Hot-melting glass with bowlder effect and manufacturing method of hot-melting glass

A technology for hot-melt glass and a manufacturing method, which is applied to glass manufacturing equipment, manufacturing tools, glass molding, etc., can solve the problems of insufficient realistic effect and texture, high processing cost, color intolerant to aging, etc., and achieves better crystallization effect. , low manufacturing cost, good effect of jade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

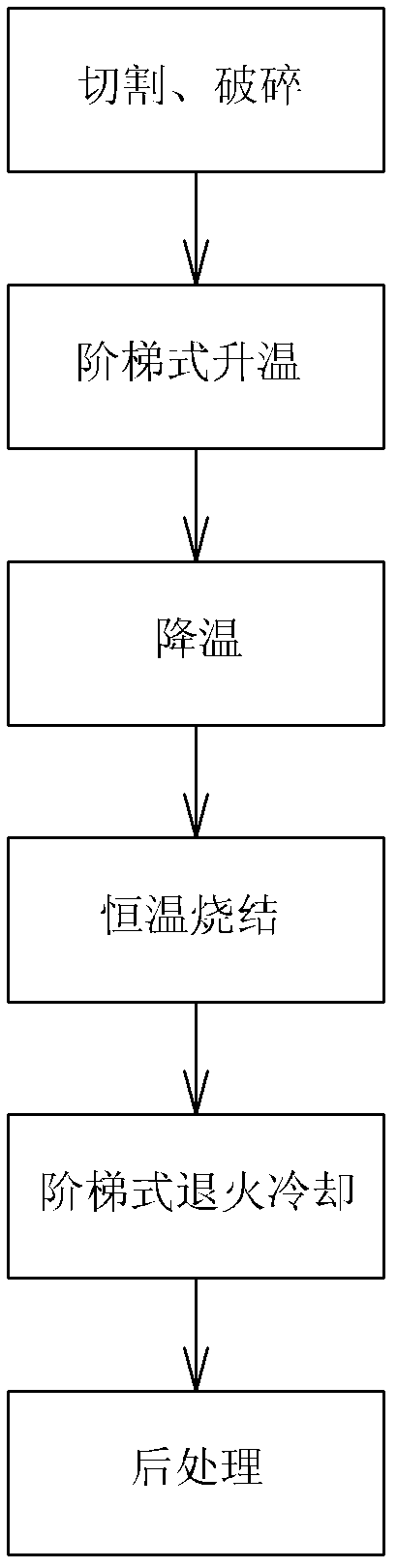

[0022] Embodiments of the present invention provide a hot melt glass with a jade effect and a manufacturing method thereof. like figure 1 As shown, the manufacturing method includes the steps of:

[0023] The pretreatment step is to break the whole piece of hot-melt glass into pieces that meet the predetermined requirements;

