Zinc oxide particles and cosmetic material

A technology of zinc oxide particles and cosmetics, applied in the direction of zinc oxide/zinc hydroxide, cosmetics, cosmetics, etc., to achieve the effect of excellent transparency and excellent makeup durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

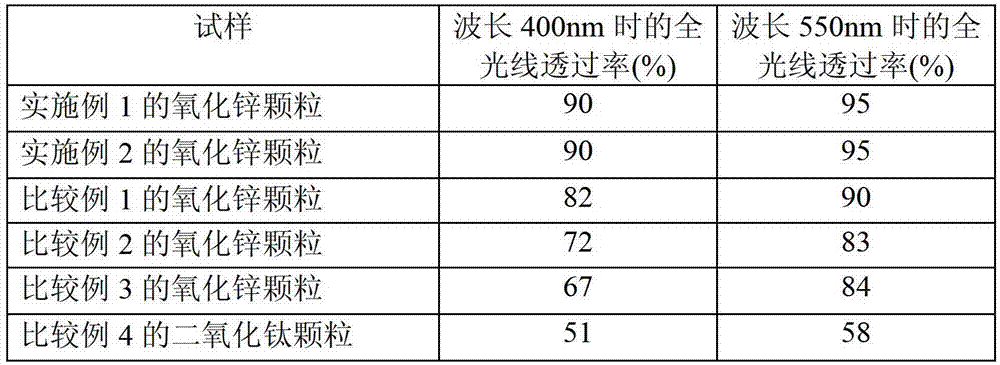

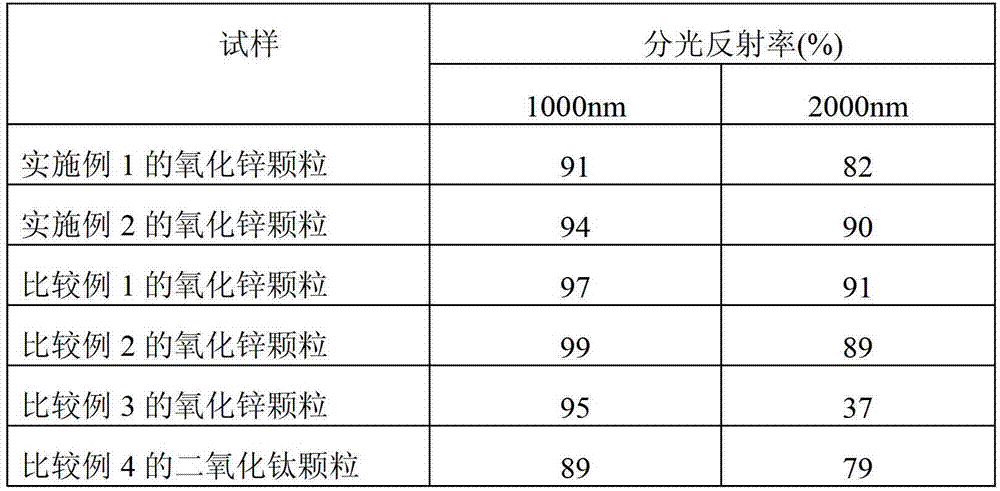

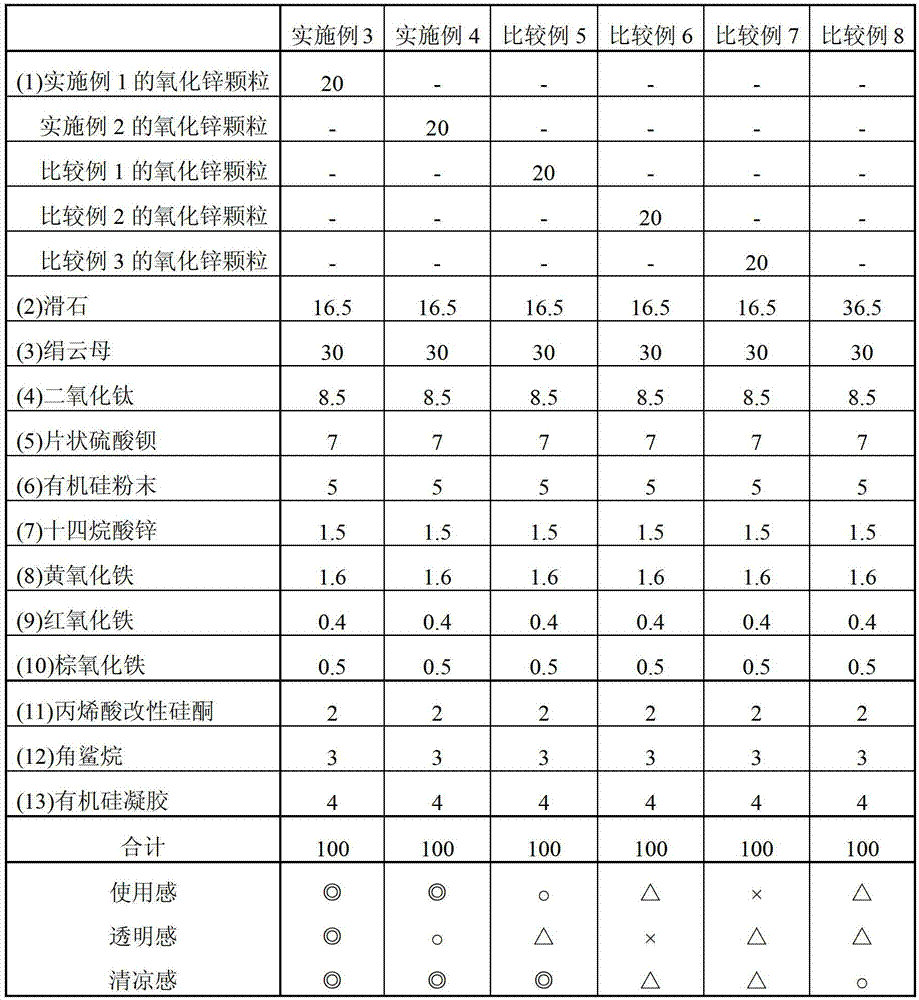

Examples

Embodiment 1

[0062] Type 1 zinc oxide (manufactured by Sakai Chemical Industry Co., Ltd.) was put into a square sagger, and fired at 1000° C. in an electric furnace to obtain large particles of zinc oxide. The average particle diameter of the obtained zinc oxide particles was 10.7 μm.

Embodiment 2

[0064] Type 1 zinc oxide (manufactured by Sakai Chemical Industry Co., Ltd.) was put into a square sagger, and fired at 850° C. in an electric furnace to obtain large particles of zinc oxide. The average particle diameter of the obtained zinc oxide particles was 5.2 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| dispersion coefficient | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com