Multi-valve linkage glue-spraying device

A technology of spraying glue and nozzles, which is applied in the direction of spraying devices, spraying devices, and devices for coating liquid on the surface, etc., which can solve the problems of strong adhesiveness, high price, and waste of glue, and achieve a uniform and smooth paste surface and ensure paste Quality, safe and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with drawings and embodiments.

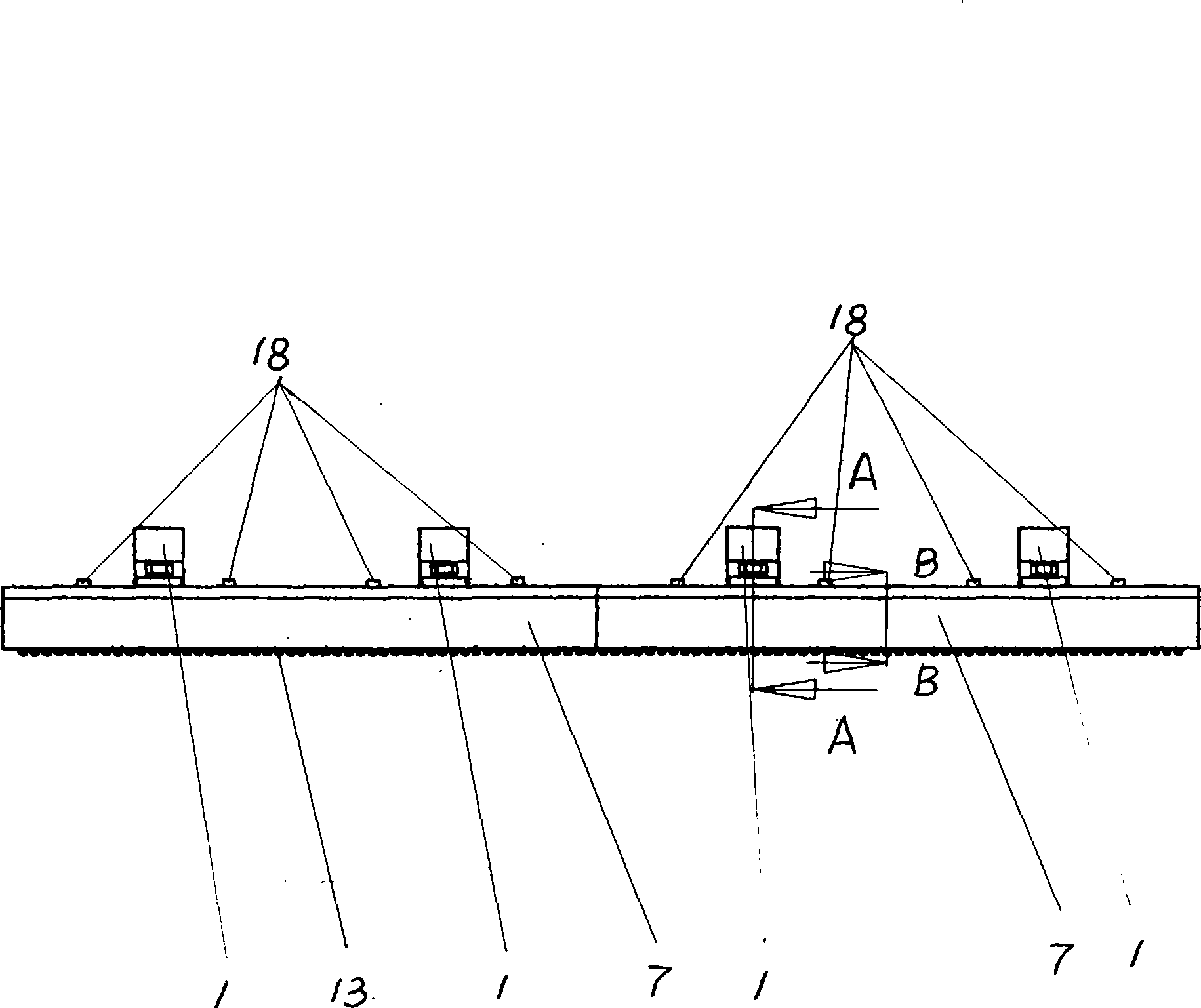