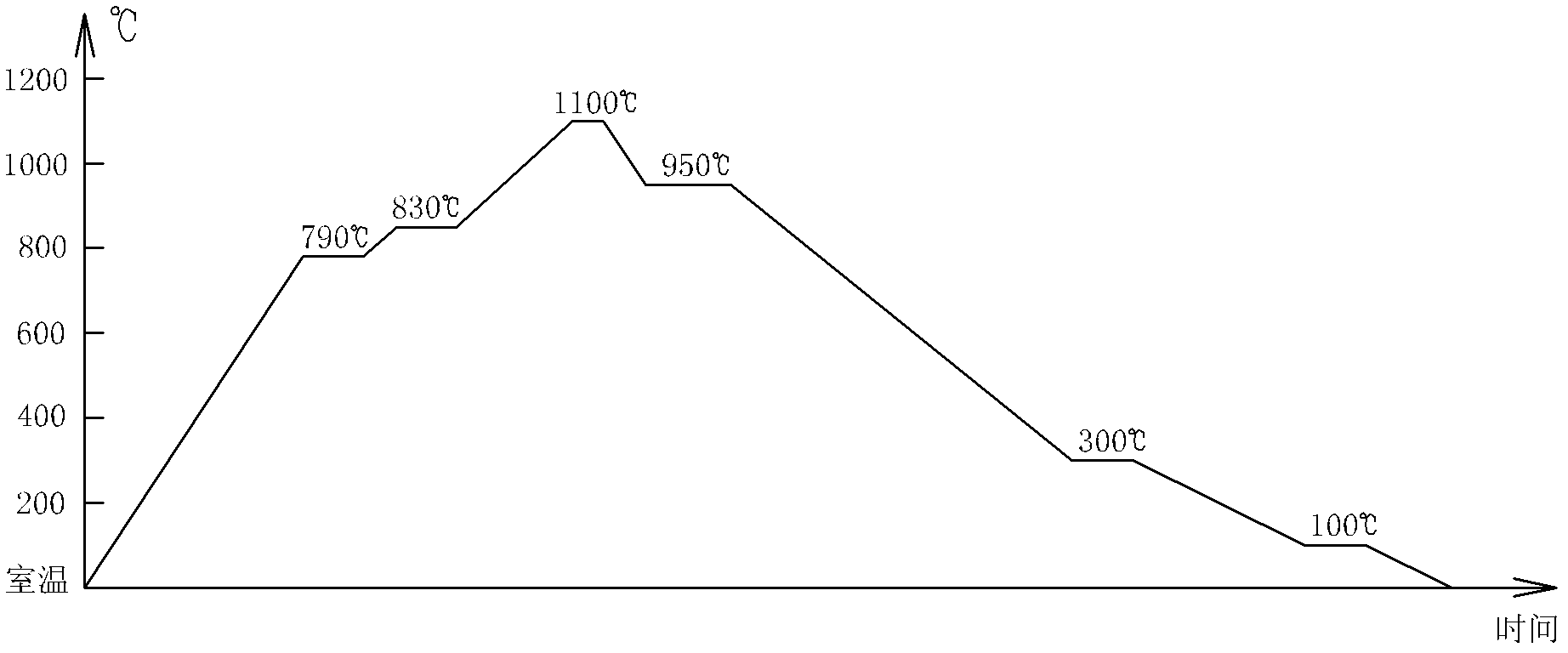

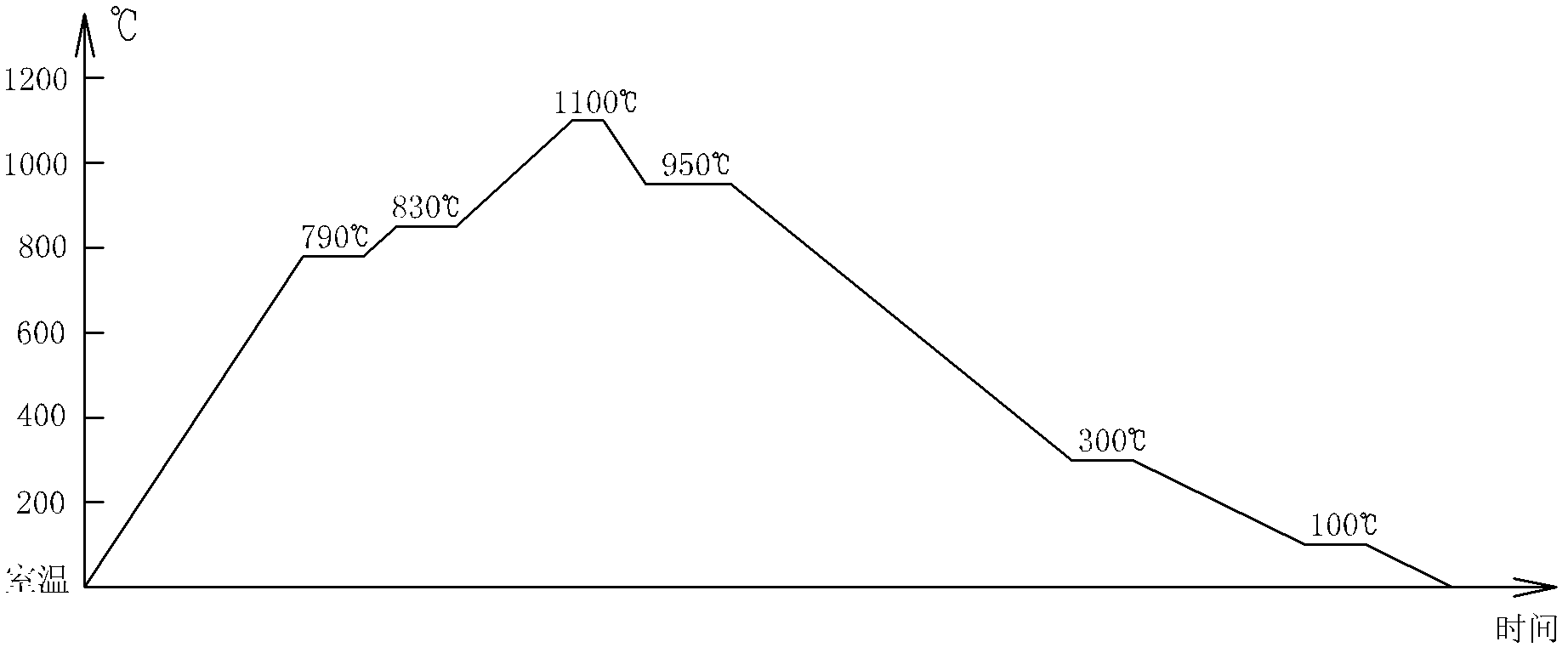

[0024] In the sintering step, the fragments are put into a mold box coated with a release agent and placed in a sintering furnace for sintering. The sintering process includes a heating stage, a cooling stage, a constant temperature sintering stage, and an annealing and cooling stage in sequence, wherein, in the heating stage The temperature is raised from room temperature to the highest temperature 100~150°C higher than the predetermined sintering temperature in a stepwise manner, and the temperature is kept constant for 5~10 minutes, while the cooling stage is to cool down from the highest temperature to the predetermined sintering temperature Keep t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com