Printing technology of PVC (polyvinyl chloride) plastic coiled material floor patterns

A technology of coiled flooring and patterns, applied in printing, copying/marking methods, etc., can solve the problems of rough surface, unrealistic, line deformation, etc., and achieve the effect of bright and vivid colors, strong sense of layering, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

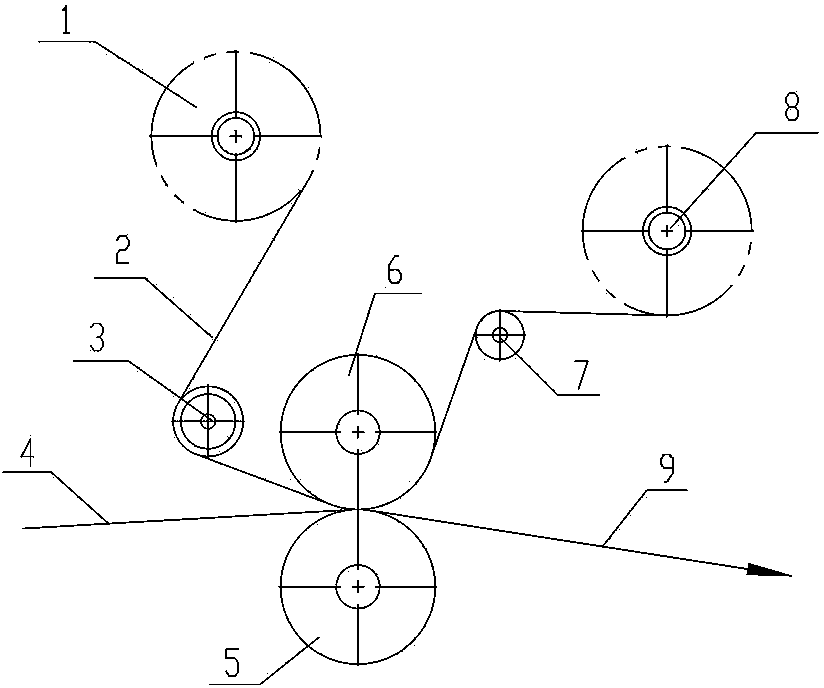

[0013] The printing process of the PVC plastic coiled material floor pattern of the present invention comprises the following steps:

[0014] The first step is to prepare the coiled flooring substrate:

[0015] 1) Preparation of calendered PVC coil floor base material: According to customer requirements, PVC resin, additives, and fillers are kneaded together in a plastic high-speed kneader at high speed, and then mixed in a closed rubber mixer for plasticization, open type In the rubber mixing machine, it is refined and plasticized into viscoelastic material, which is filtered by SL300 plastic filter and calendered by Г-type four-roller calender to form continuous plastic sheet, and the thickness can be obtained by pasting porcelain white film on the surface of the sheet to meet customer requirements. A calendered PVC membrane flooring substrate.

[0016] 2) Preparation of foamed PVC coil floor substrate: According to customer requirements, add ADC foaming agent to PVC resin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com