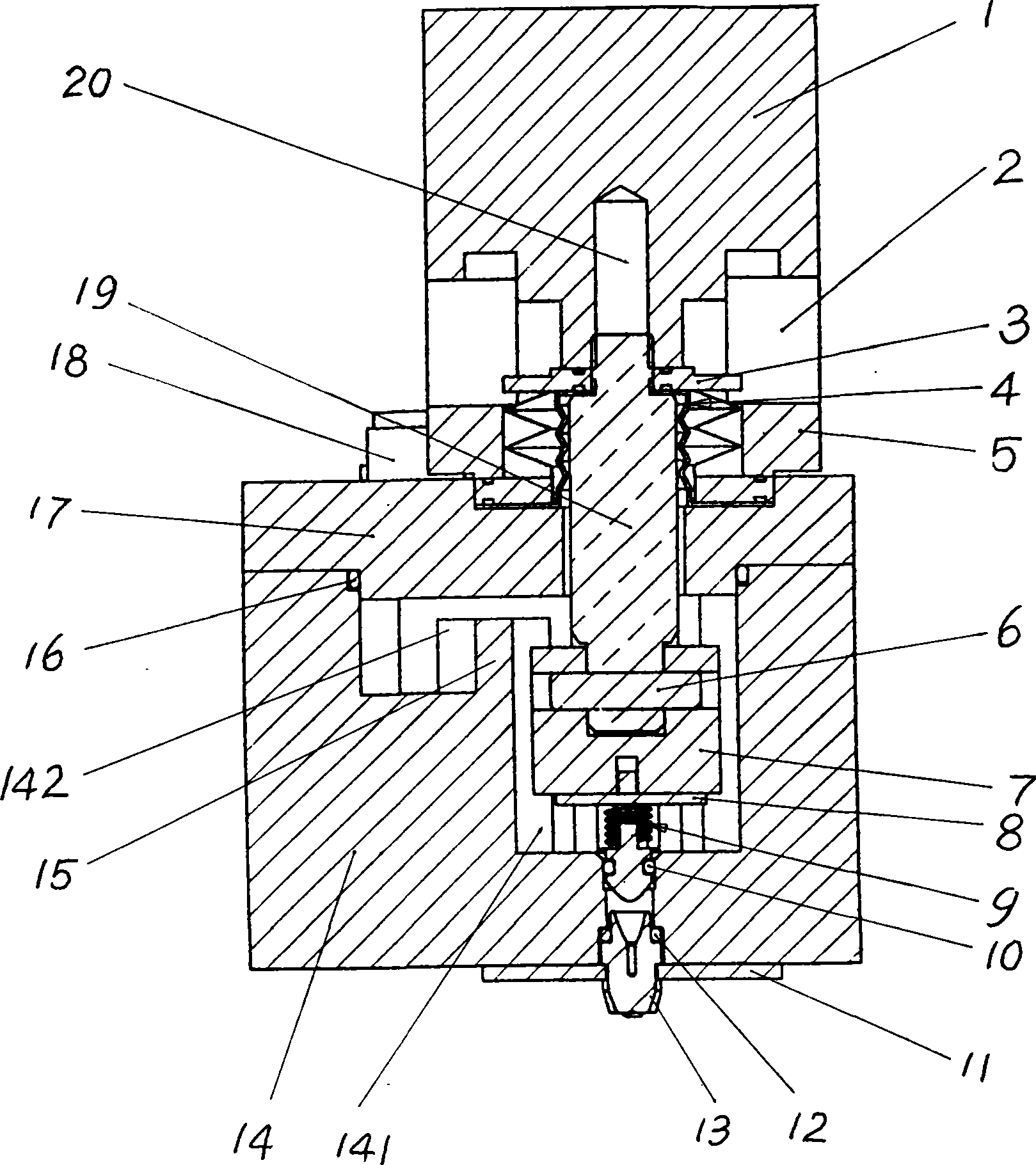

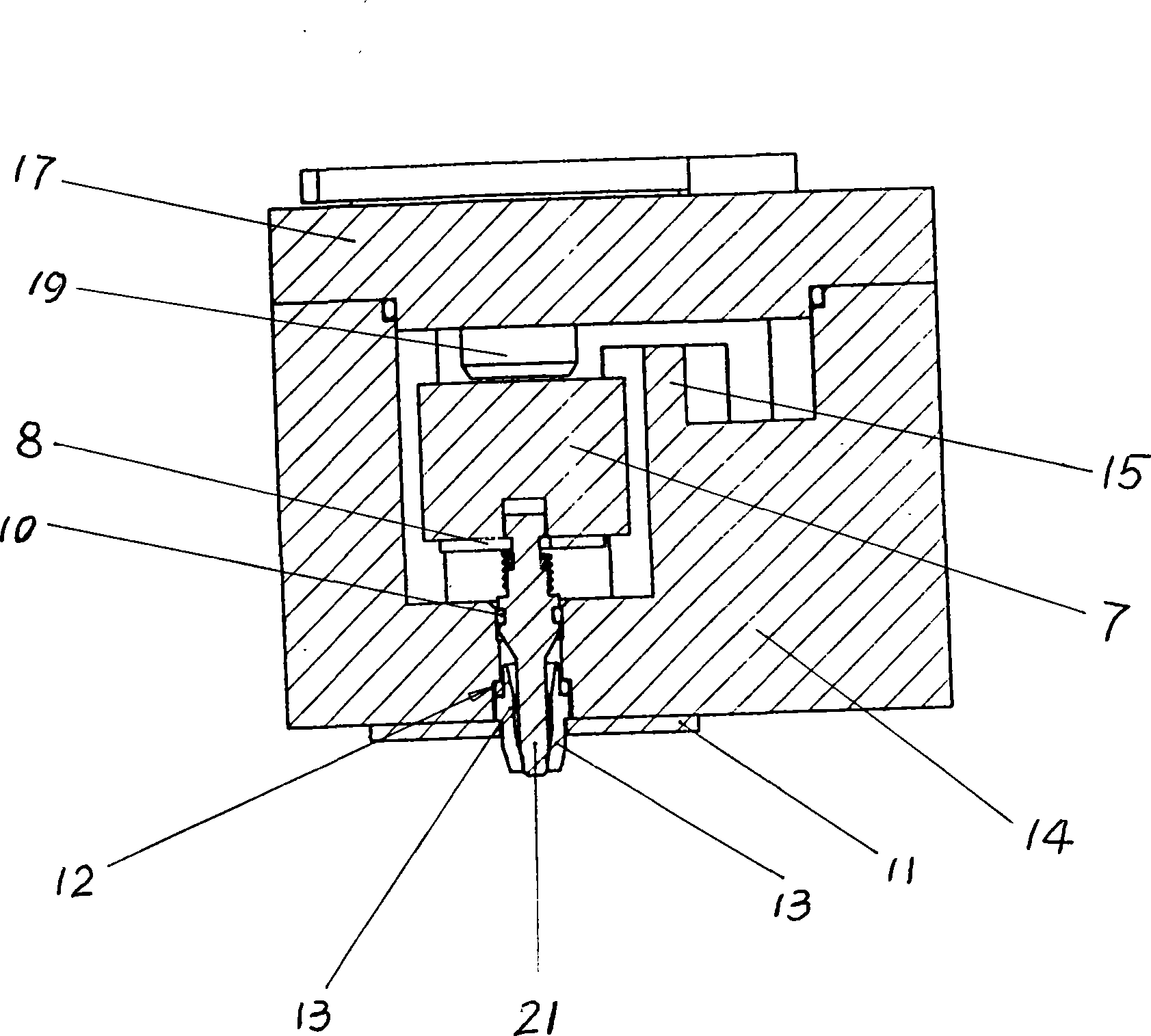

[0015] See attached Figure 1-3 As shown, in the multi-valve linkage glue spraying device provided by the present invention, the housing 14 is made of aluminum plate, and the inner bottom plate of the housing 14 is fixed with an isolation plate 15, which divides the inside of the housing 14 into a glue inlet chamber 142. And the glue chamber 141, the upper cover 17 is made of aluminum plate, the upper cover 17 is fixed on the housing 14 with screws, there is a sealing ring 16 between the upper cover 17 and the housing 14, and the upper cover 17 is provided with eight inlets. Glue port 18, four cylinders 1 are evenly installed on the upper cover 17 as the driving mechanism, there are two parallel connecting rods 7 in the housing 14, and two cylinders are used to drive one connecting rod; the two connecting rods 7 work synchronously; the cylinder 1 is installed on the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com