recovery rate, easy to separate object metal, small consumption agent, integrated valuable metal and lower pollution.

Owner:KUNMING UNIV OF SCI & TECH

Method for smelting base metal of low phosphorous stainless steel by using low-grade limonite of containing nickel-chromium

ActiveCN101092656ARich sourcesLow priceBlast furnace detailsManufacturing convertersAdhesiveHigh pressure

This invention relates to a method for smelting low-phosphorus stainless steel base material from nickel and chrome-containing low-grade limonite. The method comprises: (1) pre-treating nickel and chrome-containing low-grade limonite via sieving, pulverizing and drying to obtain ore powder and ore blocks with different particle sizes, and mixing with fuel and flux to obtain sinter ore; (2) mixing various dedusted ashes, sintered return fines, and ore powder with an adhesive and a reductant, and passing into cold-pressed balls or carbon-containing balls under high pressure; (3) drying the carbon-containing balls, adding into a converter, and reducing to obtain pre-reduced balls; (4) mixing the sinter ore with partial ore blocks, the cold-pressed balls, the carbon-containing balls, the pre-reduced balls, the fuel, the flux and auxiliary materials, and smelting in a blast furnace to obtain molten nickel and chrome-containing alloy or molten iron; (5) mixing with the cold-pressed balls, the carbon-containing balls and the pre-reduced balls, and smelting in an electric furnace or a converter to reduce, decarbonizes, dephosphorize and obtain clean molten stainless steel base material that can be directly used in steel making; (6) casting with a continuous caster to obtain solid stainless steel base material that can be directly used in steel making. The method has such advantages as low cost, little pollution, abundant raw materials, high recovery rate of alloy elements, and few harmful elements.

Owner:前海索新发展科技(深圳)有限公司

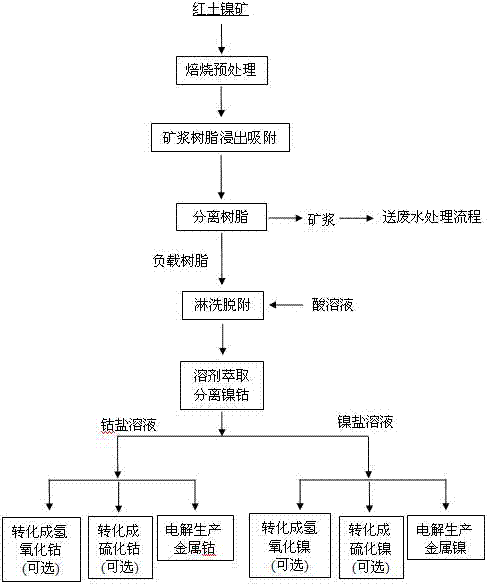

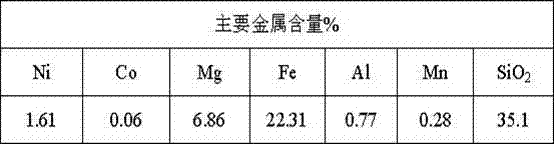

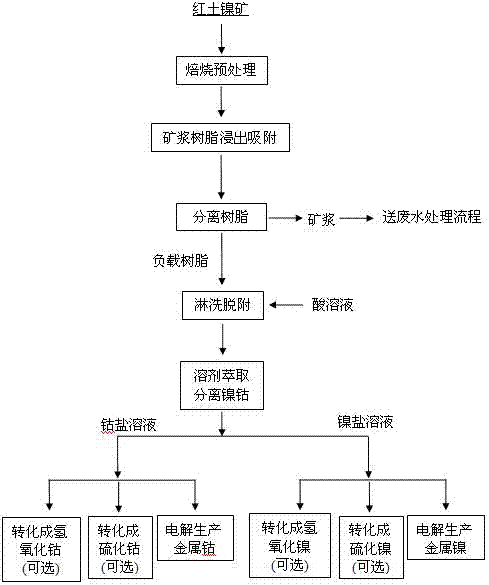

A kind of method that extracts cobalt nickel from laterite nickel ore

The invention discloses a method for extracting cobalt and nickel from laterite-nickel ore, which comprises the following steps of: performing roasting preprocessing on the laterite-nickel ore; blending the roasted material with water to obtain pulp; directly adding ion exchange resin for leaching and adsorbing the nickel and cobalt; separating the ion exchange resin from the ore pulp; eluting the nickel and cobalt in the resin by using acid; and separating nickel from cobalt in eluent by using a solvent extraction method, wherein the obtained nickel-containing solution and cobalt-containing solution are directly electrolyzed for producing metal nickel and metal cobalt, or producing corresponding salts of nickel and cobalt. By the method, a melting process for recovering cobalt and nickelfrom laterite-nickel ore through a wet process is simplified, a plurality of flows such as leaching, impurity removal, enrichment and the like of the nickel and cobalt of the laterite-nickel ore are integrated in a procedure, steps of solid-liquid separation and slag washing are not needed, water consumption, ore pulp treatment capacity and subsequent wastewater treatment capacity are reduced, the recovery rate of the nickel and cobalt in the process is high, the method is easy to implement, equipment investment cost can be saved, and chemical material consumption and multiple operation management links can be reduced.

Owner:广西银亿新材料有限公司

High-perforance compression casting aluminium alloy

A aluminum alloy material consists of Si 9.5-11.5wt%, Cu 2.0-3.0wt%, Mg 0.3-0.4wt%, mixed rare earth RE 0.1-0.3wt%, Mn is less than or equal to 0.5, Zn is less than or equal to 1.0, Fe is less than or equal to 1.0, Al residue. The mixed rare earth RE consists of La 5-80wt%, Ce 5-40wt%, Nd 1-20wt%, Y 1-20wt%, Pr 1-20wt%. It achieves good flowing, mechanical and cutting machining performance.

Owner:CHONGQING UNIV

Smelting method for low-carbon low-silicon wire-welding steel

ActiveCN104862443AGood welding performanceSolve the problem of nodulation in submerged nozzlesManufacturing convertersOxygen contentRegular Production

The invention discloses a smelting method for low-carbon low-silicon wire-welding steel. The process flow of the smelting method comprises the following procedures: pretreatment and desulphurization of molten iron; treatment in a converter; LF refining; and continuous casting of small square billet with a size of 150 mm * 150 mm. With the smelting method, carbon content is stably controlled to be less than or equal to 0.08%; silicon content is stably controlled to be less than or equal to 0.027%; total oxygen content is no more than 0.0040%; the problem of nozzle clogging is overcome; and surface and internal quality of a casting blank is greatly improved. The process flow of the smelting method is simple and has low cost; and equipment used in the smelting method is conventional production equipment for iron and steel manufacture, is simple to operate, has good versatility and saves energy.

Owner:QINGDAO SPECIAL STEEL CO LTD

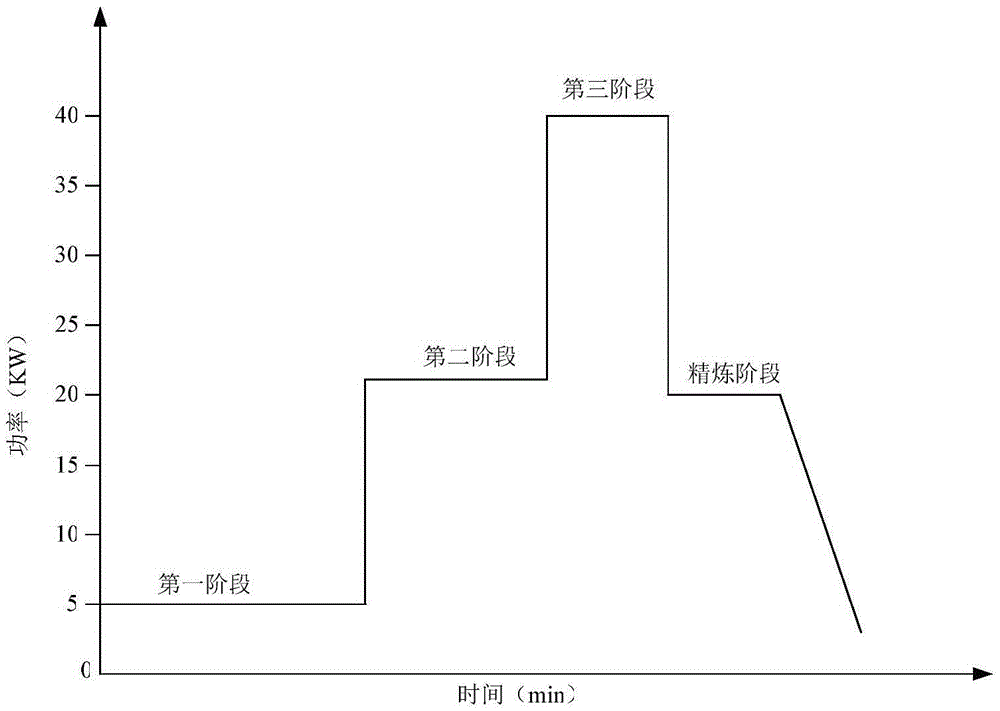

Magnesium alloy electromagnetic low-temperature semicontinuous casting method

The magnesium alloy electromagnetic low-temp. semicontinuous casting method includes the steps of melting magnesium, adding compound fire-resisting elements, adding alloy elements, heat-insulating, standing still and semicontinuous casting under the electromagnetic field. It utilizes the addition of compound fire-resisting elements to implement smelting of magnesium alloy free from coverage or protection so as to shorten technological process and raise melt quality, and utilizes the application of electromagnetic field and optimization of crystallizer structure to implement the low-temp. and high-speed semicontinuous casting of magnesium alloy.

Owner:NORTHEASTERN UNIV

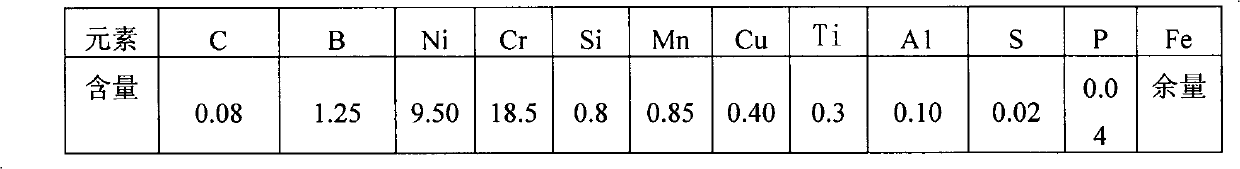

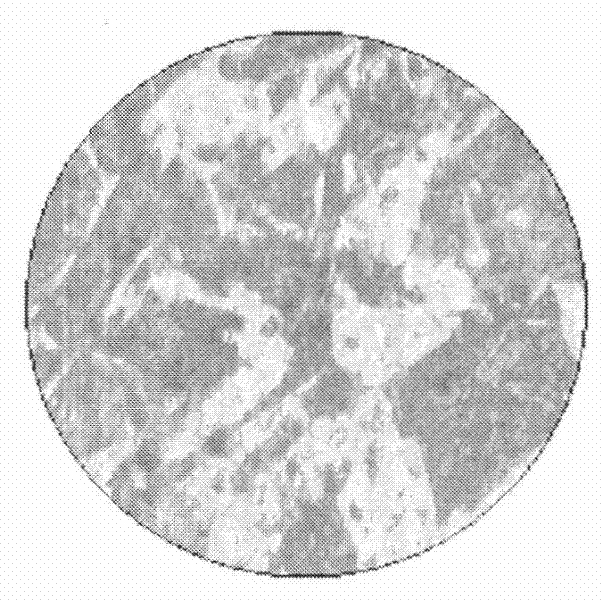

Corrosion-resisting stainless steel and manufacturing process thereof

InactiveCN102634739AHigh heat and cold fatigue resistanceReduce toughnessSmelting processHot working

The invention provides corrosion-resisting stainless steel and a manufacturing process of the corrosion-resisting stainless steel. The corrosion-resisting stainless steel comprises the following chemical components in percentage by weight: less than 0.10% of C, 15-22% of Cr, 0.6-3.0% of Mo, 9.0-10.5% of Ni, 0.40-2.0% of B, less than 0.5% of Cu, less than 1% of Si, less than 0.9% of Mn, 0.2-0.6% of Ti, less than 0.3% of Al, less than 0.05% of N, less than 0.04% of P, less than 0.01% of S and inevitable impurity elements. Therefore, the corrosion-resisting stainless steel has higher hot and cold fatigue resistance, anti-fracture toughness, thermal shock resistance, good hot-working property, and welding performance; the smelting process is simple; and the processing cost is low.

Owner:JIANGSU JINYUE AVIATION ALLOY MATERIAL

Low-alloy cast steel and application thereof in heavy lorry axle housing, raw materials and machining process

The invention discloses a low-alloy cast steel suitable for a heavy lorry axle housing. The low-alloy cast steel comprises the following elements in percentage by mass: 0.23 to 0.33 percent of C, 0.50 to 1.00 percent of Si, 0.90 to 1.40 percent of Mn, 0.10 to 0.25 percent of Cr, 0.10 to 0.25 percent of Mo, 0.20 to 0.25 percent of V, less than or equal to 0.04 percent of P, less than or equal to 0.04 percent of S, less than or equal to 0.20 percent of residual elements, and the balance of Fe. Waste steel, pig iron, ferromanganese alloy, silicon ferromanganese alloy, ferrochromium alloy, ferromolybdenum alloy and ferrovanadium alloy are used as raw materials of the low-alloy cast steel; and the machining process of the low-alloy cast steel comprises casting and thermal treatment. The low-alloy cast steel has the advantages of high mechanical property, good low-temperature impact toughness and good casting and machining process properties, and is particularly suitable for producing the lorry axle housing.

Owner:山东新达重工机械有限公司

Production method of vanadium-aluminum (V-Al) alloy

The invention discloses a production method of a V-Al alloy. The production method comprises the step of igniting vanadium pentoxide, metal aluminum and a coolant as furnace materials and smelting in a reaction device so as to obtain the V-Al alloy and slag, wherein the coolant is a defective product of the V-Al alloy with a grade same as that of the produced V-Al alloy. According to the production method of the V-Al alloy, a novel smelting method is used for smelting the V-Al alloy and successfully producing the V-Al alloy with an extremely low impurity content, wherein the impurity content of the produced V-Al alloy and the impurity content of the V-Al alloy obtained through vacuum smelting by using other methods are on the same level; the V-Al alloy smelting process is innovatively simplified, the impurity content of the V-Al alloy is significantly reduced, the production efficiency of enterprises can be increased, the production cost can be reduced, the alloy quality can be improved, the competitiveness of the enterprises can be enhanced, and the production method of a V-Al alloy has broad market prospects.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

High titanium special welding wire steel smelting method

ActiveCN104831014ASolve the problem of nodulation in submerged nozzlesPulling smoothlyManufacturing convertersTitaniumOxygen content

The invention discloses a high titanium special welding wire steel smelting method, the technical process of converter-ladle furnace (LF) refining-150 mm*150 mm small square billet continuous casting is used, the titanium content is stably controlled at 0.14% to 0.19%, on average, 0.16%; carbon content is stably controlled at 0.03-0.08%; the total oxygen content is stably controlled at 0.0030% or less, nozzle clogging problem is successfully solved, the number of furnaces of continuous casting can reach 22, welding wire welding performance is good, splash is greatly reduced, and the demand of a high-end welding wire material can be achieved. The high titanium special welding wire steel smelting method adopts steel manufacture conventional production equipment, and is simple in operation and strong in commonality, casting blank quality is stable, and the production cost is low.

Owner:QINGDAO SPECIAL STEEL CO LTD

Flux foaming preparation method for foam magnesium

InactiveCN101135015AGood flame retardant and anti-oxidation functionImprove protectionFoaming agentMaterials processing

The present invention relates to material processing technology, and is melt foaming process for preparing foamed magnesium. Through heating magnesium base material to melt, adding thickener and foaming agent, pouring the melt into a foaming tank, standing to foam inside one thermostatic oven, cooling after foaming, and machining to form foamed magnesium product. The added thickener is metal calcium powder accounting for 2-8 wt% of the melt, and the added foaming agent is calcium carbonate powder accounting for 2-15 wt% of the melt. The present invention has convenient operation, easy control and low cost, can produce foamed magnesium product of different pore sizes, and is suitable for industrial production.

