Orientation degree controllable extruded quick-cooked noodles and preparation method thereof

A technology of orientation degree and noodles, which is applied in food extrusion, food forming, food drying, etc., can solve problems such as restrictions on popularization and application of dried noodles, high product prices, and soft dried noodles, so as to facilitate product quality fluctuations and control products Quality fluctuation, good shaping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A kind of extruded quick-boiled noodles with controllable degree of orientation, comprising the following steps:

[0054] (1) Ingredients: 100 parts of high-gluten flour, 8.5 parts of high-gluten gluten flour, 0.8 parts of sodium carboxymethyl cellulose, 0.5 parts of xanthan gum, 0.4 parts of gellan gum, 4 parts of artemisia gum, 0.3 parts of edible alkali 1.5 parts of salt, 2 parts of monoglyceride, 15 parts of beef precooked and beaten into 1cm-2cm shreds, all mixed evenly;

[0055] (2) Conditioning: Dissolve 0.06 parts of high-temperature-resistant α-amylase enzyme solution with an enzyme activity of 120KNU / g (KNU is an enzyme activity unit, defined as the enzyme content that hydrolyzes 5.26g of starch per hour) in water and evenly add it to In the ingredients, the moisture content of the total material on a wet basis is finally controlled to be 35%;

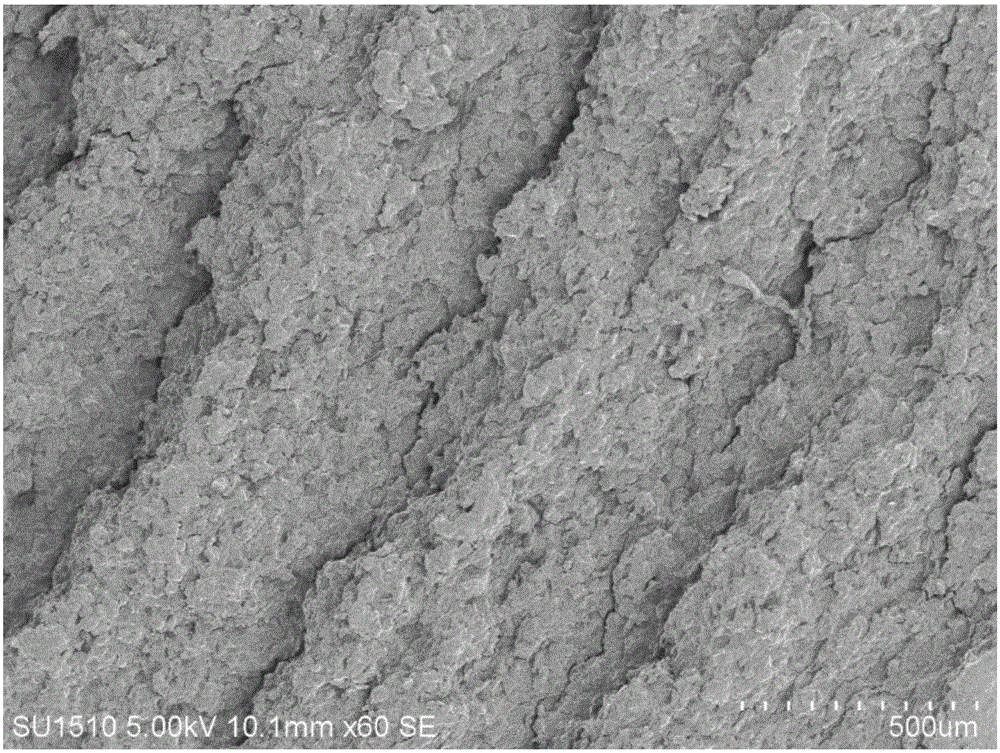

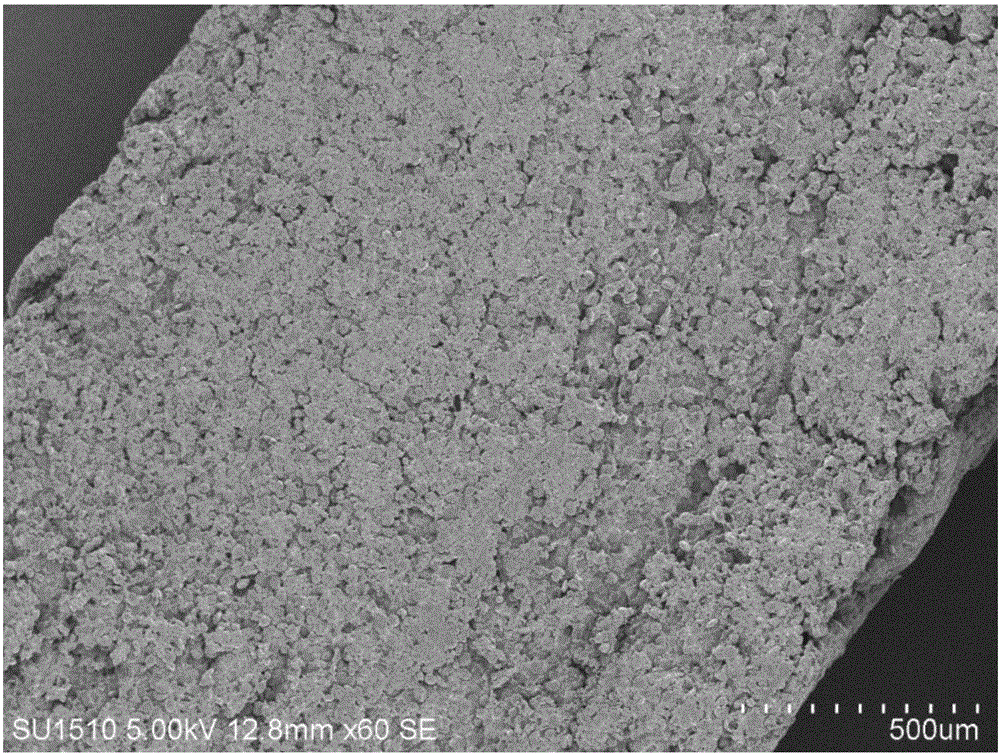

[0056] (3) Extrusion molding: Extrude the conditioned material through a screw extruder, set the temperature of the...

Embodiment 2

[0060] A kind of extruded quick-boiled noodles with controllable degree of orientation, comprising the following steps:

