Manganese and boron series low-carbon microalloy high-strength non-quenched and tempered steel and production method thereof

A non-quenched and tempered steel, production method technology, applied in the field of alloy steel, can solve the problems of increased production cost, high production cost, complex manufacturing process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with embodiment.

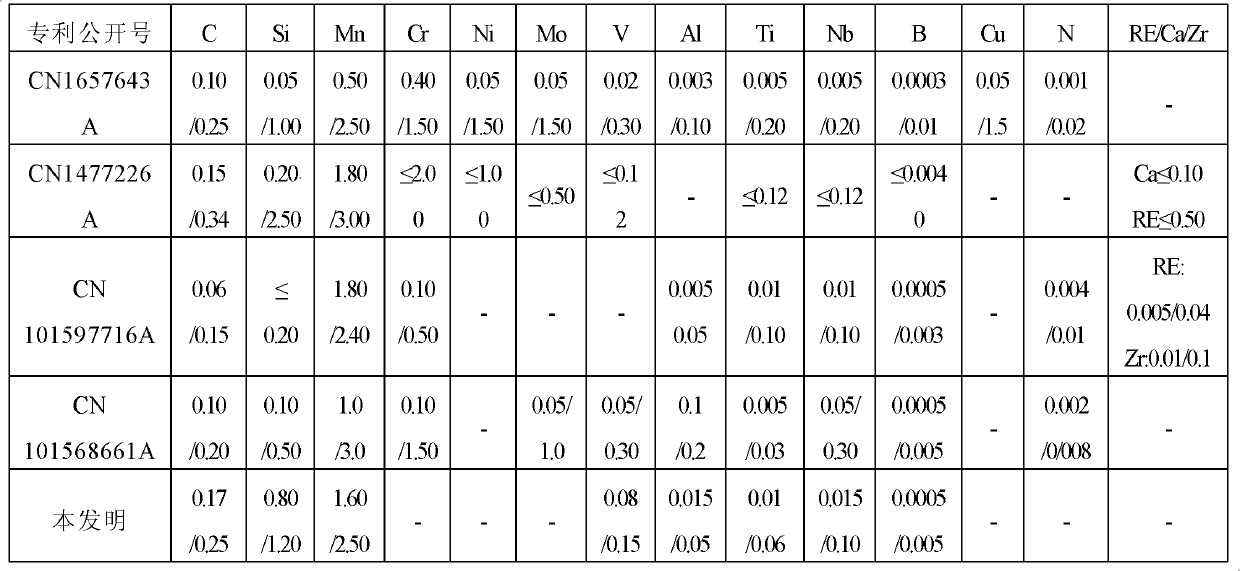

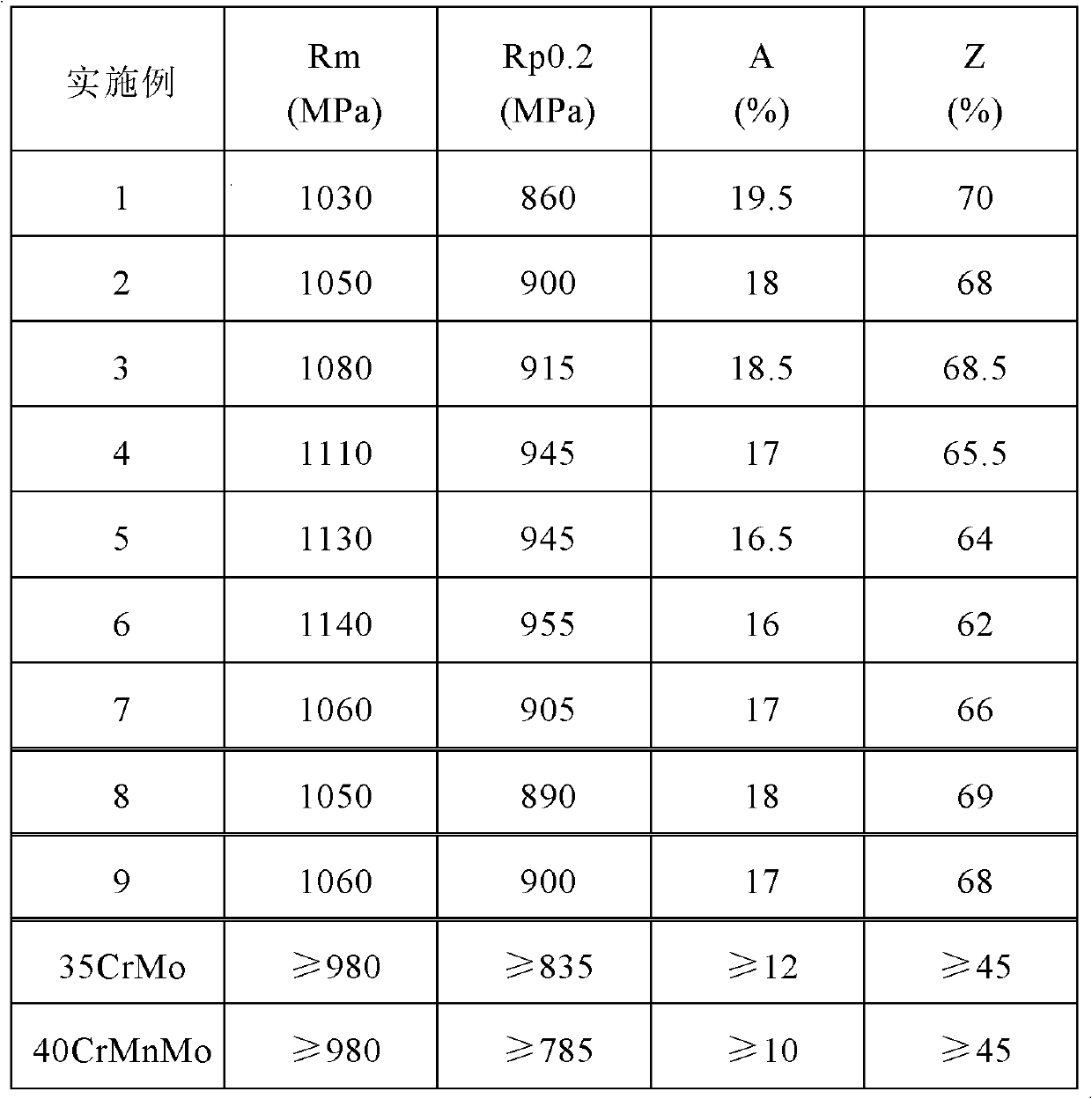

[0023] The chemical composition designed by the present invention and the specific composition of the production method embodiment are shown in Table 2. The alloys were sampled and subjected to tensile tests at room temperature, and the results are shown in Table 3.

[0024] For ease of comparison, the performance indicators of 35CrMo and 40CrMnMo are also listed in the table.

[0025] As can be seen from Table 3, the non-quenched and tempered alloy steel of the present invention can obtain excellent performance indicators after smelting, controlled rolling and controlled cooling, its Rm≥1000MPa, A≥15%, Z≥50%, and its tensile strength It meets the requirements of 35CrMo and 40CrMnMo steel ≥ 980MPa, and the plasticity index far exceeds the requirements of 35CrMo and 40CrMnMo steel, which greatly improves the safety of use, and the manufacturing cost is low. It can be widely used in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com