Environment-friendly decorative paper and preparing method thereof

A decorative paper, an environmentally friendly technology, applied in the field of decorative paper, can solve the problems of poor wear resistance, scratch resistance and weather resistance, air pollution, human poisoning, etc., to achieve vivid colors, low raw material costs, and good adhesion performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] An environment-friendly decorative paper comprises an environment-friendly base material layer, a base material functional layer, a water-based ink decoration layer and a water-based protective layer from bottom to top. The raw material composition of each layer by weight percentage is as follows:

[0023] Environmental protection substrate layer:

[0024] Calcium carbonate powder 70%;

[0025] Polyethylene resin substrate 29%;

[0026] Auxiliary 1%.

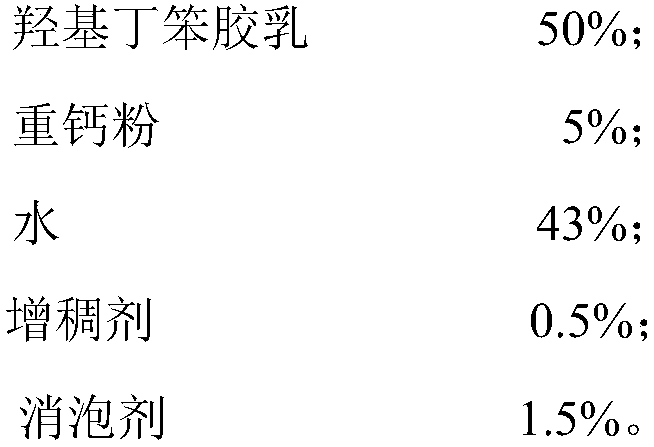

[0027] Substrate functional layer:

[0028]

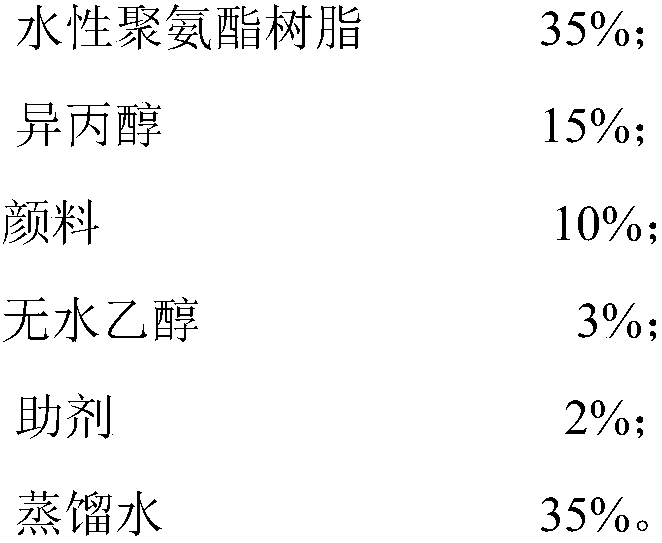

[0029] Water-based ink decoration layer:

[0030]

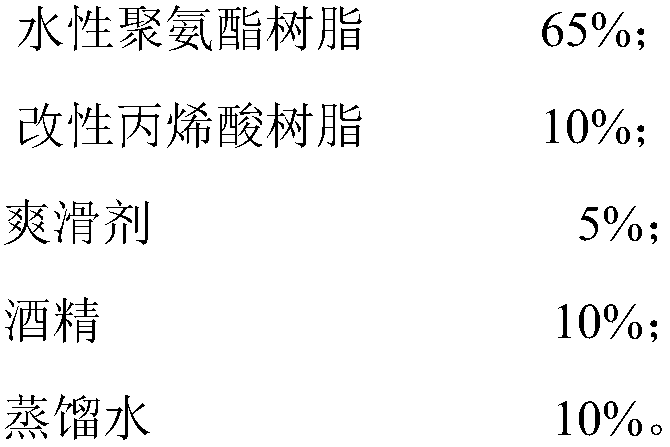

[0031] Water-Based Varnish in Water-Based Protective Coat:

[0032]

[0033] Preparation:

[0034] 1) Preparation of the environmentally friendly base material layer: mix and stir the raw material components of the base material layer according to the weight percentage, and then put them into the banbury mixer, and send them to the granulator for granulation after banburying, so as to obtain the environmentally...

Embodiment 2

[0040] An environment-friendly decorative paper comprises an environment-friendly base material layer, a base material functional layer, a water-based ink decoration layer and a water-based protective layer from bottom to top. The raw material composition of each layer by weight percentage is as follows:

[0041] Environmental protection substrate layer:

[0042] Calcium carbonate powder 80%;

[0043] Polyethylene resin substrate 10%;

[0044] Auxiliary 10%.

[0045] Substrate functional layer:

[0046]

[0047] Water-based ink decoration layer:

[0048]

[0049]

[0050] Water-Based Varnish in Water-Based Protective Coat:

[0051]

[0052] Its preparation method is the same as that of Example 1, and the finished product of the environmental protection decorative paper of Example 2 is obtained.

Embodiment 3

[0054] An environment-friendly decorative paper comprises an environment-friendly base material layer, a base material functional layer, a water-based ink decoration layer and a water-based protective layer from bottom to top. The raw material composition of each layer by weight percentage is as follows:

[0055] Environmental protection substrate layer:

[0056] Calcium carbonate powder 75%;

[0057] Polyethylene resin substrate 20%;

[0058] Auxiliary 5%.

[0059] Substrate functional layer:

[0060]

[0061] Water-based ink decoration layer:

[0062]

[0063] Water-Based Varnish in Water-Based Protective Coat:

[0064]

[0065] Its preparation method is the same as that of Example 1, and the finished product of the environmental protection decorative paper of Example 3 is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com