Silver-containing austenitic antimicrobial stainless steel and manufacturing method thereof

An antibacterial stainless steel and austenitic technology, which is applied in the field of silver-containing austenitic antibacterial stainless steel and its manufacturing, can solve the problems of material processing and performance impact, increase raw material cost, and adverse effects of stainless steel thermal processing performance, etc., to achieve excellent antibacterial Excellent performance, mechanical properties and corrosion resistance, simple and effective smelting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

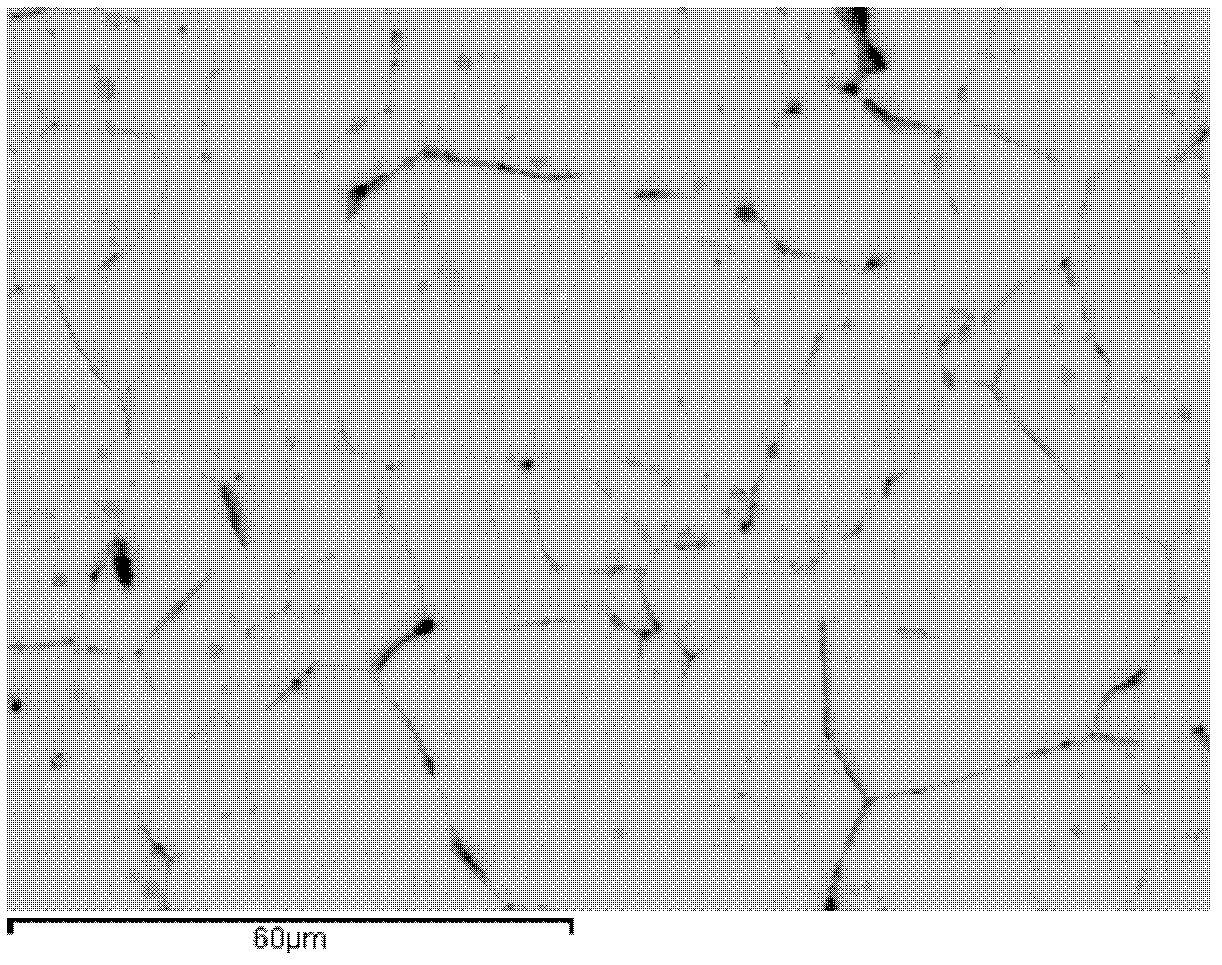

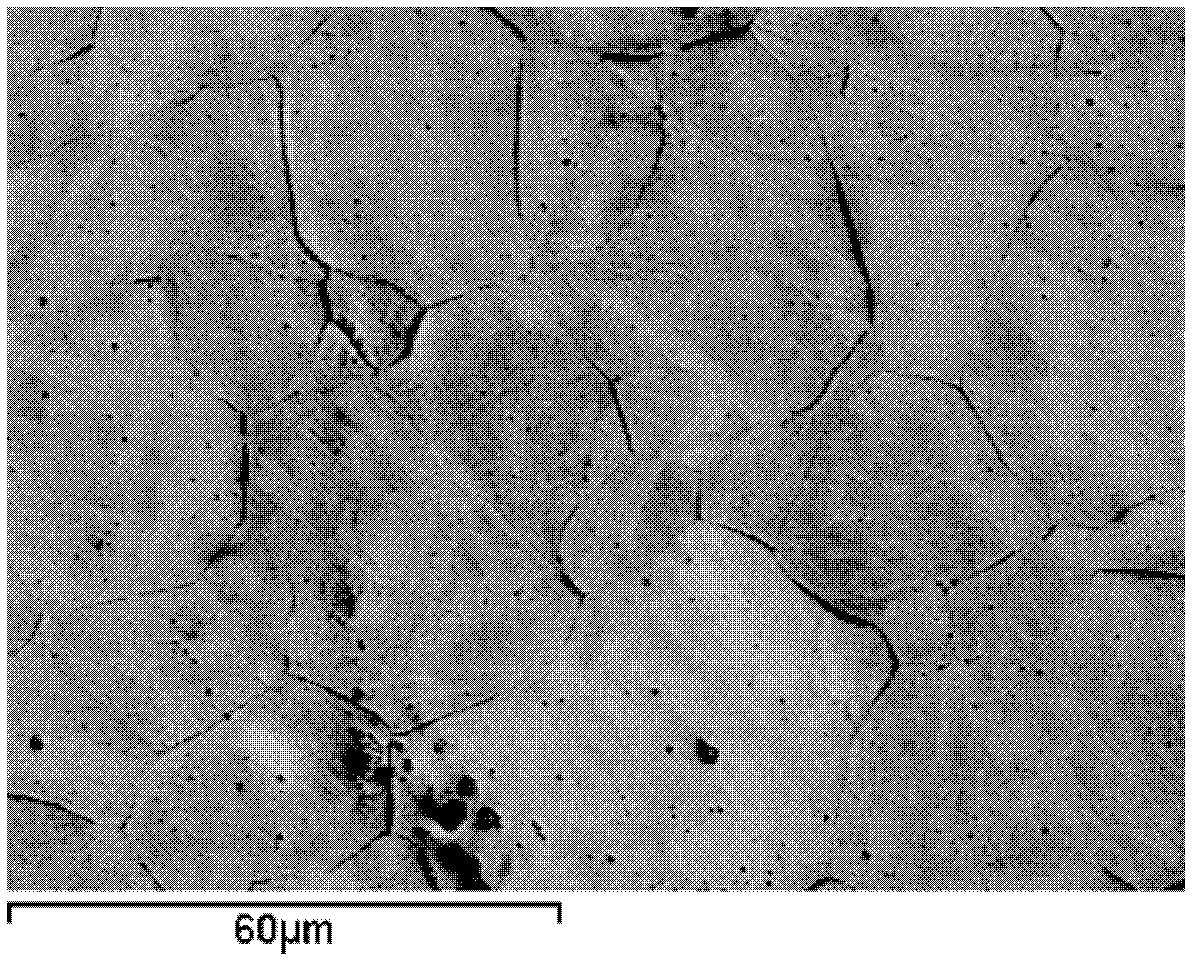

Image

Examples

Embodiment

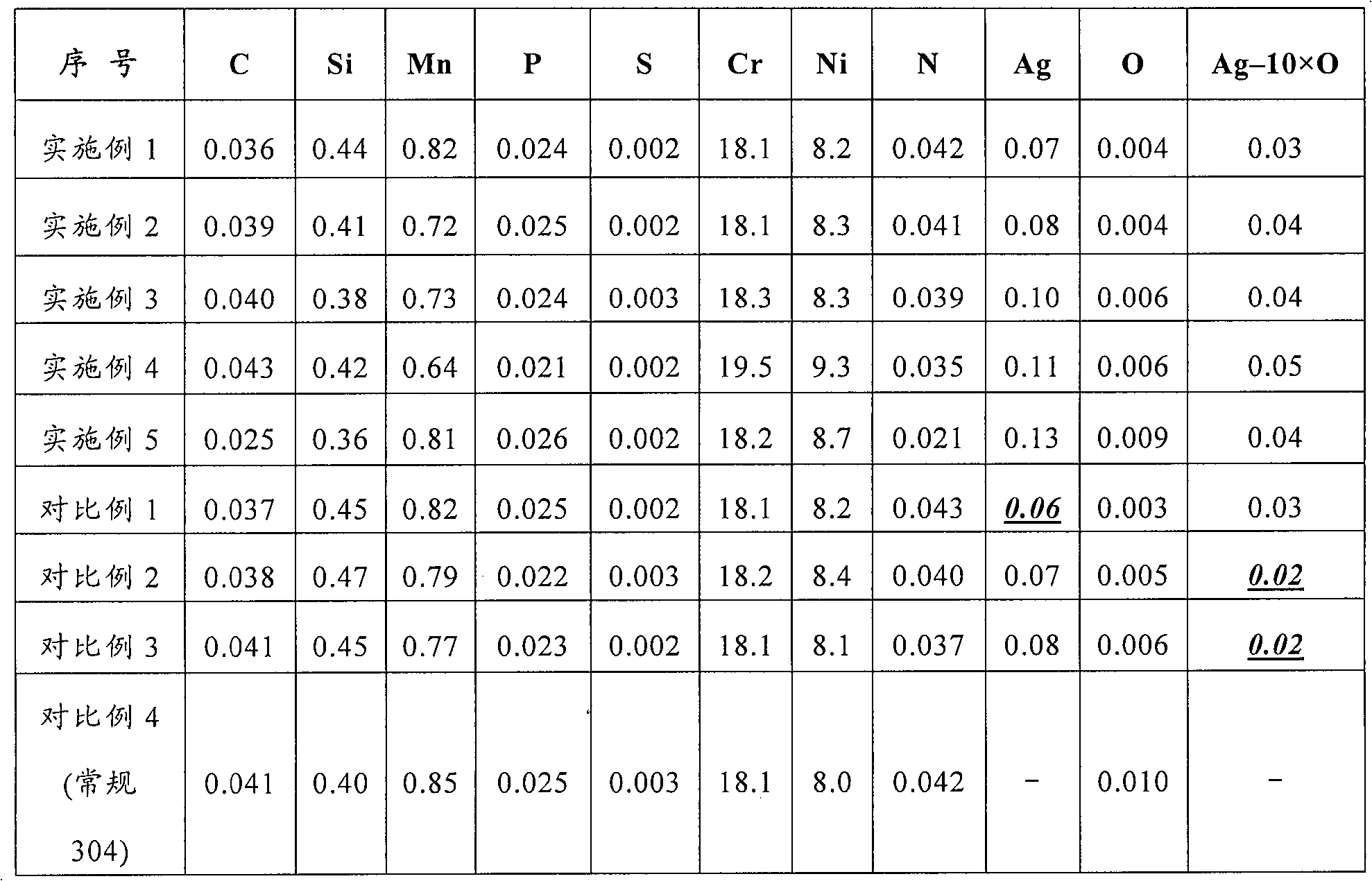

[0031] The chemical composition of the stainless steel used in the test is shown in Table 1.

[0032] Table 1 The chemical composition of the steel of the embodiment of the present invention and the steel of the comparative example, % by weight

[0033]

[0034] Note: numbers in bold italics are beyond the scope of the present invention.

[0035] First, two elements, Ag and Ni, are smelted in a certain proportion to form an intermediate alloy, which is added to the raw material of antibacterial stainless steel as an ingredient. Then use electric furnace-AOD to smelt stainless steel, continuously cast slabs, and the thickness of the slab is 200mm; hot-rolled to 4mm thick, the initial temperature of hot rolling is 1250°C; heat at 1050°C for 1 minute annealing + pickling, cold-rolled to 1mm thick, and then 1050°C Heat preservation for 1 minute annealing + pickling, polishing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com