Low-cost high-compression-strength wrought magnesium alloy and preparation method thereof

A wrought magnesium alloy and high compression technology, applied in the field of magnesium alloys, can solve problems such as limiting the scope of use of wrought magnesium alloys, and achieve the effects of increased preparation cost and simple smelting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

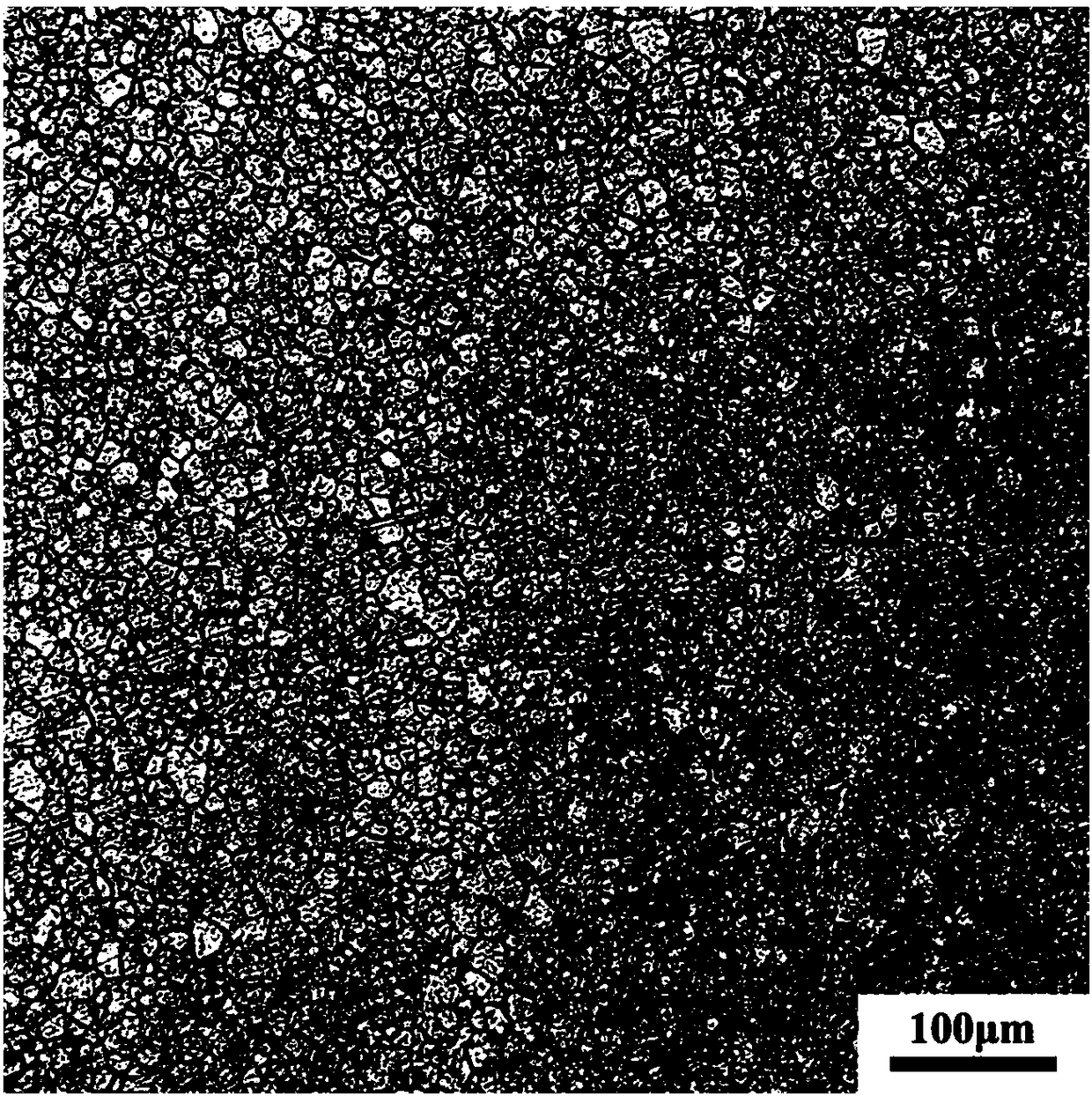

Embodiment 1

[0024] A multi-element composite strengthened high-strength magnesium alloy, the magnesium alloy raw material element content is as follows in terms of mass percentage: Zn element content 6.0%, the balance is Mg.

[0025] A method for preparing a multi-element composite strengthened high-strength magnesium alloy, comprising the following steps:

[0026] 1) Weigh the magnesium ingot according to the alloy composition, melt it at 690°C-710°C, add pure Zn after the magnesium ingot is melted, keep it warm for 30 minutes, then control the temperature of the furnace body at 700°C, and continue to pass through the melt Inject argon for 15 minutes to refine the alloy, then remove the slag from the alloy melt and let it stand at 690°C-710°C for 30 minutes to allow impurities to settle; finally cast semi-continuously at 675°C-685°C to obtain a semi-continuous ingot;

[0027] 2) The semi-continuous ingot obtained in step 1) is subjected to extrusion treatment. The specific method is: hea...

