Method for purified smelting of high-temperature alloy by using yttrium oxide crucible

A technology of superalloy and yttrium oxide, which is applied in the direction of improving energy efficiency and process efficiency, can solve the problems of purification and melting temperature limitation, increasing melting cost, increasing operation difficulty, etc., to reduce energy consumption and easy operation and control. , the effect of eliminating the influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

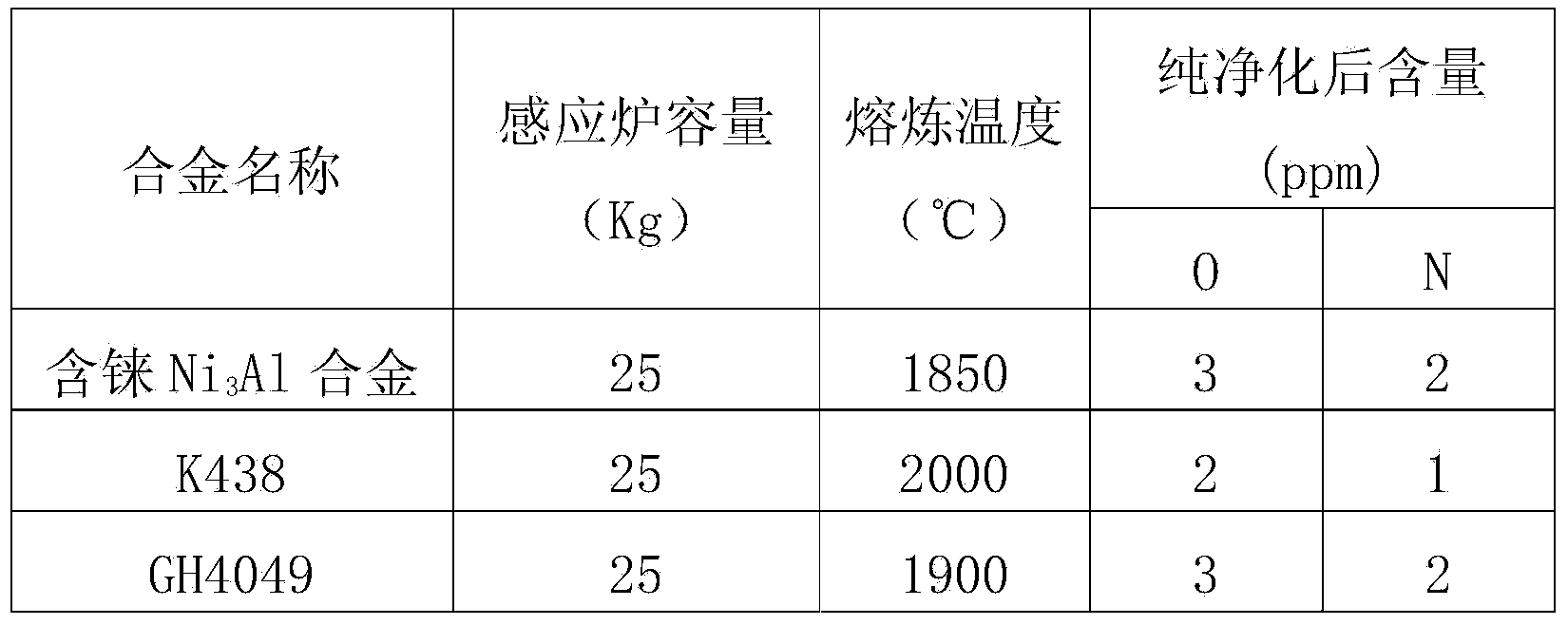

Embodiment 1

[0055] Utilize yttrium oxide crucible to 25Kg rhenium-containing Ni 3 The invention discloses a method for purifying and smelting Al-based single crystal superalloy, and the steps of the method are charging→purifying and smelting→casting molding. specifically:

[0056] Step 1: Prepare superalloy raw materials according to target composition

[0057] The purity of nickel (Ni) used in the prepared raw materials is 99.95wt%, the purity of aluminum (Al) is 99.85wt%, the purity of molybdenum (Mo) is 99.90wt%, the purity of rhenium (Re) is 99.95wt%, dysprosium The purity of (Dy) is 99.99wt%, and the purity of yttrium (Y) is 99.99wt%;

[0058] Step 2: Install Crucible

[0059] Knot the yttrium oxide crucible and install it in a vacuum induction furnace, and sinter the crucible at 900°C for 2 hours;

[0060] Step 3: Ingot Mold

[0061] Put the yttrium oxide mold shell into the molding sand box for molding, then put it into the resistance furnace to raise the temperature to 800°C,...

Embodiment 2

[0072] A method for purifying and smelting 25Kg of K438 alloy by using an yttrium oxide crucible, the steps of which are charging→purifying and smelting→casting. specifically:

[0073] Step 1: Prepare superalloy raw materials according to target composition

[0074] The purity of nickel (Ni) used in the preparation of raw materials is 99.95wt%, the purity of aluminum (Al) is 99.85wt%, the purity of titanium (Ti) is 99.76wt%, the purity of molybdenum (Mo) is 99.90wt%, chromium The purity of (Cr) is 99.98wt%, the purity of cobalt (Co) is 99.99wt%, the purity of tungsten (W) is 99.80wt%, the purity of niobium (Nb) is 99.90wt%, and the purity of tantalum (Ta) is 99.90wt%; the purity of iron (Fe) is 99.80wt%, the purity of zirconium (Zr) is 99.90wt%, and the purity of carbon (C) is 99.75wt%; boron (B) is added in the form of Ni-B alloy, Wherein the B content is 16wt%;

[0075] Step 2: Install Crucible

[0076] Knot the yttrium oxide crucible and install it in a vacuum induction...

Embodiment 3

[0089] A method for purifying and smelting 25Kg of GH4049 alloy by using an yttrium oxide crucible, the steps of which are charging→purifying and smelting→casting. specifically

[0090] Step 1: Prepare superalloy raw materials according to target composition

[0091] The purity of nickel (Ni) used in the prepared raw materials is 99.95wt%, the purity of aluminum (Al) is 99.85wt%, the purity of titanium (Ti) is 99.76wt%, the purity of molybdenum (Mo) is 99.90wt%, chromium The purity of (Cr) is 99.98wt%, the purity of cobalt (Co) is 99.99wt%, the purity of tungsten (W) is 99.80wt%, the purity of iron (Fe) is 99.80wt%, and the purity of vanadium (V) is 99.90wt%, the purity of cerium (Ce) is 99.90wt%, the purity of carbon (C) is 99.75wt%; boron (B) is added in the form of Ni-B alloy, and the B content is 16wt%;

[0092] Step 2: Install Crucible

[0093] Knot the yttrium oxide crucible and install it in a vacuum induction furnace, and sinter the crucible at 900°C for 4 hours;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com