Owner:SHANGHAI JIAO TONG UNIV

AlMgSi alloy sheet and preparation method thereof

The invention provides an AlMgSi alloy sheet and a preparation method thereof. The sheet comprises the following components by mass percent: 0.4-0.8% of Mg, 1-1.5% of Si, 0.7-0.8% of Cu, 0.3-0.4% of Mn, 0.4-0.6% of Fe, 0.1-0.2% of Zr and the balance Al. The process for preparing the sheet comprises the following steps: smelting, blank preparing, hot rolling, cold rolling, annealing heat treatment,solid solution heat treatment and aging heat treatment. The invention has the following advantages: the elements for preparing the alloy have few types, most of which are conventional metal elements,therefore, the alloy is low in cost; the alloy smelting process is simple, and the reasonable rolling process and heat treatment process ensure the ultimate tensile strength of the alloy to reach over 390Mpa; cold rolling is adopted in later stage of rolling, thereby dispensing with heating in the hot rolling process and lowering the energy consumption.

Owner:镇江市天通新材料科技有限公司

Vanadium-titanium gray cast iron and production technique thereof

The invention particularly relates to a vanadium-titanium gray cast iron and a production technique thereof. The vanadium-titanium gray cast iron contains 3.2-3.6% of C, 1.6-1.9% of Si, 0.7-0.9% of Mn, 0-0.10% of P, 0.07-0.12% of S, 0.15-0.20% of V, 0.07-0.12% of Ti, 0.25-0.35% of Cr, and the balance of Fe and other minor elements and inevitable impurities. The vanadium-titanium gray cast iron has the advantages of high tensile strength, favorable heat resistance and favorable wear resistance; and the type-A graphite content in the metallurgical structure is higher than 85%, the graphite length is Grade 3-5, the pearlite content in the matrix structure is greater than or equal to 98%, and the total content of carbides and iron phosphide eutectic is less than or equal to 2%.Late inoculation treatment is adopted to enhance the inoculation effect, improve the graphite form, eliminate the carbides and ferrite and increase the pearlite content. By using cheap vanadium-titanium pig iron as the raw material and avoiding adding noble alloys, the vanadium-titanium gray cast iron has the advantages of low cost and high performance.

Owner:陈国

Steel plate with excellent low-temperature toughness in large heat-input weld heat affected zone and production method thereof

