Oil-in-water-type emulsified cosmetic preparation and process for producing the same

A technology of oil-in-water type and cosmetic materials, which is applied in the direction of cosmetic preparations, cosmetics, cosmetics, etc. It can solve the problems that the amount of uniform dispersion cannot be added, it cannot be manufactured, and it takes a long time to achieve excellent emulsification stability and temperature stability. Excellent performance and excellent usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0109] Hereinafter, although an Example is given and this invention is demonstrated concretely, this invention is not limited to these examples.

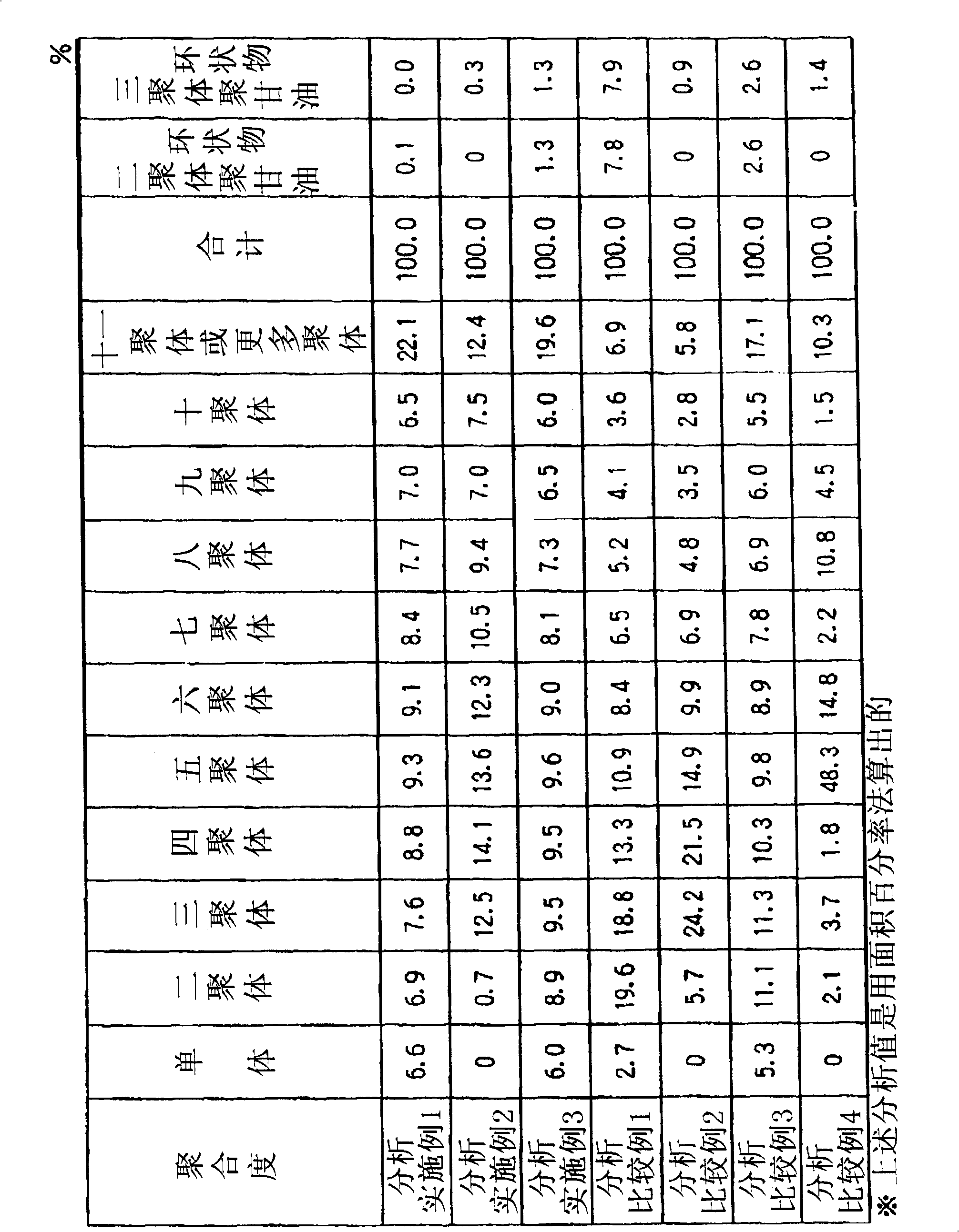

[0110] [Composition analysis of raw material polyglycerol]

[0111] Three types of polyglycerols used as raw materials for component A of the present invention (products manufactured by Taiyo Chemical Co., Ltd.: Great Oil D-10, Great Oil D-11, Great Oil D-12) and polyglycerols used for comparison Polyglycerin composition of 4 kinds of polyglycerols (products manufactured by Taiyo Chemical Co., Ltd.: Great Oil S-10, Great Oil S-11, Great Oil S-12, Great Oil S-13) used as raw materials of fatty acid esters The measurement was carried out by gas chromatography, and the analysis results are shown in Table 1. Each composition analysis value was calculated by the area percentage method. In addition, when polyglycerin contains dimer or trimer cyclic substances, the polyglycerin composition analysis values of dimers and trimers represen...

