Jet-driven medicament disperse system and pulp mixing modification equipment applying same

A decentralized system and driving technology, which is applied in the direction of dissolving, mixing machines, chemical instruments and methods, etc., can solve the problems of poor working environment of fogging discs, troubles in on-site operation and maintenance work, and excessively high speed requirements of driving motors, etc., to achieve improvement Improvement of mixing efficiency and effect, mixing and dispersing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

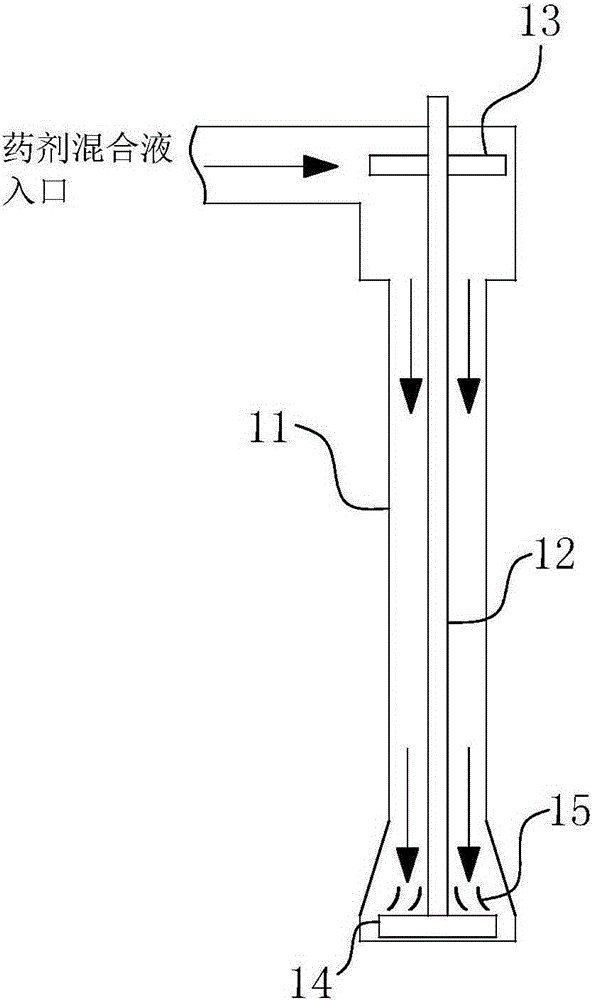

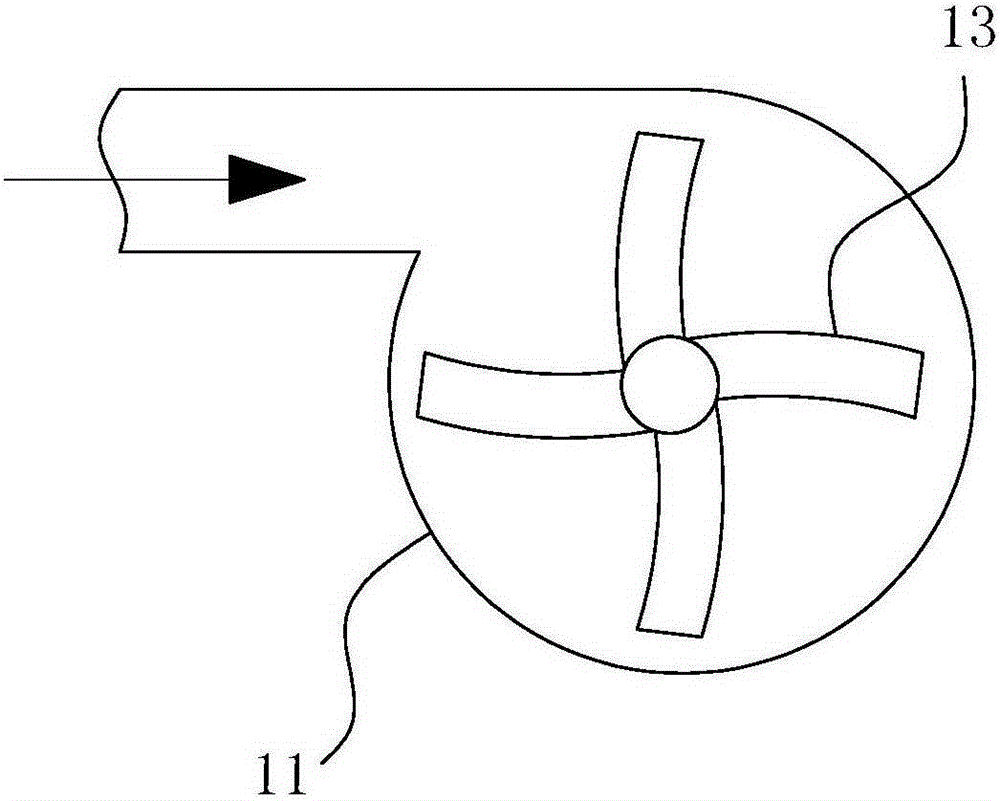

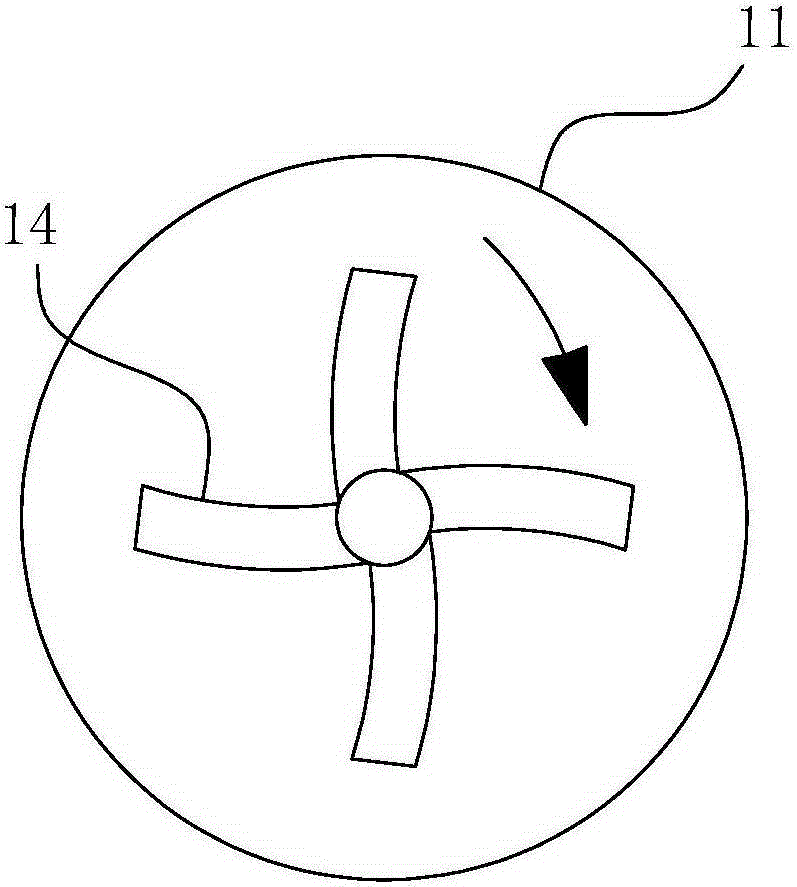

[0046] For ease of understanding, combined here Figure 1-5 , the specific embodiments of the present invention are further described as follows:

[0047] 1.1 Introduction of main components

[0048] (1) Mixing box

[0049] The design of the mixing box 20 is to fully consider the uniform feeding of the incoming pulp, so that each part of the pulp and the medicament have the same contact mixing probability.

[0050] The mixing box 20 can be cylindrical or hexahedral, and of course also can be other shapes, such as Figure 4 Shown is the cylindrical mixing box body. And as Figure 4-5 As shown, the upper box wall of the mixing box 20 is fixed with a slurry feeding tank 70 . Dilution water inlets are arranged on both sides of the slurry feeding tank 70, which is beneficial to quickly and evenly adjust the slurry concentration. In order to ensure uniform overflow all around, a cover plate 71 is provided above the pulp inlet tank 70, and the cover plate 71 is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com