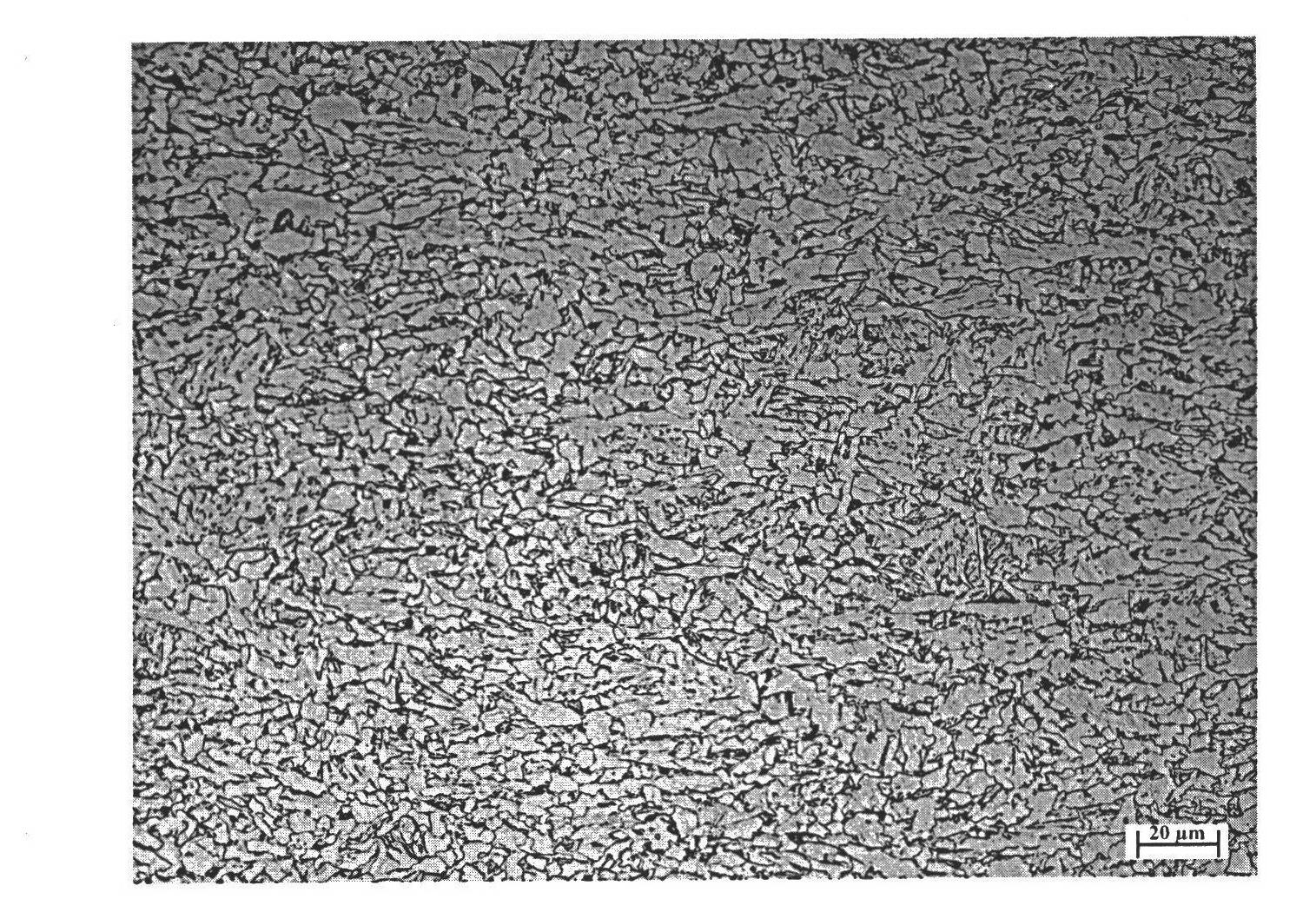

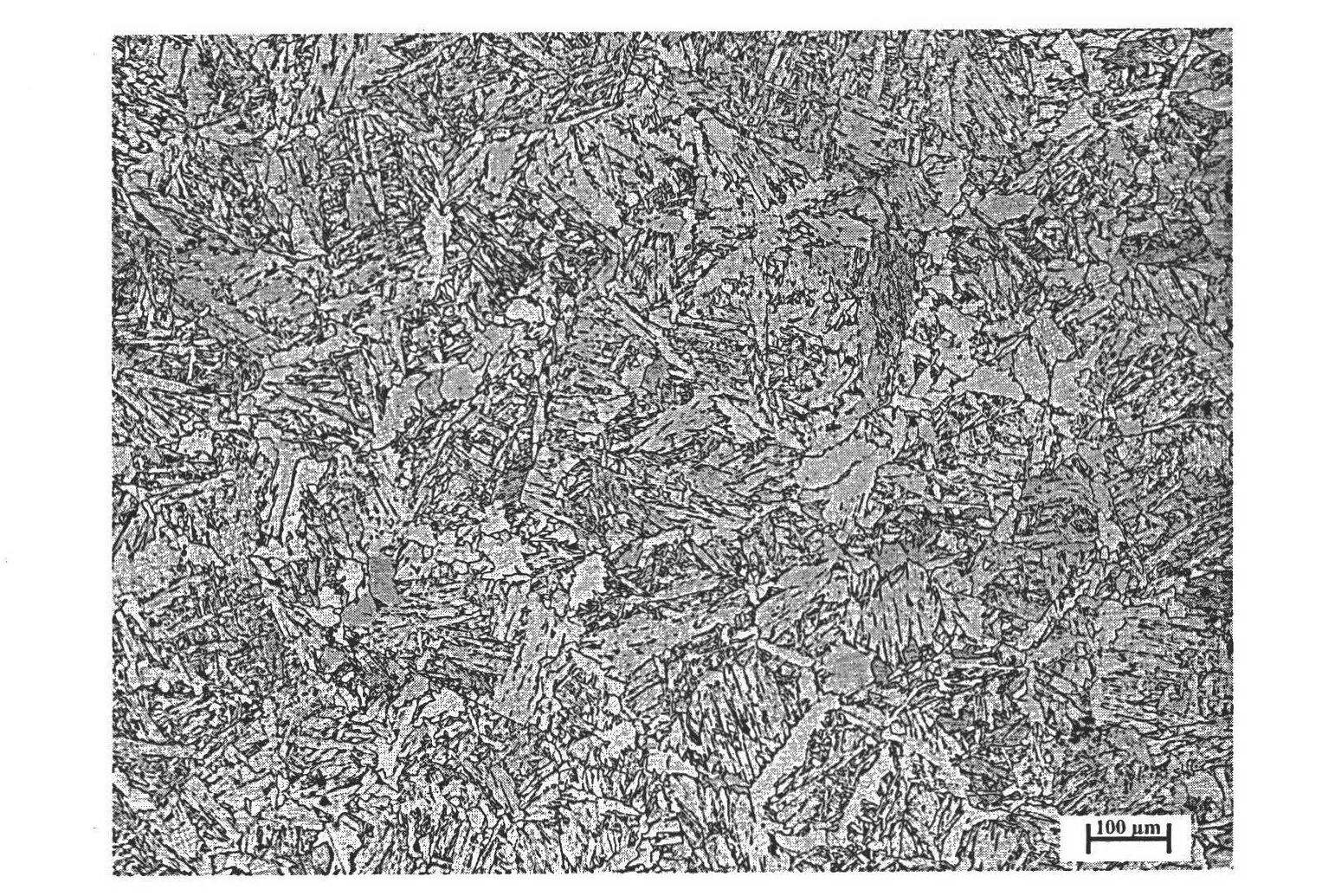

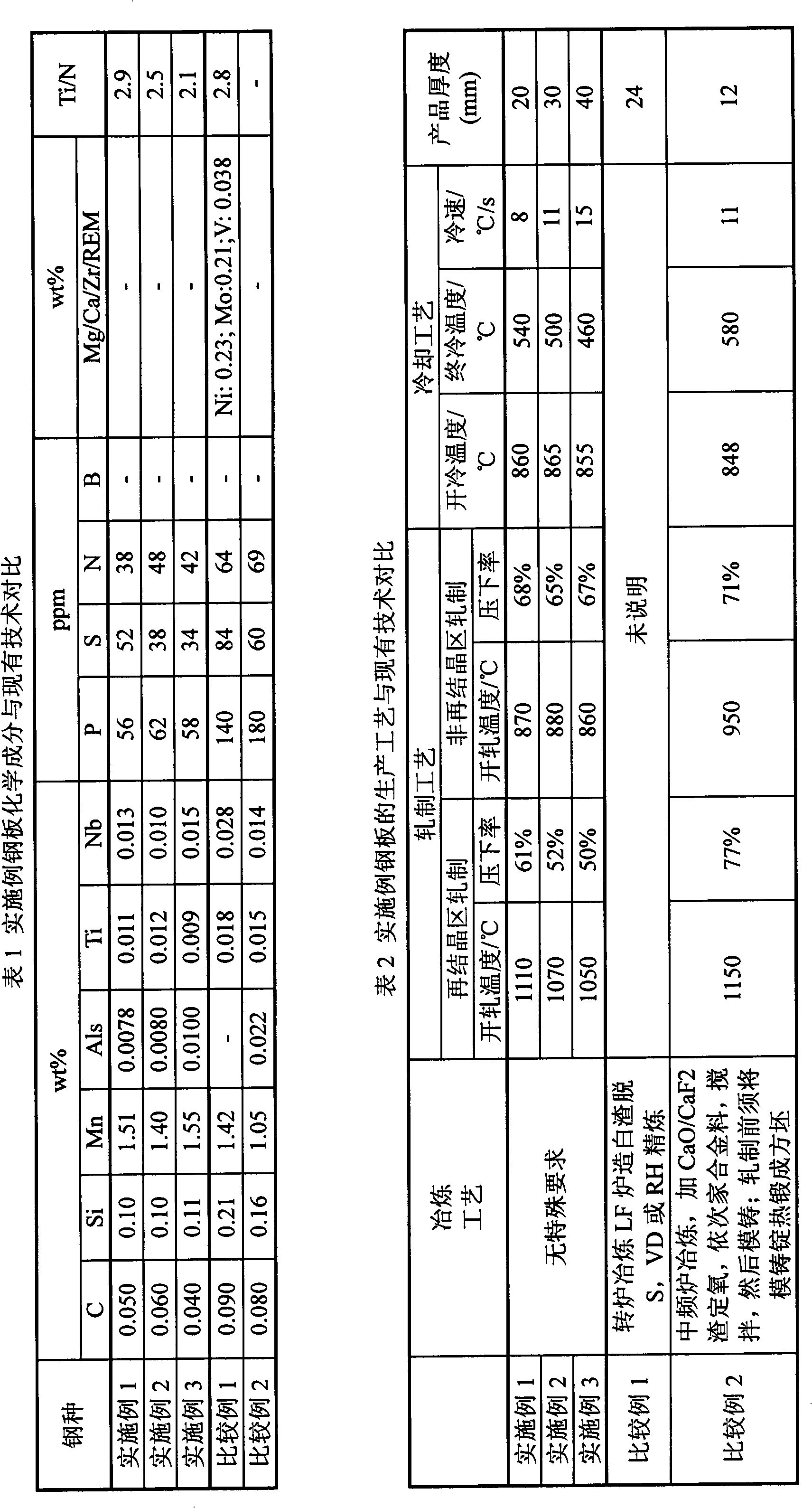

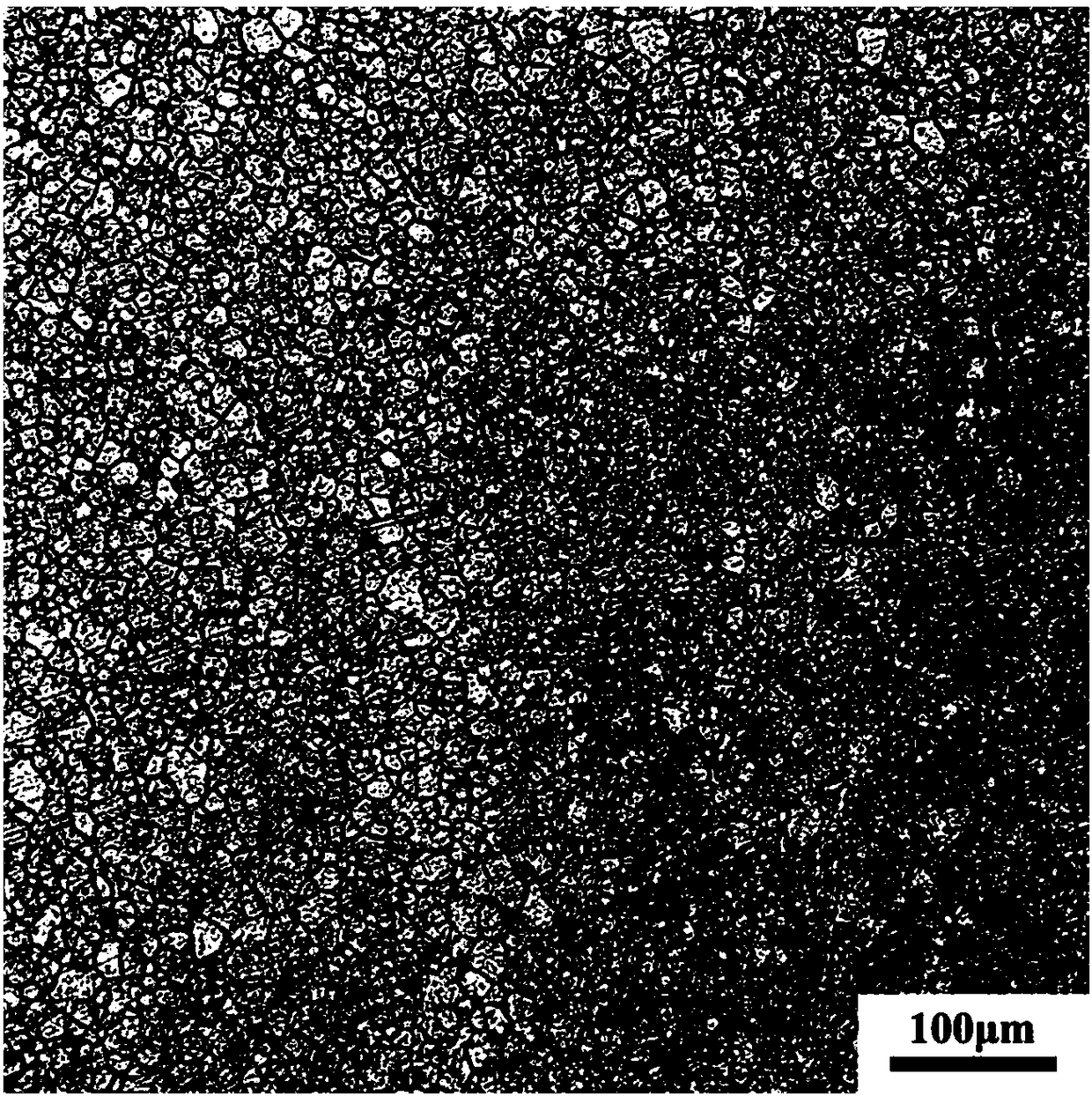

The invention discloses a steel plate with excellent low-temperature toughness in a large heat-input weld heat affected zone, which comprises the following chemical components in percentage by weight: 0.03-0.06% of C, 0.05-0.12% of Si, 1.30-1.60% of Mn, 0.007-0.015% of Nb, 0.007-0.015% of Ti, at most 0.01% of Al, 0.0035-0.0060% of N, at most 0.009% of P, at most 0.0052% of S and the balance of Fe and inevitable impurities. The invention adopts a low-C low-Si low-Al high-Mn-Nb microalloy composition, and the Ti / N ratio is 2.0-3.0. The production method adopts an advanced TMCP-AcC technique, so that the steel plate microstructure is an acicular ferrite of which the dimension is at most 10 mu m, and has excellent strength and low-temperature toughness; under the condition that the weld heat input is up to 200kJ / cm, the Charpy impact work of the weld heat affected zone at -20 DEG C is at least 179J; and the invention is applicable to ships, low-temperature pressure containers, ocean platforms and the like.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

Method for preprocessing scheelite and preparing ferro-tungsten

InactiveCN102108449AReduce dosageReduce energy consumptionProcess efficiency improvementAlloyHydrometallurgy

The invention relates to a method for tungsten hydrometallurgy, in particular to a method for preprocessing scheelite and preparing ferro-tungsten. The method comprises the following steps: preprocessing scheelite with hydrochloric acid and repeatedly utilizing remaining acid to decompose scheelite in an aright device having no pressure; and preprocessing slag to restore melting ferro-tungsten. Compared with the prior art, the method has the advantages as follows: in order to solve the defects in the background art, the closed circuit of hydrochloric acid is utilized to decompose scheelite, thereby reducing the consumption amount of hydrochloric acid and energy consumption, realizing the effective enrichment of CaCl2, reducing the production cost of subsidiary products, and improving the economic benefits of technology; the aright device having no pressure reduces the requirements on leaching equipment, and also reduces the investment of fixed assets; high-qualified ferro-tungsten can be prepared under the hydrogen reduction environment by just mixing iron powder and coarse tungstic acid according to a proper proportion, so that the energy consumption is reduced and the smelting process is simplified.

Owner:厦门紫金矿冶技术有限公司

Low-cost high-compression-strength wrought magnesium alloy and preparation method thereof

InactiveCN108118225ANo significant increase in preparation costsRich varietyElemental compositionCu element

The invention relates to a low-cost high-compression-strength wrought magnesium alloy and a preparation method thereof. The magnesium alloy material is composed of six elements, namely Mg, Zn, Mn, Sn,Ca and Cu, wherein the content of the Zn element is 4.0%-8.5%, the content of the Mn element is 0.1%-0.4%, the content of the Sn element is 0.1%-0.4%, the content of the Ca element is 0.1%-0.4%, thecontent of the Cu element is 0.1%-0.4%, the content of inevitable impurities is less than or equal to 0.15%, and the balance is the Mg; and compared with a traditional commercial grade magnesium alloymaterial, high compressive yield strength can be obtained after the magnesium alloy material is subjected to a conventional extrusion treatment, and the compressive yield strength of the alloy is obviously higher than tensile yield strength. The magnesium alloy material does not contain precious alloy elements, and is simple in preparation process and low in cost, has very important practical value for manufacturing a pressed magnesium alloy component.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Aluminum chip recovery and smelting process

InactiveCN110172582ASimple recovery and smelting processSave shipping timeProcess efficiency improvementSmelting processEnergy consumption

The invention provides an aluminum chip recovery and smelting process. The process is to perform screening, crushing, oil removal, drying, iron separation, preheating and melting on recovered waste aluminum in sequence to obtain recovered molten aluminum; and the specific steps are as follows: the recovered aluminum is vibrated and screened for crushing; then, an oil remover is used for oil removal and drying; iron is separated; and separated aluminum chips are preheated to enter a smelting furnace for smelting to obtain the recovered molten aluminum. The aluminum chip recovery and smelting process is simple and low in energy consumption, can recycle high-temperature waste gas generated in the process to achieve the purposes of energy conservation and emission reduction, and meanwhile, canshorten the smelting time to further reduce the energy investment.

