Ceramic brick with negative ion function and production method thereof

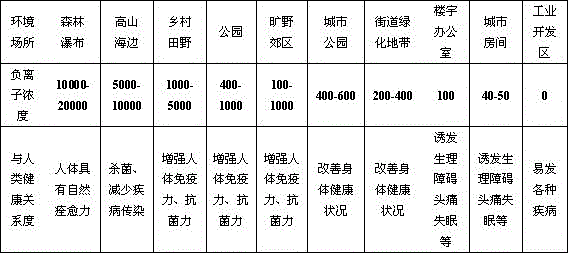

A production method and technology for negative ions, applied in the field of architectural ceramics, can solve the problems of large consumption of negative ion powder and low release concentration of negative ions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A kind of production method of ceramic brick with negative ion function, the steps are as follows:

[0049] a) prepare ceramic brick body by conventional method, set aside;

[0050] b) preparing a porcelain material with high-temperature porcelain-forming properties, the main component of which is the same as that of the ceramic tile body in step a), but wherein K 2 O+Na 2 O: 6.3%, impurity = 2.4% (both by weight percentage), negative ion additive 3%, batching, mixing, ball milling, and sieving to make porcelain material slurry that meets the performance requirements of pouring, and set aside;

[0051] The chemical formula of the negative ion additive is: NaMg 3 Al 6 [Si 6 o 18 ][BO 3 ] 3 (OH) 4 ;

[0052] c) applying the porcelain material slurry prepared in step b) to the surface of the ceramic tile body in step a), forming a porcelain layer, and drying;

[0053] d) Put the dried ceramic brick in step c) into a kiln for firing at 1210° C. for 57 minutes.

...

Embodiment 2

[0056] A kind of production method of ceramic brick with negative ion function, the steps are as follows:

[0057] a) prepare ceramic brick body by conventional method, set aside;

[0058] b) preparing a porcelain material with high-temperature porcelain-forming properties, the main component of which is the same as that of the ceramic tile body in step a), but wherein K 2 O+Na 2 O: 6%, impurity = 2% (both by weight percentage), negative ion additive 5%, batching, mixing, ball milling, and sieving to make a porcelain material slurry that meets the performance requirements of pouring, and set aside;

[0059] The chemical formula of the negative ion additive is: (Na, K)Fe 3 Al 6 [Si 6 o 18 ][BO 3 ] 3 (OH) 4 ;

[0060] c) applying the porcelain material slurry prepared in step b) to the surface of the ceramic tile body in step a), forming a porcelain layer, and drying;

[0061] d) performing screen printing decoration on the surface of the green body on which the porcel...

Embodiment 3

[0066] A kind of production method of ceramic brick with negative ion function, the steps are as follows:

[0067] a) Prepare a porcelain material with high-temperature porcelain-forming properties, the main component of which is the same as that of the ceramic tile body in step a), but wherein K 2 O+Na 2 O: 8%, impurity = 4% (all by weight), ZnO 1%, TiO 2 0.2%, amorphous SiO 2 8%, negative ion additive 10%, batching, mixing, ball milling, and spray drying to make a powder that meets the molding performance requirements, and set aside;

[0068] The chemical formula of the negative ion additive is: (Na, K, Ca)(Li, Al) 3 Al 6 [Si 6 o 18 ][BO 3 ] 3 (OH, F) 4 ;

[0069] b) prepare ceramic brick body powder according to conventional methods, and set aside;

[0070] c) applying the porcelain material powder prepared in step a) on the ceramic tile body powder that has been applied in step b), pressing and molding to form a porcelain layer, and drying;

[0071] d) In ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com