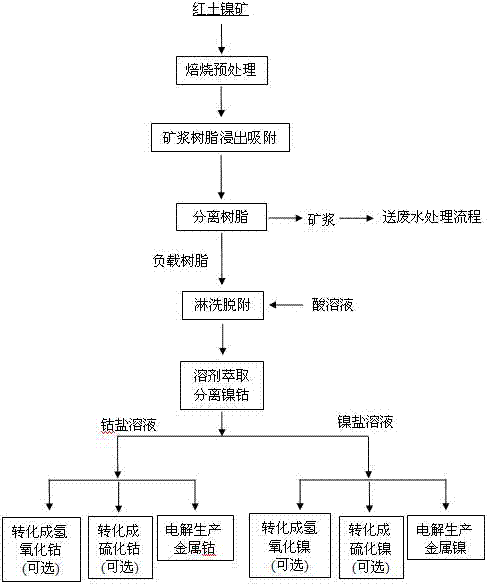

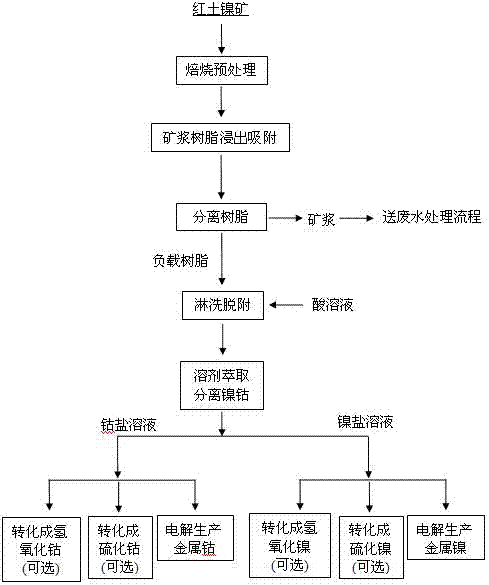

A kind of method that extracts cobalt nickel from laterite nickel ore

A laterite nickel ore, nickel-cobalt technology, applied in the smelting process field of laterite nickel ore wet extraction of cobalt and nickel, can solve the problems of multiple chemical materials, increase processing procedures and equipment, and have no advantages, and achieve simple operation and water reduction The effect of high consumption and recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

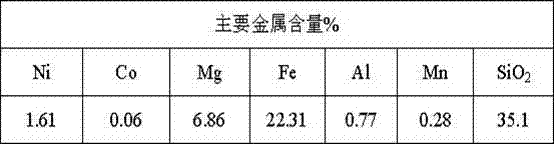

[0052] A limonite-type lateritic nickel ore, the dry ore is ground to a particle size of -100 mesh, and the main components in the ore are as follows through analysis and testing:

[0053]

[0054] Stoichiometric sulfuric acid consumption is calculated as follows:

[0055]

[0056] Do the test according to the following scheme: weigh 100 grams of 4 parts of the above mineral powder and 4 parts containing 80 grams of H 2 SO 4 After the concentrated sulfuric acid is mixed evenly, put the paste into a ceramic boat, put it into a tube-type electric furnace with a diameter of φ60mm and roast it twice, and then heat up to the temperature required for the second roasting after the first roasting is completed. In the second roasting process, 50%Vol.SO was introduced at a flow rate of 2 liters / minute 2 SO 2 The mixed gas with air, the roasting conditions are shown in the table below:

[0057]

[0058] After the above roasted materials are cooled and finely ground, put them...

Embodiment 5

[0061] Put 500g of roasted limonite-type laterite nickel mineral material (ground to -200 mesh particle size) into a small stirring tank, add water and stir to make a slurry, adjust it into a slurry with a solid content of 10%, and test the material according to the analysis Add 1.5 grams of sodium sulfide to 1.5 times the copper content (molar mass) and about 4 grams of sodium sulfite. The amount of sodium sulfite added is based on the qualitative detection of the absence of ferric ions in the pulp. Then adjust the pH value of the pulp to 2.0, add 800 grams of pretreated Dowex M4195 resin to the pulp, stir and mix gently at room temperature, stop leaching after the reaction lasts for 1 hour, and use a 50-mesh stainless steel screen of American Standard to remove the pulp from the pulp Sieve out the resin, wash the mud attached to the resin with water, put the resin into the exchange column and use 1mol / L H 2 SO 4 The concentration of sulfuric acid solution to elute the depos...

Embodiment 6

[0065] Add 300g of roasted limonite-type laterite nickel mineral material to make a slurry with a solid content of 30%. At this time, the pH of the slurry is about 2.1. Adjust the pH to 3.0 with lye, stir for 30 minutes, and then add 400mL of wet WP-2 resin with a particle size of 350-650μm, stirred and mixed gently for 3 hours, separated the resin from the pulp with a 50-mesh screen, washed the pulp on the resin with water, and used 1.6 liters of 60g / L resin first The hydrochloric acid solution of HCl was used to wash off the nickel and cobalt, and then the resin was washed with 1.6 liters of water. The residual slurry after adsorption, the obtained eluent, and its components are shown in the table below.

[0066]

[0067] It can be seen from the data in the table that the rate of recovery of nickel and cobalt is higher, and the rate of recovery of iron and magnesium is very small. The small rate of recovery of iron here is not entirely the cause of the resin. Most of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com