Owner:襄阳恒德汽车配件有限公司

Low melting point tin-zinc solder without lead and soldering paste

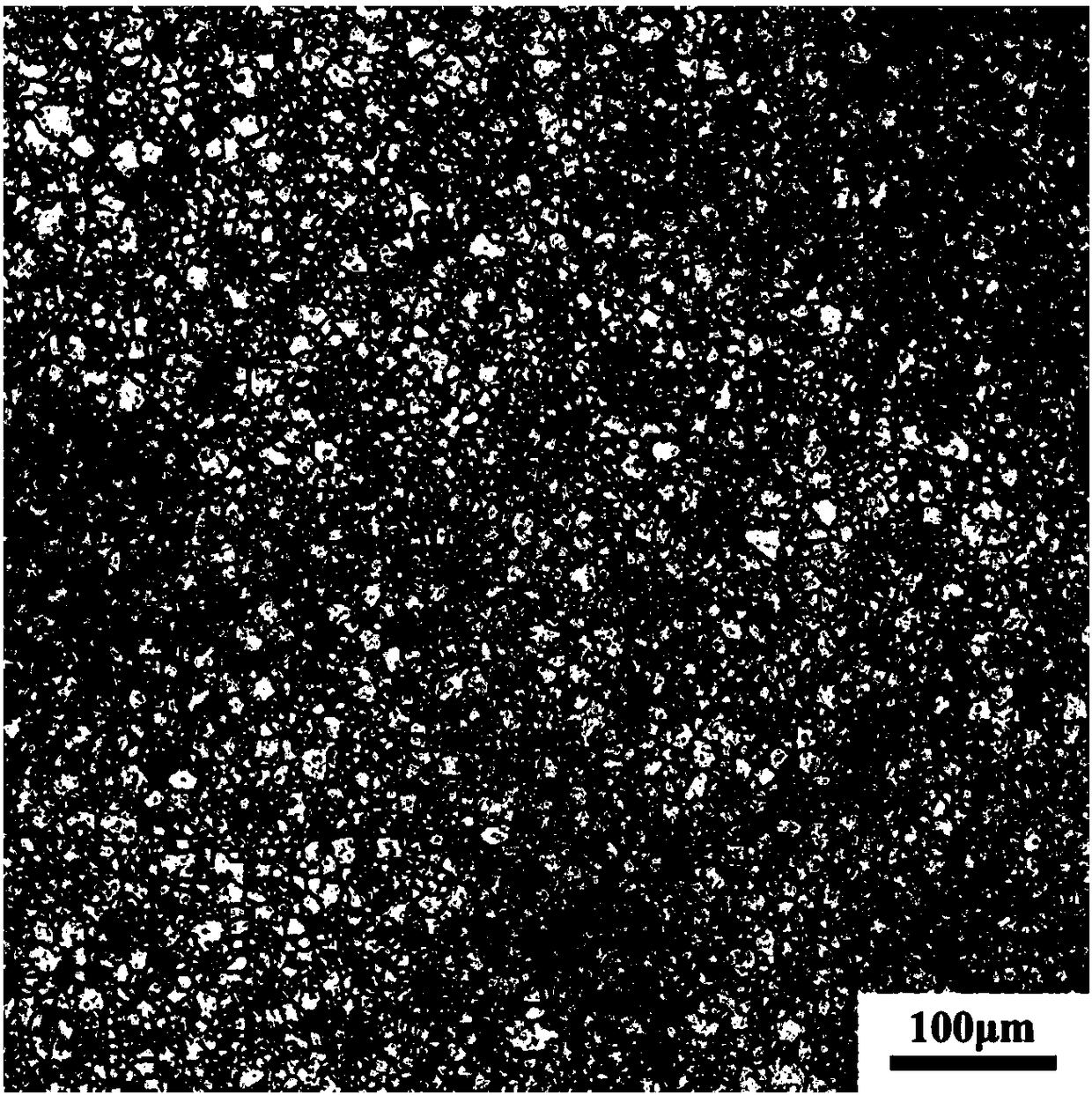

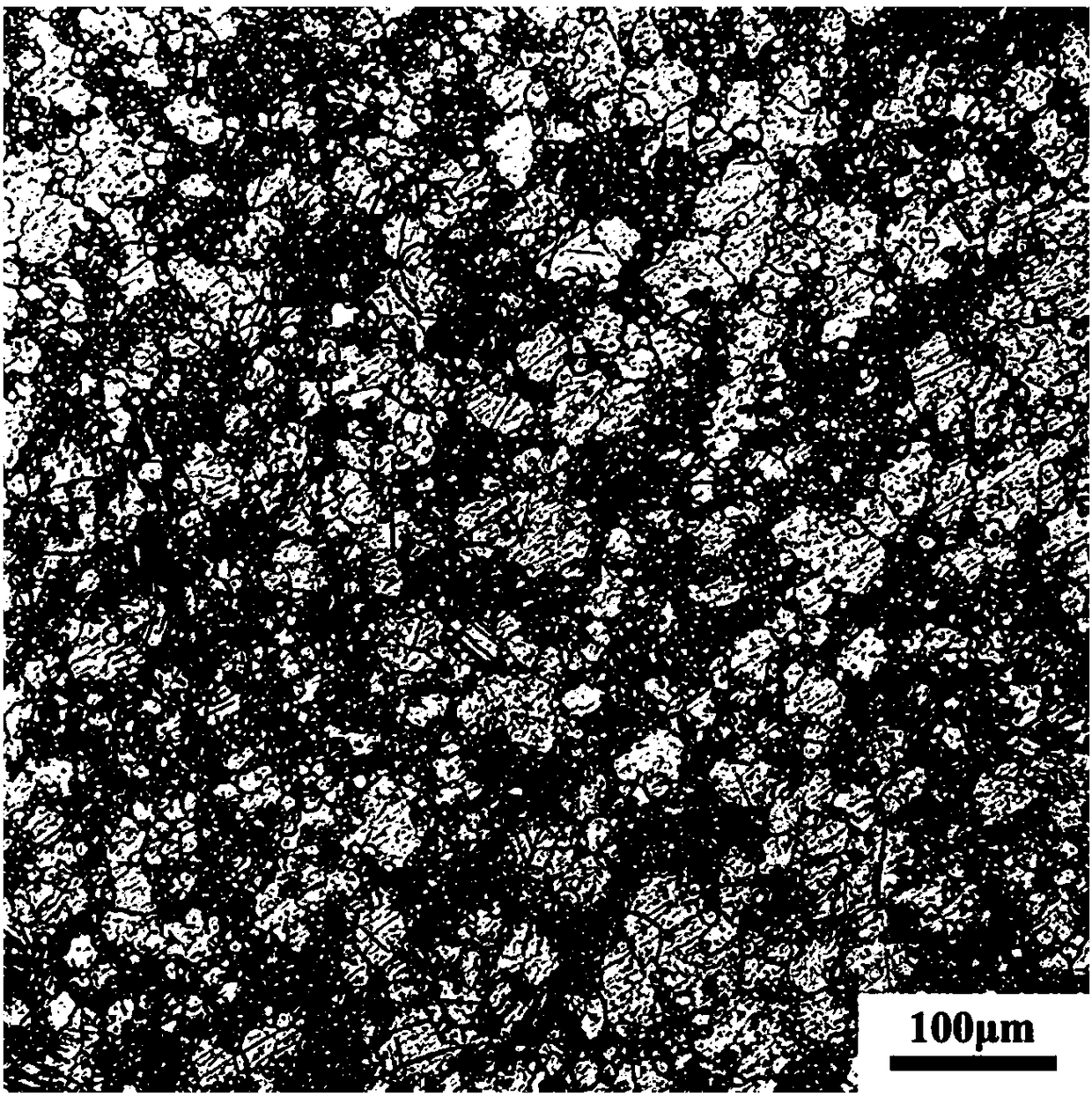

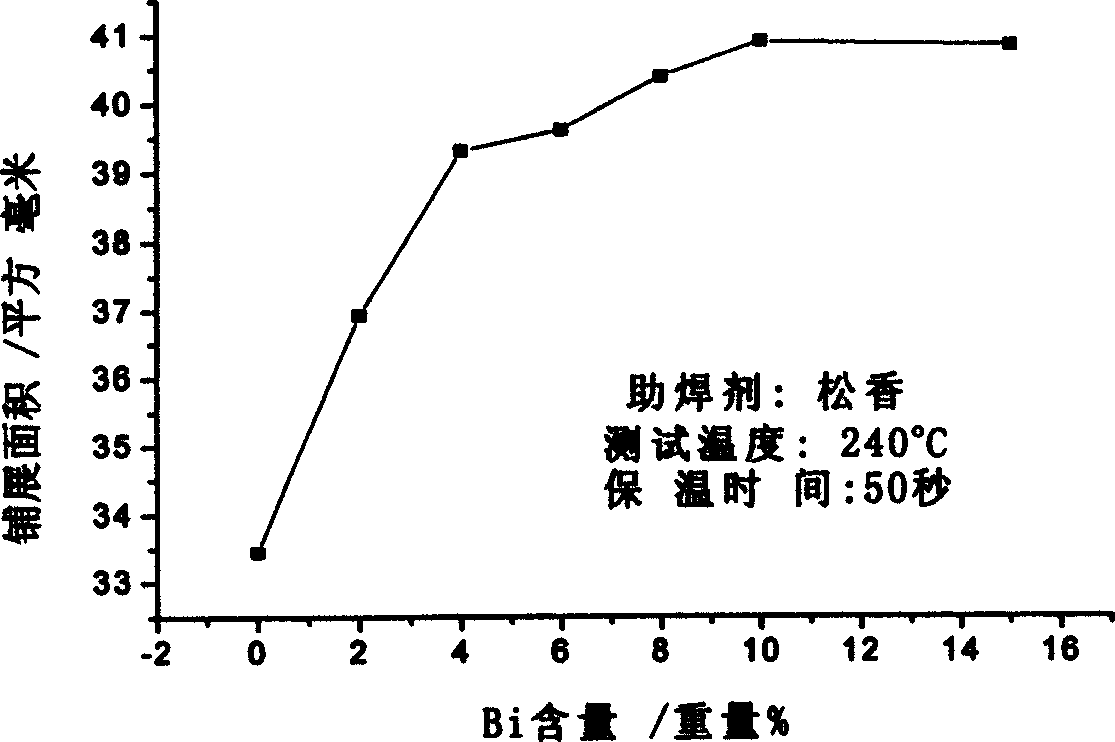

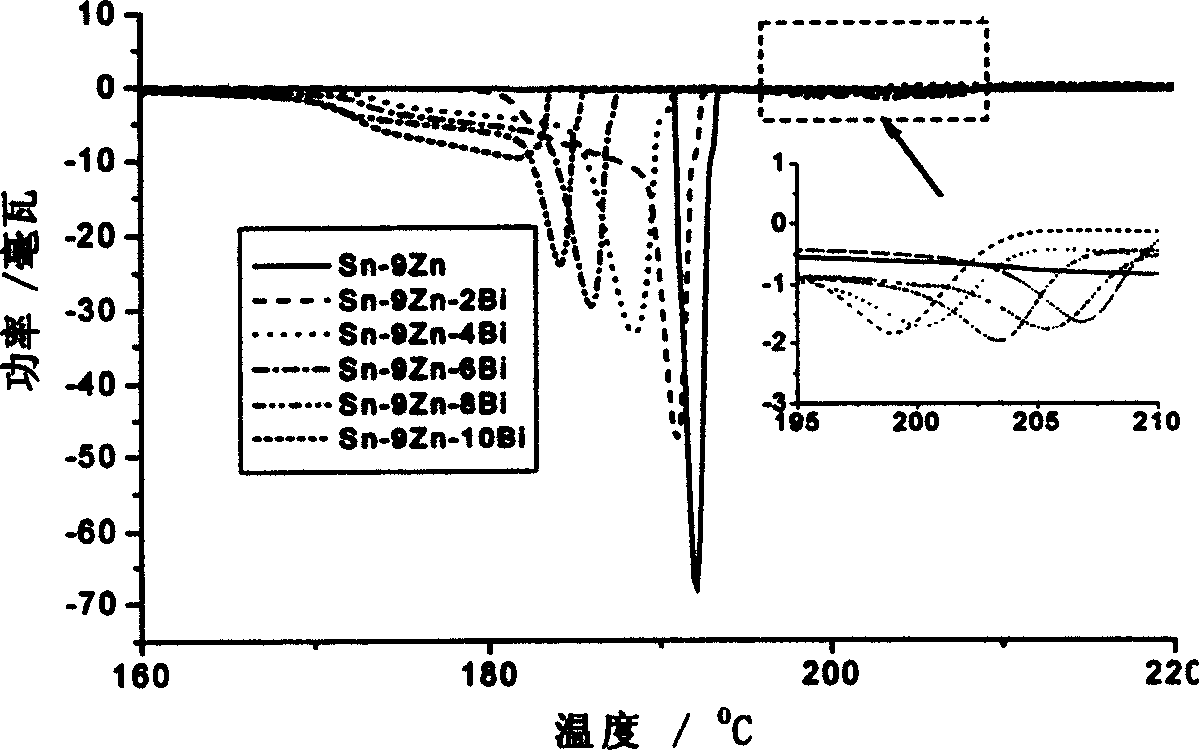

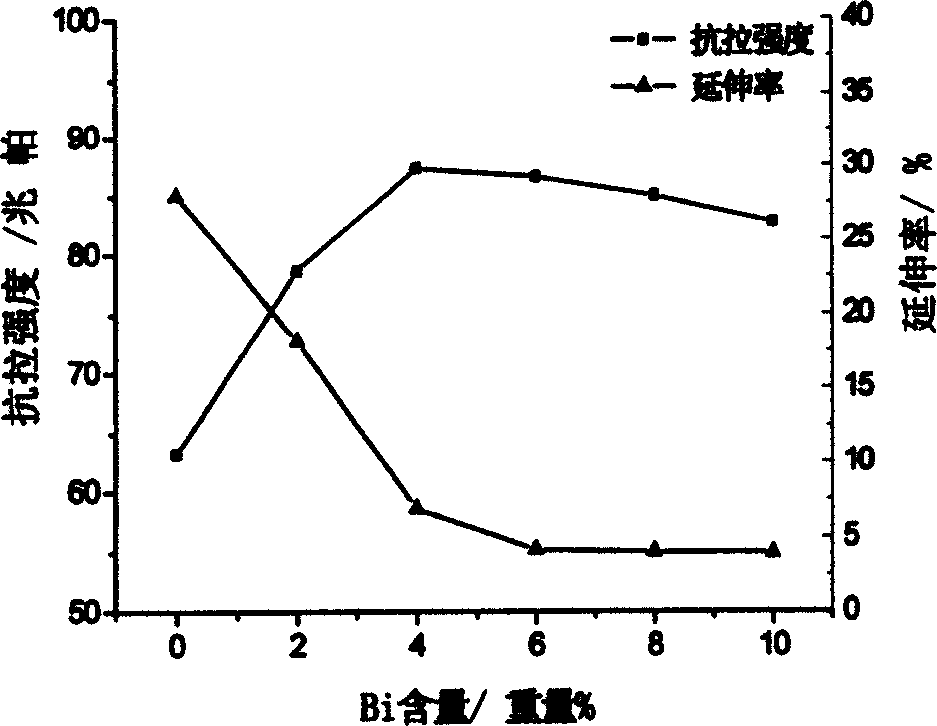

InactiveCN1644301AImprove antioxidant capacityHigh heat resistance requirementsWelding/cutting media/materialsSoldering mediaAlloyZinc

A low-smelting-point non-lead SnZn-alloy solder is prepared from Zn (5-9 wt.%), Bi (0.5-4), Nd (0.01-0.5) and Sn (rest). Its solder paste features that the Sn or Sn-alloy particles are coated on the surface of each solder particle for high stability and high antioxidizing power.

Owner:SOUTHEAST UNIV

Low-cooling-rate sensitive high-nucleation-capacity AlNbTiBRE composite refining modifier used for aluminum alloy and preparation method of low-cooling-rate sensitive high-nucleation-capacity AlNbTiBRE composite refining modifier used for aluminum alloy

The invention discloses a low-cooling-rate sensitive high-nucleation-capacity AlNbTiBRE composite refining modifier used for aluminum alloy and a preparation method of the low-cooling-rate sensitive high-nucleation-capacity AlNbTiBRE composite refining modifier used for aluminum alloy. The low-cooling-rate sensitive high-nucleation-capacity AlNbTiBRE composite refining modifier is prepared from Al-xNb-yTi-zB-kRE, wherein 0.01<x<=6wt%, 0.01<y<=6wt%, 0.01<z<=1wt%, 0.01<k<=1wt%, and the balance is Al; and RE is one of La, Ce, Nd, Er, Gd, Y, Yb and Sc or a mixture of two or more of La, Ce, Nd, Er, Gd, Y, Yb and Sc. A preparation technology is simple, and the compositions can be precisely controlled. The composite refining modifier is used for processing aluminum alloy, and the refining effect and the modifying effect are excellent; for all parts of castings complex in shape and different in thickness, namely, all parts with different cooling rates, the cooling rate sensitivity of the refining effect is low; and the mechanical performance of the obtained alloy is remarkably improved, and the performance difference between the parts with different cooling rates is remarkably reduced.

Owner:北京航大新材科技有限公司

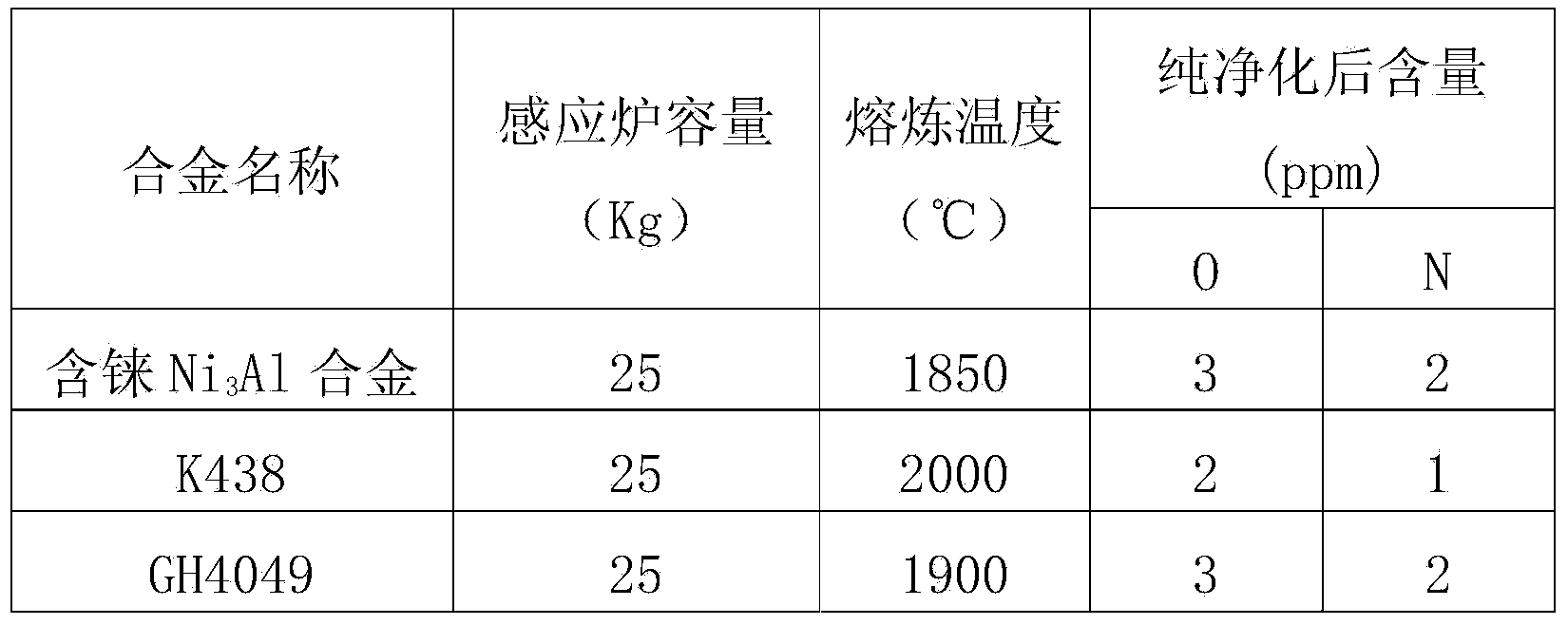

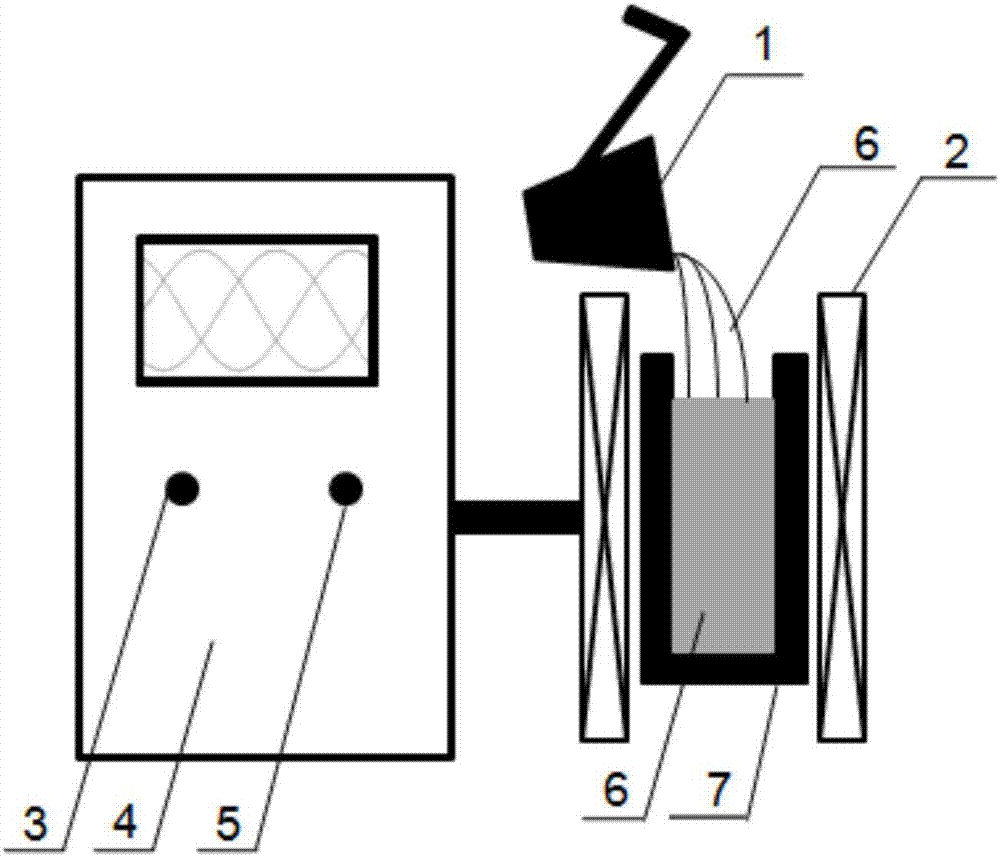

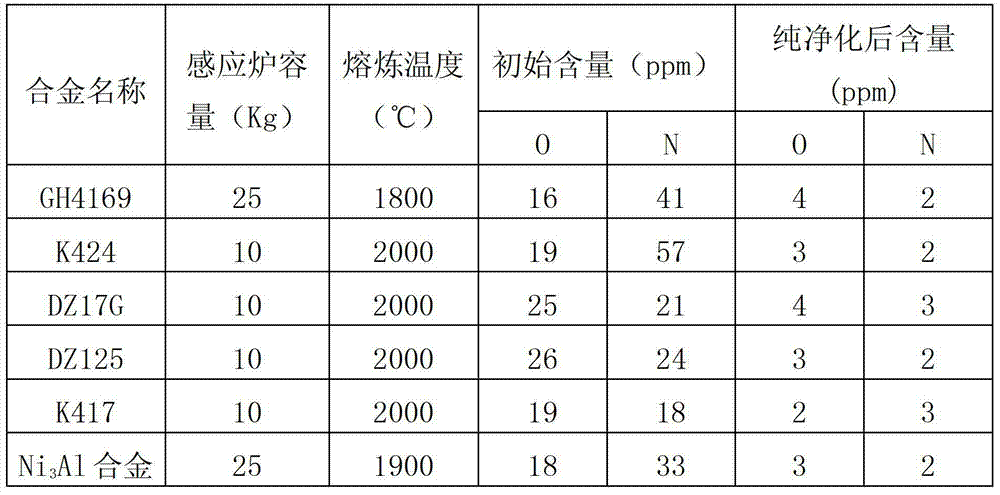

Method for purified smelting of high-temperature alloy by using yttrium oxide crucible

ActiveCN103526037AImprove stabilityPotential for reduced oxygen supplyIncreasing energy efficiencySmelting processSuperalloy

The invention discloses a method for purified smelting of high-temperature alloy by using an yttrium oxide crucible. The method comprises the following steps of loading, purified smelting and pouring. The method disclosed by the invention just adopts a simple smelting process without smelting and adding a deoxidizing agent for many times to reduce the content of O and N to below 5ppm, so that the process step is remarkably simplified and the energy consumption is remarkably reduced. According to the method provided by the invention, no strong deoxidizing agents are added or carbon element is just added in an allowable range of an alloy composition standard in the early smelting period to deoxidize without guidance of harmful elements which need to be controlled in content, so that the influence of the harmful elements on an alloy melt is eliminated while purification is carried out.

