Automatic tempering surfacing welding method for pipeline maintenance

An automatic tempering and pipeline technology, which is applied in applications, household appliances, welding equipment, etc., can solve the problems that the organization and performance cannot be effectively improved, and the workload of finishing weld grinding will be increased, so as to reduce the grinding workload and improve Microstructure and performance, the effect of enhancing the tempering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

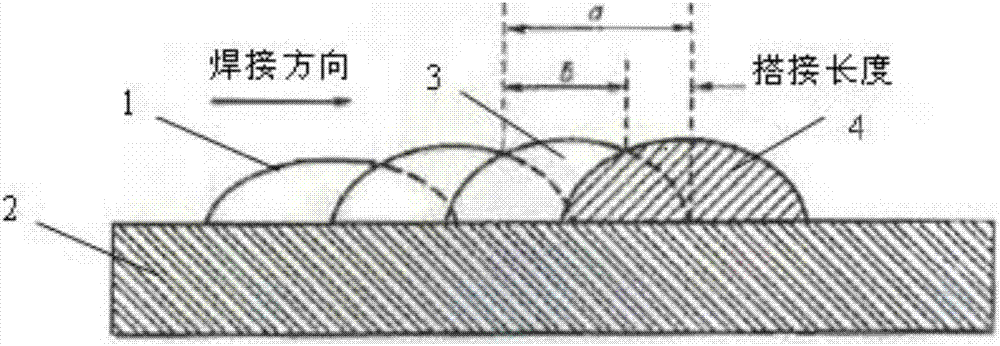

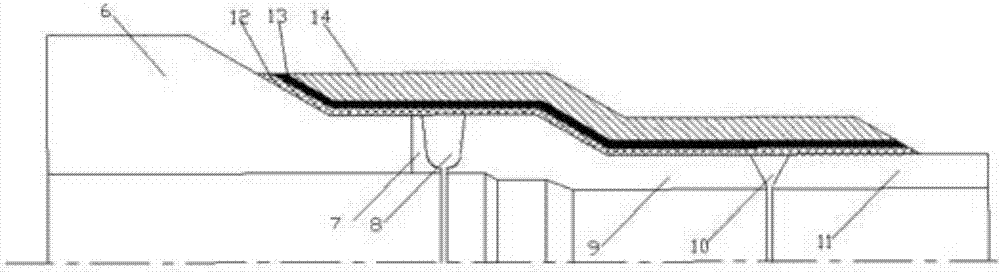

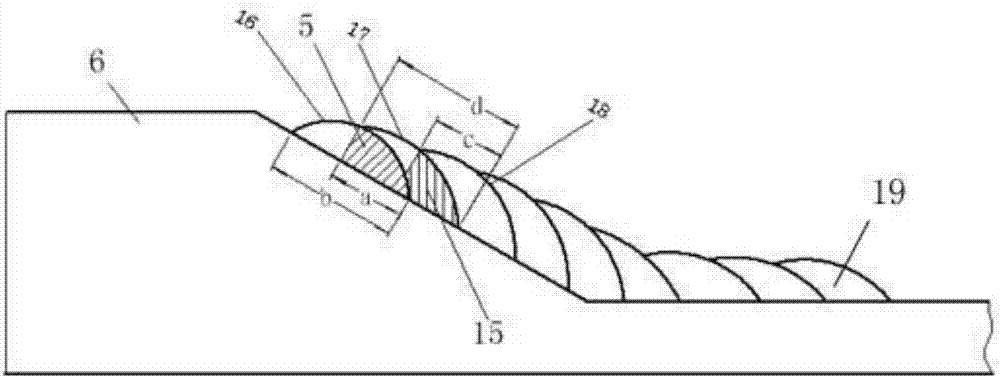

[0063] Such as Figure 2-5 Shown, the present invention is a kind of automatic tempering surfacing welding method for pipeline maintenance, as figure 2 As shown, in the maintenance of the regulator pipeline, the Inconel600 pre-stack 7 is connected to the end face of the low-alloy steel pipe section 6 by surfacing welding; the Inconel600 pre-stack 7 and the stainless steel transition pipe 9 are connected by welding to form Inconel600 weld 8; stainless steel transition pipe 9 and stainless steel pipe section 11 are connected by welding to form stainless steel weld 10, forming dissimilar metal joints on Inconel600 weld 8 and stainless steel weld 10 requires maintenance of the pipeline annulus;

[0064] The tempered surfacing layer 12 is surfacing on the low alloy steel pipe section 6, Inconel600 pre-stacking edge 7, Inconel600 weld 8, stainless steel transition pipe 9, stainless steel weld 10, stainless steel pipe section 11 by welding; the transition surfacing layer 13 is The ...

Embodiment 2

[0103] Such as Figure 2-5 Shown, a kind of automatic tempering surfacing welding method that is used for pipeline maintenance of the present invention, the surfacing welding of automatic tempering surfacing welding process technology can be divided into following 5 steps and finish, specifically as follows:

[0104] Step 1: Temper Overlay Welding

[0105] The welding adopts the automatic argon arc welding method; the welding adds ERNiCrFe-7A nickel-based alloy welding wire; the welding layer / inter-pass overlap is carried out according to the patent; the welding line energy is controlled between 0.7KJ / mm~1.0KJ / mm; The wire feeding speed is controlled within the range of 500mm / min to 700mm / min, and the interlayer temperature is controlled within the range of 60°C to 70°C.

[0106] Step 2: Transition surfacing welding

[0107] The welding line energy of the transition surfacing layer is controlled within the range of 0.9KJ / mm~1.2KJ / mm, and ERNiCrFe-7A nickel-based alloy weldin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com