[0061] (1) Ingredients: 100 parts of all-purpose flour, 6.5 parts of all-purpose gluten powder, 0.6 parts of sodium carboxymethyl cellulose, 0.7 parts of xanthan gum, 0.3 parts of gellan gum, 4 parts of sodium polyacrylate, and 2 parts of sodium alginate , 0.2 parts of edible alkali, 2.5 parts of table salt, 3 parts of celery and carrot, and mix them into a puree, and mix them all evenly;

[0062] (2) Conditioning: Dissolve 0.02 parts of high-temperature-resistant α-amylase enzyme solution with an enzyme activity of 120KNU / g in water, and then add it to the ingredients evenly through the water delivery hole of the screw extruder through a constant-flow pump, and finally control the total material Moisture content of wet basis is 40%;

[0063] (3) Extrusion molding: Extrude the conditioned material through a screw extruder, set the temperature of the materi...

Embodiment 3

[0066] A kind of extruded quick-boiled noodles with controllable degree of orientation, comprising the following steps:

[0067] (1) Ingredients: 100 parts of low-gluten flour, 2.5 parts of low-gluten gluten flour, 0.3 parts of sodium carboxymethylcellulose, 0.2 parts of xanthan gum, 0.6 parts of gellan gum, 5 parts of tapioca modified starch, and 5 parts of corn modified starch 5 parts, 0.4 parts of edible alkali, 0.5 parts of table salt, 4 parts of monoglyceride, 9 parts of Flammulina velutipes cut into 0.3cm-1cm small pieces, and mix them all evenly;

[0068] (2) Conditioning: Dissolve 0.1 part of high temperature-resistant α-amylase enzyme solution with an enzyme activity of 120KNU / g in water and evenly add it to the ingredients, and finally control the moisture content of the total material on a wet basis to 25%;

[0069] (3) Extrusion molding: Extrude the conditioned material through a screw extruder, set the temperature of the material in the melting section of the extr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com