Owner:BEIHANG UNIV

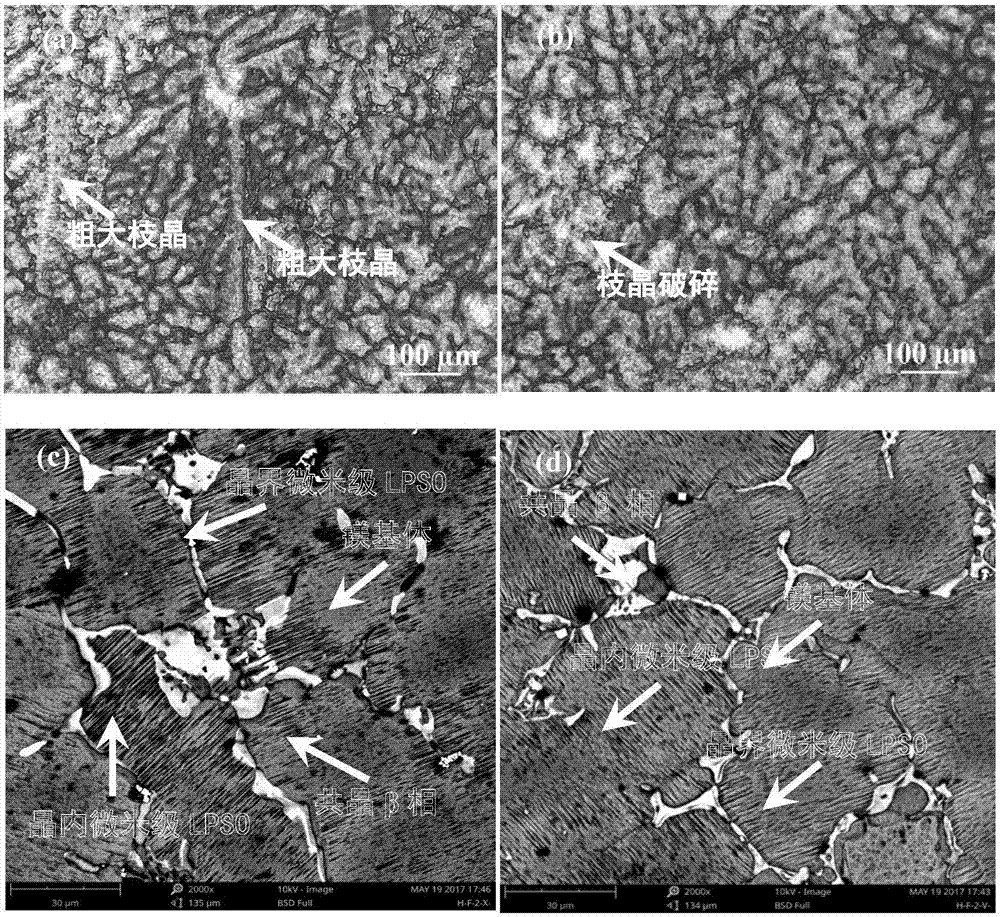

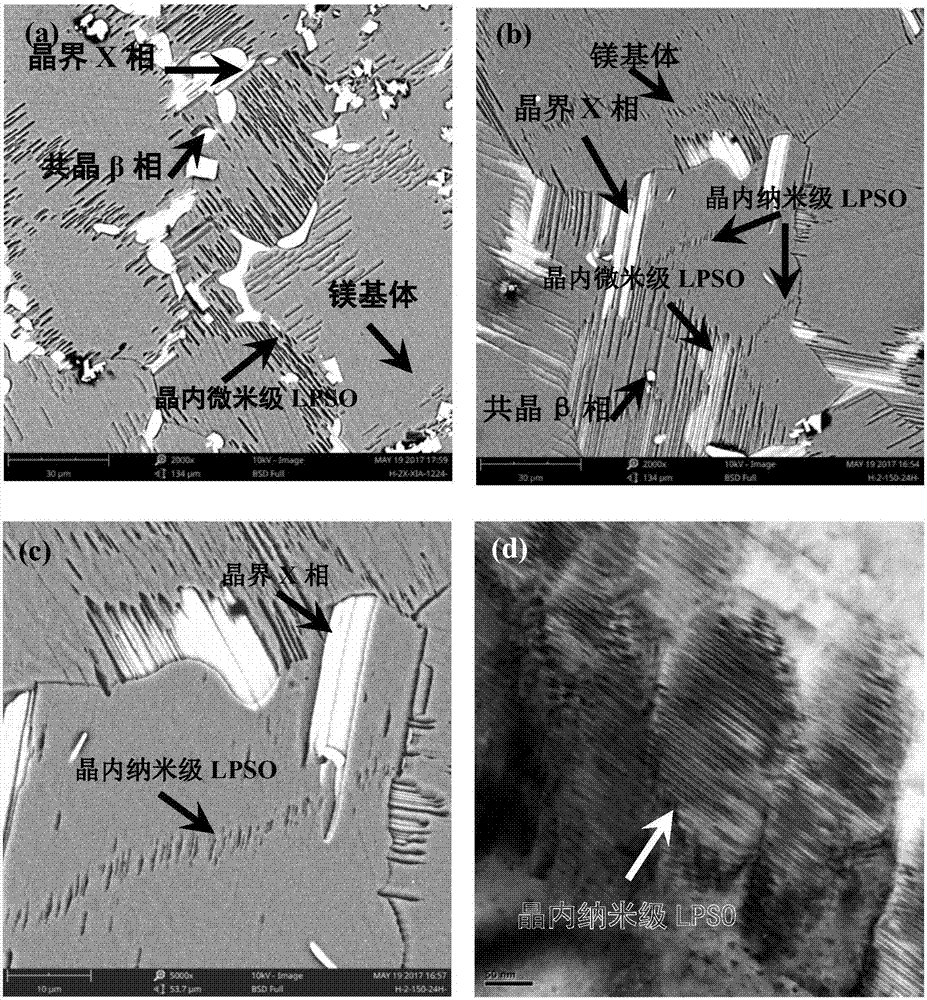

Method for preparing high-strength and toughness magnesium alloy containing LPSO structure through magnetic field casting regulation

The invention provides a method for preparing high-strength and toughness magnesium alloy containing an LPSO structure through magnetic field casting regulation. The method comprises the following steps: atoms RE and atoms Zn are proportioned in a certain amount of Mg-Re-Zn alloy, and the Mg-Re-Zn alloys are put into a crucible at a certain temperature for melting; after all the alloy raw materials are molten, the molten materials are heated to 700-740deg C and is casted into a graphite mould under a magnetic field condition, and a Mg-RE-Zn casting ingot is obtained; and the Mg-RE-Zn casting ingot is subjected to solid solution and then subjected to quenching treatment, and a magnetic field casting Mg-RE-Zn alloy with a nano-scale lamellar LPSO structure is obtained. The structure of the alloy is regulated by changing the current and frequency of the pulsed magnetic field during casting the molten alloy in the specially-made graphite mould and the temperature and time of the subsequent solid solution treatment, and the nano-scale lamellar LPSO structure of the high-toughness magnesium alloy is prepared in the Mg-RE-Zn casting alloy for the first time.

Owner:SHANGHAI JIAO TONG UNIV

TC4 titanium alloy solid welding wire for large-thickness ultra-narrow-gap laser wire filling welding and preparation method thereof

ActiveCN112872654AWill not affect subsequent weldingDoes not affect welding qualityWelding/cutting media/materialsSoldering mediaPlastic packagingIngot

The invention discloses a TC4 titanium alloy solid welding wire for large-thickness ultra-narrow-gap laser wire filling welding and a preparation method thereof. The invention belongs to the technical field of welding materials. The invention provides the TC4 titanium alloy solid welding wire for large-thickness ultra-narrow-gap laser wire filling welding and the preparation method thereof. The solid welding wire is prepared from chemical components in percentage by mass as follows: 5.0%-7.0% of Al, 4.0%-6.0% of V, 1.5%-2.5% of Mo, 0.2%-0.5% of Cr, 0.5%-1.5% of Zr and the balance of Ti. The method comprises the following steps: weighing raw materials according to the chemical components of the welding wire, mixing the raw materials, pressing into an electrode block, welding into a consumable electrode, carrying out primary smelting to obtain a primary cast ingot, carrying out secondary smelting to obtain a titanium alloy cast ingot, turning a skin, cutting a dead head, forging into a square billet, rolling, drawing, straightening and polishing to obtain a wire material, carrying out vacuum annealing, carrying out drawing diameter reduction, stress relief annealing and cleaning in a vacuum tube type annealing furnace, winding on a wire reel, and vacuum plastic packaging to obtain the large-thickness ultra-narrow-gap TC4 titanium alloy solid welding wire for laser wire filling welding.

Owner:HARBIN WELDING INST LTD

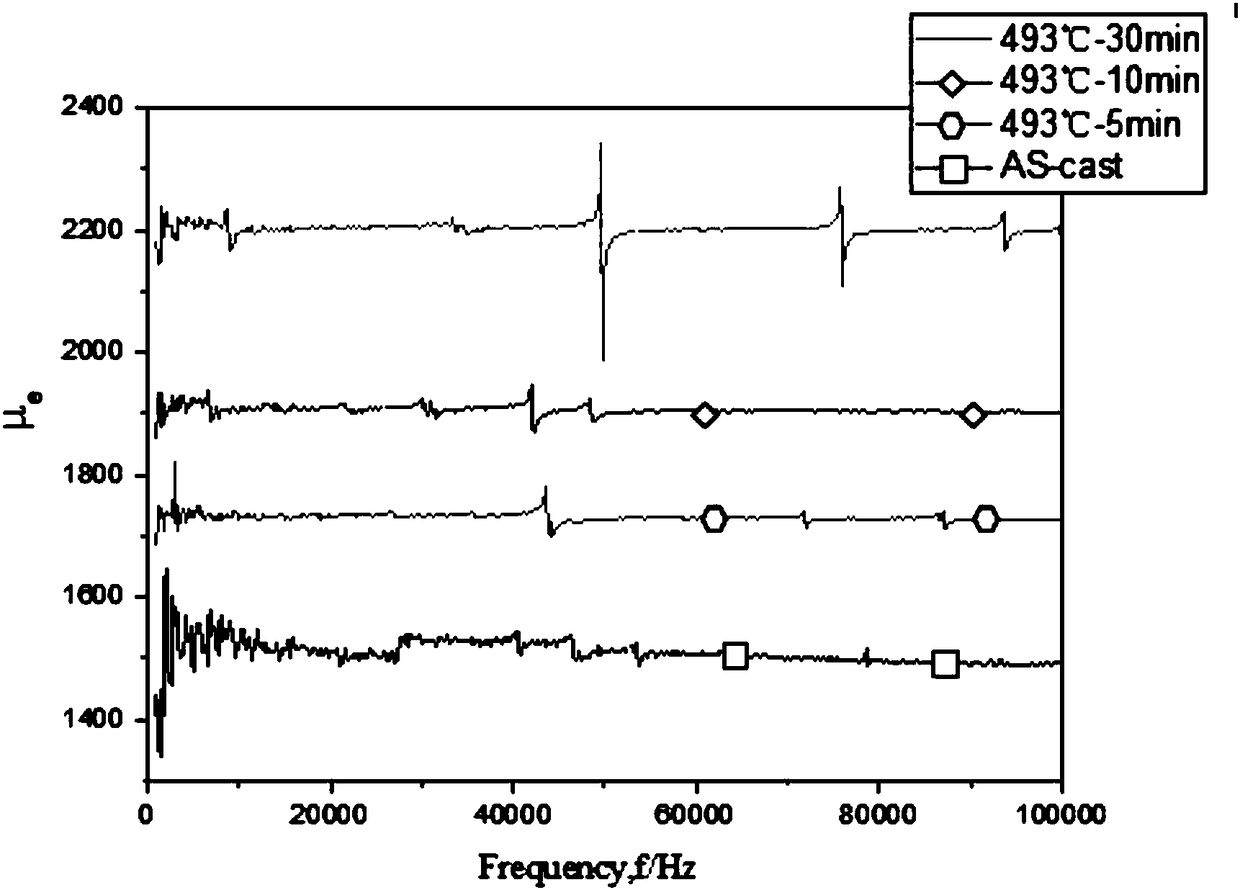

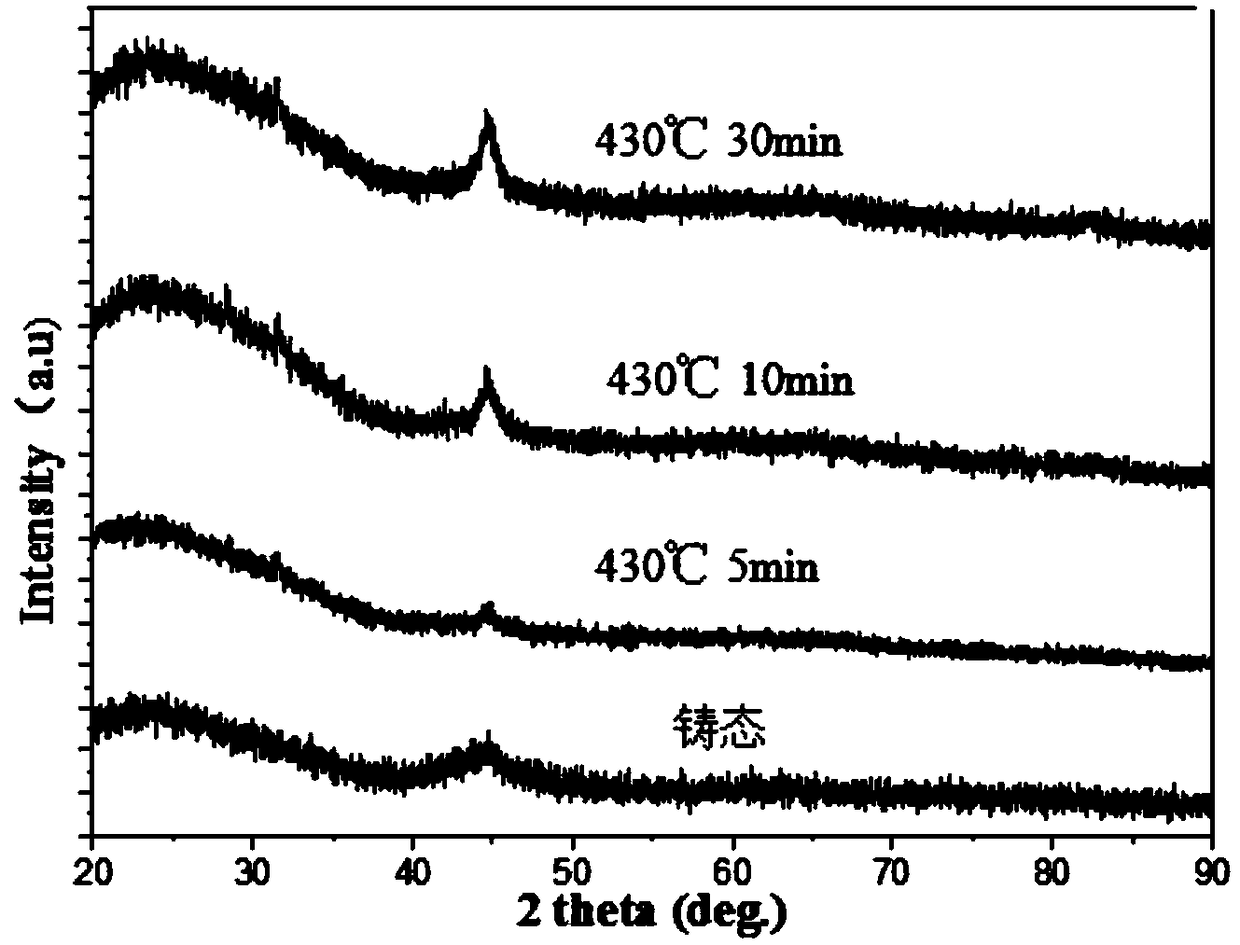

Amorphous nanocrystalline high-entropy soft magnetic alloy and preparation method thereof

InactiveCN108396262AReasonable designImprove accuracyMagnetic materialsProcess conditionsMaterials science

The invention relates to a novel amorphous nanocrystalline high-entropy soft magnetic alloy and a preparation method thereof. The chemical formula of the alloy is FeaCobNicZrdBeCuf, wherein a, b, c, d, e and f in the chemical formula represent the atomic percentage contents of the corresponding components and meet the following conditions that a is 25-35, b is 25-35, c is 25-35, d is 6.0-8.0, e is1.0-5.0, f is 0.5-1.5, and the sum of a, b, c, d, e and f is 100. The novel amorphous nanocrystalline high-entropy soft magnetic alloy has the advantages of being excellent in magnetic performance, low in cost and good in formability, and the preparation process conditions are loose and simple.

