Sludge conditioning system and sludge conditioning method

A technology for sludge conditioning and valve control, which is applied in the fields of sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc. It can solve the problems of less carbon source, high treatment cost, and low treatment efficiency in sewage plants. , to reduce anaerobic digestion time, increase methane gas production, and reduce treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

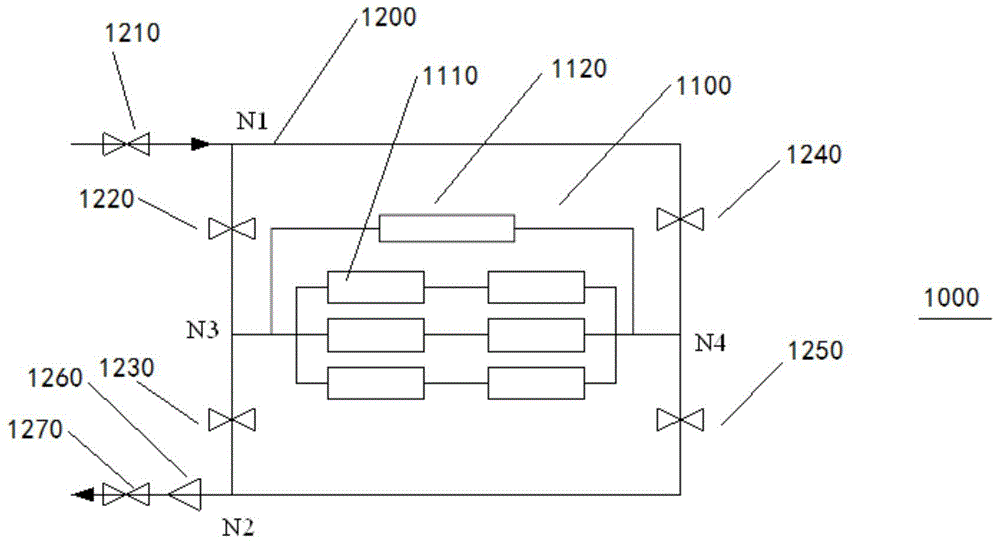

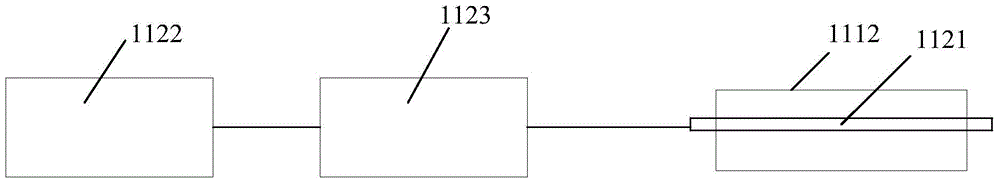

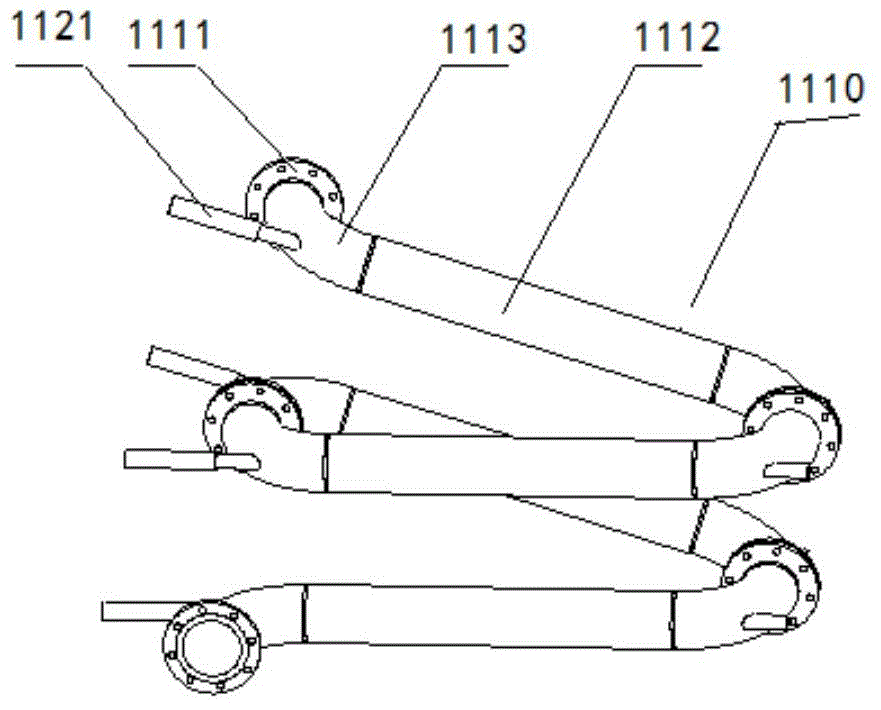

[0073] according to figure 1 The sludge conditioning system 1000 shown in one embodiment of the present invention includes: a pretreatment pipeline 1100, the pretreatment pipeline 1100 includes one or more pretreatment pipeline units 1110 and a high-voltage electric field generating device 1120; anti-clogging The pipeline 1200 forms a bridge pipeline together with the pretreatment pipeline 1100, so that the pretreatment pipeline 1100 can flow in both forward and reverse directions, thereby effectively reducing sludge clogging.

[0074] according to figure 1 Shown is a sludge conditioning system 1000 according to an embodiment of the present invention, wherein the anti-clogging pipeline 1200 includes an inlet valve 1210, an outlet valve 1270, and a first control valve 1220, a second control valve 1230, and a third control valve 1240 and the fourth control valve 1250, wherein the series pipeline formed by the first control valve 1220 and the second control valve 1230 and the se...

Embodiment 2

[0085] according to figure 1 The sludge conditioning system 1000 shown in one embodiment of the present invention includes: a pretreatment pipeline 1100, the pretreatment pipeline 1100 includes one or more pretreatment pipeline units 1110 and a high-voltage electric field generating device 1120; anti-clogging The pipeline 1200 forms a bridge pipeline together with the pretreatment pipeline 1100, so that the pretreatment pipeline 1100 can flow in both forward and reverse directions, thereby effectively reducing sludge clogging.

[0086] according to figure 1 Shown is a sludge conditioning system 1000 according to an embodiment of the present invention, wherein the anti-clogging pipeline 1200 includes an inlet valve 1210, an outlet valve 1270, and a first control valve 1220, a second control valve 1230, and a third control valve 1240 and the fourth control valve 1250, wherein the series pipeline formed by the first control valve 1220 and the second control valve 1230 and the se...

Embodiment 3

[0096] according to figure 1 The sludge conditioning system 1000 shown in one embodiment of the present invention includes: a pretreatment pipeline 1100, the pretreatment pipeline 1100 includes one or more pretreatment pipeline units 1110 and a high-voltage electric field generating device 1120; anti-clogging The pipeline 1200 forms a bridge pipeline together with the pretreatment pipeline 1100, so that the pretreatment pipeline 1100 can flow in both forward and reverse directions, thereby effectively reducing sludge clogging.

[0097] according to figure 1 Shown is a sludge conditioning system 1000 according to an embodiment of the present invention, wherein the anti-clogging pipeline 1200 includes an inlet valve 1210, an outlet valve 1270, and a first control valve 1220, a second control valve 1230, and a third control valve 1240 and the fourth control valve 1250, wherein the series pipeline formed by the first control valve 1220 and the second control valve 1230 and the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com