Method for preparing high-strength and toughness magnesium alloy containing LPSO structure through magnetic field casting regulation

A tough magnesium alloy and magnesium alloy technology, which is applied in the field of magnetic field casting to control the preparation of high-strength and tough magnesium alloys containing LPSO structure, can solve the problem of not preparing nano-scale LPSO structure, and achieve the optimization of melting process, high efficiency, and improved strength and plasticity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

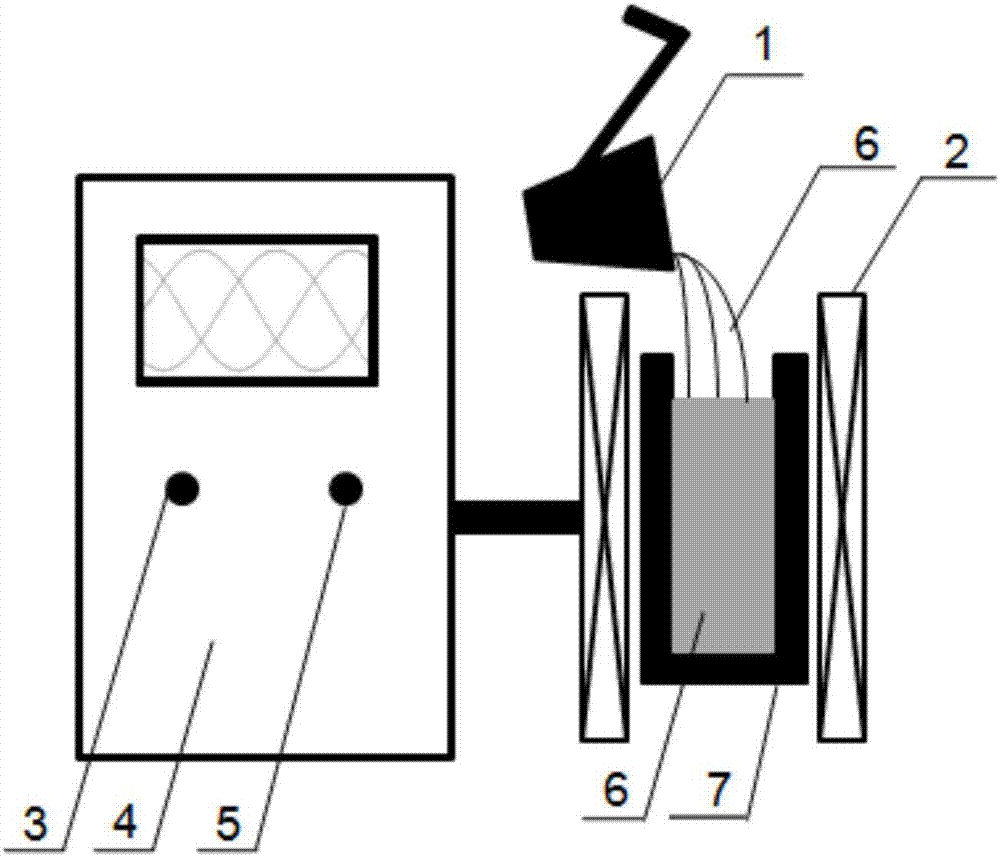

Method used

Image

Examples

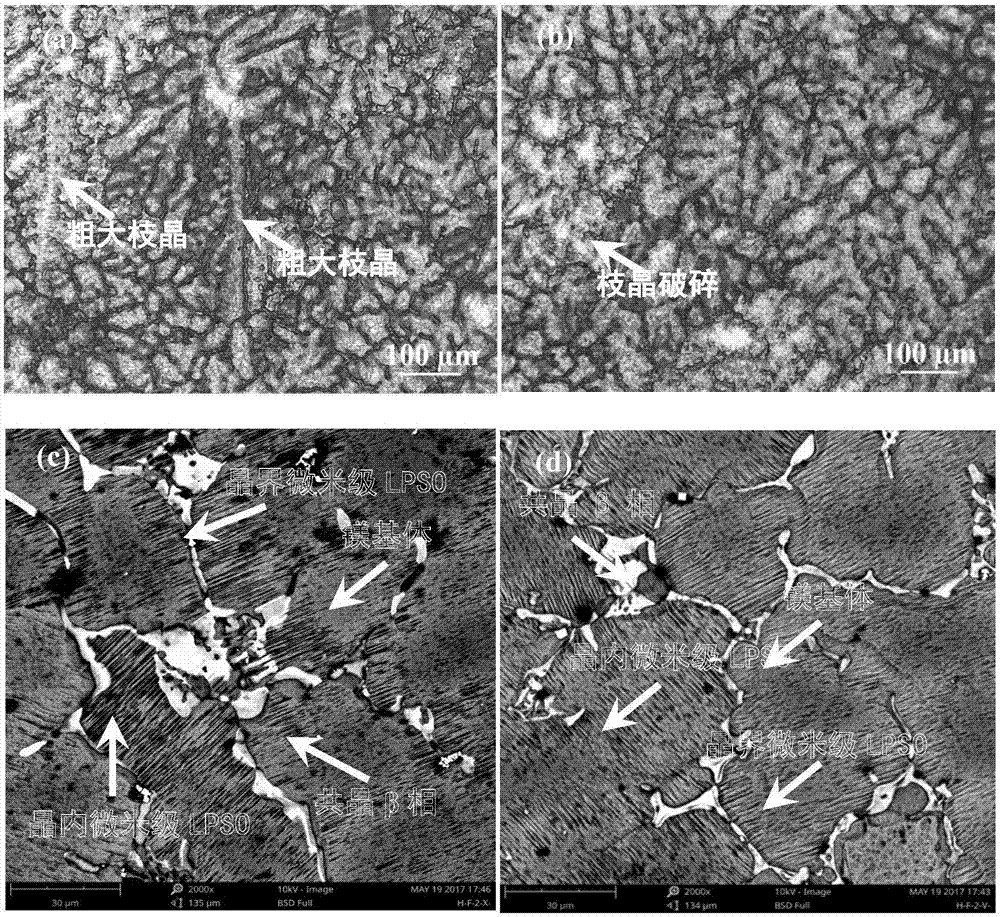

Embodiment 1

[0047] This embodiment provides a method for preparing a high-strength and tough magnesium alloy containing LPSO structure controlled by magnetic field casting, and specifically adopts the following steps:

[0048] 1) Use pure magnesium (Mg purity greater than or equal to 99.95%), Mg-20Gd (mass percentage) master alloy, pure zinc (Zn purity greater than or equal to 99.99%), according to Mg-1Gd-1Zn (atomic percentage) alloy composition distribution Ratio (reasonable impurities are not considered, when selecting raw materials, raw materials with less impurities should be selected as much as possible).

[0049] 2) The crucible used in the experiment needs to be cleaned in advance until there is no obvious residue attached to the wall and bottom of the crucible, and the stirring spoon and skimming spoon required for the experiment should be brushed and dried upside down. Mix a certain amount of talcum powder, water glass and water together to make a viscous paint, and then evenly ...

Embodiment 2

[0057] This embodiment provides a method for preparing a high-strength and tough magnesium alloy containing LPSO structure controlled by magnetic field casting, and specifically adopts the following steps:

[0058] 1) Using pure magnesium (Mg purity greater than or equal to 99.95%), Mg-50Gd (mass percentage) master alloy, pure zinc (Zn purity greater than or equal to 99.99%), according to Mg-2.5Gd-1Zn (atomic percentage) alloy composition Distribution ratio (reasonable impurities are not considered, when selecting raw materials, raw materials with less impurities should be selected as much as possible).

[0059] 2) The crucible used in the experiment needs to be cleaned in advance until there is no obvious residue attached to the wall and bottom of the crucible, and the stirring spoon and skimming spoon required for the experiment should be brushed and dried upside down. Mix a certain amount of talcum powder, water glass and water together to make a viscous paint, and then eve...

