Electromagnetic induction slag melting furnace satisfying short-process production of mineral wool and production method thereof

An electromagnetic induction, short-process technology, applied in glass production, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of difficult to guarantee the quality of slag cotton, low investment, etc., to achieve superior conditioning performance, improve thermal efficiency, and reduce energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

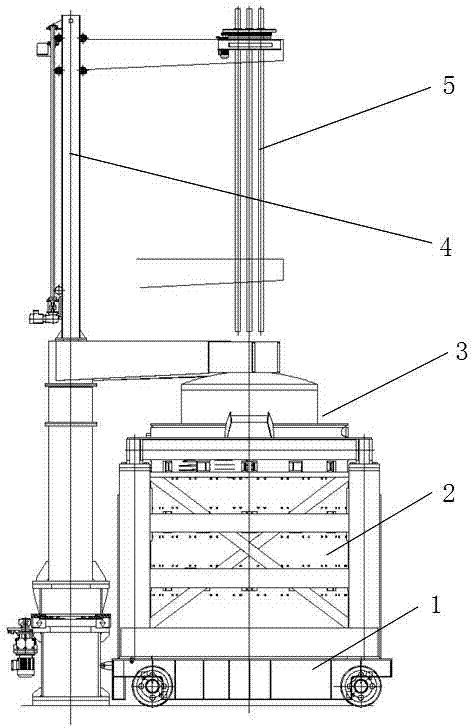

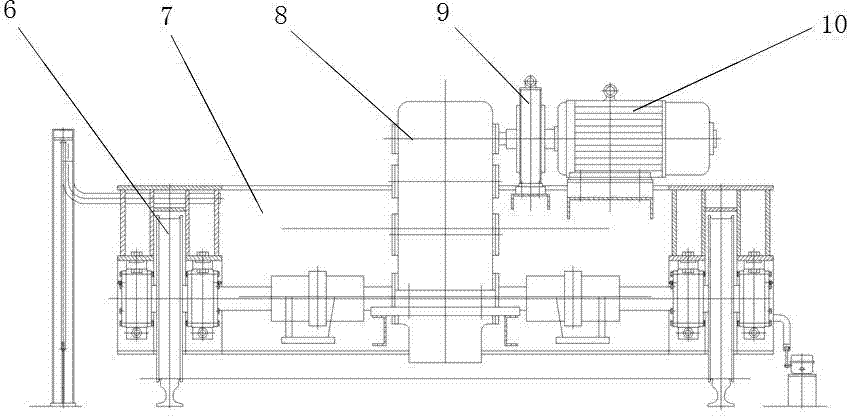

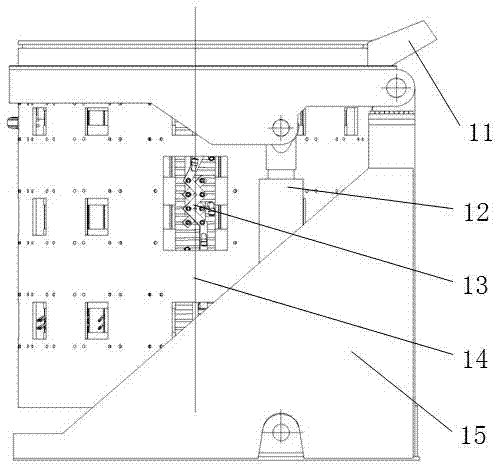

[0017] Control attached figure 1 , an electromagnetic induction slag melting furnace, its structure includes a trolley 1, an electromagnetic induction melting furnace 2, a rotating furnace cover 3, an electrode lifting and rotating stirring device 4 and a plurality of induction heating electrodes 5; wherein the electromagnetic induction melting furnace 2 is fixed on the trolley 1 with screws, The rotating furnace cover 3 is fixed on the embedded steel plate on the ground foundation, the electrode lifting and rotary stirring device 4 is fixed on the rotating furnace cover 3 with screws, and can rotate together with the rotating furnace cover 3, and the induction heating electrode 5 is fixed on the electrode lifting and the rotary stirring device 4, therefore, the electrode lifting and rotary stirring device 4 and the induction heating electrode 5 rotate together with the rotating furnace cover 3; when working, the motor on the trolley 1 is powered on, and the power is transmitte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com