Owner:HENAN ZHONGYUE AMORPHOUS NEW MATERIALS +1

Method for performing purified smelting on high-temperature alloy return material by using yttrium oxide crucible

The invention discloses a method for performing purified smelting on a high-temperature alloy return material by using an yttrium oxide crucible. The method comprises the steps of charging, performing purified smelting and pouring. The method provided by the invention can reduce the O content and the N content of the return material to be less than 5 ppm only by adopting a one-time smelting process and without smelting for many times and adding a deoxidant for many times, so the process steps are simplified and energy consumption is reduced. According to the method provided by the invention, a carbon element is added in the permitted range of alloy elements to perform deoxidation, and harmful elements of which the content needs to be controlled strictly are not introduced, so the influence of the harmful elements on alloy melt is eliminated during deoxidation and denitrification.

Owner:BEIHANG UNIV

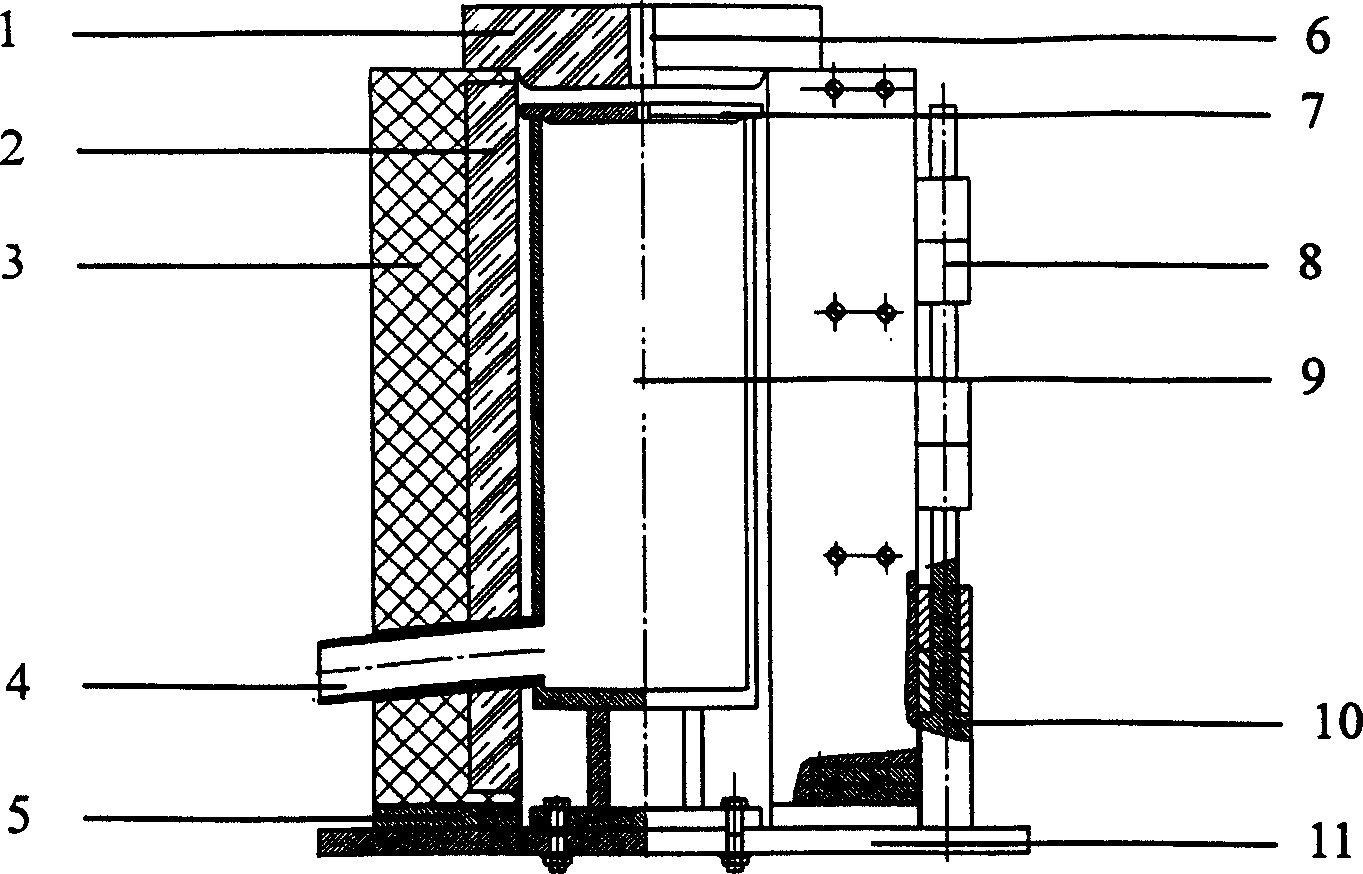

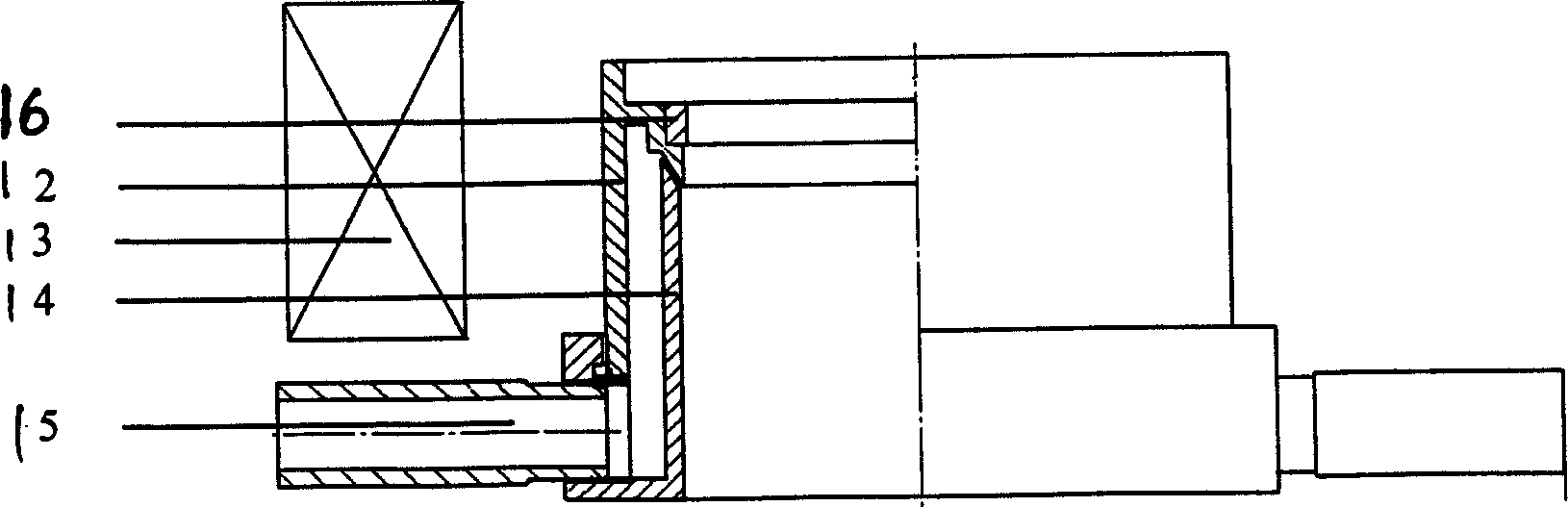

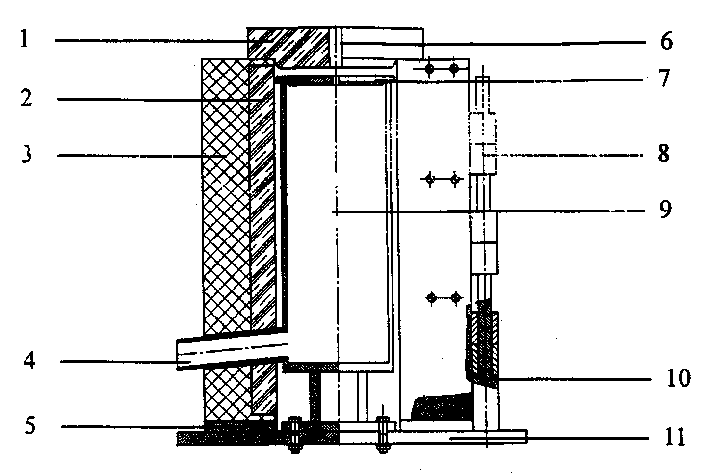

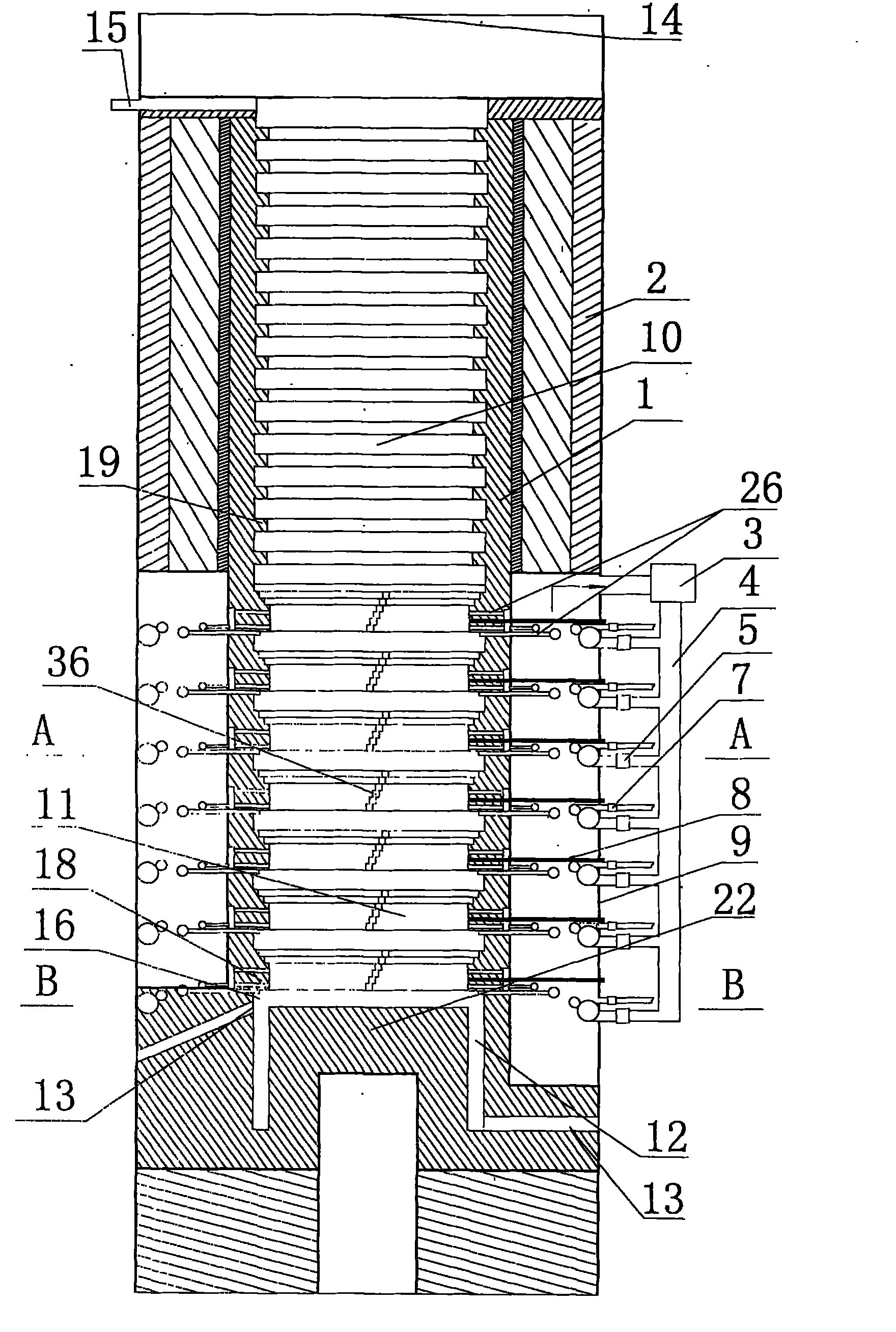

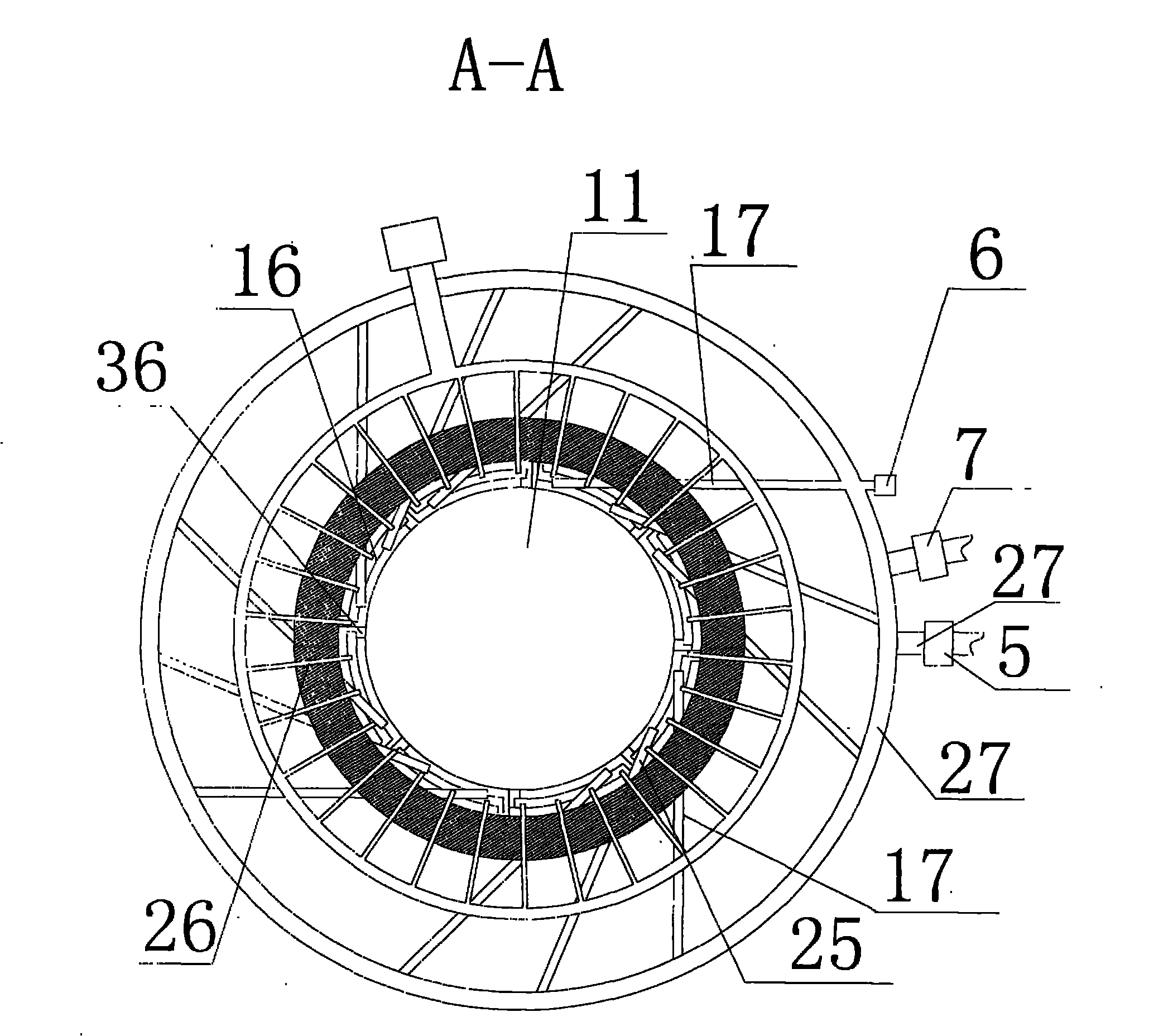

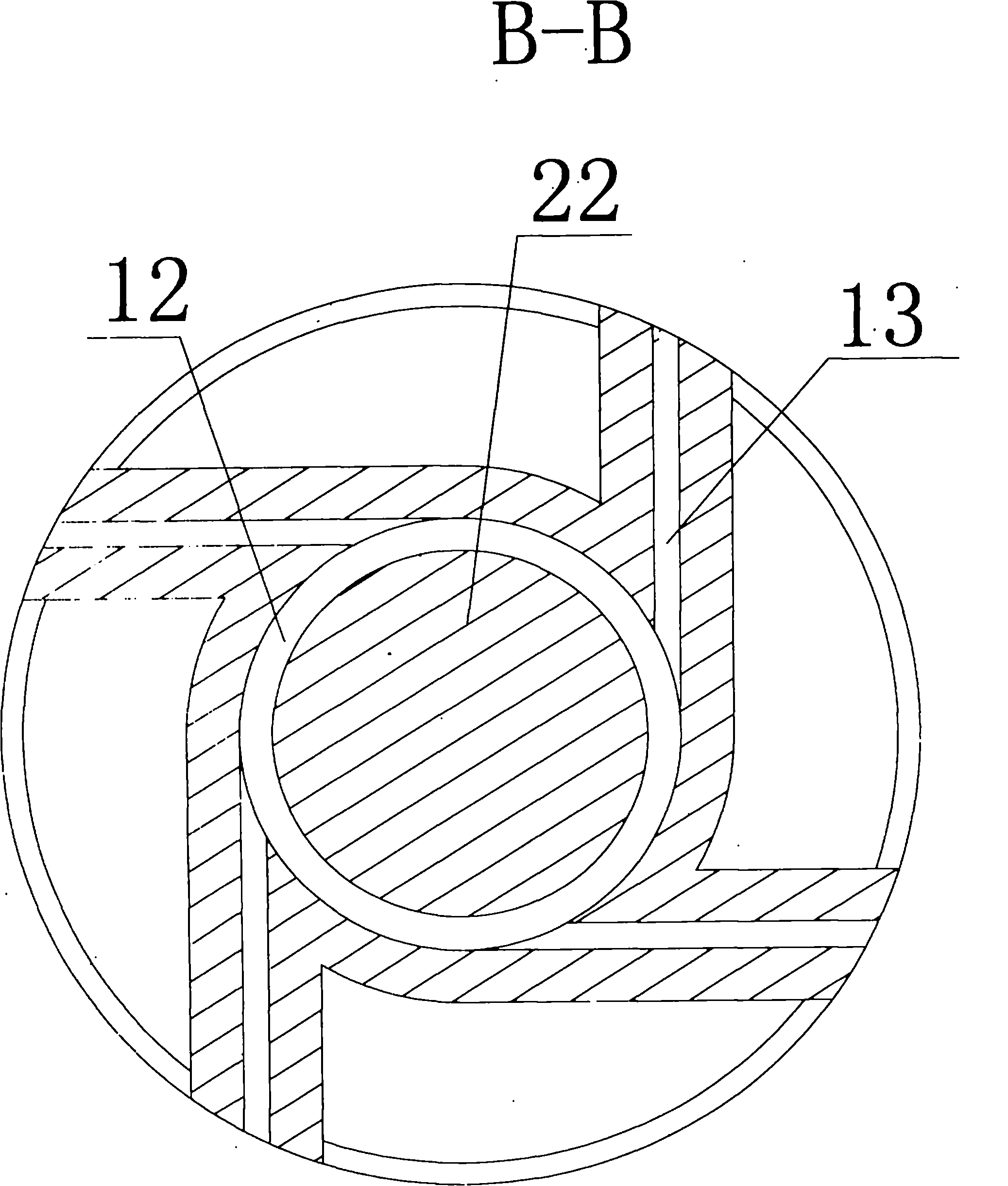

Smelting furnace

InactiveCN102121788AReduce pollutionReduce wasteVertical furnacesCeramic materials productionSteelmakingInlet channel

The invention provides a smelting furnace. The smelting furnace comprises refractory materials, heat insulating materials, a blower, a pipeline, valves, ignition devices, fuel supply devices and temperature measuring devices. The smelting furnace is characterized in that a furnace chamber is provided with a heating chamber and a smelting chamber; the lower part of the heating chamber is communicated with the smelting chamber; the lower part of the smelting chamber is provided with a hearth; the hearth is provided with hearth discharge holes; the upper part of the heating chamber is provided with a heating chamber feeding hole and a heating chamber gas outlet; at least a flame path is arranged around the inner wall of the