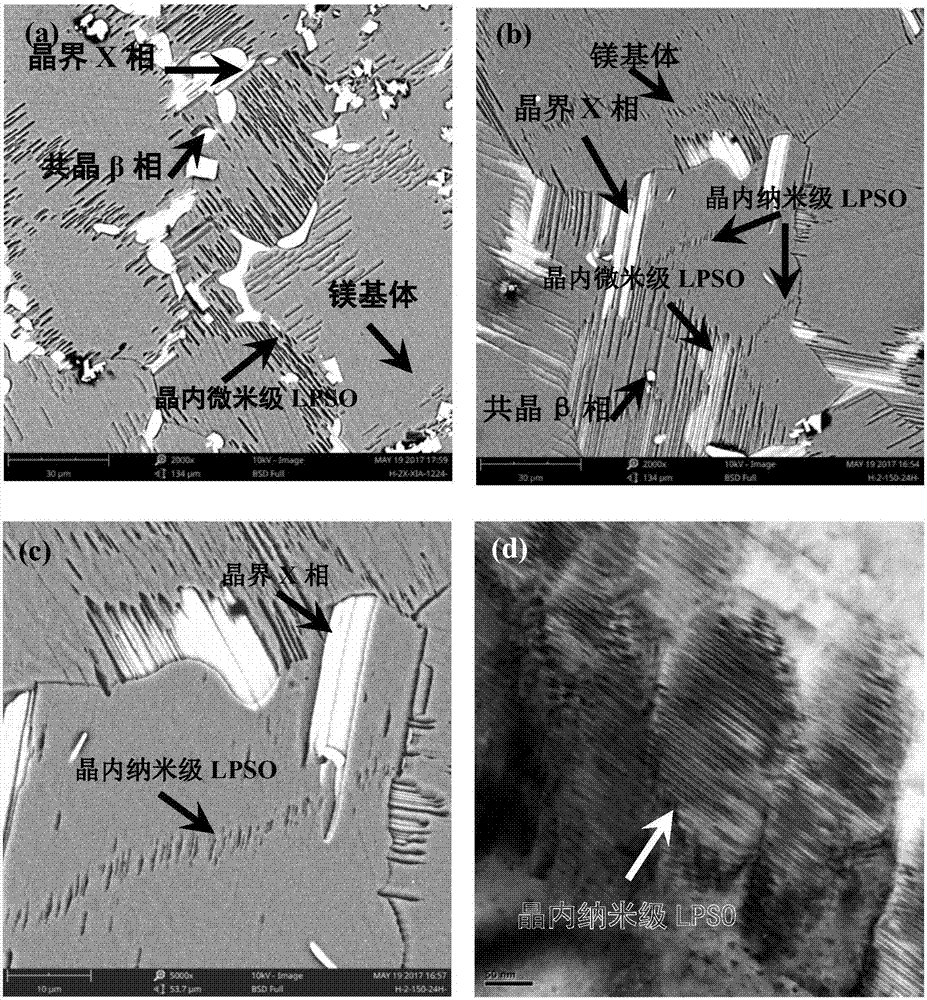

Embodiment 3

[0067] This embodiment provides a method for preparing a high-strength and tough magnesium alloy containing LPSO structure controlled by magnetic field casting, and specifically adopts the following steps:

[0068] 1) Using pure magnesium (Mg purity greater than or equal to 99.95%), Mg-90Gd (mass fraction) master alloy, pure zinc (Zn purity greater than or equal to 99.99%), according to Mg-2.67Gd-0.43Zn (atomic percentage) alloy Composition ratio (reasonable impurities are not considered, when selecting raw materials, raw materials with less impurities should be selected as much as possible).

[0069] 2) The crucible used in the experiment needs to be cleaned in advance until there is no obvious residue attached to the wall and bottom of the crucible, and the stirring spoon and skimming spoon required for the experiment should be brushed and dried upside down. Mix a certain amount of talcum powder, water glass and water together to make a viscous paint, and then evenly brush a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com