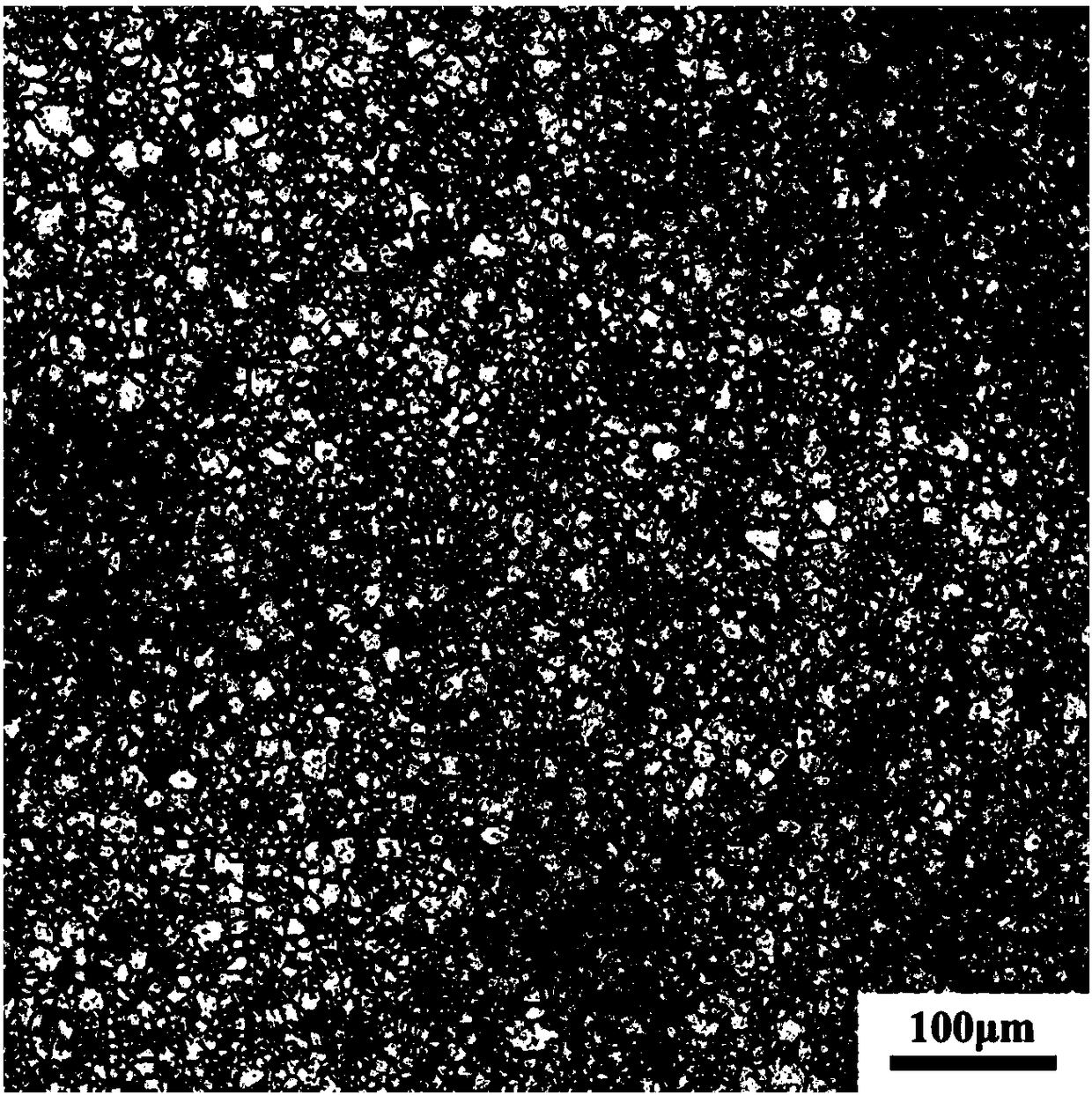

Embodiment 2

[0029] Low-cost high-compression-strength wrought magnesium alloy, in terms of mass percentage, the magnesium alloy raw material element content is as follows: Zn element content 6.0%, Mn element content 0.1%, Sn element content 0.1%, Ca element content 0.1%, Cu element content 0.1% %, unavoidable impurities ≤ 0.15%, the balance is Mg.

[0030] A method for preparing a deformed magnesium alloy with low cost and high compressive strength, comprising the following steps:

[0031] 1) Weigh pure Zn, pure Sn, Mg-Mn master alloy, Mg-Ca master alloy, Mg-Cu master alloy and magnesium ingot according to the alloy composition, and place the magnesium ingot, Mg-Mn master alloy and pure Sn at 690°C Melting at -710°C, after melting, add pure Zn, Mg-Ca master alloy and Mg-Cu master alloy to keep warm for 30 minutes, then control the temperature of the furnace body at 700°C, and continuously pass argon into the melt for 15 minutes to refine the alloy , and then put the alloy melt at 690°C-7...

