Simulated wood board and production method thereof

A production method and wood board technology, which is applied in the field of wood boards, can solve the problems of being unable to waterproof and moisture-proof, affecting the service life of wood boards, and not being recyclable, so as to reduce the damage to forests and the environment, reduce the amount of wood used, and the wood texture is real and natural Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] In this embodiment, white polyvinyl chloride micro-foamed board is selected as the base material, and the manufacturing process of the board adopts free foaming co-extrusion technology, and the density of the board is 660kg / m 3 , the surface crust hardness Shore hardness is 70, the bending strength is 20mpa.tan, the bending elastic modulus is 800mpa, and the surface density is 1000kg / m 3 ;Use precision cutting equipment to cut PVC micro-foamed boards into substrates with specifications of 8×125×910mm; use imported Haomai vertical and horizontal slotting machines to process the cut substrates into locking tenons ; Through the ultraviolet curing paint production line, polyurethane UV adhesion primer is coated on the front side of the processed substrate; the texture of natural wood is printed on the surface of the substrate coated with primer by using a four-color roller coating printing machine. The four-color roller coating printing machine is equipped with 4 printing r...

Embodiment 2

[0023] In this example, a beige polyvinyl chloride micro-foamed board is selected as the base material, and the manufacturing process of the board adopts free foaming co-extrusion technology, and the density of the board is 660kg / m 3 , the surface crust hardness Shore hardness is 85, the bending strength is 40mpa.tan, the bending elastic modulus is 900mpa, and the surface density is 1000kg / m 3 ;Use precision cutting equipment to cut PVC micro-foamed boards into substrates with specifications of 15×303×1818mm; use imported Haomai vertical and horizontal slotting machines to process the cut substrates into flat buckle tenons; The processed base material is coated with a balance layer, and the back of the base material is coated with UV paint through the ultraviolet curing paint production line. The coating process is three primers and one top coat, and the thickness of the paint film is 60 grams per square meter ;Through the ultraviolet curing paint production line, the polyuret...

