An integrated refractory fine coal slurry mixing equipment

An integrated and difficult-to-select technology, which is applied in the direction of dissolution, mixers, chemical instruments and methods, etc., can solve the problems of on-site operation and maintenance work, excessively high driving motor speed requirements, and easy to send product failures, etc., to achieve favorable mixing Space high-shear environment, improvement of processing efficiency and mixing uniformity, and improvement of buoyancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

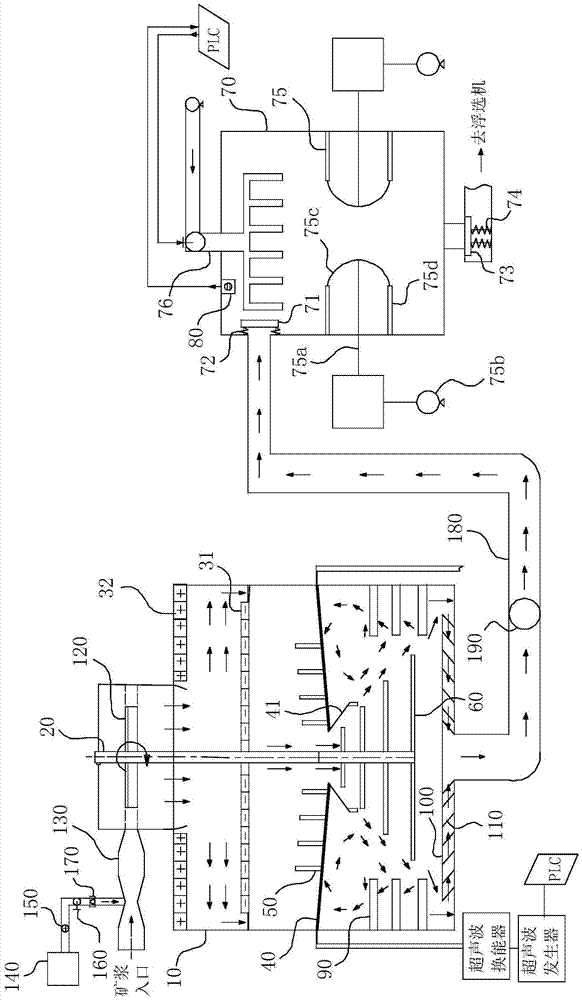

[0050] For ease of understanding, combined here Figure 1-5 , the specific embodiments of the present invention are further described as follows:

[0051] 1.1 Introduction of main components

[0052] (1) Mixing box

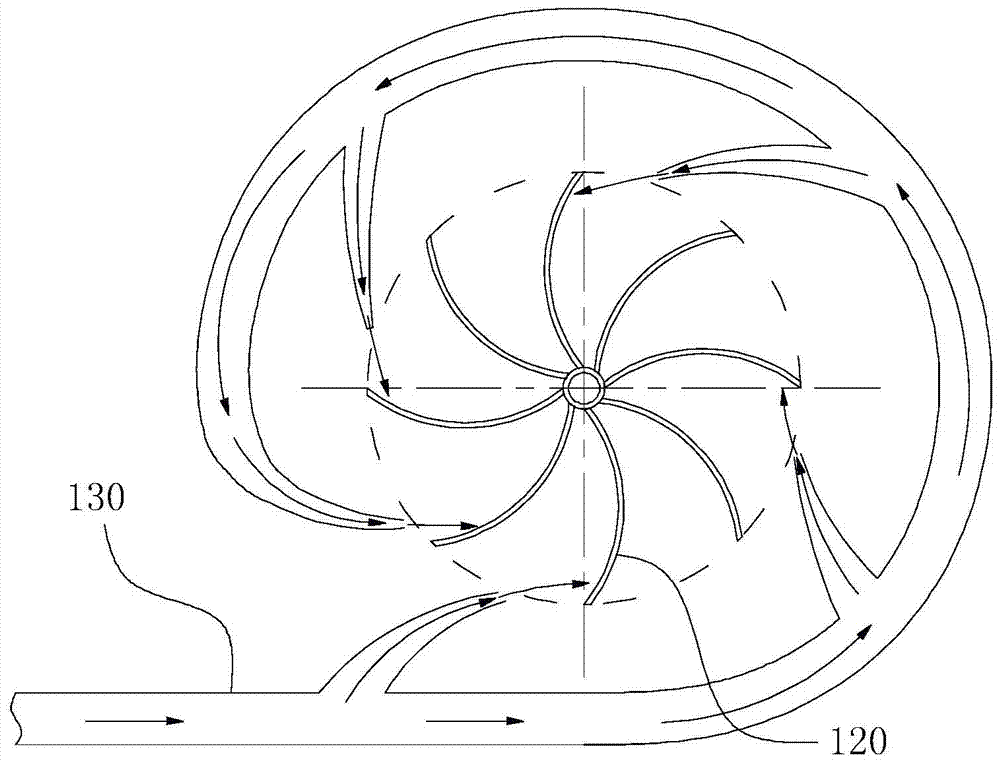

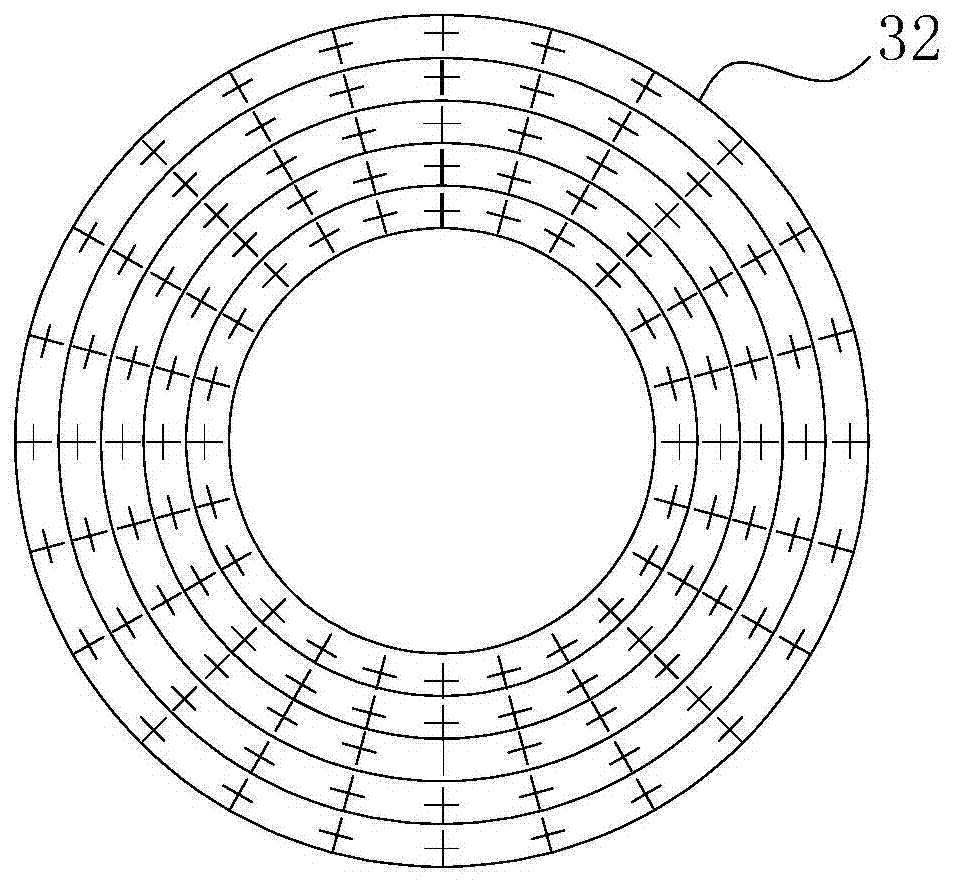

[0053] The design of the mixing box 10 is to fully consider the uniform feeding and preliminary mixing of the incoming pulp, so that each part of the pulp and the chemical agent have the same contact mixing probability, thereby finally forming a mixed solution with high mixing uniformity. The mixing box 10 can be cylindrical or hexahedral, and of course also can be other shapes, such as figure 1 A cylindrical mixing box 10 is shown. Several layers of mixing structures with different mixing functions are arranged in the mixing box 10 to form a top-down channel layered mixing structure. The mixed structure of each layer mainly includes: the first layer of electric field activation layer composed of the upper electrode plate 32 and the lower electrode plate 31, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com