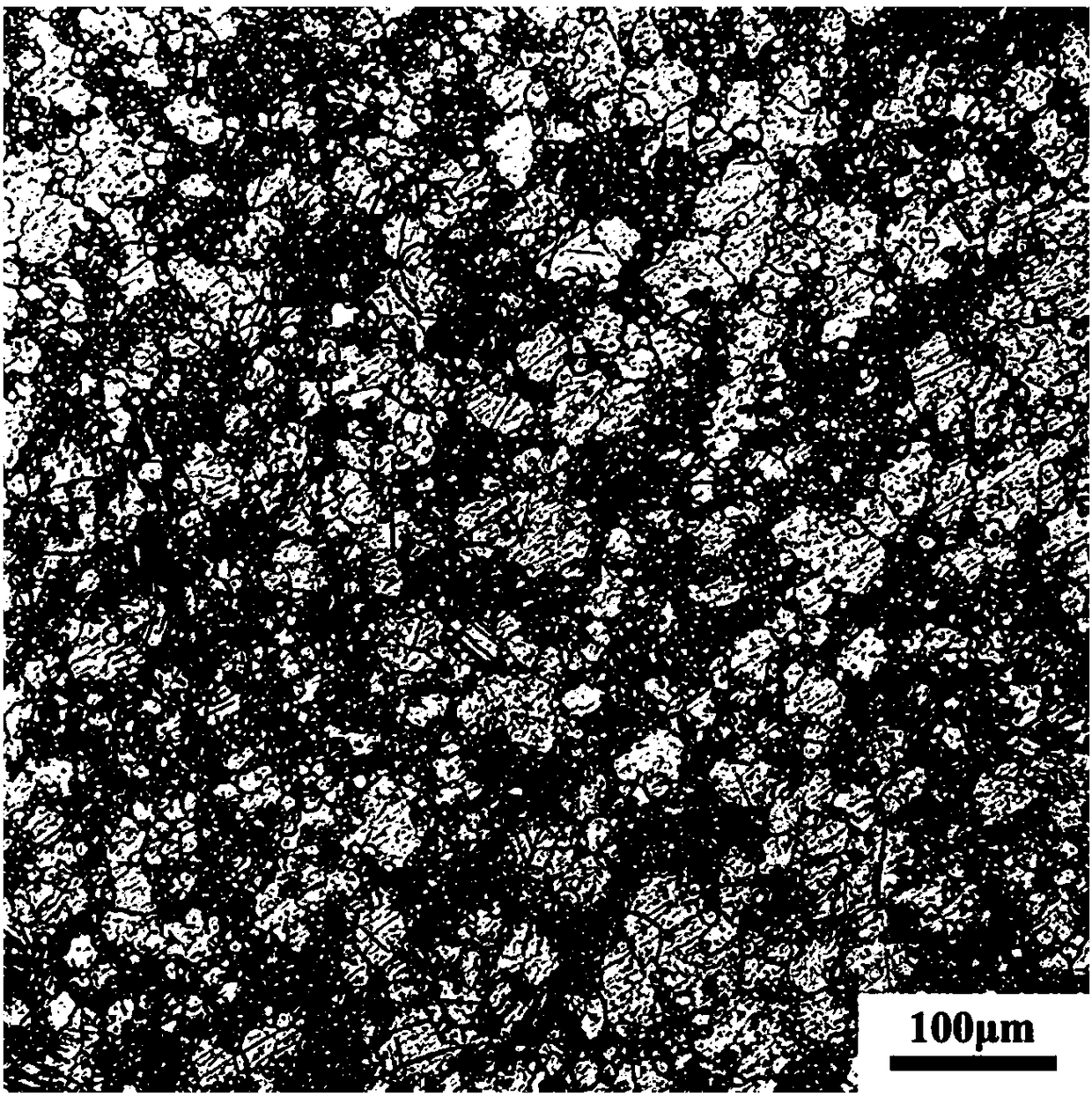

Embodiment 3

[0034] A low-cost high-compression-strength wrought magnesium alloy. In terms of mass percentage, the magnesium alloy raw material element content is as follows: Zn element content 6.0%, Mn element content 0.3%, Sn element content 0.3%, Ca element content 0.3%, Cu element content 0.3% %, unavoidable impurities ≤ 0.15%, the balance is Mg.

[0035] A method for preparing a deformed magnesium alloy with low cost and high compressive strength, comprising the following steps:

[0036] 1) Weigh pure Zn, pure Sn, Mg-Mn master alloy, Mg-Ca master alloy, Mg-Cu master alloy and magnesium ingot according to the alloy composition, and place the magnesium ingot, Mg-Mn master alloy and pure Sn at 690°C Melting at -710°C, after melting, add pure Zn, Mg-Ca master alloy and Mg-Cu master alloy to keep warm for 30 minutes, then control the temperature of the furnace body at 700°C, and continuously pass argon into the melt for 15 minutes to refine the alloy , and then put the alloy melt at 690°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com