Embodiment 3

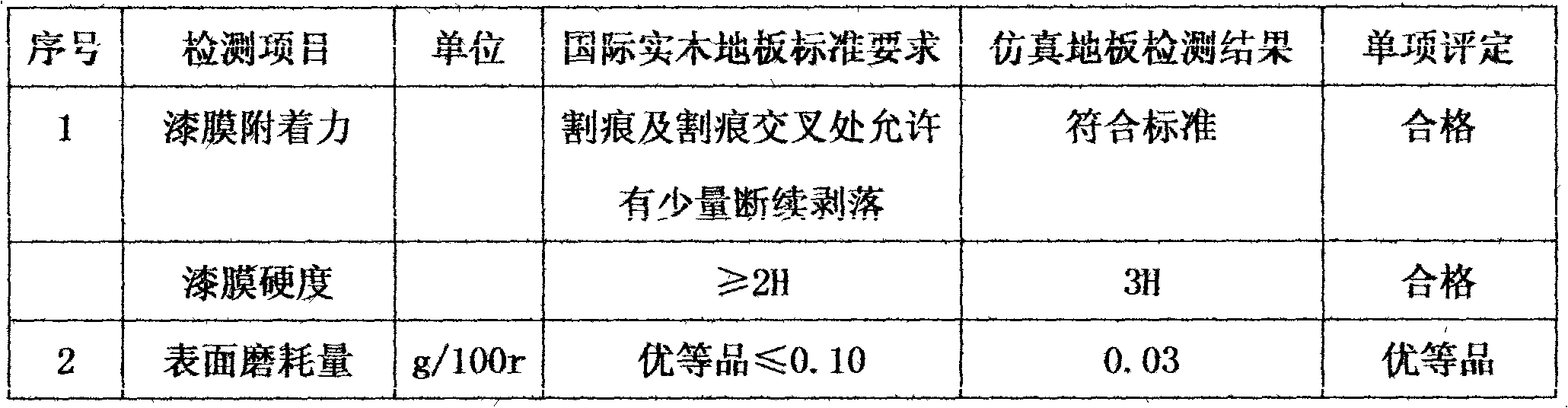

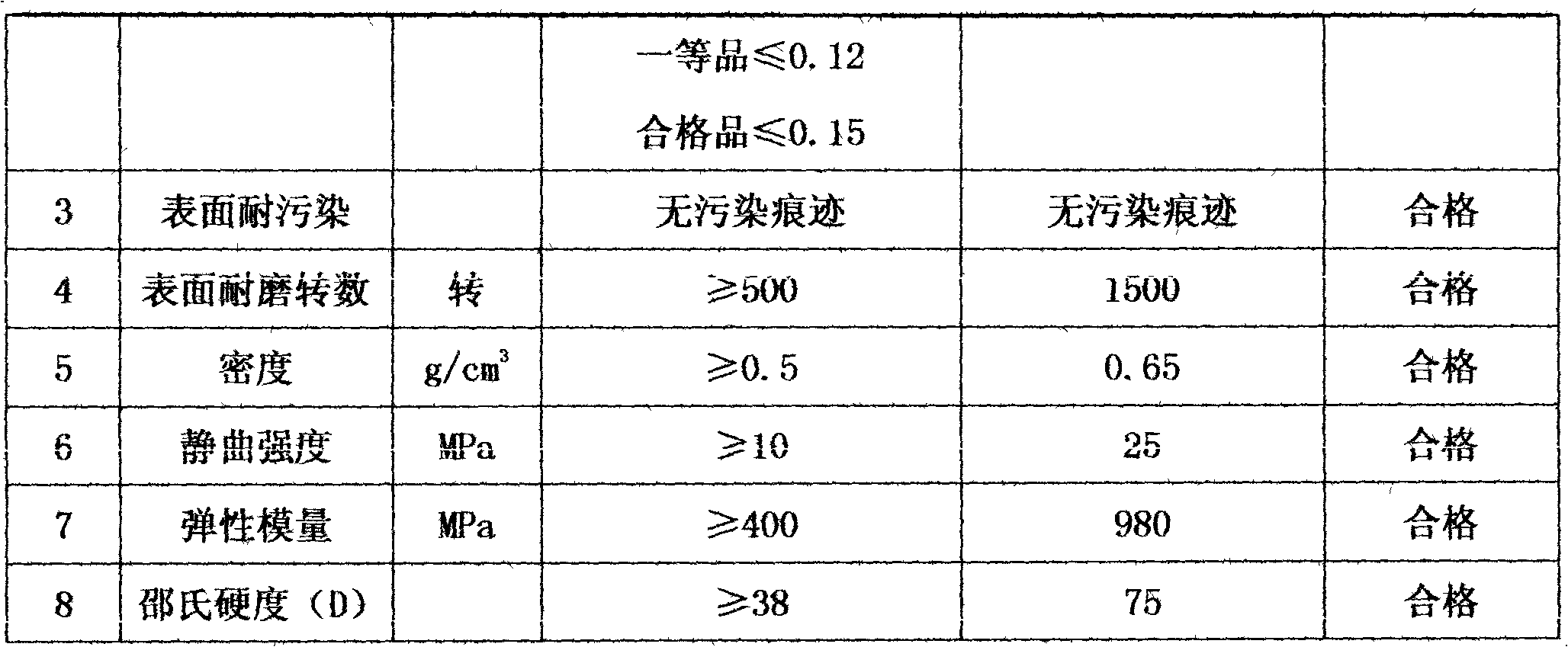

[0025] In this embodiment, white polyvinyl chloride micro-foamed board is selected as the base material, and the manufacturing process of the board adopts free foaming co-extrusion technology, and the density of the board is 660kg / m3 , the surface crust hardness Shore hardness is 100, the bending strength is 28mpa.tan, the bending elastic modulus is 982mpa, and the surface density is 920.8kg / m 3 ;Use precision cutting equipment to cut PVC micro-foamed boards into substrates with specifications of 12×145×1210mm; use imported Haomai vertical and horizontal slotting machines to process the cut substrates into locking tenons ; Through the ultraviolet curing paint production line, the polyurethane UV adhesion primer is coated on the front side of the processed and formed substrate; the texture of natural wood is printed on the surface of the substrate coated with the primer by using a four-color roller coating printing machine. The four-color roller coating printing machine is equip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com