smelting chamber; at least an inlet channel is arranged on the side walls of the flame paths; and the inlet channels are communicated with the flame paths. The smelting furnace is energy-saving and environment-friendly, can be used for smelting various metals and alloys, can be used for smelting aluminium by a fire method and can be used for refining aluminium alloys. The smelting furnace can adopt any mineral for smelting, can realize carbothermal reduction of any metallic oxide and can smelt alloys even with soil or garbage, so the smelting furnace can turn stone and soil into gold and is true alchemy. The smelting furnace dispenses with cokes and synchronously completes ironmaking and steelmaking. The heat generated through steelmaking is fully utilized and the waste gases are unitedly treated. The smelting furnace can be used for producing glass, ceramic frits, sodium silicate and the like. The smelting furnace can adopt various materials, can refine precious elements, does not produce slag and can bring metallurgy revolution.

Owner:陈久斌

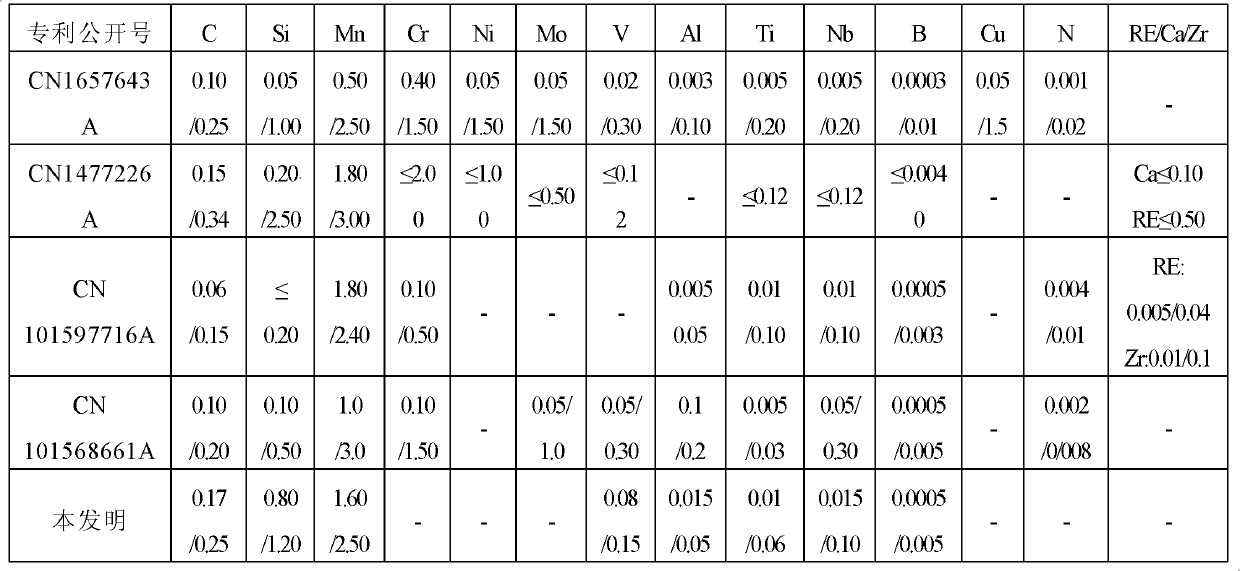

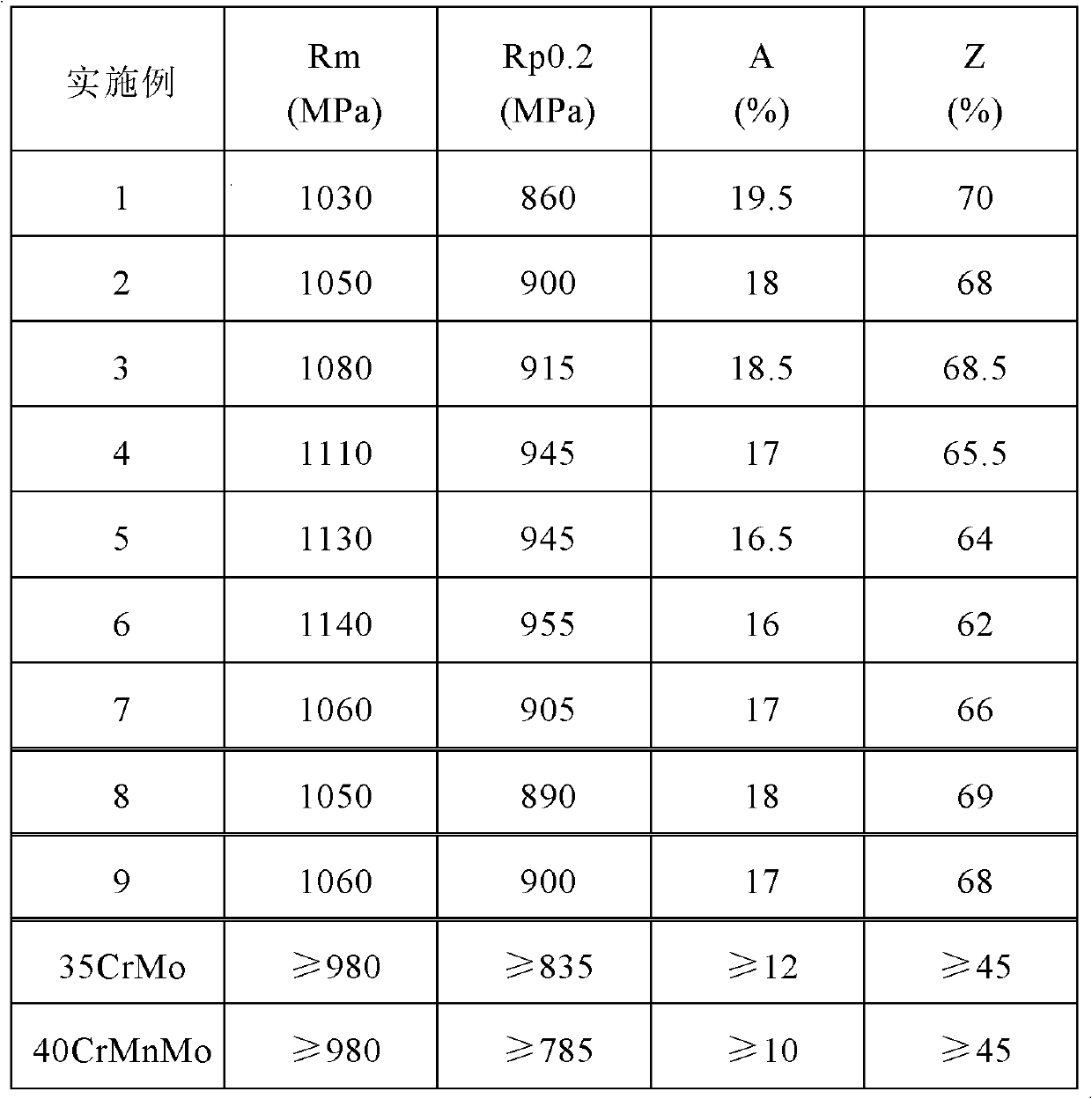

Manganese and boron series low-carbon microalloy high-strength non-quenched and tempered steel and production method thereof

The invention discloses manganese and boron series low-carbon microalloy high-strength non-quenched and tempered steel and a production method thereof. The non-quenched and tempered steel comprises the following chemical components in percentage by weight: 0.17 to 0.25 percent of C, 0.80 to 1.20 percent of Si, 1.60 to 2.50 percent of Mn, 0.08 to 0.15 percent of V, 0.015 to 0.10 percent of Nb, 0.01 to 0.06 percent of Ti, 0.015 to 0.05 percent of Al, 0.0005 to 0.005 percent of B and the balance of Fe and inevitable impurities, wherein the total percentage of impurity elements is less than 0.05 percent. Elements, such as N, RE, Ca, Zr and the like, which are not easy to control in a smelting process, are not required to be added into the steel, and a quenching and tempering procedure is eliminated, so that the production process is simplified, the production efficiency is improved, and the production cost is reduced.