Embodiment 1~14

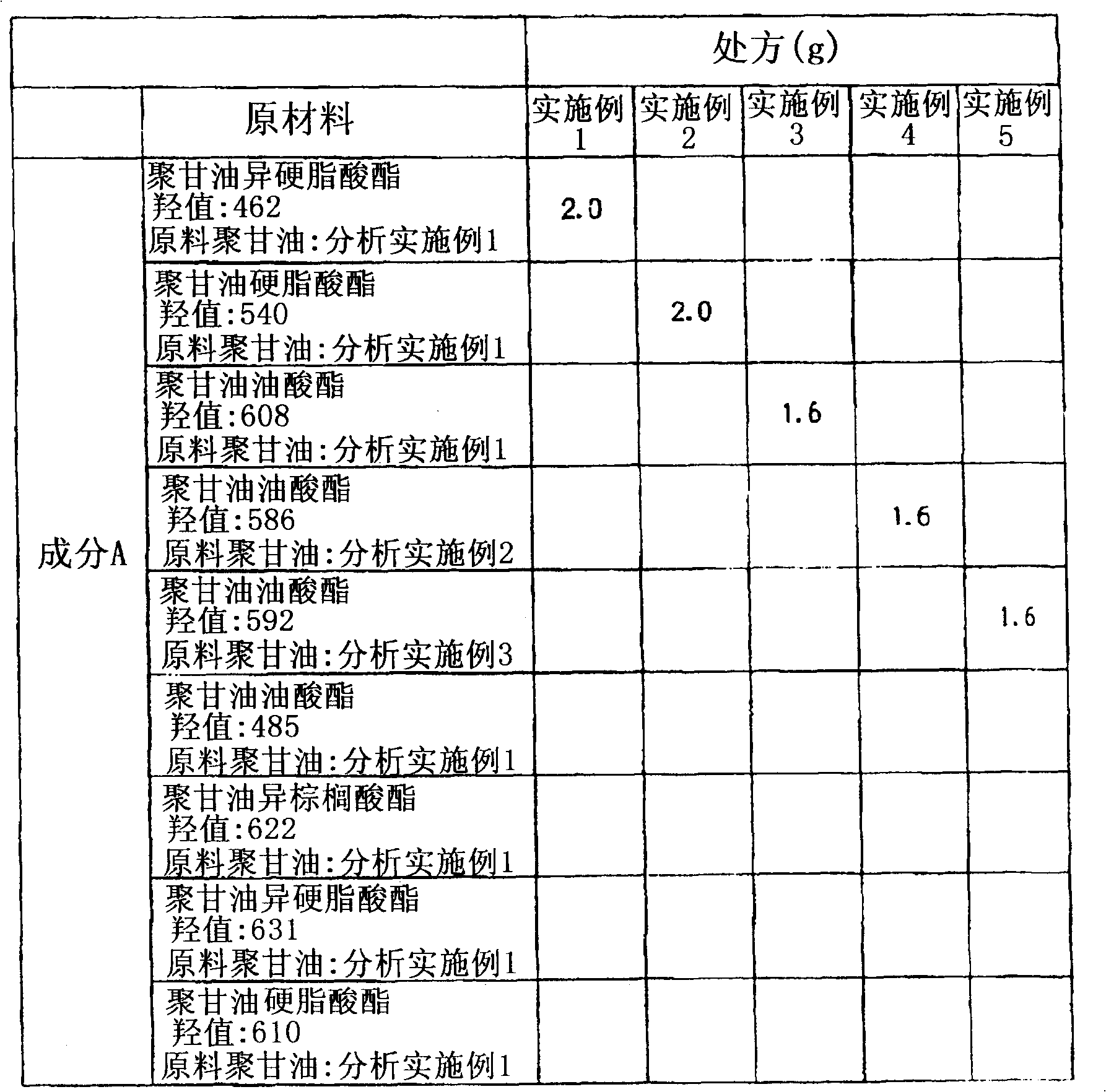

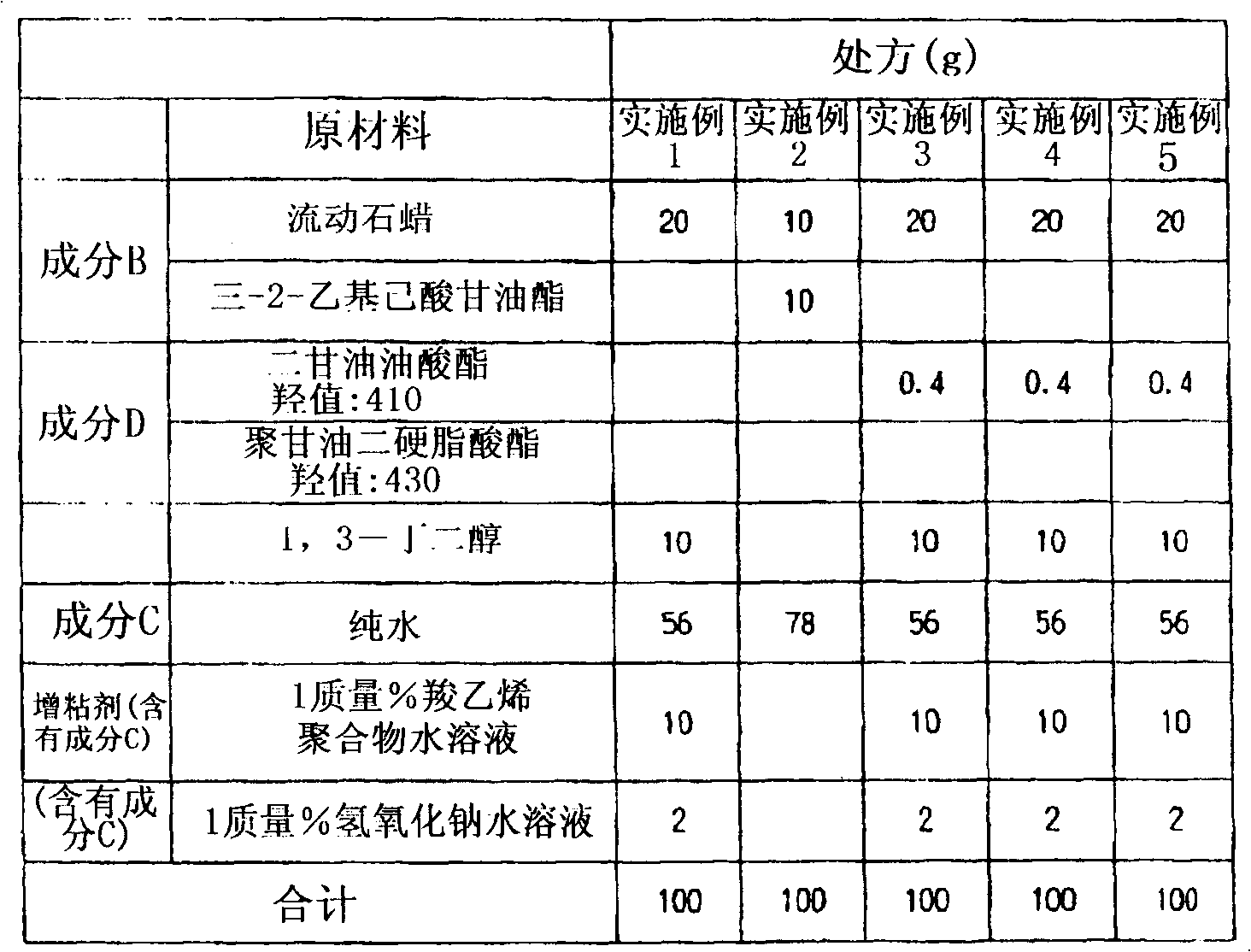

[0127] Examples 1-14 [oil-in-water emulsified cosmetic material]

[0128] An oil-in-water emulsified cosmetic material containing component A (polyglycerin fatty acid ester using any of the polyglycerols in Analysis Examples 1 to 3 as a raw material), component B, and component C was prepared. Here, components other than those in Examples 1, 2, 6, 9, and 10 contained component D. The recipes of the produced oil-in-water emulsified cosmetics are shown in Tables 5 to 10. In Tables 5 to 10, raw material polyglycerol: analysis examples 1, 2, and 3 show that the polyglycerol used as the raw material of polyglycerol fatty acid ester is the raw material polyglycerol of analysis examples 1, 2, and 3, respectively. .

[0129] table 5

[0130]

[0131] Table 6

[0132]

[0133] Table 7

[0134]

[0135] Table 8

[0136]

[0137] Table 9

[0138]

[0139] Table 10

[0140]

[0141] [Manufacture of the oil-in-water emulsified cosmetic material of Example 1 (self-...

Embodiment 15

[0220] Example 15 [moisturizer]

[0221] Moisturizers of oil-in-water emulsified cosmetics with the formulations shown in Table 27 were prepared.

[0222] First, the raw materials (1) to (7) were put into a 100 ml stainless steel container, and mixed and dissolved by dispersion stirring (3000 rpm) while heating to 70° C., to obtain an oil phase. Separately, raw materials (8) to (11) were mixed and dissolved at 70° C. with dispersion stirring (1000 rpm) to obtain an aqueous phase. Thereafter, the oil phase at 70°C was added to the water phase stirred at 70°C with a disperser (1000 rpm).

[0223]Further, the raw material (12) was added while continuing the dispersing stirring, and the raw material (13) was further added, followed by dispersing and stirring for 10 minutes. Cool to 30°C while continuing stirring, and take out the oil-in-water emulsified cosmetic material. By leaving still at 25 degreeC for 24 hours, 96 g of oil-in-water emulsified cosmetics moisturizers were ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com