Artificial stone composition, manufacturing method thereof, artificial stone and method for preparing molding

A manufacturing method and composition technology, which is applied in the field of artificial stone compositions, can solve the problems of unattractive appearance, difficulty in mixing components evenly, and poor strength of artificial stone, etc., and achieve the effects of excellent fluidity, convenient manufacture, and gorgeous patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

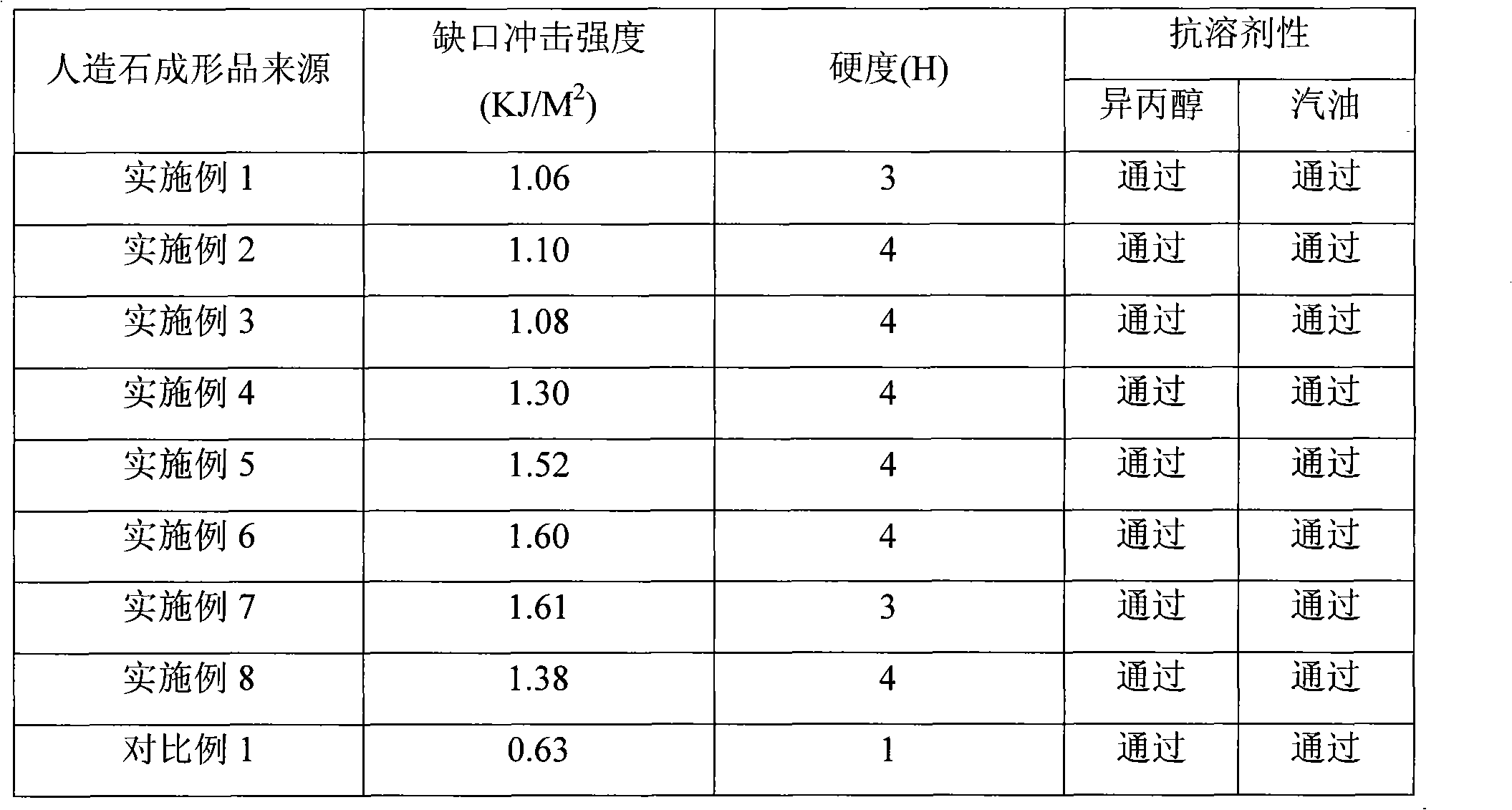

Examples

Embodiment 1

[0033] This example illustrates the artificial stone composition of the present invention, the composition, the artificial stone, and the method for producing an artificial stone molded article.

[0034] 100 grams of methyl acrylate, 75 grams of aluminum hydroxide (Guangzhou Qingkai Chemical Co., Ltd., toothpaste grade, 20 microns), 0.1 gram of methyl ethyl ketone peroxide (Guangzhou Qingkai Chemical Co., Ltd.) and 0.5 grams of defoamer ( BYK515 produced by BYK Chemicals Co., Ltd.) and stirred for 15 minutes under a vacuum of 0.01 MPa to obtain a mixture. Then directly pour the mixture into a mobile phone button mold (manufactured by Shenzhen BYD), and keep it at 100° C. under a pressure of 50 kgf for 30 minutes. Release the mold to form a mobile phone button, and then use a printing machine (Ronglong Precision Machinery Co., Ltd., UP-121-YA) to print the number "1" on the button. Then use a punching machine (Liwei Automation Technology Co., Ltd. (Shenzhen) Co., Ltd., CH-108)...

Embodiment 2

[0036] This example illustrates the artificial stone composition of the present invention, the composition, the artificial stone, and the method for producing an artificial stone molded article.

[0037] With 100 grams of methyl acrylate, 300 grams of aluminum hydroxide (Guangzhou Qingkai Chemical Co., Ltd., toothpaste grade, 30 microns), 12 grams of methyl ethyl ketone peroxide (Guangzhou Qingkai Chemical Co., Ltd.), 10 grams of defoamer and 5 g of cobalt naphthoate were mixed and stirred for 25 minutes under a vacuum of 0.01 MPa to obtain a mixture. Then directly pour the mixture into a mobile phone button mold (manufactured by Shenzhen BYD), and keep it at 100° C. under a pressure of 50 kgf for 6 minutes. Release the mold to form a mobile phone key, and then use a printing machine to print the number "1" on the key. Then use a punching machine to punch, cut off the leftover material of the button, and obtain the artificial stone shaped product of the button of the mobile p...

Embodiment 3

[0039] This example illustrates the artificial stone composition of the present invention, the composition, the artificial stone, and the method for producing an artificial stone molded article.

[0040] 100 grams of methyl acrylate, 260 grams of aluminum hydroxide (Guangzhou Qingkai Chemical Co., Ltd., toothpaste grade, 40 microns), 1 gram of methyl ethyl ketone peroxide (Guangzhou Qingkai Chemical Co., Ltd.), 2 grams of defoamer, 10 grams of cobalt naphthalate and 40 grams of polymethyl acrylate (Shanghai Tiou Technology and Trade Co., Ltd., LG PMMAIH803 series high-impact series, weight-average molecular weight 50000) were mixed, and stirred for 25 minutes under a vacuum of 0.05 MPa to obtain mixture. Then directly pour the mixture into a mobile phone button mold (manufactured by Shenzhen BYD), and keep it at 100° C. under a pressure of 50 kgf for 5 minutes. Release the mold to form a mobile phone key, and then use a printing machine to print the number "1" on the key. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com