Iron-based soft-magnet amorphous alloy with less components, low cost and high saturation magnetic induction intensity and manufacturing process thereof

An amorphous alloy and a preparation process technology, applied in the field of iron-based soft magnetic amorphous alloy and its preparation technology, can solve the influence of alloy amorphous formation ability and soft magnetic performance, unfavorable control of product composition stability, difficult control of composition, etc. problems, to achieve the effect of easy industrialization, excellent soft magnetic properties, and reduced impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

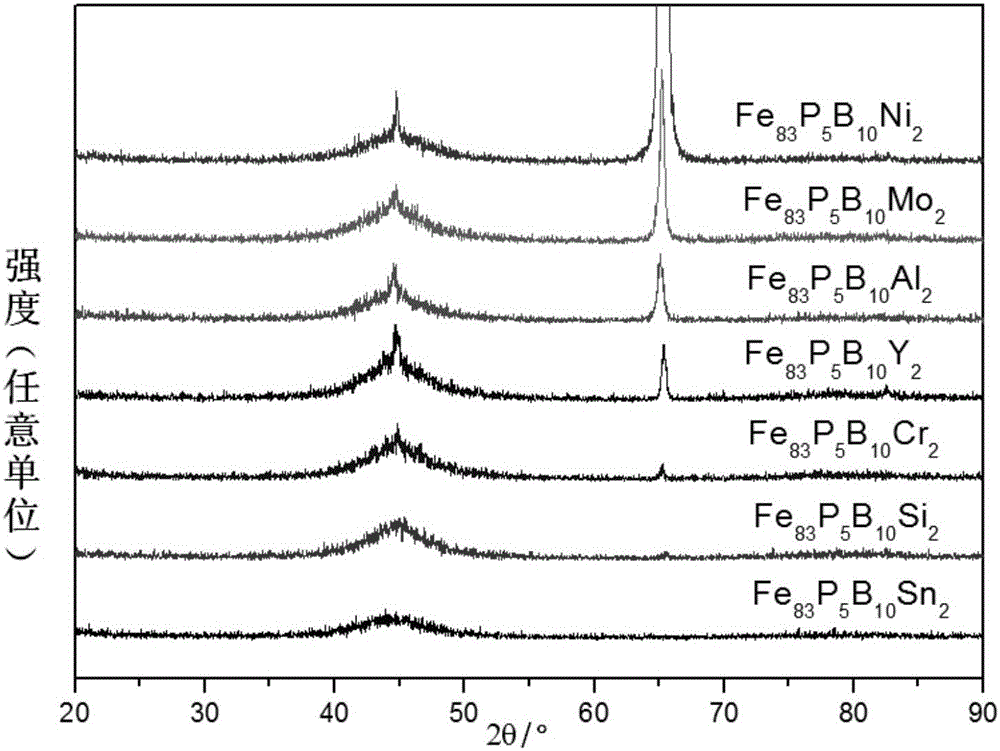

[0022] An iron-based soft magnetic amorphous alloy contains boron, phosphorus and tin elements, and the atomic percentages of each element in the alloy are as follows: 10% boron, 5% phosphorus, 2% tin and 83% iron.

[0023] The preparation steps are as follows:

[0024] (1) The raw materials are pure iron (99.99%), pure tin (99.9%), industrial-grade iron-phosphorus master alloy (the mass percentage of phosphorus is 25.1%), and industrial-grade iron-boron master alloy (the mass percentage of B is 18.9%);

[0025] Use a balance to weigh raw materials according to the atomic percentages of Fe83%, B10%, P5%, and Sn2%, which are Fe: 8.67g, Fe-P master alloy: 1.44g, Fe-B master alloy: 1.33g; Sn: 0.55g ;

[0026] (2) Put the raw materials into the glass tube in the vacuum induction melting furnace, and use a mechanical pump and a molecular pump to evacuate to 2×10 -3 Pa, filled with high-purity argon for arc smelting; after smelting, take it out and smash it to check whether there ...

