Gas-protection welding wire with low alloy and high strength

A gas shielded welding wire, low-alloy high-strength technology, applied in welding medium, welding equipment, metal processing equipment and other directions, can solve the problem of high cost and achieve the effect of low cost, stable wire rod rolling process and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

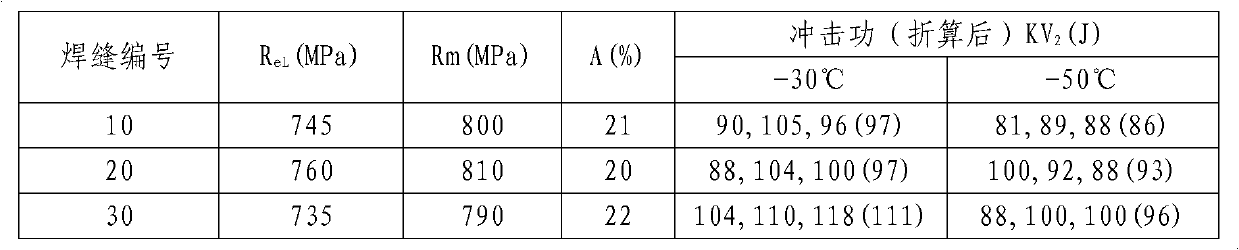

Examples

Embodiment Construction

[0029] Further illustrate the present invention according to specific embodiment below:

[0030] A 50kg intermediate frequency induction furnace is used for smelting, and low S and P scrap steel (P≤0.025%, S≤0.015%) is selected to smelt welding wire steel according to conventional methods. When the C content is lower than 0.05%, deoxidize, Ni, Cu and W are added during charging, Cr is added during refining, and Re is added by ingot hanging in the mold. Smelting uses Si iron and Mn iron for deoxidation, and strictly controls the content of trace elements and gases. The tapping temperature is 1630-1640°C, and it is best to cast into ingots. The contents of the above elements are shown in Table 1. Put the above-mentioned steel ingot into the furnace or into the hot furnace (furnace temperature <1000°C), heat it up to 1180°C and keep it warm for half an hour. The rolling start temperature is ≥1100°C, the final rolling temperature is 900°C, rolled into a billet, and air-cooled af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com