Owner:宝钢特钢有限公司

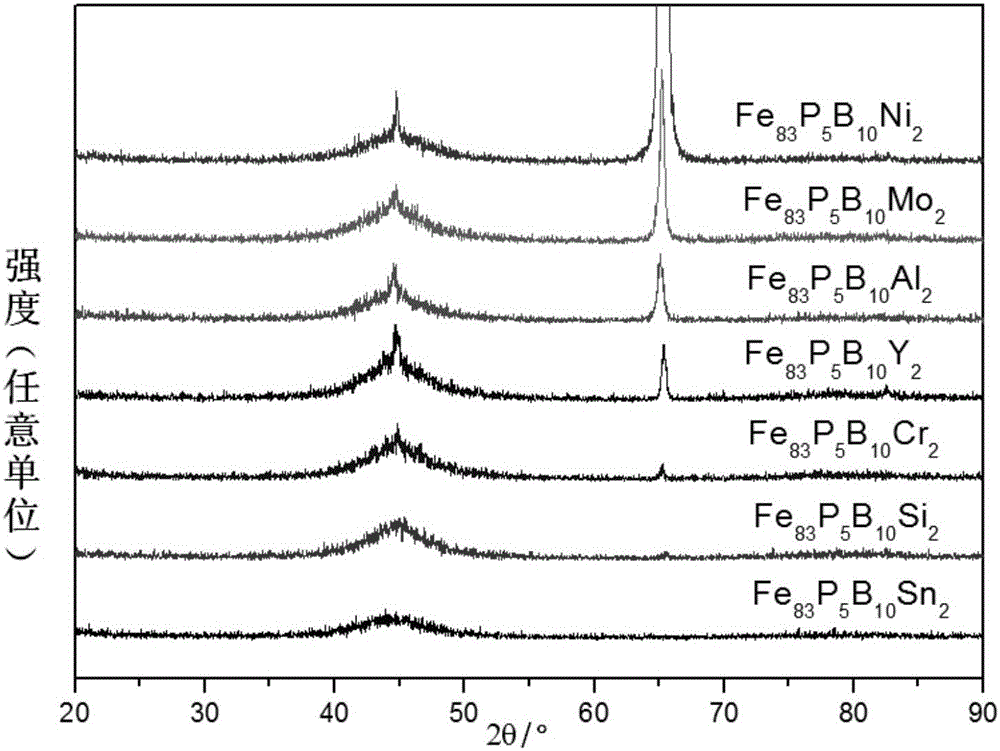

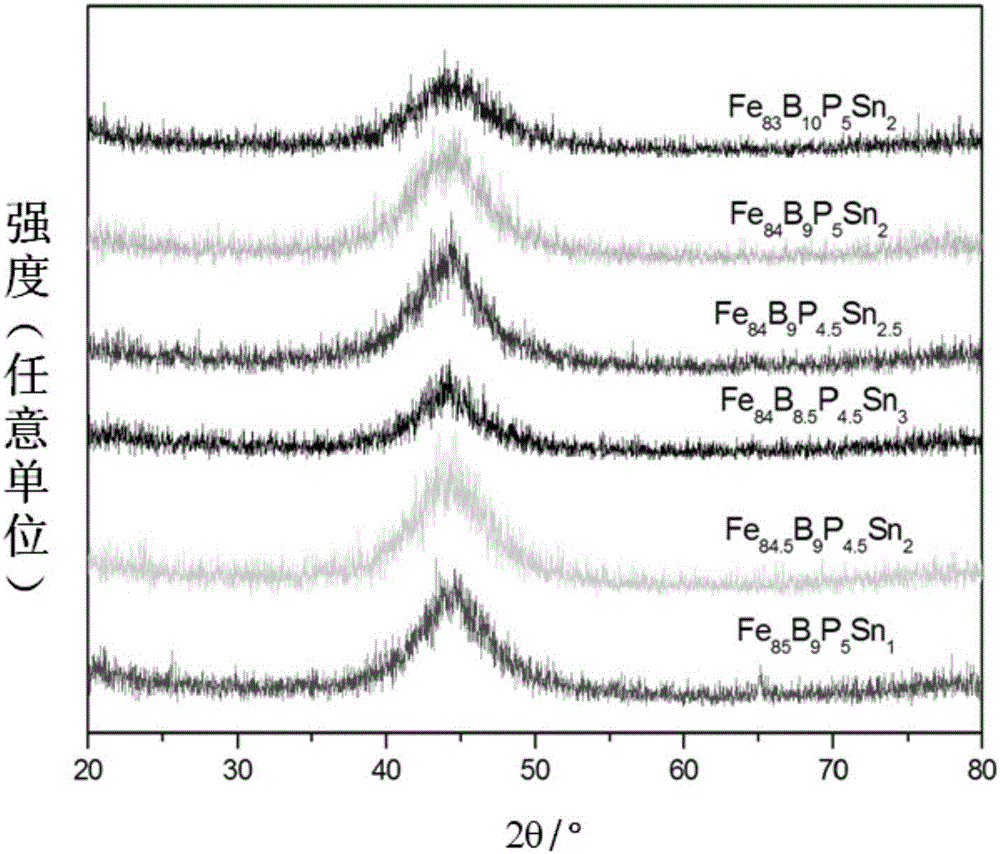

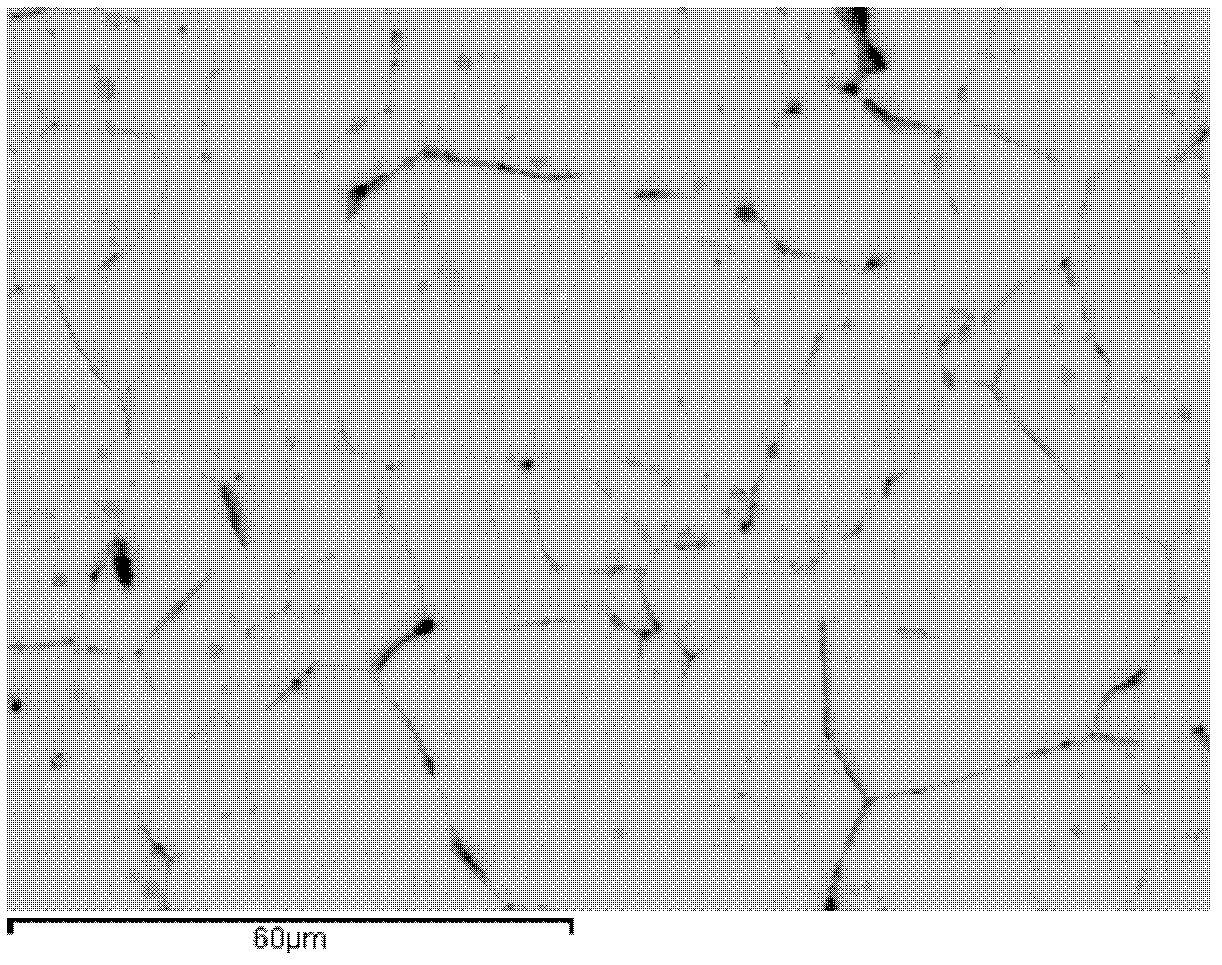

Iron-based soft-magnet amorphous alloy with less components, low cost and high saturation magnetic induction intensity and manufacturing process thereof

The invention belongs to the field of metal materials, and relates to an iron-based soft-magnet amorphous alloy with less components, low cost and high saturation magnetic induction intensity and a manufacturing process thereof. The iron-based soft-magnet amorphous alloy is prepared from the following components in atom percentage: greater than or equal to 5 percent and less than or equal to 12 percent of boron, greater than or equal to 3 percent and less than or equal to 10 percent of phosphorus, greater than or equal to 0.5 percent and less than or equal to 5 percent of tin, and greater than or equal to 80 percent and less than or equal to 84.5 percent of iron. The iron-based soft-magnet amorphous alloy is low in production cost, and is simple in process; the prepared iron-based soft-magnet amorphous alloy has the characteristics of high saturation magnetic induction intensity and low coercive force, is suitable for devices such as transformer cores, amorphous motors and the like, and is applied to the field of electric power, electronics, information, communication and the like.

Owner:SHANDONG UNIV

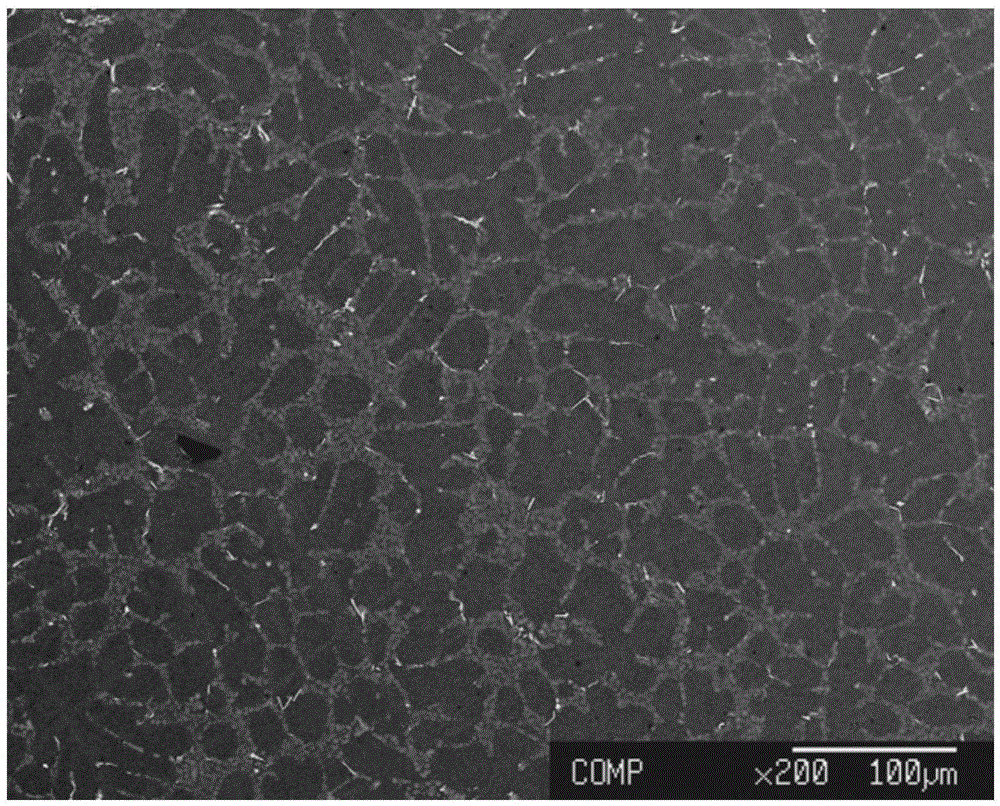

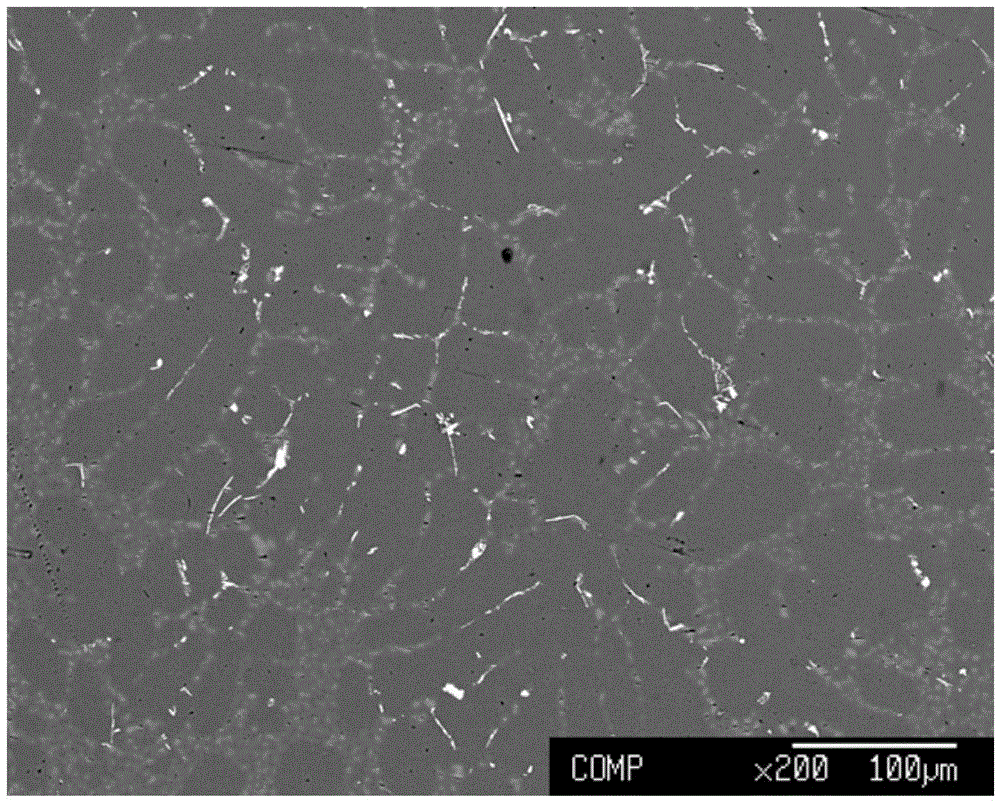

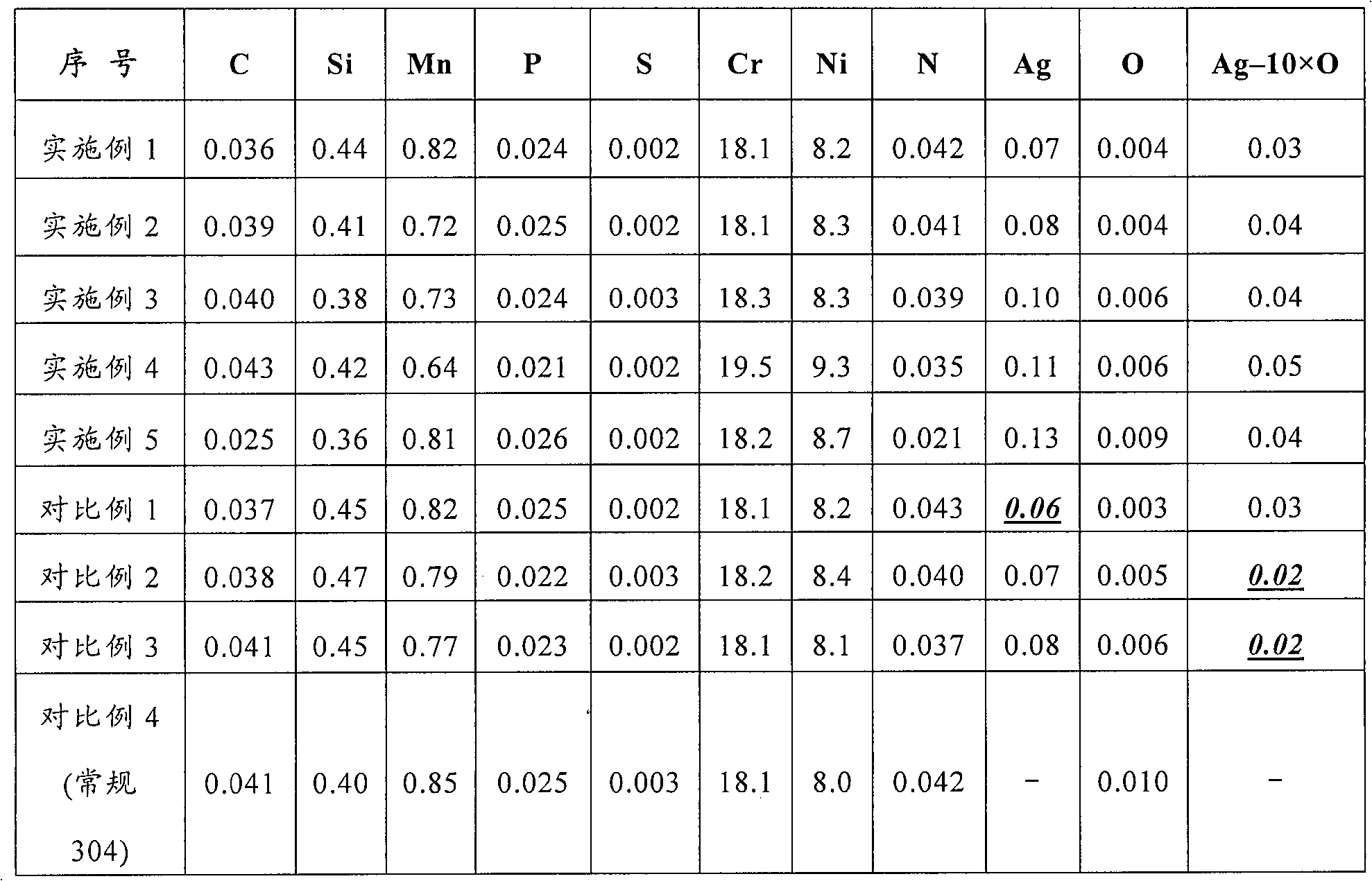

Silver-containing austenitic antimicrobial stainless steel and manufacturing method thereof

InactiveCN102534410ASimple smelting processImprove mechanical propertiesOxygenArgon oxygen decarburization

The invention relates to a silver-containing austenitic antimicrobial stainless steel which comprises the following chemical components in percentage by weight: at most 0.05% of C, at most 0.5% of Si, at most 1.0% of Mn, at most 0.03% of P, at most 0.005% of S, 8.0-10.0% of Ni, 18.0-20.0% of Cr, at most 0.05% of N, 0.07-0.13% of Ag, at most 0.01% of O, at least 0.03% of (Ag-10*O) and the balance of Fe and inevitable impurities. The manufacturing method of the stainless steel comprises the following steps: smelting stainless steel in an electric furnace-AOD (argon oxygen decarburization) or electric furnace-AOD-VOD (vacuum oxygen decarburization) mode, and continuously casting into a steel billet; carrying out hot rolling, wherein the initial temperature of hot rolling is 1200-1250 DEG C; and annealing by keeping the temperature of 1050-1100 DEG C for 1-2 minutes. The silver-containing austenitic stainless steel has the advantages of simple and effective smelting technique, favorable mechanical properties, favorable corrosion resistance and excellent antimicrobial performance.

Owner:BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com