Embodiment 2

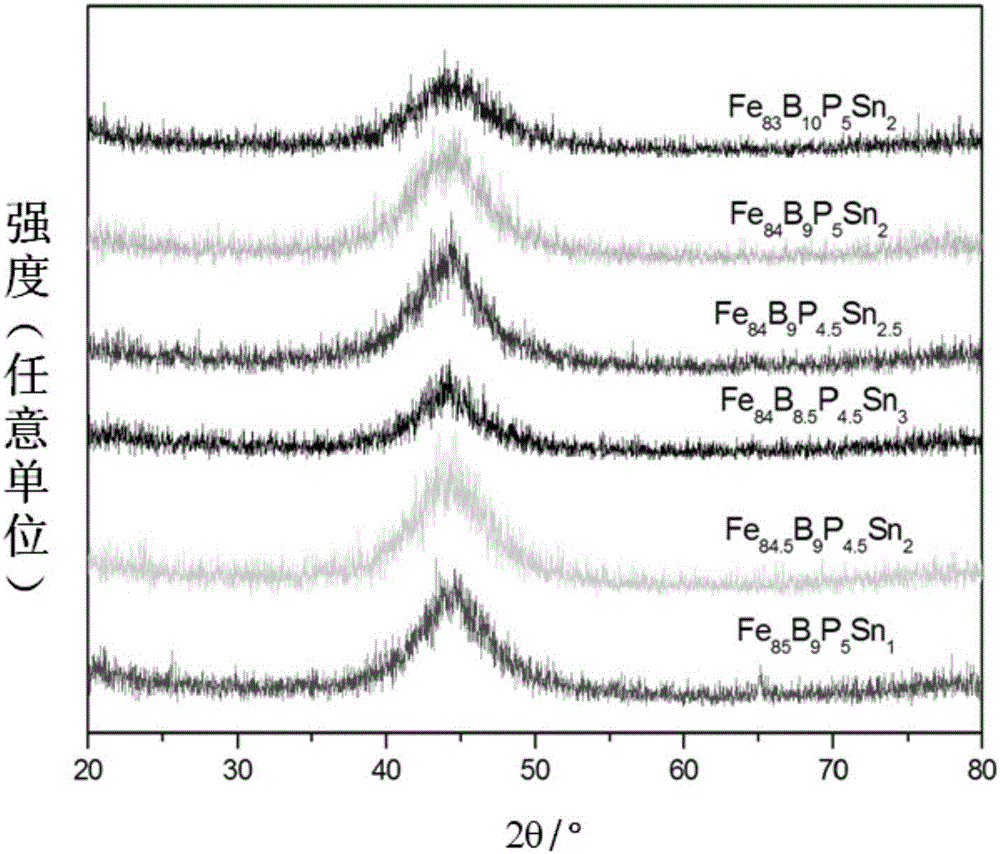

[0031] An iron-based soft magnetic amorphous alloy contains boron, phosphorus and tin elements, and the atomic percentage of each element in the alloy is as follows: boron 8.5%, phosphorus 4.5%, tin 3%, iron 84%.

[0032] The preparation steps are as follows:

[0033] (1) The raw materials are pure iron (99.99%), pure tin (99.99%), industrial-grade iron-phosphorus master alloy (the mass percentage of phosphorus is 25.1%), and industrial-grade iron-boron master alloy (the mass percentage of B is 18%);

[0034] Use a balance to weigh the raw materials according to the atomic percentages of Fe84%, B8.5%, P4.5%, and Sn3%, which are Fe: 8.82g, Fe-P master alloy: 1.26g, Fe-B master alloy: 1.1g; Sn: 0.81g;

[0035] (2) Put the raw materials into the glass tube in the vacuum induction melting furnace, and use a mechanical pump and a molecular pump to evacuate to 2×10 -3 Pa, filled with high-purity argon for arc smelting; after smelting, take it out and smash it to check whether ther...

Embodiment 3

[0040] An iron-based soft magnetic amorphous alloy contains boron, phosphorus and tin elements, and the atomic percentages of each element in the alloy are as follows: boron 9%, phosphorus 4.5%, tin 2%, iron 84.5%.

[0041] The preparation steps are as follows:

[0042] (1) The raw materials are pure iron (99.99%), pure tin (99.99%), industrial-grade iron-phosphorus master alloy (P mass percentage is 25.1%), industrial-grade iron-boron master alloy (B mass percentage is 18.9%);

[0043] Use a balance to weigh the raw materials according to the atomic percentages of Fe84.5%, B9%, P4.5%, and Sn2%, which are Fe: 8.98g, Fe-P master alloy: 1.28g, Fe-B master alloy: 1.19g; Sn: 0.55g;

[0044] (2) Put the raw materials into the glass tube in the vacuum induction melting furnace, and use a mechanical pump and a molecular pump to evacuate to 2×10 -3 Pa, filled with high-purity argon for arc smelting; after smelting, take it out and smash it to check whether there are unmelted raw mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com